Everything posted by Tractorman

-

No cold start problem.....help

@Doubletrouble, I am glad to hear that your gelling problem has been resolved. I suspected that it may clear itself when you said that the engine ran for thirty seconds and then died with zero fuel pressure. Your subsequent attempts to keep the engine running likely brought treated fuel to the fuel filter and then to the VP44. @W-Tand I were replying to an earlier post at nearly the same time. After reading his post, I did not post my reply, but rather sent it to him just from sheer respect for his knowledge about many things. He readily suggested that I post the reply anyway. So, here it is, albeit a bit late. I personally have not done what you have suggested, but I question the ability to hear the fuel returning into the fuel tank. The volume of fuel returning to the tank is very limited because the VP44 internal vane pump is not rotating. So, the lift pump forces internal leakage around the vanes of the internal vane pump at a greatly reduced volume. That fuel works its way to the tiny orifice in the overflow valve and returns to tank. If the fuel basket is still stock, that return fuel enters the tank below fuel level. With the reduced fuel flow and with fuel returning to the tank below fuel level makes me think that it would be very difficult to hear the return fuel - assuming the fuel system has a stock fuel basket. I certainly can be wrong about this, The photo below shows the reduced volume of fuel returning to the tank with engine off and lift pump running. So, I am curious to know if you have done that procedure with your truck and were you able to hear the fuel returning into the fuel tank? Also, does your truck still use the OEM fuel basket with accompanied fuel return flow? I was also going to add that I thought it may be wiser to use the lift pump circuit in its normal operation (for 20 seconds at a time) because it was unknown where the fuel blockage / restrictions was located. If it was in the in-tank suction screen (assuming OEM fuel basket), then prolonged use of the lift pump with the blockage / restriction could possibly harm the lift pump. If the blockage / restrictions was in the fuel filter mounted on the engine (downstream), then I would not be concerned for lift pump running continuously. Once the OP said that his engine ran for about 30 seconds and then lost fuel pressure and died, I was fairly certain that his engine may run after many attempts of priming and starting, just because the treated fuel in the tank was slowly making its way to the injection pump. - John This response clearly adds value to this thread, because now we know for sure there was a gelling problem and we know for sure the cause of the gelling problem. Your last post (the most important one) is very informative and shows all of us how we can sometimes create our own problems. Thank you! - John

-

Truck Not Running Right

I do recommend to install the 150 amp fuse. This fuse will not protect the alternator as the alternator is only capable of about 130 amps under the right conditions. However, this fuse offers protection from a potential engine compartment fire. Should the an aged alternator acquire a short to ground, there will be nothing to stop very high uncontrolled current flow from two Group 27 batteries to flow directly to that short to ground through the alternator charge wire. This wire could quickly reach a nice cherry red glow and remain that way anywhere from a second or so up to a couple of minutes. Ripe conditions for an engine fire. I installed mine on my OEM air filter housing. An alternate location could be in a protected area on the fan shroud near the passenger battery. This is what I purchased from Amazon. - John

-

No cold start problem.....help

@W-T, would it be okay to send you a private message? - John

-

No cold start problem.....help

@Doubletrouble, in the early stages of diesel fuel gelling, wax crystals form. The wax crystals typically collect and block a filter or a suction screen. The rest of the fuel in lines and the fuel in the tank are usually okay. The fuel in your fuel filter may look good, but the wax crystals may have formed which will make it difficult for fuel to passed through the filter. If you have a stock fuel basket in the tank, then the fuel inlet screen is likely to be restricted in the same manner. Not much you can do about that one, except maybe build a protected area under the fuel tank and apply heat with an electric space heater - carefully! You could put a drop light with an incandescent bulb under fuel filter housing in the engine bay and block the air flow around the filter housing. I would not crack any fuel lines open anymore, as there is no benefit and you do risk introducing air each time. The likely reason the engine lost fuel pressure and died is because the VP44 internal vane pump (you know, the one nobody talks about) is pumping fine and was trying to draw fuel in faster than the lift pump and related components could provide. I don't think your lift pump is damaged. Be patient - think it through..., enjoy your Christmas Day! - John

-

Getting on site

I am only guessing here, but sometime in November I could not access the site from my computer nor my wife's Ipad. Turned out the that Mr. Nelson's updated firewall would not accept my IP address. He called me and he fixed it in a matter of minutes. Could be something like that happening to you. - John

-

Insulating Heater Hoses?

