Everything posted by Haggar

-

Cracked intake plenum eyelet

Leather, I can't picture which one is broken, but you could weld a "wing" to the nut? This would allow it to swing and stop providing the resisting torque. Like the blind nut on the track bar. HTH Hag

-

Power Steering (hydroboost)

Wow John, Look what I found too! An article by Cowboy on helping the flow!!! Nice write up Cowboy!

-

Rear Driveshaft Universal Joints

Be careful, we are starting to mix some of theories of operation and terms. A single cardan joint that has an exit angle different than the input angle (the front half of a normal drive shaft (forget carrier bearing atm)) will have a relatively constant input velocity (as constant as our diesel can produce) but the output of the shaft will have a constantly variable velocity. ( If measuring the velocity and acceleration of the output of that single shaft will make a sinusoidal output graph. with two high and lows per revolution) If you could feel it with your hand, it would be "jerky" or cause a vibration. The greater the angle of the shafts, the greater the amplitude of the output velocity differential. The addition of a second joint exactly opposite phase of the first joint, will smooth or dampen the angular velocity difference back out. So theoretically the rear differential will "see" a nice constant velocity input. As the angle approaches zero...(if there were no parallel offset of the rear of the engine and input pinion) the cardan joint would be a poor choice. The cardan joint needs to bend so the rollers inside will roll. If the joint didn't bend all the load would stay on the same needles and eventually brinell the races. In our system, the front universal going to the carrier bearings should be pretty straight. (I don't think the angle is zero, but it is very small) (yes poor use of the cardan, but I think all the oems just live with it from a logistical and cost perspective.) The angle is from and corrected by the other two cardans. In the front, the system is pretty much the same, but due to the very short shaft length, the double cardan joint does most of the bending and the input to the front differential is fairly straight. (unless you have added a lot of frame lift, without rolling the front pinion.) So it is "like" our carrier bearing system in the rear, just no room for a carrier bearing. We can go into driveshaft whip too if you want... I hope this helps a bit! Hag

-

Cleaning Radiator?

Joe, just a hose a brake or carb cleaner (I like Me's simple green idea!), a soft brush, and maybe some compressed air. You don't want to use enough force that would bend a fin, but something to cut the oil and push it out. Here is a picture of my youngest helping clean the intercooler. Not much oil there, just dust and dirt.

-

Power Steering (hydroboost)

John, We may need to re-think. I have found a couple articles that have said if the pressure to operate is enough, then it is more flow rate is needed. (I realize that flow and pressure, while different, are highly dependent on each other in a small system like this.) Here is a neat how to. http://www.gmtruckcentral.com/articles/2013/powersteeringmods/ I would only concentrate on the flow aspects. The FSM seems to confirm this: The 01FSM shows no pressure difference between all the pumps for all Rams. EXCEPT that Diesels and Hydroboosts (which in that year meant the same trucks) Had a HIGHER flow than all the others. by as much as 30% See page 19-5. and that goes along with DF's statement, if you are foaming oil, there could be trapped air totally messing up flow rate. GL HTH Hag

-

Power Steering (hydroboost)

John, The power steering pump just helps you do the things. If you are feeling "loose" that is usually a mechanical issue, unless your power steering pump pressure is changing. Is "loose" a place where the wheels are not following the commands of the steering wheel, or is it pressure fluctuating making it easier to turn and harder to turn. (whether you have power steering pressure, the wheels should follow the commands of the steering wheel.) You are in a tough spot... which came first the chicken or the egg? I would do what you suggested. Clean the filter and regulator. You can also try a thin washer behind the spring. This should increase your PS pump relief pressure. You could do a complete flush too. If that doesn't fix it you are going to have to try a pressure test and see if it is going wonky on you. GL!!! Hag

-

Front axle alignment

What end links? Sway bar? If so just slide the sway bar left or right. The frame mounts of the sway bar do not resist lateral movement of the sway bar. They have straight holes through them with no axial load capability. You may have to loosen those mounts to allow the sway bar to shift laterally, but it should move easily then. (as easily as rusty metal moves in rubber/polyurethane bushings) a little bit of silicone spray will help. HTH Hag

-

Front axle alignment

The front axle "should" be centered on the frame. But parallel offset of the front and rear axle is not a terrible thing. So I would probably make it a balance between the two if the body is that far off.

