Everything posted by Tractorman

-

Alternator Question

I don't think it is a bad idea. My view is a bit one-sided because my only experience is with a Bosch alternator. I ran that alternator for 215,000 miles before I replaced the brushes and bearings. There was no performance issue - I just did it for maintenance. And, since my grid heaters have not post-cycled since the truck was new, this could be why my alternator has been very reliable. However, when I had about 120,000 miles on the truck, I asked a very reputable auto-electric repair shop about replacing the brushes and bearings on my alternator. He asked which one do I have - a Bosch or a Denso? I told him Bosch and he said that he would be happy to change them out, but the brushes are about at at there half-life and the bearings at about one-third life. He recommended that I just keep running it for awhile, which I did. - John

-

Alternator Question

I am still using my original Bosch alternator. Two sets of brushes, one bearing set, and still original diodes. Still passed the AC voltage test last time I checked. One thing I have done different is that I rewired control of the grid heaters to a momentary switch inside the cab. I choose when to use them and they never operate after the engine starts, so there is minimal impact on the alternator. I did the mod when the truck was new - the current odometer reading is 344,000 miles. Just another way of looking at alternator problems. - John

-

Bleeding new VP44 and injectors

Only when he is towing his travel trailer... - John

-

Front brakes dragging

@jtrakel, did you perform the above test? If so, was the passenger side rotor significantly hotter than the driver's side? No. The brake booster doesn't know left from right or front from rear. Are you sure that you are smelling brakes? If you are smelling brakes caused from a dragging pad on a rotor, I would pull off the road and check each rotor on both axles. The one that is overheating should be obvious. - John

-

3rd or 4th gen fuel pump in 2nd gen

Not comparing the supply system in my truck to the supply system in your truck at all. Just pointing out that regardless of which fuel supply system is used, if a positive pressure is present at the inlet of the VP44, I believe there will always be flow over the 14 psi overflow valve because the internal vane pump dictates that flow by engine rpm at a higher pressure (over 100 psi). One thing for sure. Lift pumps cannot push more fuel flow through the internal vane pump than the internal vane pump is displacing at any given moment because the internal vane pump is a fixed displacement pump. Simply stated, the lift pump and the VP44 internal vane pump are plumbed in a series circuit. The outlet pressure for each unit can be different, but the flow is the same while they are both operating in a series circuit. Of course, nothing is ever simple. Example: At a given moment the lift pump may have a flow rate of 30 gph, and let's just say it is returning 5 gph to the tank. This would mean that the VP44 internal vane pump would be flowing 25 gph in that same moment (matching the actual flow from the lift pump (30 gph - 5 gph (return fuel) equal 25 gph). The fuel pressure could be10 psi at the lift pump outlet at that moment, but the VP44 internal vane pressure could be 120 psi if that is what the relief valve is set for. The actual relief valve pressure setting for the internal vane pump is still a mystery, but I believe it is somewhere around 120 psi. Also, my VP44 replacement and in-tank lift pump conversion covered under warranty was done at 87,000 miles on the odometer. Lift pump pressure was 6 psi at idle and 3 psi at WOT with the new system. The original engine mounted lift pump acutually never failed. At 250,000 miles on the odometer (over 4 years ago) I removed the in-tank lift pump and installed a used FASS lift pump on the frame. The in-tank pump was still working fine, I just wanted an easy roadside repair in case the lift pump left me stranded. The FASS lift pump shows 12 psi at idle and 6 psi at WOT. The current odometer is now 344,000 miles. The current VP44 has never seen any inlet pressure higher than 12 psi and that is only at idle, but I believe that the 14 psi overflow valve is always operating and returning adequate fuel flow to the tank for the above stated reasons.. - John