@JAG1wants to insulate them so they will already be warm when he starts his truck on a cold morning. He's thinking ahead! (Holding back sarcasm makes me physically ill, so I had to let some out) 5 below zero here this morning. - John

-

Unpaid members

You don't know!? Well, I'll be gobsmacked! - John

-

01 24v dead in the water....

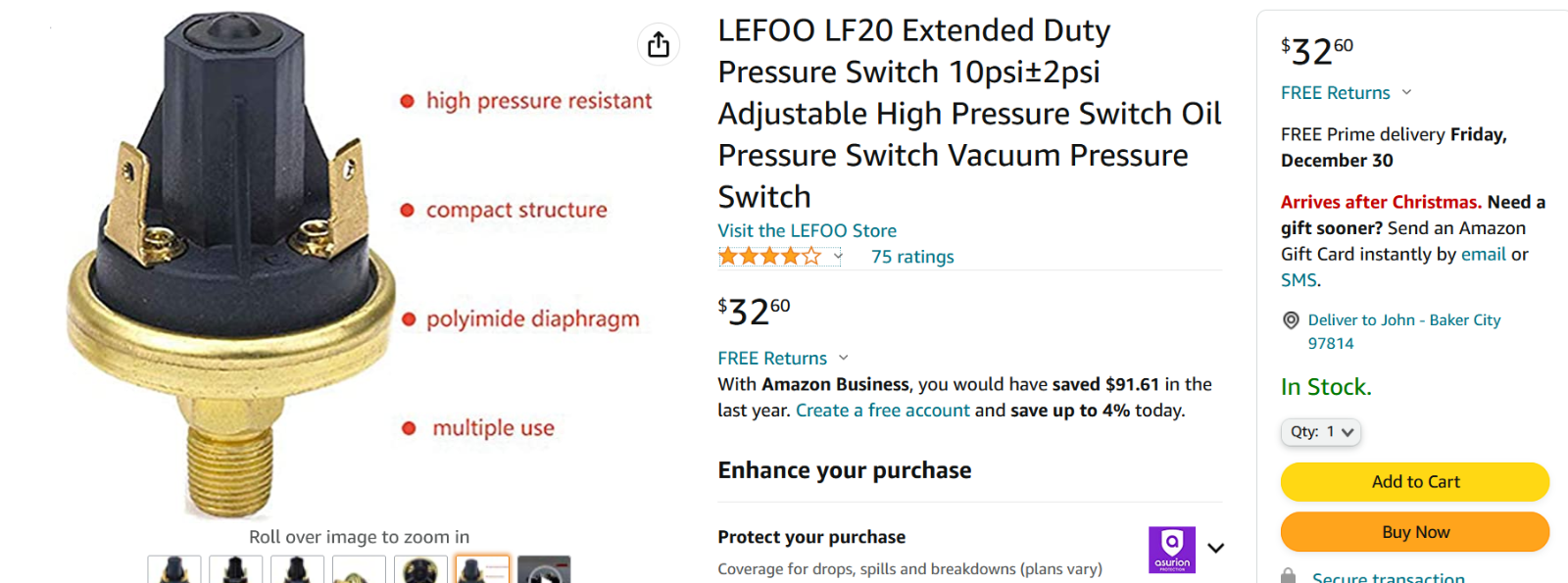

I have tried several engine oil pressure switches, but they don't last. The high frequency pulses from the VP44 destroy them in a relatively short period of time, even with a snubber. The longest lasting one lasted for about a year. I installed the switch in the photo below one year ago this month (10,000 miles ago). So far, I like this one the best. It comes with 3 terminals - common, normally closed, and normally open. It is adjustable (a winner here) and comes preset at about 10 psi. I also like this one so far, mainly because it is still working! I am posting the following information because I think you have not purchased your AirDog Raptor 150Gph lift pump, yet. I think that lift pump volume is way overkill for your application. After years of thorough research I have found at least two groups of people who have installed a flow meter in the return flow line between the VP44 and the fuel tank and test drove their trucks under many different operating conditions. I have done my own fuel return flow testing of the VP44, as well, In fact, I even went one step further and disabled the lift pump and routed a hose around it. The return flow from the VP44 remained unchanged. I drove the truck for 30 miles under all kinds of throttle applications. It drove no different than it did with an operational lift pump. All of our test results have come to the same conclusion - lift pump pressure has no bearing on the volume and pressure of fuel flowing inside the VP44, or how much fuel is returning to the tank from the VP44. We have all learned that it is the VP44 internal fixed displacement vane pump that provides the fuel flow for the operational and cooling needs of the VP44 injection pump. The lift pump does not provide this. However, the lift pump does provide a flow of fuel greater than the volume required by the VP44. As long as there is a positive pressure at the inlet of the VP44, the fuel supply required will have been met, even under the most demanding VP44 operating conditions. How a fluid under pressure and flow behaves is much like how electricity behaves. In electricity you have the following:. * Electromotive force (electrical pressure) measured in volts. * Electron flow (current) measured in amperes * Resistance to electron flow (resistance) measured in ohms So you have pressure, flow, and resistance In fluids you have the following: * Pressure - usually measured in pounds per square inch (psi) * Flow - usually measured in gallons per minute (gpm) or gallons per hour (gph) * Resistance -something restricting the flow of fluid - also usually measured in pounds per square inch (psi) Again, you have pressure, flow, and resistance When working with electricity, we have relatively inexpensive meters to measure voltage, amperes, and ohms (electrical pressure, current, and resistance). We use these meters responsibly to measure the appropriate property of electricity to draw responsible conclusions. Would you modify an electrical system based on one gauge - a voltage gauge - and not consider the current flow or the resistance of electrical loads? Probably not. When working with fluids, the only inexpensive measuring device is a pressure gauge. Flow meters are very expensive and can be difficult to install. So, we usually end up with only a pressure gauge as a tool to diagnose a fluid flow problem. Without a solid understanding of the physics of fluid under pressure, flow, and resistance, diagnosing a fluid flow related problem with only a pressure gauge can be difficult. Misunderstandings of how things operate can easily occur. Now, we get to our VP44 fuel