Everything posted by 2000Ram2500

-

revisiting two old and ongoing electrical gremlins

I think I’ve found out a direction to go for this finally! And the speedometer hasn’t acted up since cleaning out that connector. So. Last week I was sitting there and the quadzilla was running its warmup mode when suddenly, the engine returns to normal idle for a second then goes back. So I looked at my coolant temp on the QZ app and it was still around 95*, when it did it again! This time I was already watching and I saw it display a 0* reading at the same moment that it idled down before idling back up again. So now, I’m staring at wiring diagrams related to the coolant temp sensor. Is there a known problem area for coolant temp sensor ground issues? A bad splice somewhere? Keep in mind this particular problem (referring to how it’ll intermittently act like the TCC lock/unlock but it’s not the same behavior) has been going on since before I did all that work to it last month. I think what’s happening is a very intermittent loss of coolant temp signal is causing the ECM to derate for a second before returning to normal.

-

revisiting two old and ongoing electrical gremlins

I like these suggestions. I'll be having a car day at my friends house tomorrow I'll give this a go and report back what I find out edit 1: fast forward to the next day now 1/1/24 He got sick overnight so im gonna have all day tomorrow to see what I can find. I did drive it over to his house and back. after approx 15 minutes of driving and at about 42mph it was hunting between 3 lock/unlock real bad and then further up the road now 20 minutes of driving at about 55mph it started jerking around a bit, just single jerks or maybe a few at a time but not the typical TC lock/unlock that I had years back. didn't see any anomalies on the gauges and the data log hasn't shown me any strange outliers yet. no codes of course. everyday it becomes more and more tempting to buy my own DRB scanner. ill start with the abs connector tests here first and see what I can find tomorrow. depending what I find I think ill then review the AC voltage test and see if I can't find what my alternator is putting out with a borrowed fluke meter in a couple days edit 2: 1/3/2024 on Monday 1/1 I went out and at least pulled apart the drivers side connector behind the wheel well. It was full of dirt so I sprayed it out 3 times with some electrical cleaner and let dry before putting together. I ran out of time so I didn’t get to test the abs wires but I confirmed my meter does have a beep function so I will get to it asap Today, Wednesday 1/3, the alternator stopped charging, or rather the gauge displayed no charge voltage and said “check gages”. I shut the truck off to check the belt and alternator connector, which were both in place. When checked with a meter I saw 12.9v at the battery terminals so I restarted and saw 14.1 charging at idle. My meter is not a fluke so AC voltage testing isn’t possible until I get a chance to borrow a fluke meter. But for the next 30 minutes of messing with it and a short drive to get food and come back and this new voltage problem didn’t reoccur. edit 3: 1/8/24 my backup car is suffering badly I need to give it attention before I have no cars. 99 Toyota Camry 2.2L with 280k miles on it. original struts are about ready to fall out of the mounts. its all rusted together. ill get back to the truck shortly. bear with me as I attempt to stay on here and reliably take notes of everything I notice as I go along so I can finally figure this out.

