Everything posted by Tractorman

-

Where'd Everybody Go?

This site has been a great source for information on second generation trucks - especially VP44 trucks., but considering the newest second generation truck is now 20 years old, most of problems have been figured out. And, of course, as time goes by there will be fewer of these trucks on the road. I do think the subscription price is too high to encourage long term membership. I understand the reasons behind the price increase, but even I have considered dropping my subscription a couple of times. The main reason I stay on the site is because I have invested much time already and I have met some very knowledgeable people here. I also have turned wrenches most of my life and I like to help anyone learn a little more about their truck to be able to repair it and have the satisfaction of doing a great job performing the repairs. I am a member of the Turbo Diesel Register (since 2004). The annual subscription is $35.00, much less than the $100 annual subscription for this site. Again, I understand about this site's operational costs, but nevertheless, people are likely to shop around. - John

-

Steering questions

As you drive your truck for the next few days, make sure the steering wheel movement is very free in the straight ahead position. If steering feels like it is hanging or sticky in the straight ahead position, the adjustment is too tight. Too tight can also stress the worm gear drive assembly that interfaces with the ball nut. The adjustment you made sets a minimal clearance between the sector shaft and the ball nut and this adjustment must be done with the steering gear centered - not necessarily the steering wheel centered. When done properly, a preload will be established between the sector shaft and the ball nut with steering gear centered. When the steering gear is turned either left or right from center the preload will disappear and the clearance will grow. This is normal. Usually, this adjustment is done on the bench and the drag is measured with an inch-pound torque wrench on the steering input shaft to establish the correct preload as the steering gear passes over center. It is fine to make the adjustment on the truck, but one must remember there is no real feel for the proper setting because the steering wheel input and the pitman arm output (with associated steering linkage) will mask the feel of the expected drag when the steering gear is passing over the center position. You may already know this..., but, just in case you don't. - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

You made my day! - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

Neil, I have been thinking about how to put in words what I have enjoyed most about this conversation, but I think you nailed it in another thread you started this morning. Referring to this thread, you said, "As many would have noticed myself and @Tractorman have had what you would call a really interesting debate/aurgument in another thread, no crossed words, no fisticuffs, no nukes just different opinions, doesn't matter the outcome". I could not have said it any better. It is how you wrote that made this conversation worthwhile. Anyone who reads this conversation can easily take away what they want without having to filter through irrelevant words or thoughts, regardless of opinion. This is what I believe this forum is about - to put out the best information possible from forum members to help readers make informed decisions regarding maintenance and repairs of their Cummins powered trucks. This has been worth hijacking my own thread. - John

-

Steering questions

Have you ever had alignment checked and recorded? A positive caster of 3° to 4.5° would be a good setting for the steering to return to center well and keeping the truck tracking straight on its own. What are the miles on the truck? Is the steering gearbox original? Have you always had the death wobble, or did it just start? Check steering gearbox mounting bolts for tightness and recheck your newly installed track bar for tightness, especially where it attaches to the axle. Sometimes the bolt is not tightened enough to clamp the metal ears to the inner steel bushing inside the track bar end. Can you give details of your method of checking steering components and upper / lower ball joints? How new are the tires? Are they wearing evenly? Has the death wobble occurred before and after scheduled tire rotation? Lots of question, I know, but the more information you post, the more likely for you to get some good information from other members. - John