-

3rd or 4th gen fuel pump in 2nd gen

@Haggar, thanks for the reply and the video information. I have watched this video a few years ago. I would really like to hear what the narrator has to say in English. I think it would be very informative. Some people were seriously trying to figure out the mystery of the VP44 back in 2001 (before I even bought my truck). The return flow testing that Mopar-Muscle did in 2001 supports my belief that the internal vane pump provides the fuel flow for the 14 psi overflow valve. The lift pump only ensures that there is a positive pressure at the inlet of the VP44 - a positive pressure means adequate flow. Part of my factory fix from the dealer when my VP44 failed at 87,000 miles was to install an in-tank pump that operated at 6 psi (idle) and 3 psi (WOT). I currently have 257,000 miles on that VP44. @wil440, you may be interested in the following read, as well. Test # 1 well some of you guys ain't gonna like this , especially those led to believe (and those that believe it) ... the bigger is a MUST theory . spent a couple minutes running some tests with a DIGITAL/mechnical flow meter and a MECHNICAL fuel pressure gauge , items under test ... 2000 RAM , DD2's , DD TTPM on level 2 (??) and a HOT PE , ( all levels tested the same at WOT)factory pickup , factory lift pump , factory fuel filter housing unmodified , all banjo bolts intact and unmodified except the banjo to the input of the lift pump is replaced with a 90* swept areoquip type -6AN hose end , the bolt at the lift pump had the schrader cut off and drilled and tapped to a 1/8 npt ( for the gauge) and the banjo fittings between the lift pump and the fitler housing have been drilled to 9/32nd . again all banjo bolts are not drilled out as i have on my ram ( test conducted on the DTT RAM ) . we installed ( LaserBob is helping me and getting #2 fuel poured on his head ) a Sonnex digital flow meter ( inside ID is 5/16") in the return line back to the tank , cut in right at the trans crossmember . gph numbers are fuel returned to the tank . DD2 , DD TTPM (True Torque Power Module) FP volume idle 11 psi 18gph cruise 8 psi 24gph WOT 2 psi 30gph DD2 , TTPM , HOT PE ANY LEVEL FP volume idle 11 psi 18gph cruise 8psi 24gph WOT 0 psi 30gph yes you read that correctly , fuel pressure went to 0 and the fuel volume back to the tank did not change from WOT with 2 psi . the truck did NOT stumble , buck , spit , fart , fall on it's face , nothing , ran like all heck at 0 psi , i will note , my truck ran the same at 0 psi with the DD3's , EZ and a HOT PE . tomorrow we will install -8 lines and an HP carter pump , take flow readings in exact same spot and see what the results are . Mopar-muscle, Apr 24, 2001 Report Test # 2 well , here we go again , todays test was interesting to say the least , and we believe we have it figured out . added the carter HP 15psi 110gph pump on the frame rail next to the tank , -8 bulkhead in the bottom center of the tank , -8 line to the pump , -6 line from this pump to the inlet of an unmodified factory 2000 fuel filter housing , the rest of the system is as delievered from the factory except for a banjo bolt that had the schrader cut off and tapped to 1/8 npt for the gauge , the digital flow meter in the exact same location reading flow back to tank after the tee on the engine . with DD2 , DDTM (True Torque Power Module) psi volume idle 11. 5psi 18gph cruise 9psi 24gph WOT 6 psi 30gph with the HOT PE on any level idle 11. 5psi 18gph cruise 9psi 24gph WOT 4psi 30gph with the addition of the new pump and larger gravity fed pickup point the flow to the tank did not change , though pressure was up , the carter having an internal bypass is living with the backpressure on its output . the concenus is the VP44 is the restriction . the return line from the pump is only returning the excess fuel from the VP44's own internal pump , the more you feed it the higher the backpressure on the line to the pump . the guys with the large pumps , bigger lines and regulator mounted as close to the VP44 as possible have a large amount of the excess flow returned directly to the tank , this is not a bad thing ,( except that at a low fuel level it is possible to foam the fuel in the tank with the large amount of fuel dumping back into it from 2 sources ) but is really overkill as the vp44 uses a set amount of fuel and this is proved by the higher pressure seen with no increase in flow back to the tank . again , the higher the pressure , the lower the flow , BillW explained it perfectly on the prime loc bashing thread and no one ( including myself) understood it or tryed to test it to see if it was true . someone asked if there was a pump that was between 60 and 100 gph , again carter to the rescue , there street pump , 15 psi , about 70 gph , this pump mounted as close to the tank as possible is the best scenerio . the factory designed the system to have the least amount of restriction with the most flow given the flow characteristics of the VP44 . i have not seen the info on HVAC's 34 hp increase with fuel system mod , i will be talking to him to find out the poop on that . we also felt what happens when you have no flow , we had a low fuel level in the tank and under the bulkhead at the botom of the tank , the engine cutout , if the 0psi had no flow , we would have experienced this same bucking . next we will move the factory lift pump back in place of the carter hp pump [This message has been edited by Mopar-muscle (edited 04-26-2001). ] Mopar-muscle, Apr 25, 2001 Report