-

revisiting two old and ongoing electrical gremlins

If anyone remembers my old post, I have done a bunch of stuff to it and just did a ton more this last month. Decided to make a new thread because the other one was getting old and enough has changed I think I need to start over. So this began with me fighting what seemed like EMI in a particular spot in town. At the time with the Edge programmer, I could watch the boost signal drop to 0 then back up to the true value and back to 0 again, truck was fluctuating between tuned and not tuned is what it felt like. Then as I left the area the tuner would kick in again and it would pump smoke out and off it would go. No amount of throttle would change its behavior. It was weird. One day my fuel pressure was 0. Found a melted wire for my air dog lift pump relay so I replaced the relay with another weather-resistant relay and taped it up and its been good ever since. So I'll get everyone caught up. Truck now has 208k miles. Transmission fluid is now valvoline ISO32 (napa p# 041) and has been for about a year. Rear diff has synthetic 75w140 plus additive. Well the Edge died so I ripped it out and ran a super chips downloadable tune for a while and I actually believe the edge was responsible for picking up the interference as I haven't had any since I ripped it out, but other gremlins still haunt me. Now, my problems are a really intermittent speedometer and also occasionally the transmission will flare up at about 40 mph and 3rd unlocked/locked. I did rebuild this myself, had to flush a ton of old fluid out and messing up the OD unit caused the OD piston and thrust bearing to bind and come apart which resulted in metal chunks everywhere and I believe to have cleaned hopefully all of that out and thats when I first replaced the sensor as well. Another important piece of the trucks history is that I sunk it in a giant mud pit 3 years ago, which is why the transmission went out and it also filled my rear axle with water which ive also flushed twice. The transfer case and front axle did not get water intrusion. In the past here's what I did to address this. Changed transmission fluid enough times I got sick of buying ATF and got this 5gal iso32 for half the price and added a transmission additive. I have replaced the trans output sensor once and cleaned it later on. I have a feeling I need to replace it or clean it again because sometimes, only sometimes the speedometer fails to work. Or maybe the rear ABS sensor (truck has 2 wheel abs) but I have changed that sensor as well. Sometimes it comes back if I restart the truck. But it also came back on its own about 3 hours into a 6 hour drive last weekend. (edited to add) I have also changed the APPS. I think, I have an Oreilly unit on the truck right now. I don't actually remember. Ive changed it several times over the years between a calibrate it yourself one with the adapter plug and I have or had 2 factory ones I was swapping between back and forth. Recently, the front main seal exploded. The actual dust seal part was missing completely, the seal part looked and felt abrasive, oil was everywhere. So I parked the truck for a bunch of work... Replaced front main seal, found that my killer dowel pin has been staked in already, extended breather hose down to a new catch can, replaced both oil cooler gaskets, replaced A/C suction line, new control arm bushings, shocks, sway bar end links. Cleaned radiator, fan, and shroud, extensively, also cleaned almost everything else. I stopped counting how much degreaser I used. Scraping grease and junk off with a screwdriver/scraper.. If I saw a ground connection I pulled it off and cleaned with brake cleaner. Removed the super chips tune and finally got a quadzilla. Amazing tune right out of the box. I discovered while changing the a/c line that I didn't fully remove the old noise isolator from the truck, it was disconnected from the harness but I left it dangling from the ground end so I finished that off. Of course gave it fresh rotella t4 15w40 oil and a factory oil filter. I have spent a couple weeks searching about different forums and on here trying to come up with clues. So far, I found an old TSB about handheld radio interference; in the factory wiring diagrams I traced the speed signal to the 14 way ABS plug pins 8 and 12; and someone on a post here mentioned the bolted down junction block connector under the dash as a possible point of corrosion. I am actually looking at the 2000 trucks engine wiring map right now and am wondering why the dark blue alternator wire needs to go to the transmission relay or is that even a problem. I am going to inspect the transmission solenoid connector for any oil saturation or damage in general.. and I also have this sneaking suspicion that I may have a rear axle problem brewing but I haven't been under the back of the truck yet. As for codes, the only codes ive seen in the last year was for the output speed sensor and the grid heater. I thought maybe the governor/transducer combo but those always give a code is what I thought unless im wrong about that. another wild thought.. years ago I thought the TC lockup switch was a good idea for me, is it possible I messed up and as a result the TCC driver in the PCM is intermittent? unrelated.. I was also curious is there is a reason to have a "26v" in chalk under the oil cooler. I thought that was weird, im not aware of the truck having a junkyard engine so its gotta be factory for something

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

long overdue update guys thank you to everyone so far so, as far as parts I've replaced this year since the last posts.. edge programmer actually died so I removed it entirely. I just can't leave it alone so I downloaded my antique 2004 edition superchips tune into it and its fine it runs great. got new tires, replaced steering box, replaced steering linkage (same 2010 complete assembly from the dealership), new steering dampener. replaced the output speed sensor on the overdrive housing. at the amount of fluid I've began to need for this truck I bought a 5 gal pail of valvoline hydraulic fluid (ill update with the specifics) with a can of BG transmission additive mixed in, it was $130/5gal at my local Napa compared to $10+ per quart of atf+4 since nobody carries it in gallons anymore I cannot find it here in a gallon. also added the power driven diesel cooler line kit which brought my heat exchanger back into the picture so I have properly regulated transmission fluid temp. still using an extra cooler mounted in front of everything. one of the mechanics was kind enough to let me borrow his fluke meter for a few minutes today. I've been dealing with the lock/unlock syndrome again. its not behaving like the true symptoms though. its not the insanely rapid jerks, this is slower and way more dramatic which has me wondering about the alternator and the APPS. I also have the GM style VB solenoid upgrade and I'm not sure of the symptoms those display when they go bad. these symptoms are not exclusive to the current condition of the truck but that has been happening with the edge, without the edge and with the superchips. I did not have a chance to find the information about the millivolts AC and where to check for readings or what the specific numbers were so I did my best to get the most logical stuff quickly I didn't have much time but I should at another time if I can hopefully gain some more education here I did all testing with the positive lead touching the alternator charge wire, where it meets the passenger side battery (I've modded my wiring already) with the ground lead at the passenger battery, I was reading 19mV AC with some fluctuation up to 34 with the ground lead at the alternator case, I was ready 33-34mV AC with some fluctuation up to 80 so as not to ignore the subject matter of the whole thread in the first place, I am still getting that interference at the same spot in town, again its with the edge, without the edge, and with the superchips. that whole situation is still beyond me. I will say the edge definitely amplified the effects so I barely notice it with the edge ripped out but its still occurring. maybe alternator combined with some weird residual from the power lines in that specific spot?