system with a pressure gauge and ONLY a pressure gauge. No flow meter in conjunction with other pressure gauges to evaluate a complex operating fuel system. Nope. Just one pressure gauge location for over 20 years of VP44 operation with many folks making decisions and drawing conclusions based on the reading from that pressure gauge without even considering fuel flow and the resistance to fuel flow. Even worse - not even considering that there is another fixed displacement feed pump in series within the same circuit (the fixed displacement vane pump inside the VP44). This is only my opinion, of course, but I completely disagree with the "it is imperative to monitor fuel pressure and prevent it from dropping below 15 PSI at all times." part of that statement. Similar statements have appeared over the years on this site stating that the VP44 could be harmed by having fuel pressure fall below 14 or 15 psi. This is simply not true. It has also been stated on this site that when fuel pressure falls below 14 psi, there is no fuel from the VP44 returning to the tank, so no VP44 cooling. Again, simply not true. W-T, my original VP44 failed at 64,000 miles and was replaced under warranty at 87,000 miles. The warranty also covered the "fix" at the time, which was to install a relayed in-tank lift pump modification. Before I took the truck in for repairs, I had already heard of the horror stories of faulty lift pumps taking out the VP44. Of course, at the time I believed them - why shouldn't I? So, I strapped a fuel gauge onto the driver side wiper arm and drove the truck back and forth to work for a week (250 miles). The lift pump pressure stayed between 12 psi (idle) and 7 psi (WOT) one hundred per cent of the time. Hmmm. After the repairs the truck drove much better. The very next day I strapped the same fuel gauge onto the wiper arm again and went for a drive. 6 psi at idle and 3 psi at 2000 rpm wide open throttle. Hmmmm..., again. I went back to the dealer and talked directly to the mechanic - a very knowledgeable guy. He said that those low readings are normal but he readily stated the he did not understand why this was the direction Chrysler decided to go. I told him not to worry about it because with my background in fluid power, I figured that as long as there was always a positive pressure at the inlet of the VP44, the VP44 would be happy, so I would be happy. I have currently logged 283,000 miles on this re-manufactured VP44. I used the in-tank lift pump for 160,000 miles (6 psi at idle, 3 psi WOT). According to a lot of information from this site, this VP44 should have been killed in short order. I elected to replace the in-tank lift pump (still working fine) with a used frame-mounted FASS (65 gph, I think) on the frame rail just in case of an in-tank lift pump failure. The used FASS lift pump shows 12 psi at idle and 6 psi at 2000 rpm WOT (with a mild tune on the Smarty S03). That lift pump is still being used and has logged over 120,000 miles. So, in conclusion my re-manufactured VP44 has never seen over 12 psi...., ever. Just for the record, I use no fuel additives nor any two-stroke oil. So...., @Basranabread, if I haven't bored you to death by now, the pressure switch in the photo can easily be adjusted to suit your needs. I adjusted mine to turn off the warning light quickly after the engine has started. I didn't set it at a specific pressure. In one way you can make it behave similar to a gauge. Set the gauge at a fuel pressure that would make the warning light come on under a heavy throttle at a specific rpm of your choice. Then when you drive your truck under those conditions, the light will begin to flicker when the fuel pressure nears your setting. @W-Tand @Mopar1973Man, I mean no disrespect to either of you. Both of you have provided information many times that has helped me resolve problems or, in many cases, has provided me information to make my truck a nicer vehicle to operate. So I thank you both for that. - John