-

3rd or 4th gen fuel pump in 2nd gen

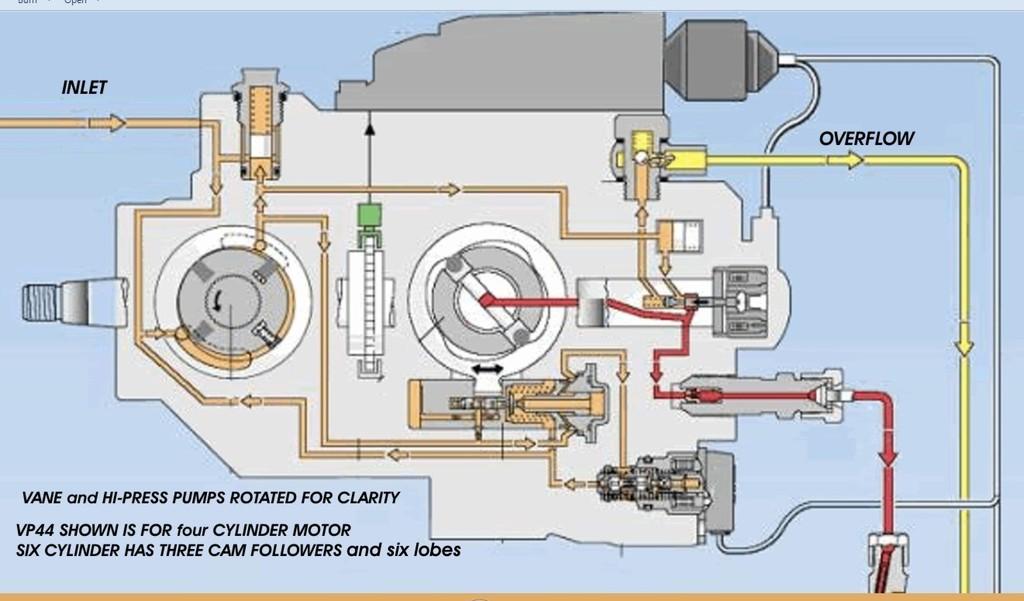

It would seem that it should be that simple. I am trying to find my source of information regarding the internal workings of the VP44. It was posted around 2007 in the Turbo Diesel Register. From what I understand, the internal vane pump displaces more fuel than can be used by the injectors and all the internal working components of the VP44, including the 14 psi overflow valve. As fuel is metered into the inlet area of the high pressure pump the fuel becomes common with the 14 psi overflow valve. I believe it is because the inlet flow into the high pressure pump being metered is why the vane pump will send the portion of the unused fuel flow over its own relief (over 100 psi) and the overflow valve will operate at the lower pressure of 14 psi. I will find this information and post it here. It may take awhile. The photo below clearly shows that the overflow valve is not in the vane pump inlet. - John

-

Gear Ratios and Transfer case failures - related/unrelated

Whew!! That sounds better. - John

-

Gear Ratios and Transfer case failures - related/unrelated

"Trigonometry"? That's a big word. - John

-

Gear Ratios and Transfer case failures - related/unrelated

To answer your question - yes, both wheels need to be rotated or one wheel needs to be rotated two revolutions. You can also do it another way. Jack up one front wheel just off the floor. Using a marker of your choice, mark the bottom of the tire near the tread and place another mark on the floor. Have someone hold the tire in that position while you take up the slack in the front driveshaft. After taking up the slack, mark the end yoke and the pinion case for a reference point. Now rotate the drive shaft 3.55 turns and check front wheel position. If the front wheel has turned two full revolutions, then you have 3.55 gears. If not, continue rotating the driveshaft until 3.73 turn have been completed and check again. Or, 4.10 turns - you get the picture. - John

-

2nd gen PCM functions

Electrical noise can come from several sources - poor battery condition, poor electrical connections, poor grounds, a bad diode in the alternator, etc. There is also a wiring modification article (called the WT Wiring Mod) that corrects all lot of electrical problems. As I am writing this, I see that @Me78569 has posted that information. - John