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

Air dog appears to be pumping. Relay definitely was toasted. Connector was cracked from the heat. Just got a new connector and relay spliced in with good connections. Battery connections are all clean and right. I’m using the military grade terminals that Napa sells and the copper lugs that you have to pound tight with that wedge tool and a hammer. No visible corrosion on any of the wires outside of some oxidation on the galvanized pieces. tested it with a jumper wire and it is pumping. So I just finished heat shrinking and taping the wires for the new relay and connector. Guess we’ll see how this goes

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

What did you say about the fuel pump lead becoming an antenna? I’m about to do some electrical work today. Late last week I noticed my fuel pressure gauge was at zero but it’s been a nightmare to keep it working reliably so I didn’t think anything of it until I noticed yesterday when I wanted to drive the truck to work that I didn’t actually hear the fuel pump cycle on, and and a bump of the key did not run the pump for 20 seconds only clicked the relay a couple times. So I checked underneath made sure my pump was still connected and then popped the hood and looked at my relay and saw a slightly melted wire and the relay connector was falling apart and a pin wasn’t even in its slot anymore. what’s even more of a mystery is it showed absolutely no signs of not having a lift pump. When the previous one failed it barely ran. I was running the truck like normal as if everything was fine. Do these pumps siphon? Would a larger fuel line allow it to siphon enough to not die or run terribly? I’m hopefully about to find out more edit for clarification: I have another car so I wasn’t driving the truck all week with no pump just one trip across town

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

in an interesting turn of events I just had a customer saying to avoid the very place I bought my injectors from saying he had a bad set of 1st gen injectors. At a certain point I did suspect that one or multiple might not be popping 100%.. I mean they were $189 for all 6 with no cores.. I knew what I was getting into… his knowledge base is supposedly based on him buying and selling and maintaining dozens and dozens of ram trucks all I have is his word I don’t personally know the guy but he may be on to something i did just roll over 200k and as far as I know this is the original vp44.. I know I’ve never changed it. i won’t have a chance to actually do any real work on this until New Years weekend with other things going on between now and then.. I’ll report back with what I discover

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

I never would have thought to translate radio electronics into vehicle but it’s still just electronics at its basic sense so it’s not that different. I play guitar and wanted to learn how to build a pedal for my electric so I bought some bulk packs of resistors and capacitors and diodes etc etc. and learned a bit. De-soldered a bunch of dead electronics I had laying around and a couple pieces of scrap from work. I happen to have about 1000 capacitors but lack a 0.01 my smallest is 0.1. The point being I’m at least slightly familiar with the concept of modifying a signal with capacitors to ground and opposing diodes in parallel.. I’ll dig into it some more and see what I don’t happen to find. So far I’ve managed to distinguish two separate issues. This one and then what I’ll outline below. it shouldn’t go without mention that I did the w-t mod I’m sure I said that if it wasn’t obvious in the title. And several years ago I changed out the alternator diode with one that mopar1973man was selling for the torque converter issue. I threw that BD ground isolation in the trash immediately. Well I’m getting torque converter glitches again and not just in that area of town I’m having the other issue this is definitely two independent problems. But the lock/unlock is nothing like they were in the past. It’ll do it at 35mph, sometimes. And at 35 it normally does float in and around lockup but only sometimes will it jump in and out. And then again in overdrive about 52 to 55 it’ll do the same thing, sometimes. Give it some light throttle to maintain speed, not accelerating, and that’s when it’ll act up, again it’s only sometimes but more often when the trucks warmer than cooler but it does do both. Its non-rhythmically and slower whereas years prior it was very fast and had a bit more predictability to it. Had me curious if maybe I’m having a diode issue again. I have a better multimeter now than I did then but still not a fluke. this is a lot of food for thought I’ll say. I definitely have my work cut out for me now. Lots to inspect.

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

It’s been a while. Been carefully observing how the truck is behaving and all that. My friend borrowed it many times. Towed a skid steer. Enough driving to continue on with the diagnosis. I’ve been taking note is what gears, lockup yes or no, speed, whether I was stopped at the red light or not and how long I sat there if I did, and so on. Through all of this I’ve left the edge connected. Now just so we’re all on the same page this truck sat for a year. I forgot how it drove and behaved. I needed to remind myself what was normal and what wasn’t. Now I’m ready to go a little further. Like I said I’ve been paying attention. And so far I haven’t been able to pinpoint any consistency outside of the fact that it would actually not happen on weekends and only during the week. Well just yesterday I was doing an evening drive across town and I could feel the truck slow down in that spot but this time I actually caught the boost psi flickering between 0 and 3 at a throttle position where I know I should have been seeing 3-5 psi and no flickering back and forth. It wasn’t even displaying 1 or 2 just back and forth 0 and 3. But you guessed it as soon as I got away from that area the readout started displaying normally. Finally! Something I can go off of. Now I feel better about pulling the edge out and inspecting the harness for problems. w-t I knew you’d known your stuff but good lord man.. the sad part is I actually understand the majority of that without google lol. Good stuff man

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

I’m definitely going to pursue the edge as a suspect because I’ve had issues with it in the past and although I may have the wires connected securely like you’ve mentioned it’s more exposed right off the bat. Not to mention the number of issues people have with the edge in general at least based on how many posts and threads I’ve seen related to it. last I remember and it’s been a little while but I’m pretty sure I saw that you have to actually disconnect the edge from everywhere you can’t just unplug it from the obd or anything simple.