-

Steering questions

First, I will say that I have never experienced death wobble, nor do I know of anyone who has. However, I have done much reading on the topic over the years just because it interests me. It seems that there is no absolute cause and effect which can make diagnosing the problem very difficult. One thing that seems to stand out is that trucks with larger than stock tires and wheels favor getting the death wobble compared to trucks with stock tires and wheels. I am not in any way suggesting that larger tires / wheels are the cause, but larger tires / wheels do carry a lot more rotating mass, so when the death wobble is triggered, that energy can keep it going if conditions are right. Many have done a single repair and said, "It's cured!", only to find out that it was just masked and returned a few months later. If I were in your shoes, I would post all relevant information regarding the history of your truck such as, total miles on truck, total miles you have driven it, tire size and wheel size, when and what steering / suspension repairs have been done, etc. When did your death wobble first occur? The first thing I would is get an alignment check from a reputable shop and get a printout of the measurements for caster, camber, and toe. I would especially be interested in the caster setting. I personally don't think it would be the cause, but it could definitely be a contributor. The cause for death wobble (coming from some in-depth sources) seems to be when a specific resonance is generated by a trigger, usually a certain type of bump in the roadway. When this resonance is set in motion, it is sustained by using the energy released from dynamic suspension components and the rotating mass of the wheels / tires. The resonance has to change amplitude / frequency before it will stop. This is usually done by slowing the vehicle. Another consensus is that several slightly worn steering / suspension parts can also cause the death wobble. I would think it through thoroughly before I would start changing out components. - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

Yes, the four stroke cycle engine does take two crankshaft revolutions to complete one cycle. I believe I allowed for this in the first step of my calculation, "If a vehicle is decelerating with an engine speed of 1800 rpm, that would mean a camshaft speed of 900 rpm." The rest of my calculations are based on the number of camshaft revolutions, not crankshaft revolutions, so I think my numbers are correct. Maybe you can give me another double check. You wrote, "so compression and power stroke would take 0.66 seconds for one revolution and exhaust and intake take the same, 180deg per stroke for a total of 720. In your example one stroke would take 0.33 seconds ?" I am guessing just a typo error here - should be ".066" and ".033". I also did one other test the same day that really supports your "engine compression holdback" theory. As mentioned in my previous post, my testing was done in 3rd gear. I did another test at the same location using 4th gear. Here are the results: Truck stopped, engine off, 4th gear selected, park brake released, foot on brake pedal - upon releasing brake pedal truck would creep forward very slowly, slightly gaining sped, then in a few feet the truck would suddenly completely stop. This event repeated itself in lurches endlessly. In this scenario I believe the weight of the truck used gravity to push though engine friction to get the truck in motion and then the effect of engine compression definitely took over to repeatedly stop the truck. While the truck was stopped, engine compression would bleed off, thus allowing for truck movement again continuously repeating the cycle. I also think that under this condition whichever cylinder is in the power stroke would provide resistance as well, This cylinder would start to pull a vacuum while truck is in motion and then bleed off when truck is stopped. A person feels the same events when hand barring an engine over. In conclusion, I would agree that there can be significant engine compression braking, but at only extremely low engine rpm. I believe that as soon as engine rpm increases, cylinder compression efficiency increases greatly and very rapidly, becoming very efficient at higher rpm's. Consequently, the work being done by the compression stroke would be undone by the expansion of air in the following power stroke. The operation of a compression release engine brake supports this concept. I perused the internet as well and found sites supporting both of our theories. Here is some information from Wiipedia - which everyone knows is Gospel (it's as good as "I saw it on TV."). Engine Braking Gasoline engines The term "engine braking" refers to the braking effect that occurs in gasoline engines when the accelerator pedal is released. This causes fuel injection to cease and the throttle valve to close almost completely, greatly restricting forced airflow from, for example, a turbocharger. The restriction causes a strong manifold vacuum which the cylinders have to work against, sapping much of the potential energy out of the system over time and producing the majority of the engine-braking effect.[1] This vacuum manifold effect can often be amplified by a down-shift, which induces a faster spinning drivechain to engage with the engine. Engine braking is a viable method of controlling the speed at which a vehicle travels downhill. By shifting to a lower gear in a manual transmission, or selecting the "low" mode on an automatic transmission, engine braking reduces the need to repeatedly apply the foot brake, lowering the risk of the brakes overheating.[2] While some of the braking force is produced due to friction in the drive train, this is negligible compared to the effect from the manifold vacuum caused by the air-flow restriction. On an automatic transmission, engine braking often spontaneously increases the engine RPM, causing a sudden revving to occur even without applying the accelerator pedal. Diesel engines Diesel engines in personal cars provide little engine braking as they are not equipped with a throttle body and thus cannot draw a vacuum in the intake manifold. In heavy vehicles the engine is often made to provide extra braking power to take some strain off the vehicle's regular brake system and to help avoid overheating the brakes. In its simplest form this consists of a butterfly valve that stops the exhaust flow. This is referred to as an exhaust brake and mostly found on older trucks. It has a limited effect, and more advanced systems as described below are near universal on newer heavy vehicles. Compression release brake A compression release brake (also known as a Jacobs brake or "jake brake"), is the type of brake most commonly confused with real engine braking; it is used mainly in large diesel trucks and works by opening the exhaust valves at the top of the compression stroke, so the large amount of energy stored in that compressed air is not returned to the crankshaft, but is released into the atmosphere. Normally, during the compression stroke, energy is used as the upward-traveling piston compresses air in the cylinder; the compressed air then acts as a compressed spring and pushes the piston back down. However, with the jake brake in operation, the compressed air is suddenly released just before the piston begins its downward travel. Having lost the energy stored within the compressed air, there is no "spring back" so the engine must expend yet more energy pulling the piston back down again. It is very effective, however, and creates immense amounts of braking force which significantly extends friction brake life – a 565 hp (421 kW) diesel engine can produce up to 600 hp (450 kW) of braking power at 2,100 RPM.[3] Exhaust brake An exhaust brake works by causing a restriction in the exhaust, much like the intake throttle causes in a gasoline engine. In simple terms, it works by increasing the back-pressure of the exhaust. Nearly all of these brakes are butterfly valves similar to a throttle valve, mounted downstream of the turbocharger if there is one. Once again, you have forced me to "think" and consume more coffee..., - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