-

2nd gen PCM functions

If it is only doing this in third or fourth (overdrive), it could be that the converter is unlocking and relocking - about 100 -200 rpm difference. That could feel like slipping. If this is the case, the cause could be electrical noise. - John

-

3rd or 4th gen fuel pump in 2nd gen

I don't think that there is any mystery here. To my knowledge the lift pump feeds directly into the inlet of the fixed displacement vane pump inside the VP44. The discharge flow of the vane pump is regulated at over 100 psi. The 14 psi overflow valve is one of many components is in the path of the internal vane pump discharge, consequently there is always return flow through the 14 psi overflow valve - even when there is only 5 psi lift pump pressure. - John

-

Clutch Engaged and Screeching/Screaming

@TheGreatWhite, all of what @dripleysaid is here is right on. You guys now have me concerned as I have about 47,000 miles on my new stock clutch and throw-out bearing. The original clutch lasted 297,000 miles with nothing wrong with the original throw-out bearing. I have always put the transmission in neutral with my foot off of clutch pedal at intersections. @dripley, it sounds like you had a bearing failure even though you were using the clutch properly. @TheGreatWhite, even though you may not have used the clutch as recommended, the throw-out bearing should never have failed so early. It is very disappointing to learn that the manufacturing of the throw-out bearing may have degraded to such a poor quality. - John

-

Partial dead pedal???

Just for clarification, I don't think you are experiencing a "dead pedal" (engine dropping to idle and staying there). I believe the engine is going into "limp mode" because the ECM or PCM is detecting some abnormality somewhere and therefore de-rates engine power for damage control. I know that you probably already know this, but I just wanted to clarify the terminology. Maybe your code reader is not picking up a code that could help to diagnose. I don't have much experience in this area, but others have said that different code readers can give different results. - John

-

Front brakes dragging

Thanks for the response, however I don't think I was clear about my question. What I meant was, is there any loss of braking performance with the exhaust brake being mounted farther from the engine? - John

-

Front brakes dragging

I like the idea of an in-line PRXB exhaust brake, but I wonder any performance is lost being further from the engine. Anybody know? I also have logged over 400,000 miles with the my vacuum operated direct mount PACbrake - 69,000 miles on my previous '99 truck, plus 343,000 miles on my current truck. It has been an excellent unit. - John

-

Front End and 4WD

If this is happening on asphalt or concrete, what you are talking about could be quite normal. The front axle shafts do not have constant velocity u-joints (CV joints). Consequently, when the steering is turned sharply in either direction, each tire will speed up and slow down twice in one revolution due to the steep angle of each u-joint per axle shaft. With excellent traction on asphalt or concrete, the front tires develop severe wheel hop because something has to give. And furthermore, since the transfer does not have a differential, there is also binding between front and rear axles, just not as severe. - John

-

Front brakes dragging

You may have a problem, or you may not. At this stage I would not do anything with the brakes until I could drive the truck and make a better assessment. The piston in the caliper moves very little when the brakes are applied and released. When the brake pedal is released, the piston inside the brake caliper has no reason to move away from the rotor on its own. So that means other forces have to be introduced to retract the piston slightly. One of those forces is rotor runout which will push the piston slightly back into its bore, but that means truck has to be moving down the road for that to happen. The other force is the square cut o-ring sealing the piston in the bore. When hydraulic pressure is applied, the o-ring twists slightly as the piston forces the pad against the rotor. When the hydraulic pressure is released, the square cut o-ring attempts to return to its original shape. So, between the o-ring forces and rotor runout, the piston slightly retracts and removes the force against the rotor. When you park your truck in the garage, the last thing you do is step on the brake. At this point any rotor may have a varying degree of drag, and not all rotors will have the same drag for the above stated reasons. When you can, take your truck for a test drive. Use the brakes only as much as needed. After driving for awhile, pull off the road and check the temperature of each front rotor. You can use your hand (carefully) or an infrared thermometer. If you don't feel or see a major difference in temperature, then probably all is well. If the passenger side rotor is much hotter than the driver's side, then you know you have a problem. - John