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

@W-T I’ve made some changes to my assumptions over the last couple years. At first I thought it was the torque converter glitching I think I was at speed approximately 50. But quickly I changed to thinking it was a warmup issue because at the time I was heading out passing it but coming back another way due to the stops I had to make on those days. Eventually after living here long enough the first time I got the full dose of the error and I came to pass that spot with a well warmed up truck. I was trying to accelerate to keep up with traffic. Truck was into 2nd by this point and I was pushing the throttle but no go. It was maintaining speed and the throttle could be let off but it wouldn’t “go”. I am no stranger to dead pedal my dad had an 02 with a manual trans and we’d go so far as to key off while rolling down the road to reset the throttle. This wasn’t dead pedal I realized. And suddenly the truck whipped back to life and I unintentionally smoked out the people behind me. Out of all 75k miles I’ve put on it I’m about 99% sure that I’ve never experienced this anywhere else. edit: any speed I’ve traveled between 0 and 55. There’s 2 lights here and it’s common to catch both red or while they’re changing and be sluggish to accelerate out of there but be fine at the previous light and the next light and all the other lights in town. Ill make it a point to mess with disconnecting the edge and maybe doing a couple passes sometime this week. It’s not a huge issue to me just a really weird one. I wasn’t even gonna write a thread but it’s persisted since 2020. Got me curious as to why

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

Now that you mention it I’ve seen quite a few additional grounds in newer vehicles. I used to think they were just putting them in visible or convenient places but now you have me wondering if they’re targeting specific components

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

I haven’t gone too far into it so much as I’ve been paying close attention and trying to get more aware with what could be going on and it’s just kinda left me at a dead end with no real clue where to turn. I’ll pop the hood and make sure all my important connections are as good as they can be. And then I’ll disconnect the edge and do some testing. To be fair there’s a couple poor or not ideal aspects of the edge harness that have had me looking into buying a new harness or a quadzilla.. but haven’t had the budget or time to really pursue it any further than remind myself of the price. But even so, I’d expect issues more frequently if it’s a harness issue. Then again it could be some sort of weird interference that’s just exactly right to affect whatever oversight I’ve made and it’s some crazy coincidence. edit: I’m by no means an electrical or wiring professional but I try to maintain a pretty high standard for what i use or how I connect them. All my battery terminals are the “military” ones that Napa sells. 3/8” bolt for your connections and you’ll never have any issues with them I love them. Batteries are Walmart deep cycle and i was hesitant but it’s all I could afford at the time. They seem to do great though don’t have any complaints about them. I solder whenever I can and when I can’t I’m using quality connectors and the weatherproof heat shrink always. I keep my wires tidy and protected the best I can. Clean grounds when I’m there. Try anyways I’m not perfect It’s just speculation though really. I have no firm ground to stand on for anything other than how it’s behaving when it does occur.

-

We've all done the W-T mod.. but has anyone dealt with interference from outside the truck?

As best I can describe it, if anyone has been driving a car when the catalytic converter melts down or plugs up the engine gets generally sluggish and struggles under its own weight. Throttle works but no not really because its just bogging it further in a sense. Or how about those of us with Edge tuners who take off driving before it loads and you get that sudden burst of power when it does start working. That sudden contrast between no tune and tune. However in my case only 200 yards prior i was running the tune and it just suddenly fell on its face then as i said its a sudden burst of power when it clears up. I hope that description makes sense because its what my entire issue is but i'll explain it specifically here and just refer to it as "symptoms" to save some typing I have to pass by a particular factory very frequently. Its the main road through town and my route to work or stores unless i take the back way or long way. As i approach this segment of road that these "symptoms" occur for, (haven't measured it exactly but maybe a few hundred yards or so), my edge tuner is typically at level 4 with the boost compensation backed off or level 5 if im in a mood, regardless of load you can feel that level. Suddenly i get those "symptoms". Throttle works. No lights or anything out of the ordinary. I make it that short distance up the road and depending on where my foot is even in level 4 with the boost comp backed off it'll usually dump a little smoke and then back to normal as if nothing happened. I bought this truck in 2016 when i lived in california. maintained it in arizona. still have it in florida. i've literally crossed the country and can solemnly swear this is the only place this has ever happened to the truck. the factory iteslf isnt necessarily close to the road. the nearest power transfer station is about 3/4 of a mile away. no cell towers that im aware of. there is the helicopter field but my house is much closer to the field than this segment of road is. the only other businesses in proximity is a handful of restaurants and stores and i think a parts house and a oil change place and a carwash. I did the W-T mod years ago and even changed the diode if im not mistaken. I've taken care to make sure my batteries are all kept in good shape. APPS is weeks old. There was even a year period of time when the truck was down and it was acting up then too. Happens on both sides of the road but not every single time just 50/50 probably. I thought APPS but its done it with at least 3 different sensors from 3 different companies (OE, Pensacola Fuel Injection, Oreillys Standard ignition currently). Im not exactly expecting results so much as im sharing in hopes someone has some sort of clue because i absolutely do not have any idea what would cause something like this outside of some sort of interference violations i mean this is just weird to me. Im not saying im jumping for a lawyer at all its just one of the weirdest things ive encountered and ive seen some pretty wild complaints having been in dodge dealerships for so long