I agree with your statement, but I think the amount of energy lost would be insignificant at higher engine rpm's. If a vehicle is decelerating with an engine speed of 1800 rpm, that would mean a camshaft speed of 900 rpm. Dividing 900 rpm by 60 seconds equals 15 revolutions per second. Dividing one second by 15 revolutions equals .066 seconds to complete one revolution. This means that four strokes of the four stroke cycle are completed in .066 seconds. This would also mean the time to complete the compression and power stroke (two strokes) would be .033 seconds, or the time to complete the power stoke only, would be about .017 seconds. I just can't visualize that much energy being lost in 17 micro seconds. Feel free to double check my math. Not necessary to perform the test because you and I would agree with the results - yes, first gear would be slower. But, I am saying it would be slower for a different reason. That reason would be resistance from friction (overcoming engine internal resistance by forcing the engine to rotate) which applies to all engines. I did perform a test that I think demonstrates this. I have a level tool that allows me to measure percent of a grade. I found a down grade that averaged just over 3 percent and performed the following tests. Test #1. With truck stopped, engine off, transmission in 3rd gear, park brake released - truck did not move (observed this condition for over a minute). This indicates to me that engine friction in combination with gear reduction is holding the truck from moving. Any compressed air in a cylinder on compression stroke would have long been bled off. Test #2. Started engine and brought truck up to 20 mph in 3rd gear, then shut off engine. Truck speed very slowly began to increase. This indicates to me that engine compression is not doing much to hold the truck back. This testing may not be very scientific, but it supports how I think it should work. I think I hijacked my own thread...., - John P.S. I posted this late so you would have something to look forward to in the morning.

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

Not arguing this point. but it seems that your focus is on the compression stroke only with no consideration of what happens on the next stroke (the power stroke) which is key. At the beginning of the power stroke the cylinder is filled with stored energy in the from of highly compressed air just generated by the previous compression stroke. That stored energy will now drive the piston downward with the same force that was used to compress the air in the first place. Compression stroke - stores energy in the form of highly compressed air by resisting and slowing the upward speed of the piston - results in momentary engine braking . Power stroke - releases energy of same parcel of highly compressed air driving the piston downward and accelerating the downward speed of the piston - results in no engine braking and piston acceleration is momentary. The actions of the compression stroke and power stroke cancel each other which nets zero engine braking. The number of cylinders in an engine is not relevant as each cylinder operates independently in the four stroke cycle process. This is why I simplified my explanation using a single cylinder engine. The only thing individual cylinders have in common are air intake, exhaust outlet, and crankshaft connection. If this is true, then can you offer an explanation of what is happening with energy from the highly compressed air during the power stroke? Just want you to know that I have always respected your point of view and continue to do so - you have clearly shown that you are a knowledgeable person through many posts on this forum. In the end we may have to agree to disagree, which is okay with me - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

