Everything posted by notlimah

-

Edge juice or iQuad

Check out the classifieds on CF, they show up every so often. If you want better throttle response, I hear a Timbo APPS upgrade is another good thing to add to the list.

-

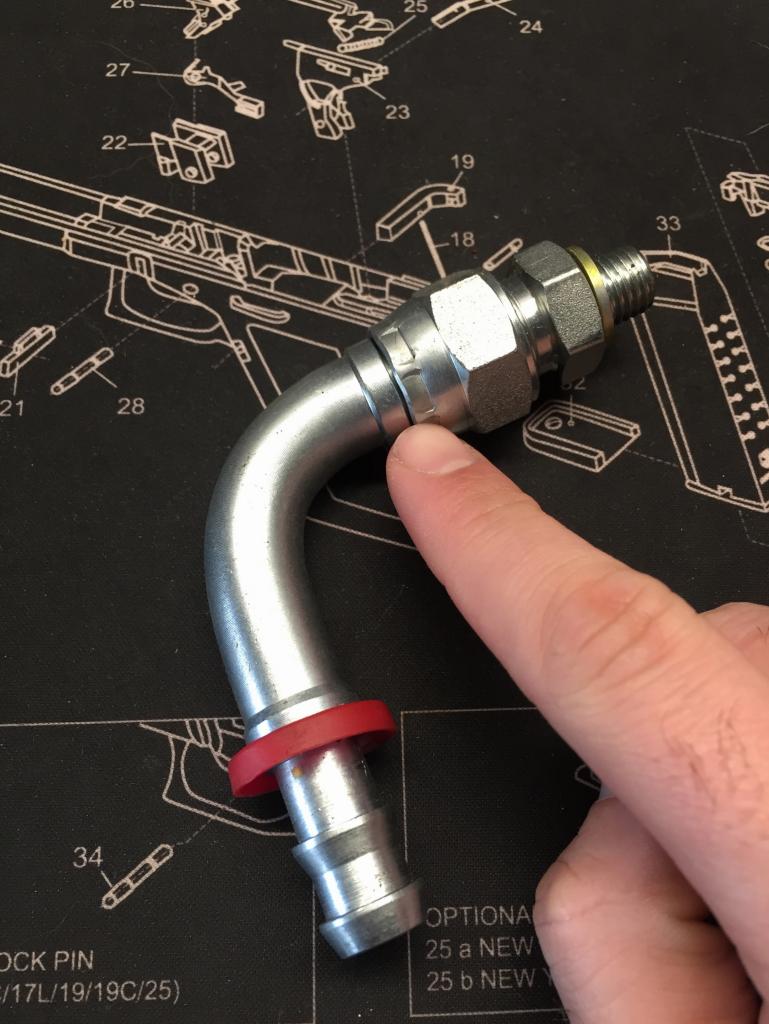

Snubber, needle valve, or both?

Katoom makes a good point, its really hard to pin point leaks on these fittings, although once my FASS was installed, anything on the input side came out with some decent pressure so it was easier to find leaks then it was before. I'm not sure what happened to the fitting I posted but something wasn't right. I cranked down on it as much as I felt comfortable for it being down on the VP and it still leaked. I may have been doing something wrong as thing was quite a while ago and was a lot less knowledgeable of these things then. I found the best way to tighten them down was a small crescent wrench on the bulkhead fitting and then a bigger crescent or appropriate wrench for the push lock JIC fitting. Either way it freaks me out every time. I always feel like I'm going to over tighten and snap something off in the pump!

-

Teardown and Rebuild

I've read a ton of good things about the FTE resonators. They seem help a ton with drone and don't effect sound to much. Dauntless over on CF did an amazing write up of his drone woas that was finally solved by a 17in FTE resonator placed right after the doe pipe. Definitely worth the read.

-

removing fuel sending unit

That doesn't look like it has the in tank pump but can't tell for sure by those pics. I believe you'd use a drawstraw 1 but don't quote me on it, just check Vulcans website or call Eric to verify you get the right one for your module. Here's how I modded mine, but keep in mind it's replacing the in tank setup and I also added a 1/2in return line.

-

Snubber, needle valve, or both?

I don't neccesarily think the hose needs to be tight against the plastic washer, but it should but at least flush with it. I have had a couple fittings be just shy of sitting completely flush and still functioned ok.

-

Teardown and Rebuild

I've read that some people think that the 5in is less 'drone-y' then a 4in. I really think that it's a truck by truck case on whether it'll drone or not. What at brand exhaust is it Mike?

-

Snubber, needle valve, or both?

I had an issue here before When you have a push lock fitting that doesn't have the bend, if that same area were defected or got damaged it could make it appear like it was leaking through the push lock end. I find it highly unlikely that the push lock end would leak due to it breaking or anything. If you used a torch on the hose it could've affected the hose playability and it might not be grasping the push lock end like it should be. Just my though, could be way off.