-

Bug screen behind grill/winter covers

I lived in Leadville, Colorado for 12 years - very much a winter climate as Leadville' elevation is over 10,000 ft. I made a daily roundtrip going over Fremont Pass (11,300 ft) twice a day in my '91 Ford F150 4x4 pickup powered by a Cummins 4BTA engine. I used a winter front with a zipper to control air flow. I always left it 1/3 open no matter how cold it got. I did this because I found that some air flow is always necessary so the thermostat on the viscous fan will sense the proper temperature. The small opening also maintains a more laminar air flow (much less turbulence) around the fan. On a below zero degree day I could ascend Fremont Pass with normal engine operating temperature and descend the other side with my heater still working at the bottom of the pass. The fact that they salt the roads heavily in your neck of the woods will make a difference on the material to select and the method of controlling the opening. - John

-

Bug screen behind grill/winter covers

Not "did", it still does! If you decide to install a screen, I think that you will be happy with it. I have used a plastic screen, but I found the diameter of the wire in an aluminum screen was much smaller so my thoughts are that the aluminum screen would be less restrictive when comparing the same mesh size. - John

-

Bug screen behind grill/winter covers

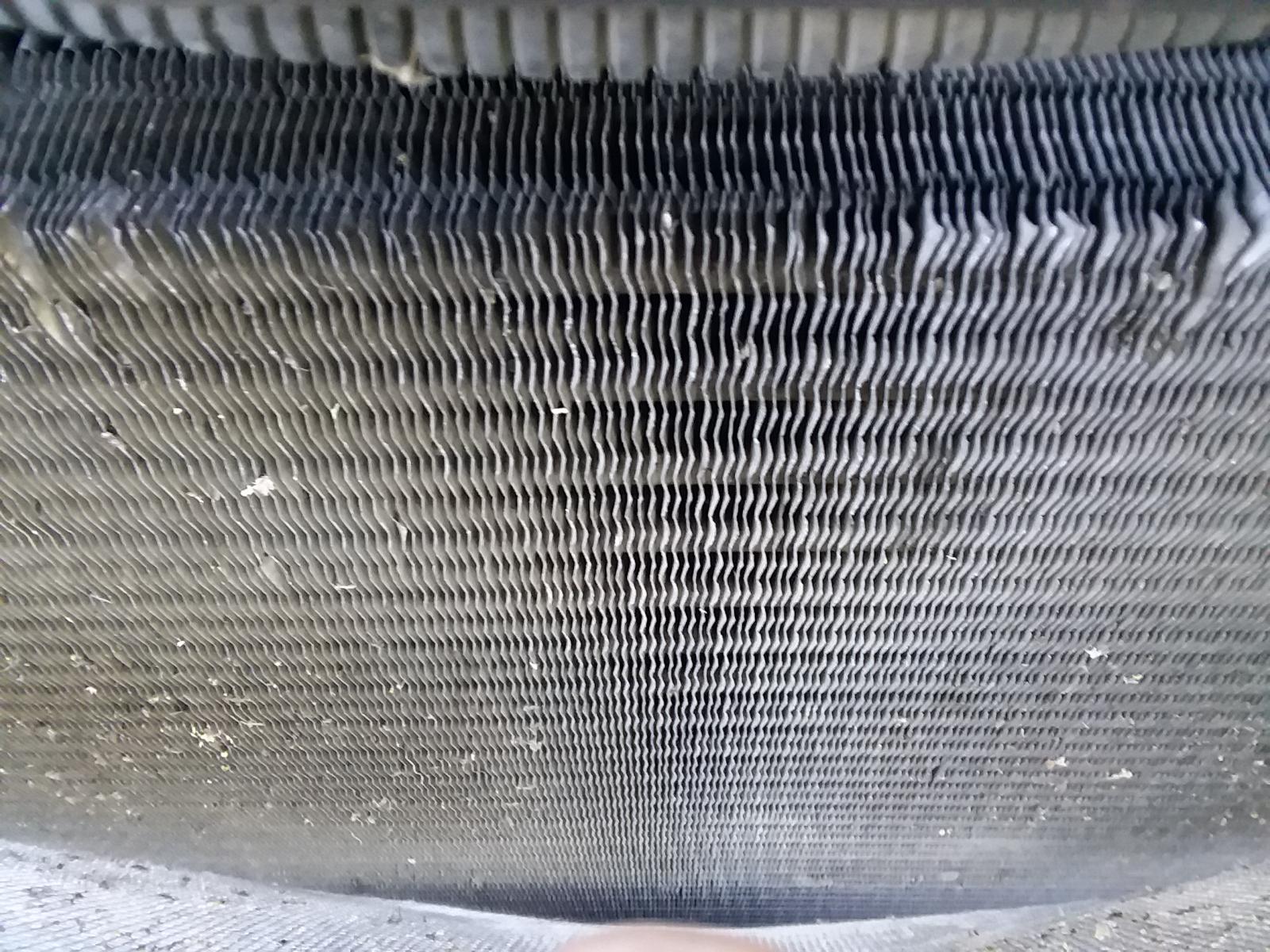

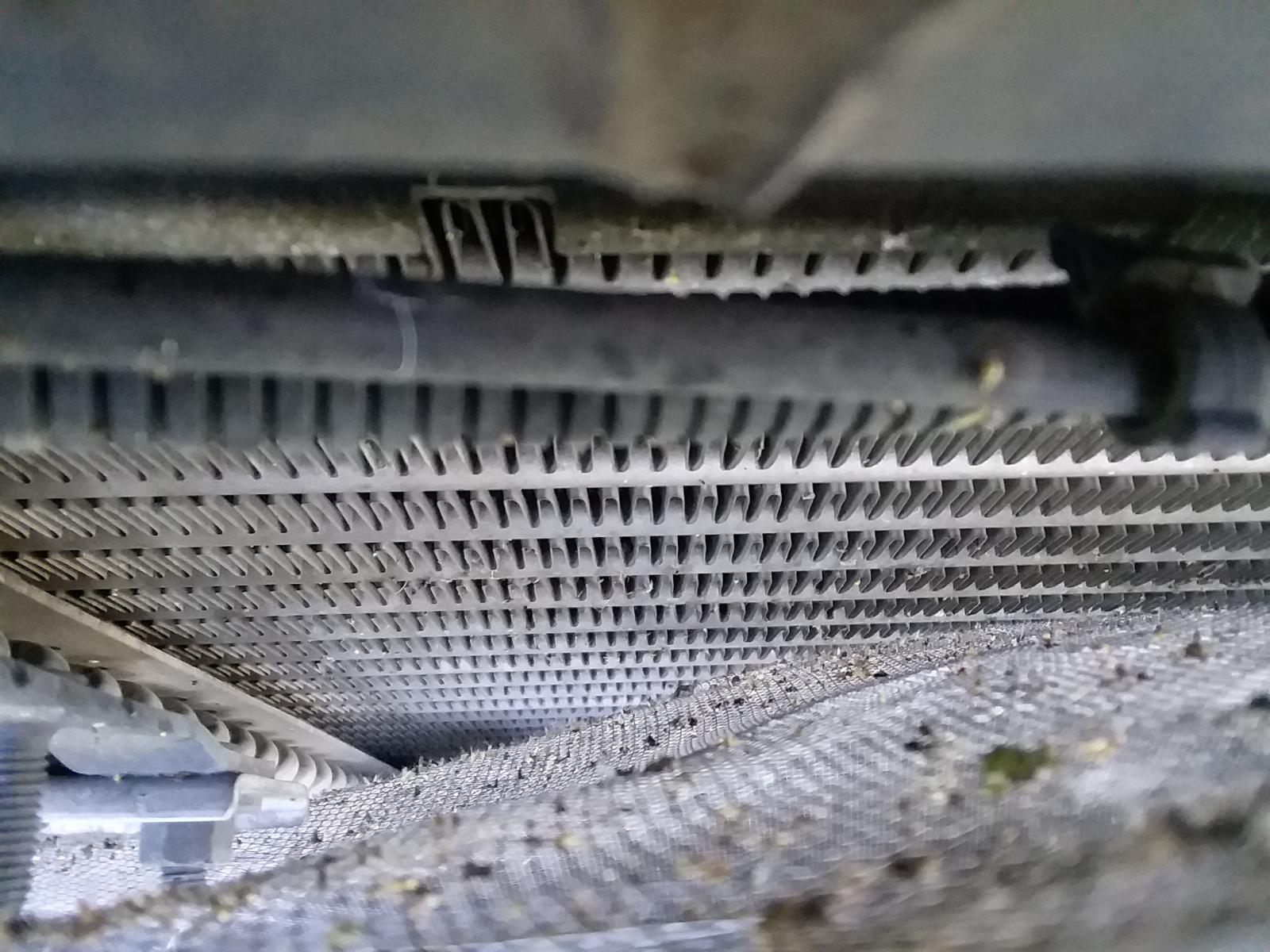

I have made and used a bug screen for the life of my truck - almost 19 years and 343,000 miles so far. I have found no ill side effects. I am still running the original condenser and charge air intercooler - the two components directly in the path of bugs and other debris. I use screen door material (aluminum). Most of the bugs just bounce off of the screen. The ones that stick to the screen just dry up and fall off or get cleaned off when I am driving in the rain. I rarely ever need to clean the screen. The photo below shows the typical condition of the screen. The