-

47re line pressures when engine braking

I edited mine also.

-

47re line pressures when engine braking

I’m agreeing with what your saying I tried telling a dealership mechanic about how gear oil and engine oil are weighed on different scales etc.. as a parts guy working in the same store as him so he already knows me… and it was like talking to a wall. Nobody seems to understand the science here i tried to tell him that at a certain temperature a 10w engine oil and a 75w gear oil are gonna behave the same (not knowing the exact science or numbers I tried to generalize for him) and he all but laughed me out of the room because sure gear oil is like honey and engine oil is like water by comparison. So I don’t blame someone at the surface but an axle will see high temperatures and pressures as the bearings squeezing the fluid out. I think there’s a lot involved in the additives that isn’t necessarily broadcasted to the public that may help the thinner fluids stick to parts much like the thicker fluids do naturally. I’ll have to double check myself at work but I’m pretty sure mopar superseded the G56 fluid to ATF+4 a while back. That’s when I got the lecture from the BG chemicals guy about how fluid viscosities aren’t measured the same as what they seem to imply with the obvious thickness of gear oil and kinda scary lack of thickness in ATF.

-

47re line pressures when engine braking

Based on the ATSG specs on line pressure: unmodified valve body of course line pressure in drive with gauge in the accumulator (middle) port at idle should be 54-60 and stall 90-96. I can’t comment on stall psi but my idle psi is about 85psi at ambient temp of about 80 or 85 with the shift kit installed by the transmission shop. I also don’t have an exhaust brake just trying to help. i think the lower pressure at operating temp is due to the fluid expanding and thus becoming “thinner”

-

Just rebuilt 47re myself and it went out 5 days later

So far so good. Moral of the story is don’t assemble your overdrive the wrong way I guess. Hopefully I don’t have a different story in a week. ABS sensor didn’t fix the speedometer right away but I still had the digital one on my edge. Then after a couple hours of various driving on a couple different trips the speedometer came back and has been working so far. No check engine lights. All gears work although I haven’t tried manual 1 or 2 yet. The only and probably the weirdest problem I’m experiencing right now is I have one main road through town that I have to take no matter what. And if I pass this one specific stop light my throttle goes limp. It’s about as close to a dead pedal as you can get without actually being a dead pedal. I still accelerate but it’ll barely go. Then when I’m clear of the area it returns to normal. Doesn’t matter if I’ve been running the truck for 3 seconds or 3 hours it will do it almost every time and it only ever happens at that one specific spot in town. Never anywhere else along the 10 freeway from almost coast to coast has it done that and I mean that literally. Only that one spot. There’s an chemical plant there but no power stations or anything else that would normally cause “interference” if that’s what’s going on. It’s also done it with 3 different APPS sensors, OE factory, Oreilly, and whatever Pensacola fuel injection sells. But this is really for another thread

-

Just rebuilt 47re myself and it went out 5 days later

Also my first rebuild. These are pretty straight forward but plenty of room for error. I should be seeing the last of my parts today. I’ll be flushing it some more and crossing my fingers. If I have to do it again then I guess I have to do it again but I’m learning as I go.

-

Just rebuilt 47re myself and it went out 5 days later

You’re not the first to suggest another transmission I’ll say that. i haven’t drilled the check valve it was just recommended that I do drill it out to prevent clogging. i am aware that fluid does pass through bores within the shafts but haven’t yet come across any mention of issues with clogging inside those bores. previous failure wasn’t “catastrophic” I just lost my rear forward clutch pack and thus all momentum but also had water contamination which was a root cause so I replaced all the clutches. Fluid condition at the time of draining and initial rebuild wasn’t anything other than black and no pieces of metal were found at that time at all. Input shaft wasn’t a problem but was found cracked not broken and then replaced. All of this debris can be found inside the output housing and in my pan. I do suspect some pieces to be hiding above the valve body though. But I can’t see any way that any of that debris could have made it beyond the pan and filter from the back. This happened entirely inside the overdrive housing. im no pro by any means im just trying to fix this thing. Im working on my back at my apartment with hand tools and borrowing space in a friends garage if he’s able to let me. Im just doing the best I can with the little income and facilities that I have.

