Everything posted by Silverwolf2691

-

Quick Connectors and the Art of AWG Cable Ratings

@wil440 ctrl + shift + v

-

Midna's build

Just to keep this semi up to date, and because I don't take pictures of things very often, after this the only big things were a head gasket swap and I started sled pulling. Everything else was maintenance for the most part. Current things: Need a new turbo (hope to finally get the final word on the rules tomorrow for the pulling club). Need to fix my head again. Valve guides and seals went bad since I didn't replace the valve guides the first time. Whoops. Need to add some traction enhancing stuff like traction bars and bump stops, Have new tires ready to go on, but we hit the ice box this week, low teens for highs. Future plans are a full data logging setup and some strategic weight removal and/or shifting.

-

Quadzilla with an HO motor

Long version is, the Magnum and LA blocks have very large tolerancing for the factory machining. So much so that the block is machined with the deck higher on one side vs the other, and/or the block is not square front to back. Because there is so much material left over the pistons end up .010 -.050 in the bore combined with a .054 thick head gasket. There is some thing called quench/squish. It is the measurement between the piston and head surface. When its over .060 i think you lose the benefits of quench. The benefits are that it mixes the air fuel mix better and it forces the flame to burn in the valve area of a wedge head. It also keeps heat out of the rest of the piston and head area that is really close to each other. This lessens the chance for pre ignition. Best quench is .030-.045. People have run tighter, down to .028.. pumping losses start going up after that though. Best way to get quench is to square the block then deck it down to "zero deck" then use the head gasket to set the quench height. The hard part is when you get below a certain height, material temperature stretch, clearances of your bearings, and rpm all start coming into play. Best for tight quench is the factory cast iron rods, hyperutectic (sp?) Pistons and lower rpm (sub 6k).

-

While I was on stock tuning...

If i had to hazard a guess.. it wouldn't matter what injectors you had (to a point). If everything was stock besides injectors, it would pull fuel based on boost and rpm.. Computer doesnt like going over like 20 psi..and will pull fuel pretty aggressively after 27-2900 rpm. I've seen that in my sled pulling data logs.. As long as the rpms stay constant-ish, (ie not going up too quickly) the computer will full fuel. Any semi-rapid increase in rpm and the canbus fuel starts dropping off.

-

Intermittent vacumn

Might need that number to go up.. Just relooked around.. The cast version from a 4bt powered "bread van" is ~$400. The billet aluminum and chrome one is probably a lot more..

-

2001 RAM 2500 Heat Exchanger

AN/JIC conversion? Might be as expensive though..

-

Intermittent vacumn

You can. Power driven diesel sells a billet and chrome one but its like 4-500 bucks or something like that..