-

New VP44 No Start! Codes P0382 , P1689

I understand. A question for you, even though it is not related to your starting issues. Does your lift pump normally keep running with the key in the run position and the engine not running? Hopefully, you have the engine started by now. - John

-

New VP44 No Start! Codes P0382 , P1689

I watched your video. Your "wait to start" light went out at 15 seconds into the video yet you didn't crank the engine until 45 seconds into the video. Why did you wait? Since it sounds like the truck is close to starting, I would just bump the starter and leave the key in the run position. The lift pump will run for approximately 20 seconds. Do this two or three times and then try starting the engine immediately. If the truck is inside a shop or garage and the temperature is above 40 degrees, then don't wait for the grid heaters to cycle - it is just pulling down more battery power. - John

-

Turbo Theory-Small Compounds

Same here for my '02. Plus I would have to relocate the exhaust brake - didn't want to do that. - John

-

Turbo Theory-Small Compounds

I think so. I already do that with the original OEM turbo (HX35), RV275 hp injectors, and mild tune with a Smarty S03. My travel trailer is light - a little over 5,000 lbs (GCW is 12,500 lbs) and I pull 6% grades for 5 or 6 miles in 6th gear 60-65 mph (1,800 - 1,900 rpm) with egt's staying right around 1,150°. Kind of similar to what you are asking. I can easily attain 30 psi boost above 1,700 rpm, but a 6% grade will call for about 25-27 psi boost. - John

-

Unpaid members

I think it is because you are on the other side of the world. - John

-

Truck Not Running Right

All of your statements of understanding are true, so I would not worry about harming the pump. One thing you could do if you have any issues at all with the new VP44 is to check continuity of all the wires that connect the ECM to the VP44. Inspect the connectors and make sure that there are no pins pushed back into the connector body. These codes are from you July 18 log entry. Just FYI: P0251 (M) Fuel Inj. Pump Mech. Failure Fuel Valve Feedback Circuit / Problem sensed with fuel circuit internal to fuel injection pump. P0252 - could not find this code in the 2002 FSM P0253 (M) Fuel Injection Pump Fuel Valve Open Circuit / Problem sensed with fuel circuit internal to fuel injection pump. P1688 (M) Internal Fuel Injection Pump Controller / Failure Internal problem within the fuel injection pump. Low power, engine derated, or engine stops. - John

-

Replacing head gasket

Something doesn't quite make sense here. The cylinders are numbered 1 through 6 with #1 being the front. The firing order is 1,5,3,6,2,4. If you are saying that the the three rear cylinders are not firing, that would be 4,5 and 6 are not firing and the engine us running on 1,2 and 3. Can you clarify? - John You posted the above on November 11. What does "confirmed the hot wire test on the vp44" mean? Does this mean that the engine idled smoothly on all six cylinders? If so, this would mean that there is no mechanical problem and all of the other tests were unnecessary. If the statement means something else, then we need to know what it means. - John

-

Truck Not Running Right

Thank you for the historical log in chronological order. Just one question. The July 18th entry does not say anything about the VP44 that was currently in the truck at that time. How many miles / years? original VP44? or do you not know any information about the VP44. How many miles / years have you owned the truck? Is the "theory" referring to "THE diesel shop to go to" or are they referring the the re-builders of your previous VP44 pumps? - John