All four strokes of the four stroke cycle engine must be considered for engine braking effectiveness - not just the compression stroke Since all engines have internal friction of varying degrees, this friction is not considered in the examples below for holding a vehicle back on a downgrade. For simplicity, consider the following operation on a single cylinder engine: Diesel engine without throttle plate intake stroke - intake valve open, no holdback compression stroke - all valves closed, air is compressed, holdback power stroke - all valves closed, compressed air expands, cancels compression stroke holdback exhaust stroke - exhaust valve open, no holdback Net results - no engine holdback Gasoline engine with throttle plate intake stroke - intake valve open, throttle plate closed, negative pressure produced, holdback compression stroke - all valves closed, throttle plate closed, air is compressed, holdback power stroke - all valves closed, throttle plate closed, compressed air expands, cancels compression stroke holdback exhaust stroke - exhaust valve open, no holdback Net results - engine holdback on intake stroke. If a closed throttle plate introduced a negative pressure of 25 inches of mercury (approximately 12 psi), then 12 psi would be working on each piston surface area to aid in holdback. Available atmospheric pressure is the limiting factor for engine braking. Diesel engine without throttle plate, with exhaust brake actuated intake stroke - intake valve open, exhaust brake closed, no holdback compression stroke - all valves closed, exhaust brake closed, air is compressed, holdback power stroke - all valves closed, exhaust brake closed, compressed air expands, cancels compression stroke holdback exhaust stroke - exhaust valve open, exhaust brake closed, holdback Net results - engine holdback on exhaust stroke. Diesel engine without throttle plate, with engine brake actuated (a real Jake brake) intake stroke - intake valve open, engine brake turned on, no holdback compression stroke - all valves closed, engine brake turned on, air is compressed, holdback (major) power stroke - all valves closed, engine brake pops exhaust valves open briefly at TDC, compressed air suddenly released, negative air pressure during stroke, holdback (minor) exhaust stroke - exhaust valve open, engine brake turned on, no holdback Net results - major engine holdback on compression stroke, minor engine holdback on power stroke. Please let me know if there are any errors or if something doesn't make sense in the above examples. - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

No hydro-lock would occur. The small amounts of fuel would be injected at regular commanded timing. Since you mentioned the phrase "throttle closed", that could be inferring there is a throttle plate - which there is not on a 5.9 liter Cummins diesel engine. Just mentioning this for clarity. Diesel engines without a throttle plate will not hold back the truck on downgrades with foot removed from throttle. The energy generated on the compression stroke without fuel is immediately released on the following power stroke , so any engine braking is cancelled. @Great work!, thank you for that explanation! That is the answer I was looking for. - John -

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

Thanks for the quick response. Just for clarification, are you saying that there is no fueling happening when canbus command is 3 or 13 with throttle position at 0% and engine rpm well above idle? Just making sure I understand correctly. - John

-

Me78569 Datalog repository

You did a lot of work to post this information and hopefully others are using it. I very much appreciate your work. I occasionally use your graphs and charts to help me understand what is going on under different driving conditions. The information your charts and graphs provide allows one to see how the engine performs under various operating conditions simulating real world driving. Great job! - John