-

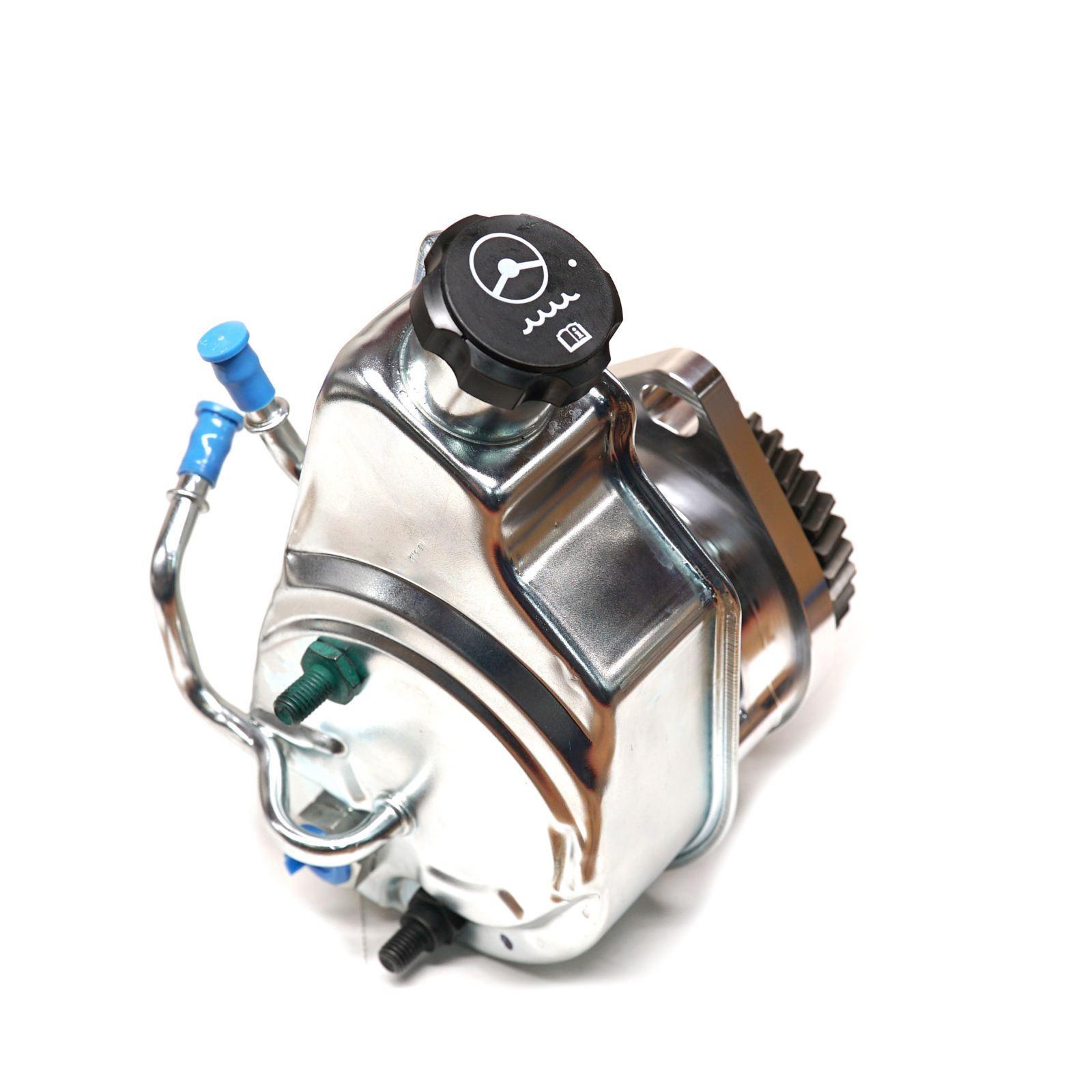

Intermittent vacumn

Not really. There's the bundle from the HVAC controller. That goes into a quick connect for heater box removal, then its just the inputs for the vacuum motors. I think its 5-6 lines plus the "feed" line? If one has a manual trans and no CAD, the only vacuum operated stuff is the hvac box. I've thought about using the 3rd gen vacuum pump (its electric), and removing the gear driven vacuum pump. There are kits that put a gear and flange on the PS pump. I think its a 4bt kit actually..

-

While I was on stock tuning...

Far as I recall from my reading, our trucks will pull fuel. The other reason for the boost fooler is preventing the overboost code.

-

LED headlights dual yellow and white

Seen them, keep going back and forth if they are worth it due to the chip offset for the dual color. To switch them its usually either every other on/off cycle or a fast on/off cycle and will store the last color used for the next use. Personally, id rather double up fog lights, one for each color, than get sub-optimal out of one housing.

-

Tuner for an already tuned Cummins

Like @wil440 said, its as complicated as you want it to be. you can download a tune and never look at the quad again. Or you can build an entirely custom tune based on your truck or your usage. The jury is still out on the battery charger, but definitely for jumping a vehicle you want to pull the quad. Some of the quadzilla stuff when used with other vehicles show different parameters. TC lockup I don't think is one for second gens, but I know slip is. It just doesn't work on manuals.. @wil440, 315s and 3.55s probably are the reason for the 12 mpg(uk)

-

24v nightmare

Auction truck, he's gonna need to buy a donor or piece meal parts..

-

24v nightmare

I'm gonna say sensor signal. The computer wants to see something there even if its not signaling any data. For instance, I run a mechanical fuel pump on my truck. It had a gen 1 or 2 airdog on it. When I unplugged the airdog relay from the pump connector I had a check engine light. So I cut the power wires from the relay and plugged it back into the fuel pump. No more check engine light. The computer was just looking for a load and the relay provided enough to keep the computer happy. Not exactly like a sensor, but might be similar to what's happening. Not sure what you can do besides swap all the stuff from an 01-02 truck that's listed in the article..

-

Tuner for an already tuned Cummins

I think that's the problem. He doesn't know what's programmed into the truck. Digging deep in my memory banks on this one.. there are only 1 or 2 flash style tunes for a Cummins, Smarty for sure and I think a power puck, not sure on that one. Way way early on in the 24v lifetime, there was something called a Jim Jessup tune. It predated or was the creator of Smarty. You sent the ECU in to get manually flashed. I've never had to do it but I would think a factory flash from a dodge dealer would clear out all the tuning. Not sure if a smarty can do that or if it reads the ECU first to make a return to stock file..

-

24v nightmare

I think someone grabbed a 2001 model year truck and just popped the engine into your 1999. Not good to do that.. Only thing I don't know is when that transition happened for the engines. Because from the way it sounds the engine is the right year.. The in tank pump was a replacement for the block mount pump. Just please tell us you bypassed the in-tank pump for the fass? If not, you are gonna loose your brand new pump.