-

Sudden loss of all power

The way you describe that sounds right to me. How long did you crank for? I had to crank for 10-15 seconds and it tried to start, from there I finger tightend them down just to the point of SLIGHT resistence. That way the engine will hopefully fire up and you can get out and tighten things down. Obviously this is assuming it's by yourself.

-

Live Eagle Cam

Nice! Hopefully they have some local videos installed.

-

Sudden loss of all power

Ok seems like your mixing up the bleeding steps a bit. Try this... Tighten up everything at the fuel filter and loosen the suction (right side when looking down) banjo bolt on the VP, bump the starter a few times, it may take a couple times since it will need to fill up the filter prior to sending fuel to the VP but once it's flowing fuel out of the VP banjo, tighten it down once the airs out and then bleed the injector lines and do the same thing you were doing and see if that works.

-

Snubber, needle valve, or both?

More then likely the push lock fitting isn't leaking. Unless some random phenomenon happened or it's not all the way pushed on, it's more likely to be leaking from the fitting end then the push lock end. I've had push lock fittings be bad so could just be that.

-

Teardown and Rebuild

Well at least now you know. Im thinking I'm going to go with a 5in too whenever I get one. You should do a before and after video!

-

Teardown and Rebuild

Glad you finally got the axle balance thing figured out, you've been chasing that for a while it seems. Did you go with a diamond eye exhaust? Why you ditching the 4in?

-

Helping a friend - Rear Axle

Looks like he made out with fairly minimal damage for what happened. Wish I had welding skills (or a welder ) for situations like these. Do you guys have almost the same truck?

-

Morning Pic For Today...........Post A Pic around your place.....

If that's not global warming, I don't know what is!

-

Longer cranking...

Yea I think I'm going to work on swapping out the whole battery cable setup out for something better quality with the military style connectors.

-

Longer cranking...

Awesome, thanks for the insight on that! I'll hold off on batteries for now then. In the meantime I contacted the guy at the link you posted about getting new cable and terminals made so waiting to hear back on that. Another theory to this harder starting that I'm thinking is with my fuel pressure gauge. I don't run an isolator, and my gauge has been giving erratic readings and the needle has gotten stuck many times. In wondering if something internal is broken down and causing air to leak in somehow.

-

Longer cranking...

Yea that's sorta what I was thinking too. Figured since it's cracked it's not getting a constant solid connection so when cranking it could be in and out of connection causing the longer crank times without it feeling bogged down and turning off one batterey. Or it just hasn't been cracked that long so it hasn't had time to drain the one batterey. I know the batteries aren't that old but I'm half tempted to get new ones just to start fresh. I know from 08-15 the truck was only driven 60k-ish so it wasn't driven much so that batteries sat a decent amount in their lives. Plus they're already lookin a little worn, and they don't fit in the stock trays haha

-

Snubber, needle valve, or both?

Is there a reason you don't want to use the 545? It sort or seems like your making things harder on yourself since that will work and you already had it.

-

Weepy JIC Fitting

Technically no you're not supposed to need any sort of pipe dope or sealant. I've had the same issues before. Just tightened them down a tad bit more and the leaking stopped

-

Longer cranking...

Yea definitely going to replace it. What's the specific name for that cable that links the two? Also if I'm not showing any signs of leaks anywhere else what else is there to check? I have been getting erratic/stuck needle reading on my isspro since install, just haven't had time to call to see about a replacement. I guess I could run my test gauge for a while as a bandaid fix.

-

Longer cranking...

Ok checked the T and back of the head and no signs of anything moist or wet. Back of the head I can't say with 100% certainty since I can't see it but feeling around its dry. Double checked the banjos at the VP and they were dry! This was after running errands and the truck got up to full op temp. So I checked all lines and fittings all the way back to the tank and nothing's leaking moisture. I guess that doesn't rule out an air leak but I don't know what that'd be coming from. I double checked my batterey terminals to make sure they were clean and tight and found this on the passenger side batterey. Could this be the culprit? I know the truck started quicker this morning but it was also warmer and hadn't sat as long as the previous night so not sure.

-

Longer cranking...

I checked the T last night and it looked dry as can be. Where exactly at the back of the head? I suspect it's coming from my input bolt to the VP. I felt down there last night and it had some 'moisture' just couldn't tell if it was fuel or not. Same thing happened on my 99 too, minus the longer crank times.

-

Longer cranking...

Alright so parked nose downhill last night. Did the same exact thing I did yesterday morning, made sure the key was on for about the same amount of time and she fired right up. Soooooo.... That means a leak somewhere right?

-

Brake squeakssss

I don't think it's a joint of any kind as it doesn't happen when turning, typically only when lightly applying the brakes and sometimes a little after that. I'll look into the caliper check Mike. I'm pretty sure the brakes were serviced not that long ago too. I'm going to get under there and look to see if anythings obviously out of place or could rub.