-

Just rebuilt 47re myself and it went out 5 days later

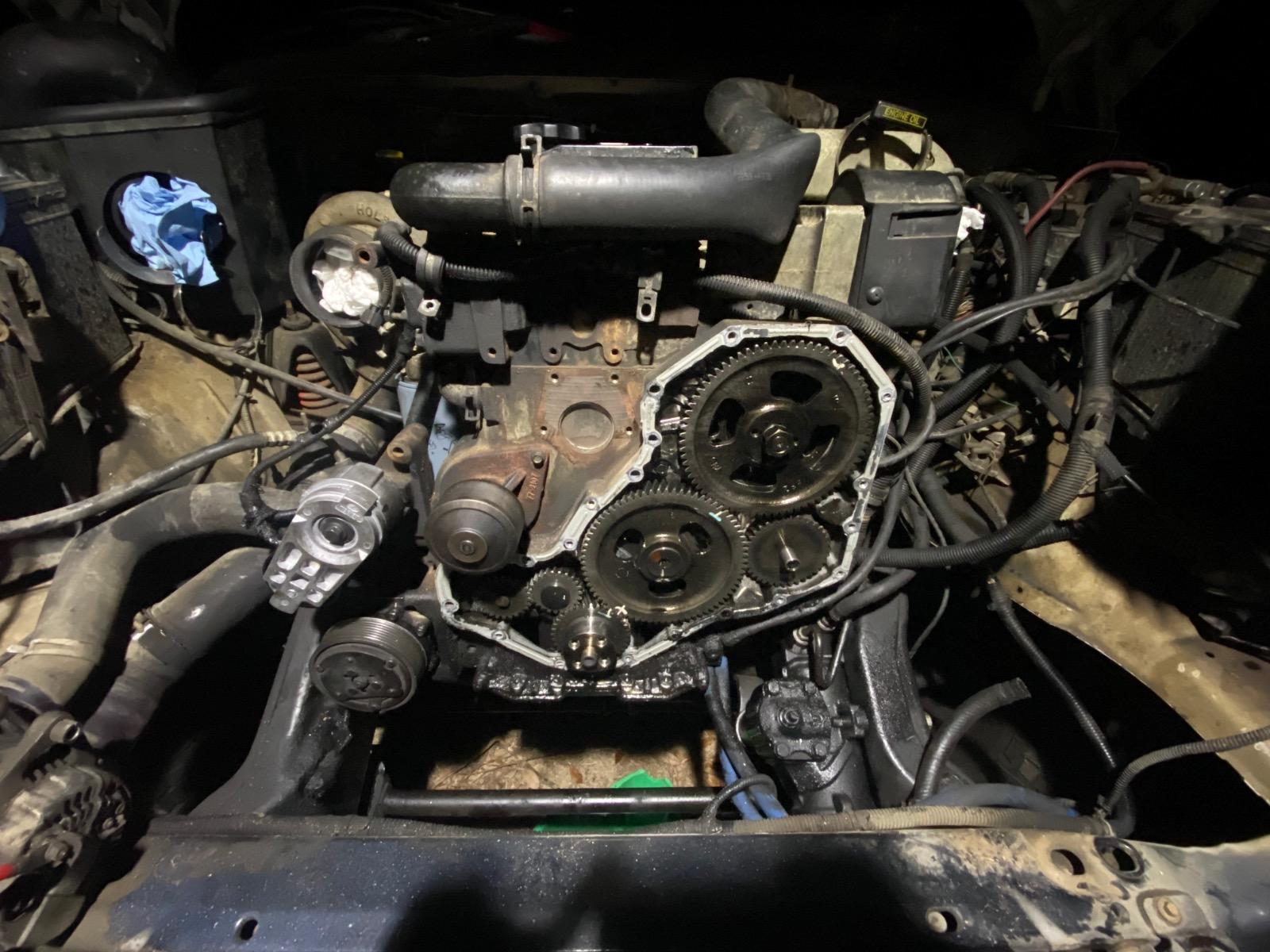

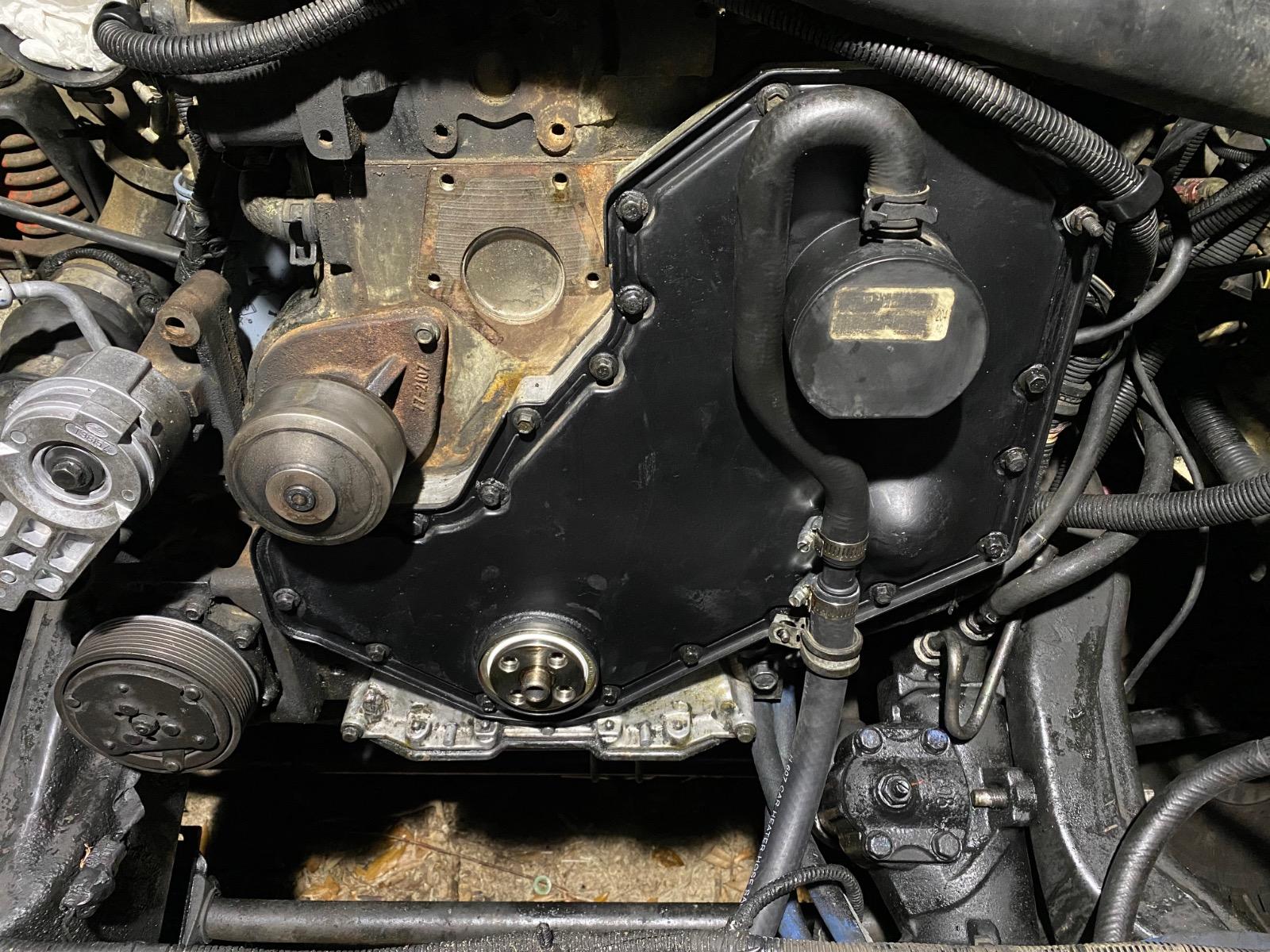

Alright so I’m not sure where I went wrong but I’ll never know. Bearing was the overdrive piston thrust bearing. Overdrive brake clutch was cooked. And when I put the unit in the press and removed the snap rings (yes both of them) it would not come apart. I’m not brave enough to find out why so I got an assembly from eBay. Should arrive today or tomorrow and I’ll be inspecting it thoroughly before installing it. it was highly recommended that I drill out the check valve inside the cooler line but my check valve is inside the cooler itself because I do not have the factory cooler lines and still have a check valve preventing back flow. Has anyone drilled that check valve out before and maybe has some pointers?

-

Just rebuilt 47re myself and it went out 5 days later

got the OD unit off the back. Bearing chunks falling out with it. Cooked the OD clutches messed up the piston and pulled that small snap ring out of its groove. I'll be swinging into my local transtar tomorrow and getting some of this stuff on the way. It makes me wonder what caused this. I didnt replace any hard parts only clutches so in theory the clearance should have been fine. I wasnt able to tell for sure if the big bearing groove was worn out and the actual unit itself inside with the spring seems to be together correctly When i rebuilt this thing the input shaft and rear/forward clutches were wasted. input up was cracked all the way through and the shaft had spun inside the hub. Im wondering if that had covered up an issue in the OD that i didnt notice when i had it apart

-

2001 Dodge 2500 Heat Exchanger Replacment

Ive actually been curious as to how one would delete the heat exchanger altogether Im not recommending this to anyone simply saying that i really messed up my cooler lines a while back and found barb fittings and half inch hose went right to the cooler and back and sawed the exchanger lines short and out of the way. I eventually added a cooler in front of the condenser because i then understood how hot coolant can help regulate fluid temperatures. But it looks like all you would need to do is find a big pipe plug for one of the block offs and then there was one other piece that looks like it wouldnt be difficult to change in order to just remove that thing all around. You'd definitely need to add in a substantial cooler because the heat exchanger is a really powerful part of keeping the fluid temp down when it wants to climb