- 1 review

-

-

- 1

-

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

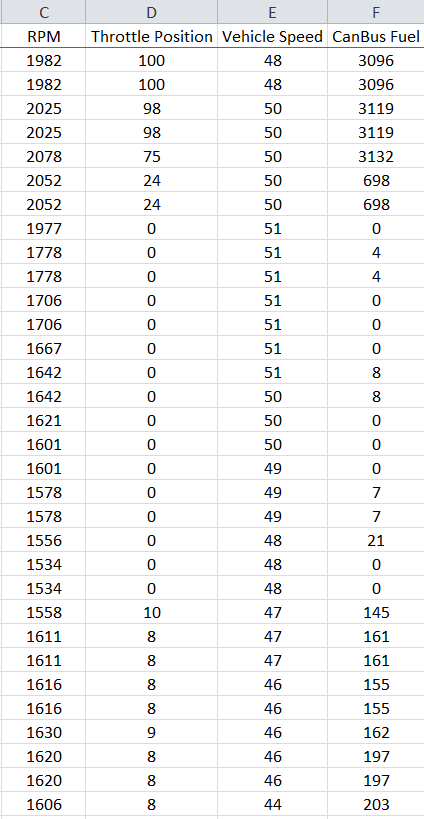

Actually, before I posed my question I reviewed some of @Me78569's data logs. I looked at several of them and they all showed very similar recordings. The one posted below is titled "Stock". Note when the throttle position goes to zero (engine rpm 1977 and vehicle speed 51 mph), the CanBus fuel goes to zero followed by an occasional bump of fueling even though the throttle position remains at zero and engine rpm remains well above idle. This kind of supports what @Silverwolf2691is saying. - John

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

I can't seem to find a source that has a conclusive answer to the question, "Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade?" It would seem to me that the VP44's high pressure solenoid valve would stop receiving signals under this condition if the APPS signal was at 0% (foot off throttle). Does anyone know if this is true with certainty? An example would be: truck with a manual transmission coasting along on a down grade at 1700 rpm with foot off of throttle. - John

-

Allow us to reintroduce ourselves!

It is nice to see a vendor take the time to let potential customers know where they can get professional help when it comes to replacing very expensive electronic components. You will probably hear from me one day when my high mileage truck needs a PCM or an ECM replaced. I am sure it's only a matter of time. Thank you, - John

-

Squirrels Got Me Good

Good job!

-

Squirrels Got Me Good

@LorenS, I would suggest disconnecting the grid heaters while performing the test if the engine is cold. If the grid heaters are cycling, it would be hard to determine if the alternator began charging for a moment or so. - John

-

Squirrels Got Me Good

Kind of like you started to do. I would use a multimeter on the voltage setting and hook it to one of the batteries in a hands-free manner. Then I would perform the "wiggle test" at the wiring locations you suspect varmints have visited. Do the wiggle tests slowly so you have time to a see a response with the multimeter. - John

-

Fuel pressure issue, works but doesn't.

Okay. Does the FASS lift pump use a relay that is operated by the ECM, or is the lift pump directly wired to the ECM? - John

-

Fuel pressure issue, works but doesn't.

Another thought - is the lift pump fuel pressure gauge electric or mechanical? If it is electric, does it have power when the bump start mode is used? - John

-

Fuel pressure issue, works but doesn't.

Overflow valve operation has little effect on lift pump operation. In the bump start mode the lift pump output flow is basically deadheaded against a non-rotating vane pump in the VP44. This is why lift pump pressure is usually the highest in this mode. Also, overflow valves rarely fail - they get misdiagnosed many times - but rarely fail. Since it is not mentioned, I will asked the question. Can you hear the lift pump running each time the bump start mode is used? While pumping into the bucket in the bump start mode, did you try restricting the flow to build pressure? If not, that may be worth a try. Is the lift pump being operated by the ECM directly, or has a relay been wired with the ECM operating the relay coil? I agree with @LorenS, it does not sound like a lift pump problem. - John

-

What shocks are you running and why?

I installed Bilstein 4600's front and rear about 140,000 miles ago. I have no complaints and the truck still handles well. I installed a Rare Parts track bar about 130,000 miles ago and so far it is doing what it is supposed to do. I have never experienced the death wobble or anything close to it. - John

-

Anybody Else Experiencing Global Warming?

Happened again this morning. This the third 5 inch-plus snowfall this week. I think this might be the last one - but, that is what I thought about the other two. - John

-

Holy crap moment!

I am thinking the same. The safety factor (working pressure versus bursting pressure) would be significantly higher with a steel line. - John