-

Front axle alignment

It is kinda funny.... It should be established from frame centerline. But the body is on mounts, so it could be correct to the frame, but look wrong because the body is on crooked. You can't really use the rear end, the track width is different and it has a +/- 4 degree thrust angle tolerance. With the wheel straight measure from the RIM to the frame on each side. The hard thing is making sure the wheel is straight. Looking at some pictures, you could probably measure from the spring to the frame on each side. Or center the sway bar in the sway bar mounts. You could hang a plumb bob from the centerline of the frame, then measure to the rotors too. Hope that helps.

-

O-Rings ?

It seems to be Power Steering Hose O-Ring MOPAR 05205254 (I don't know this for a fact found it in the parts manual) I am not finding a cross for it. It looks like it was used in many applications, so your local dealer may have it. HTH Hag

-

HELP... rear brake issues

I hope that was all it was!!!! Hopefully the rear brake problem is behind you. (pun intended lol) Focus on that front. The Right Front seems to be very susceptible to the collapsed hose thing, and therefore not relieving the pressure on the caliper. I have had this failure and 2 Weekends ago one of my venture crew members went through that too... and due to not listening, he ended up with having to install a new rotor, caliper, wheel bearing assembly and drive shaft. (messed up the threads on threads on the drive axle.... those axles are not cheap btw...)

-

NV4500 fluid no longer produced.

Perfect fatigue failure. Notice the smoother quadrant from 6 oclock to 9. (and also looks like a small point around 5.) that is where the failure started. most likely from a machining mark at the diametral change. The smoothness comes from it being loaded and unloaded as it rotates. The less smooth area is where it moved faster or fatigued but not as long. The really rough areas are where it "tore" as it catastrophically failed. The smear at 12 o'clock is damage after it failed. Right under that looks to be the roughest so was the last thread still together and failed. It is so hard to tell from a picture though... If you have a loupe or a really good magnifying glass take a look around the edges, you may see the very beginning of the starburst.... the beginning of the failure.

-

HELP... rear brake issues

DDN, One thing I thought of over coffee, make sure you put the primary (smaller braking surface) shoe forward. This makes a HUGE difference. (the self actuating nature of the bendix brakes depend on this to NOT over apply) I would go combination valve before MC. See the FSM page I have attached. It tries to control early pressure balance (see metering function). Brake pressure testing is not that expensive (though I want the killer OTC kit at 500 bones...) It looks like Jegs/summit have kits at the 50 buck mark. Just check your bleeder screw size to make sure the adapter is in the kit. Good Luck! 2001 FSM Ram 5-9.pdf

-

HELP... rear brake issues

DDN, Take a peek. Lets see what anti-lock you have. the computer would light the light only if it "thinks" it has a problem. If it is getting false/bad information, but within the realms of its limits it will think it is OK. Does your "ABS" light light up properly during key on test? From what I am seeing the RWAL also has a CAB (controller anti-lock brake)... The picture in my FSM shows a pump too, but that could be wrong..... Here is a trick, unhook your CAD, drive the truck in 4 wheel drive. (the TC will turn the front drive shaft, but with the cad disconnected you won't get the hopping and such. I would avoid parallel parking though..:)) The computers will tell the ABS system to not work. It will cost a bit of fuel for a day, but this would take the ABS system out of the sequence. The FSM says for rear brake grab or pull (if affects both rears) master cylinder or proportioning valve. If you have the RWAL only, it looks like it could be an accumulator only system.. If something in the valve or the accumulator has locked up, you get no relief of over pressure to the rear brakes, meaning they work too much. (no proportioning.) I am sure the 4wABS is similar, but uses a pump to pulse the systems. We may have to do a brake pressure test at the wheel cylinders..... Hag