-

Just rebuilt 47re myself and it went out 5 days later

Finally have an update to this thread As it turns out I managed to clog the filter with leftover debris in the cooler and torque converter. Flushed about 7 gallons of fluid through it so far. Changed filter added fluid and drove it.. TPS/APPS was sticking and cutting out and almost made it undriveable but i pressed on. Went easy on it for about a mile to the nearby park where i stopped on mostly level ground checked fluid levels and for leaks. Headed then to the main road a little 2 mile cruise did exactly 1 pull from low 3rd lockup to OD it all was going great. So i got a new APPS the next day (yesterday) and swapped that out. Decided i should drop the pan again and give it another filter based on the quality of previous fluid. Im now skimming through tiny shards of metal and actually found 3 rollers that are no longer within their cage and now in my waste oil bucket. So i filled her with fluid and test drove it again and realized my ABS sensor must be bad because the speedo isnt working below 30mph. Yes i drove it last night after finding the bearing pieces. Went pretty good i just needed to make sure the APPS wasn't gonna stick so i didnt go far. But I also drove it to work and back today. It all went pretty good but I did keep it out of overdrive on my way home for fear of damaging my OD piston as thats the thrust bearing that im suspecting came apart. So now its parked and cooling down. I got a new ABS sensor that i'll install at some point this weekend. I am borrowing the alignment tool from work and pulling the OD unit off the back because its about as much as i can do without pulling the whole transmission and im pretty sure i messed up that tolerance anyways or possibly my case is worn in the back and i need to get a shim or a new one. Finding the rollers was a little unsettling and i hate that i cant take it apart right now but i should have more to post at a later time Its been several months now but thinking back and researching the proper way to measure for that piston spacer im really beginning to doubt that i measured that correctly. Im staying positive though.. I'll either pull the OD and see my problem immediately or I wont see it and I'll know what i have to do next. Im even tossing around the idea of ordering one of those preassembled overdrive cases from ebay at this point and just putting my guts or clutches in it and i'll even get my own alignment tool to keep. But this we wont know until i get under the truck and get it apart again. I skipped alot of the deductive reasoning but it seems most likely to be the OD piston thrust bearing. But those rollers were skinny and short and the only thing that even uses rollers is those thrust bearings. My 47re only has 3 and 2 of them are in the OD unit. I have seen plenty of pictures of the carnage that happens to the thrust bearing under the sun shell in the main case but I really dont think these pieces of metal could have escaped that shell. However, I am noticing that OD engages in a really inconsistent and poor manner. There also happens to be a large hole in the casting where a piece of metal the size of the one i saw could have fit through by the park rod. Im not hearing any noises. Im not noticing any other issues with the transmission or how it drives other than a single instance where it felt like it was hunting for 3rd but i think its related to the ABS sensor because it started to hunt for 3rd immediately after the speedo came on and read about 33 and climbing then grabbed 3rd and lockup. And it does feel like 2nd comes on way too early at like 8mph but i cant tell with no speedometer until 30. More to come edit- atf+4 is expensive and tough to find but i cant sell myself on buying the ever plentiful 5 gallon hydraulic fluid. but at the rate im using this stuff its looking more and more appealing. its hard enough to find more than 6 quarts of atf+4 around here but every store will have like 3 or more 5 gallon pails of tractor hydraulic fluids in several different grades. 15w40 t4 is also super easy to find in 5 gallons around here thankfully

-

Just rebuilt 47re myself and it went out 5 days later

never air tested any transmissions before so that’ll be a learning experience. and yes I did do the clutches under the big spring they were a nightmare and a little sketchy to say the least. I bought a press from northern tool and used about a 10 inch piece of 3” PVC cut down with a window to get the snap rings in and out. Literally the only lip seals I didn’t change was behind the forward clutches in the front drum. I did the rear forward piston and got the gap set with the correct size snap ring and definitely changed those seals. Just the ones under the little springs I didn’t change but I never even took the springs out to inspect it so there’s that. The one-way roller clutches were easy. I just set them in a safe place until assembly and they went in the same way they came out. I verified direction with the book but I never moved them and definitely had 5 days of solid problem free smooth driving out of it so I’m sure they are fine. i followed the factory diag flowchart (I work at a dodge dealer) and Chrysler says to look at the regulator valve inside the valve body. At this point it seems I’m looking at a line pressure issue with a leak I can’t pinpoint until I get this thing out and I can’t get it pulled until my buddy clears me a spot in his garage. So when I get a chance I’ll be draining fluid and pulling the valve body and inspecting as much as I possibly can without actually pulling it and proceed from there. I’ll also update with any codes since I keep forgetting to pull them