screen has not been cleaned for well over a year. The photo below shows part of the condenser just behind the screen. Note that there is nothing lodged in the fins and that the fins are straight. The last photo below shows the charge air intercooler just behind the screen. Again, nothing lodged between the fins and the fins are straight. All the above photos were taken just a few minutes ago. You are probably wondering if I ever had any overheating problems because of the screen. The answer is no. I had about a two year period that I was experiencing the engine running hot while towing up long grades. I replaced the fan - still ran hot. I removed the screen - still ran hot. Eventually, after reading some posts regarding overheating, I removed the radiator and found the motor side of the radiator caked with grime caused by the crankcase breather. I cleaned it up and re-installed the screen and I have never had a heating problem since. I have had the truck twice in Death Valley, once with a camper (combined weight of 12,000 lbs). I pulled from the valley floor (minus 200 feet) to the pass at 5000 feet. The distance was 16.8 miles. It was late afternoon and the temperature at the start of the incline was 116 degrees and about 90 degrees at pass level. I had the air conditioner on for the whole climb. The engine did not overheat. I think that was a pretty fair test. I tow a fair amount at times - most of the time the combined weight is between 12,000 to 16,000 lbs. The screen does what I want it to do - it keeps debris from wedging between cooling fins. You will probably hear different opinions about using a screen, but for me it has proven to be worthy. - John

-

W-T ground mod

The battery temperature sensor has only one purpose. It is to sense the overall temperature of the battery under normal operating conditions. It does not monitor temperature to correct problems, nor does it fix anything. It is placed in the tray of one battery (does not matter which one) so that a stable temperature wil be recorded and be directed