-

HELP... rear brake issues

DDn, Yes the master cylinder could, but you would see the residual pressure at the wheel cylinders. Since you are not seeing this, it has to be something else!!!! (temperature rise can cause this too, but you would have residual pressure...) Grrr this is frustrating!!! If you can put your hands on the drums they are not hot at all. So it seems like a dragging brake is not the problem either. (neither is a residual pressure problem) Do you have the 4 wheel abs (3 channel?)? I wonder if it could be actuating after temperature. (mine performs differently in the cold than the hot. need to get it fixed, but not totally broken yet) For giggles, disconnect it. Drive for a day and see what your braking results are. You will lose the speedometer, but that is the only down side. HTH Hag

-

NV4500 fluid no longer produced.

Great discussion! This explains why my cold shifting performance is less than optimal.... I run the Gorilla Juice. Almost out, so looks like I am looking for my local Mobil distributor! Fun!

-

HELP... rear brake issues

lol, he is right and immediately wrong! He makes fun of an engineer calling it a "proportioning" valve, then he himself calls it a pressure reducing valve! W-R-O-N-G. It may be a pressure limiting valve, but it has no circuitry to reduce a downstream pressure once it is already there.... omg... then he goes on and says 500psi line pressure on 6 square inches is 3000 psi!!!! 3000lbs force yes, 3000 psi... ummm maybe he shouldn't be pointing fingers at enginerds. Sorry, his explanation is decent, just don't get hung on the details.... The engineers used the valve to set the proportions of brake bias. So I can see how they came to calling it a proportioning valve. At least they didn't call it a "pressure reducing valve". Bluto: "What? Over? .... Was it over when the Germans bombed Pearl Harbor! Heck No!" (Otter: Germans? Boon: Forget it he's rolling)

-

Power Steering (hydroboost)

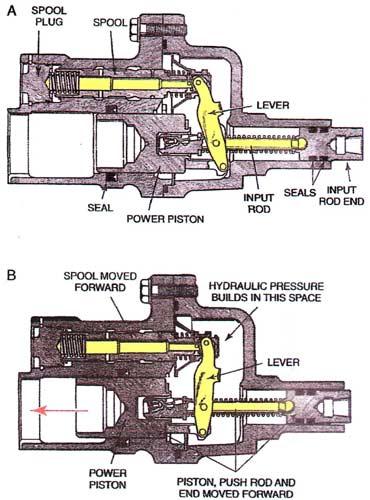

Here is a great picture of how the hydroboost adds pressure to help you actuate the brakes. Here is a great explanation of the hydroboost operation specifically. http://www.brakeandfrontend.com/operation-diagnosis-and-repair-of-hydro-boost-power-assist-systems/ The pictures are just crazy small. Here is where I found the operation picture. It looks like a great basic explanation of braking systems in general. (I have not read through it for technical accuracy though.) http://www.winbrake.com/training_autofundamentalsbrakes.html Notice when you push the "input rod end" the assembly moves forward. This opens a valve letting hydraulic pressure to help you push the "power piston" forward. The hydraulic pressure on the added area of the piston is what helps you "push the brakes harder".

-

Power Steering (hydroboost)

John, Yes, A high pressure hose goes from the ps pump to the hydroboost. A high pressure line goes from the hydroboost to the steering gear. Both the hydroboost and steering gear have separate low pressure return lines to the ps pump reservoir. The hydroboost helps your braking by storing hydraulic power. When you push your brake pedal, you release some of this stored pressure it forces a piston in the hydroboost to help push the master cylinder piston. If the hydroboost leaks, it usually leaks on the firewall or into the cabin behind the brake pedal. The steering gear can leak anywhere there is a seal. The return lines can leak and there are O-rings on the high pressure lines that leak pretty easily. The pump can leak from the front seal and from the reservoir O-ring. Hope that helps!