-

2001 RAM 2500 Heat Exchanger

I did actually forget about that function..

-

Squirrels Got Me Good

Sold the ecodiesel and got the passat? The 19-20 Cummins with the cp4s are similar. seems if the pump is gonna die its gonna be in the first 30k. otherwise you're mostly good. They did finally come out with a recall for it though, no parts are issued though. Essentially, there's a fix in the works that everybody approved of but now we need to actually get and distribute all the parts and fixes. and if I had to guess, since I'm not on the hdrams forum often, it's the 21+ timing cover and pump plus the programming for it.

-

2001 RAM 2500 Heat Exchanger

Jus so I'm clear, especially since the last automatic second gen I had was a 1500, you have the canister that sits under the exhaust/turbo/manifold. Then there should be another one, I think, that is sitting next to the condenser in front of the intercooler. Or was that part of a special tow package? I thought that the in-radiator one was gas engine only? @BDK, from the sounds of it you have the finned cooler next to the condenser and the oil to coolant exchanger under the exhaust. And your plan is to upgrade the one in front to the mishimoto and remove the oil to coolant one to reduce the chance of getting forbidden strawberry milkshake in the coolant system and transmission. If that tracks, I'd say maybe upsize the cooler to help dissipate the BTUs like @Mopar1973Man said. Maybe add a thermostatic fan if you need it. Just keep an eye on it if you tow.

-

Electronic Gauges

Isspros here as well. Had an issue with mine and it turns out that one of the Isspro employees was on Cummins forum I think. His name was Michael Pliska. He helped me get everything straightened out. Issue was a design update of the gauge between when got one and when I got the other 3. Wiring was simple enough, I did get the programming cd and cable (doubt I could find it now..) but nothing seemed to get programed when I did the change. Probably user error at this point. The only issues I have is my boost gauge occasionally goes max travel on its own and my EGTs sometimes are doubled. My gauges are close to 5 years old now and the issue happens infrequently enough that I don't worry about it. It is on the list however to look at. Think you found him lol. I'm not unhappy with the gauges, a bit disappointed at the hiccups I've had but overall I'd get them again

-

rear brakes adjusting to tight

I don't think that is a serviceable part. Just replace as an assembly.. All I know is the parking brake assembly is a pita to get to unless I'm doing something wrong.

-

Squirrels Got Me Good

@LorenS, hows the ecodiesel?

-

Custom injectors

Month later but just an update, finally having the rules meeting for my pulling club on Jan 16th. Hope to contact you shortly after to discuss injectors and a turbo. Cant come fast enough, I miss driving my second gen..

-

Squirrels Got Me Good

I think most Volkswagens are similar. Turbo issue = car on a lift with entire k-frame/engine cradle coming out from below.

-

Squirrels Got Me Good

Wha.. bu.. huh..? How?! How does an assembly line get that wrong? I get the assembly of assemblies to make a car, its just that it leads to.. interesting ways of dealing with some "regular" maintenance. I believe that there are quite a few vehicles that want you to drop the subframe/k-frame from the vehicle to do sparkplugs. Or like the super duty, that to take care of the turbo or things related to it, want the cab and nose taken off.. I think the connectors that got eaten were the ecu/pcu connectors. Since its a Cummins engine and not a Dodge engine, the engine and body were entirely separate so just have everything needed to make the engine run on the engine, then anything needing to talk to the pcu go into a set of connectors that get attached at assembly. No messy wiring bits just connect and go.

-

Squirrels Got Me Good

When my truck was parked for a while (week or two at most) in the early summer, I popped the hood and staring at me from a partially built nest of firewall insulation was a rat.. like body (not including tail) was as wide as the valve cover.. no munched wires at the time but I have a feeling he just moved down to the tranny tunnel. A while later found a nest on top of my tranny by the shifter. I don't think any piece is better than the other per se.. The biggest thing to get right is the crimp(s), followed by the correct sized wire seals and/or plugs. After that its what package/footprint do you want. For reference, the apps connector is a deutsch connector. Specifically a dt series. @LorenS, whatever kit you get, just make sure you have the correct crimper for that kit/connector series. Weatherpack, metri-pack and deutsch have different crimpers/way of crimping I believe. Way of crimping meaning how much to strip, where (dimensionally) to attach the crimp, whether or not to attach to the insulation.. It gets complicated the more you dive in to automotive wiring.. ceautoelectricsupply.com has a lot of the info/parts/tools I have found. Don't know their price vs. what's the average/normal.. Also not the easiest site to navigate..