to the PCM. If the ambient air temperature is 100 degrees, the battery temperature will sense this and send a message to the PCM. The PCM will reduce the alternator output upper limit voltage to - say to 13.8 volts, just guessing - so that the batteries don't gas excessively and over heat. Just the opposite, if the ambient temperature was 10 degrees, then the battery temperature sensor will send a different message to the PCM. The PCM will increase the alternator output upper limit - say to 14.2 volts, again just guessing, to compensate for the cold temperature. The PCM is constantly monitoring the battery temperature sensor (and battery voltage) and continually tells the alternator what to do - so, the battery temperature sensor makes batteries last longer under all types of driving conditions and it is working all of the time. - John

-

Hard start when hot/sitting

A couple of things you could try... When parking the truck overnight, point the front end down hill. It will reduce the amount of fuel leaking back to the tank if that is the problem. It should start quickly in the morning. If most of your hard starts are after the engine has reached full operating temperature, then the pump control module on the VP44 may be on its way out. Some have tried pouring cold water on the module and if the hot module was the cause, the engine would start right up afterward. - John

-

Sport light conversion issue

I can't answer you question regarding your kit, but I have a sport headlight conversion. I made up the relay system myself. Here is the way the factory sport headlights work: The 9007 bulbs are the outer headlights. The 9004 bulbs are the inner headlights. The low beam filament on the 9004 bulb never gets used. Low Beam Function: 9007 bulb - low beam filament on, high beam filament off 9004 bulb - low beam filament off, high beam filament off High Beam Function: 9007 - low beam filament off, high beam filament on 9004 - low beam filament off, high beam filament on I set mine up this way and they work well. - John