-

Wood Heat

I tried it once, but to me, oak just doesn't taste that good. - John

-

Wood Heat

My wife and I were selling our home in the Willamette Valley on the west side of the Cascade Mountains in 2019. I had a 12' x 24' wood shed full of split well seasoned oak firewood (seasoned well over 2 years). By then, we had purchased a 5 acre parcel of land near Baker City in eastern Oregon. I used my dump trailer to haul firewood from the Willamette Valley home to the eastern Oregon property when we traveled there to work on the property. Ended up hauling over six cords of firewood. In February of 2021, the Willamette Valley had a very destructive ice storm. It especially hit hard where I used to live. My neighbor there had two mature oak trees that went down. The following spring I took my 14,000 GVW equipment trailer and tractor there to help clean up my old neighbor's yard. Each of the three loads I brought backnetted over 10,000 lbs. - so well over six cords of firewood, again. We moved into our newly constructed house near Baker City in October of 2020. It is a 2200 sq ft home that is heated solely with the wood stove - propane furnace backup. We are in the middle of our third winter now and I have lots of oak firewood left. I just finished insulating the 30' x 36' shop that I am building and I am now heating the shop with a wood stove, as well. I am really going to miss burning the oak when it finally runs out. The firewood source around Baker City is red fir and tamarack - good firewood, just not the same as oak. - John

-

Hello from California

I agree. I currently have 370,000 miles on the OEM head gasket with running a mild tune for the last 100,000 miles. No studs. The truck has done its share of heavy hauling (up to 21,000 lbs gross combined weight) over long distances throughout its life. - John

-

Hello from California

If I were in your shoes, I would investigate the cause of the above-mentioned turbo performance issue before I started making any modifications to the engine. You could have something simple such as a broken clamp on a hose connection on either end of the intercooler or at the intake plenum. The leaking connection will only be heard under boost and the sound produced can vary widely. And, of course, black smoke would come out of the tail pipe due to not having enough air for the amount of fuel injected. If the turbocharger is found to be at fault (determined after a close inspection), then I would want to know what caused the failure and why before moving forward. - John

-

Hello from California

Dennis, welcome to the forum. Turbos are usually pretty bullet proof. Could you elaborate a bit more on "the turbo started acting up"? - John

-

Truck Not Running Right

Maybe you could put together the historical log mentioned earlier? - John

-

Slight acceleration hesitation when cold

My truck is also an '02. The original VP44 set the P0216 code at 64,000 miles. Drove it that way for another year (learned how to get around the limp mode). VP44 replacement and lift pump relocation to tank was performed under warranty at 87,000 miles. The re-manufactured VP44 installed then has now logged 283,000 miles - no 2-stroke oil and maximum lift pump pressure ever observed is 12 psi, and that's at idle. The re-located in-tank lift pump ran for over 150,000 miles (over 11 years) at 6 psi idle and 3 psi wide open throttle. I changed location of the in-tank lift pump to a frame mount lift for easier access in case of failure. The in-tank lift pump never failed. I think there is a wide range of quality control with re-builders. The professional VP44 re-builders not only use new PSG' and fully test the pumps, but also use updated internal parts. - John

-

Truck Not Running Right

@Timburrr, since your particular problem has been hard to diagnose and it has occurred over a long period of time with many actions taken, can you make a log showing the history of your truck before and after the problem occurred. The log would show events that happened, things you observed, repairs you made, checks that you performed, etc. The log would like like the example below: Date Odometer Description 5-5-21 259,820 Installed new VP44 injection pump with new PSG by (vendor name) 6-9-21 260.020 Truck died on way to work. Would not restart, required a tow to dealer 6-25-21 260.020 Dealer called and said the PSG on the VP44 failed I think a log would help everybody see a clear picture of the events as they happened. And, the log could be copied to the latest post so that it would be fresh information for any forum member to respond to. Even if the dates and mileage were approximate, it would still help greatly. - John

-

No low beams

Saying that you are "on your own" was a poor choice of words on my part. I apologize for that. However, the forum will need information regarding how the your headlight relays and bulbs are wired since your current headlight wiring is not likely to match the FSM wiring diagram. Also, if you let the forum know your skill set, then the forum can ask the right questions and help get this figured out. It is possible, although not likely, that both low beam filaments are burnt out. You don't want to skip this step. While you are checking, identify the bulbs - that will help with troubleshooting. - John