Everything posted by ISX

-

4x4 CAD System

What does yours have? Why do you always have to be different?

-

Brakes, brake vacuum, ABS module.

Well for one, the brakes have nothing to do with the vacuum.. The vacuum and power steering pump connect to each other to share a common shaft but are not related to each other. The power steering pump is what assists your braking. I would bleed your brakes though, they sound like they have air in them if you can stand on it and nothing happens. Your pads might also be done for.

-

4x4 CAD System

Here Mike, make an article around this video Fine I will later.

-

New Arrival

Congrats Elshadow! I was looking at the time and can't believe she is only like 5 hours old! How old is the first great one?

-

Hot vp44

Well theres the man with the plan! Try to get as many of the wiring/sensors as you can. I saw a few tear downs but they never show much on the electronics. Try and show the whole tear down of it showing where the sensors went, everything.

-

New tires!!!

I am almost positive they have electric/heated versions of that mirror. But they are $$$

-

nv5600 junk

Theres pictures in this thread. http://forum.mopar1973man.com/showthread.php/2029-Clutch-and-tranny Did yours do the same thing his did?

-

Now What

You coulda p-pumped it by now Problem would have been solved. Anyhow Mike told me a scratch on the connector tube tips will do that and I see those are scheduled for today so maybe that will fix it.

-

Any clue what happened?

Anchors=staples pretty much. It's fine. Looks like you did a good job on it

-

Hot vp44

For some reason I remember a couple threads with people who start their truck after a while and it starts and dies and next thing you know they find out the VP is dead. I think the heat gets to them eventually while sitting there and you start it and now it has to run in that heat until it cools. Or it is broke and starting it finishes it off. The heat didn't leave as fast as you might think. So on the first few minutes of driving after the fuel temp is hot, that would probably be the most probable time for failure.

-

Hot vp44

Alright I have an 01 here for a while and he has a fuel temperature thing on his edge monitor that gets its info from the VP sensor (pretty sure). After going to town (10 miles, 55mph) it was 50F outside and the fuel temp was about 80F when I stopped. When I got back outside (20 min later), it was 110F. So we have a 60F jump over ambient. This was surely from the heat soak of the engine block. I am not sure how hot the components can get before they start failing but if the margin on an engine that has been shut off is 60F, then on a 100F day it would be 160F.. Whats more, I went back home and after 1.5-2 hours went by, I went back out and checked it, 110F. So no matter what you do, the engine will heat it right back up. Now remember that this was on a 50F day, where heat transfer to the air would be more than on that 100F day.. So when you turn your engine off on that 100F day, the chip could be over 150F for SEVERAL hours (maybe 5+). The aluminum housing easily collects the engine heat, if only there was a way it could easily shed it. Turning the fuel pump on (if you had a way to make it actually flow) would cool it, but only for the time that it was on. I don't think your batteries are going to be to happy for a several hour use every time you turn it off, or for however long the engine is above the safe temperature limit, as the VP will just keep matching the temp of the block.

-

Brakes, brake vacuum, ABS module.

I wonder if that is some sort of auxiliary vacuum pump.. Does it have anything else running to it or just the lines we can see from the pics?

-

Brakes, brake vacuum, ABS module.

Dang it! I knew my dead battery and having to find another cam would cost me time!Here is what I got for vacuum lines. You will have a few more for the 4x4 CAD thing.

-

A/C Compressor Leaking, new gasket or new compressor?