-

HELP... rear brake issues

DD, wow. If you found pressure, we were going to work through what it could be (MC not returning properly, internal hose failure etc.) Since it is not retaining residual pressure.... I can think of 2 things (I thought of one last night....) First thing since you have turned the drums, are you reshaping the shoes to the drums? Assuming the brake manufacturer got the radius right (missed more often than you might think) it is the new drum radius. as you turn the drum that radius gets larger. the smaller radius of the shoes only contacts the drum in one spot (the middle), possibly making the shoe very hot. (reshaping shoes is not hard) The other possibility I don't think we have considered... could the front system not be performing properly putting more of the stopping load on the rears? I realize that sounds stupid, but usually our fronts do so much of the braking, if the rears were not used we would hardly notice it. (until we had a load etc) So for yours to act up during normal driving, seems odd. Hag

-

Anyones interested for engine aluminum oil pan???

Nice work! That is looking good! Hag

-

HELP... rear brake issues

Sorry missed the word bypass in your first post..... (doh) If we take out any problems with the physical mechanical parts in the rear brakes there are only two other choices: 1) The factory setup proportioning valve is applying too much balance to the rear system. (this seems like it would be all the time, not just worse when hotter. and like you said most people don't have this problem) 2) The master cylinder or proportioning valve (or tubing/hoses) to the rear axle are leaving too much residual pressure in the rear system. When you remove your foot from the brake pedal, a molecule of brake fluid (should it wish) could move un-hindered from the rear wheel cylinder to the reservoir of the master cylinder. (all lines should be open, and all valves should be too.)(this is how the brake springs compress the wheel cylinders so the brakes will not be engaged.) The next time your truck starts acting up, quickly release the bleeder on one of the rear wheel cylinders. you should only get a tiny dribble, if any flow at all. If it squirts you have some residual pressure that should not be there, and you just let the wheel cylinders relax. See if you have some pressure when the problem gets pretty bad. HTH Hag

-

HELP... rear brake issues

The rear "level sensing unit" or Height sensing unit is not THE proportioning valve. (there is also some proportioning from the master cylinder itself, based on bores and strokes there.... most of us don't mess there but there can be some tuning available if needed.) The proportioning valve (now called combination valve) should still be located near the master cylinder. It should have both the front braking circuit running into it (and out) and the rear circuit running in (and out). It has a check valve in it, that should the loss of continuity of one circuit, ALL braking will only go the the circuit with integrity. This prevents un-needed loss of fluid, and signals the brake light on the dash that there is a problem. (this will cause a constant on lighting of the brake light. not flashing like parking brake on does.) This proportioning valve is sized such that the larger diameter but low stroke of front discs can be combined with the small diameter but larger stroke of rear drums to work together. The "level sensing unit", is a rear axle system. It "sees" the relationship (in elevation) of the frame to the axle. It allows more pressure to the rear brakes based on the assumed load in the bed. It sounds like you need to re-adjust that rod. You have too much rear braking force, for the weight you are carrying. (or the valve you have is damaged.) Take a peek at this site. The information is really good. Read about the height sensing proportioning valves. http://stoptech.com/technical-support/technical-white-papers/proportioning-valves Hope that helps! You just may need to do a simple adjustment. It sounds like your Height sensor is thinking you are carrying more weight. Hag

-

NV4500 finally died...

Michael, I bought a brand new 4500 a couple years ago. A company called High Gear LLC, bought all the left over GM NV4500s. They put a dodge tail shaft on it, and boom new trans. (I had to use my shifter, as the new shifter was GM...) but has worked out well for me. They were great to work with. I don't see the new transmissions listed anymore. Give them a call though. I want to see pictures!!!!! I was going to rebuild mine, but there were multiple teeth from third in the bottom of the case, so I bit the bullet. Hag

-

Front passenger brake problem

DDN, Check the backing plates!! There are 3 or 4 points per pad, where the backing plate supports the Shoe. (If you think about it, this is what resists the springs that hold the shoe to the plate.) These get grooves in them over time. (most people never lubricate these points.) They need to be smooth without grooving. I usually hold the shoe against the backing plate and make sure it can move easily. Take a peek at the FSM page. HTH Hag 2001 FSM Ram 5-27.pdf