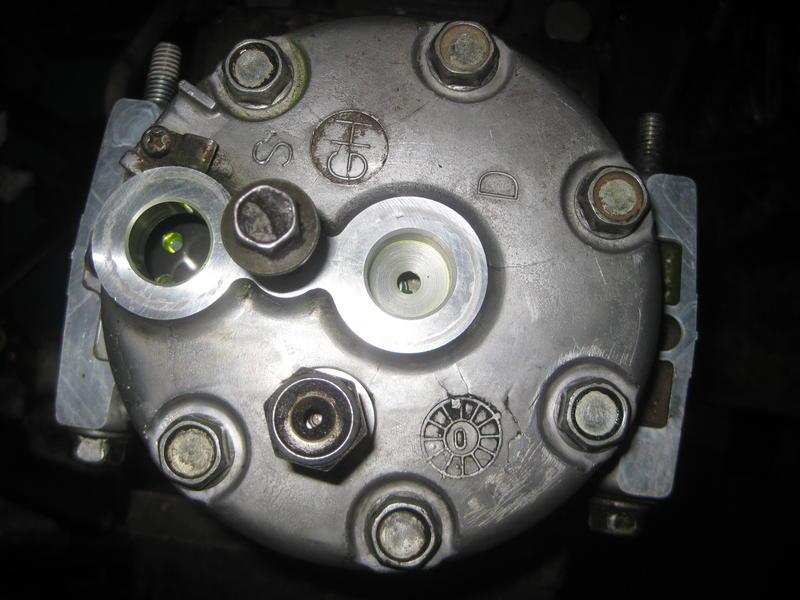

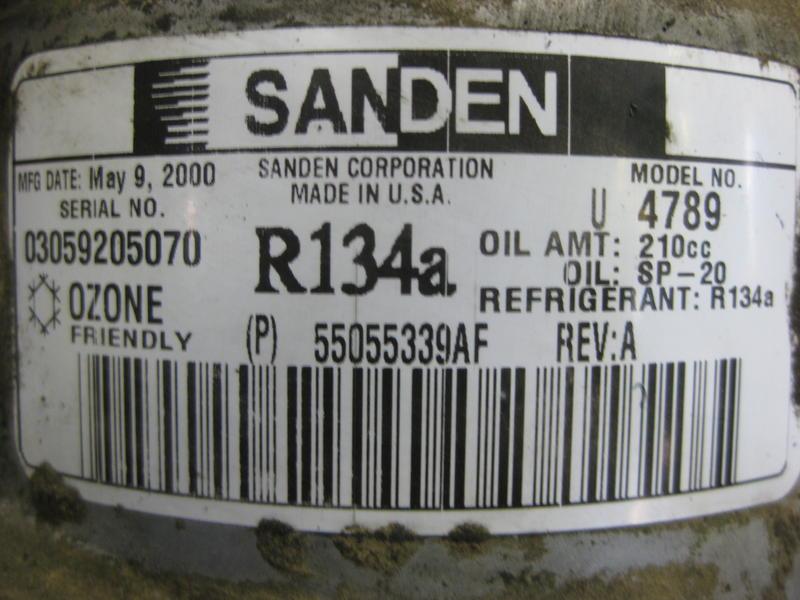

On a side note, I put that compressor back together making sure it was as clean as possible. Should be a lot easier to spot a leak now rather than tracking wet mud. It is back in the truck awaiting freon.

-

A/C Compressor Leaking, new gasket or new compressor?

Well I thought that youtube video was crap so I just went out and made my own. I skipped the time consuming process of taking the clutch stuff off. Though I think it would have taken just as long to do it properly rather than use a hammer :rolleyes:That one is off my ford and is an R12 system. I don't know if regular ones (like the one I took apart earlier in this thread) are double acting or not, I think they just use more pistons. Smaller pistons but more of them actually works out to having more area so it makes sense how they are using more in newer technology. Cars work the same way (24V vs. 12V, more flow in the same area using more smaller valves).

-

washer fluid pump

I think I would just look in a junkyard or something. There has to be a million of them out there. The wires for it are tiny but that pump is quite a pump. My pump/reservoir is in the toolbox in my bed and I have a hose running all the way up to the squirters and when I connected it back there, as a test, it was going over the windshield and hitting me. They are noisy and powerful little things lol.

-

Bird Cage blower... NOT ME. I got a

If it does turn out to be vacuum controlled you can get a check valve for a buck or two. I stuck one on my HVAC and it will stay on whatever vent I want indefinitely now.

-

A/C Compressor Leaking, new gasket or new compressor?

I assume they are part of the pistons or something. Inside is just a plate that has a lobe on it (I think, might just be a plate that is angled) and as it turns it just pushes the pistons up, one after the other. Then they go back down from a spring in them I think. I tried turning my ford's into an air compressor, worked really good but the threads on those things are weird so I couldn't get anything to seal very good and couldn't figure out the threads. http-~~-//www.youtube.com/watch?v=xt8wiIplRqM

-

A/C Compressor Leaking, new gasket or new compressor?

No this is on an 01'. It wasn't really wet in that bolt hole so it may have been residual from something else but it was soaked around the bolt, you can see it is wet looking so I think it is just that slow or something. I think I am just going to put it back together with thread sealer and make sure the o rings for the lines are good also and that it is all seated good. I couldn't see any die so I think it was just that slow or something. Have to see what happens.

-

A/C Compressor Leaking, new gasket or new compressor?

Actually it only looks like that around the freon lines because it all come out when I took it apart. The only green was around those 2 bolts. I'm thinking just retorque it all and maybe some fancy thread sealant on the bolts and see what happens. Is there a way I can check it for leaks with just an air compressor?

-

A/C Compressor Leaking, new gasket or new compressor?

I took this compressor apart because it was leaking through the bolts (I'm thinking the 2 that have green inside the threads, top left/top right). The gasket on it looks fine so I am wondering how it was leaking. Can I get a new gasket for it or will that not fix the problem? Can I put some thread sealant on the bolts maybe?

-

J-Hook

Does a chip fool the ECM?

-

power door locks

Do you mean lock when you turn the key on or what?

-

Timing cover broken

I *think* there have been sparse reports of even the later year 24v's having issues, very rare though. That is why nobody is giving you a clear answer, they might not need it but then the next day it will break and you will be another rare victim and you will be hunting us all down for telling you not to do it

-

05 removing negative battery cable problem.

Well the nut looks the same size as stock (I think they are 7/16") and the square on the other end looks the same as stock. So I think it is all the same that was on it OEM. I don't know why the bolt would corrode that bad. I wonder if the bolts are zinc plated so it has a sacrificial anode seeing as how bolts are much easier to replace and cheaper than a terminal that has all those wires fitted into it. That battery must have been leaking around the terminal pretty good or just out of the vent and got directed to that terminal. When you get it all off, you might get a felt washer to put over the terminal just in case it is the culprit that is leaking. I've actually heard of a lot of people having good luck with vasoline, but just as many have the same luck by just checking their oil and letting the dipstick drip on the terminals.