Custom Quadzilla Tuning R & D Thread

- Replies 477

- Views 71.6k

- Created

- Last Reply

Most Popular Posts

-

and a spare room for me to crash in while I tested about 50x different tunes and setups hahaha

-

Close your eyes and click it. That's how I order truck parts these days.

-

I think with these vp44 trucks, the biggest downfall here is no 2 are the same... I feel like the quality control was subpar. It seems like 5 identical trucks would behave in 5 totally different ways

I didnt want to mix up the threads by posting unrelated information so I figured I would start a new one. This thread is for figuring out what works and what you find your truck likes.

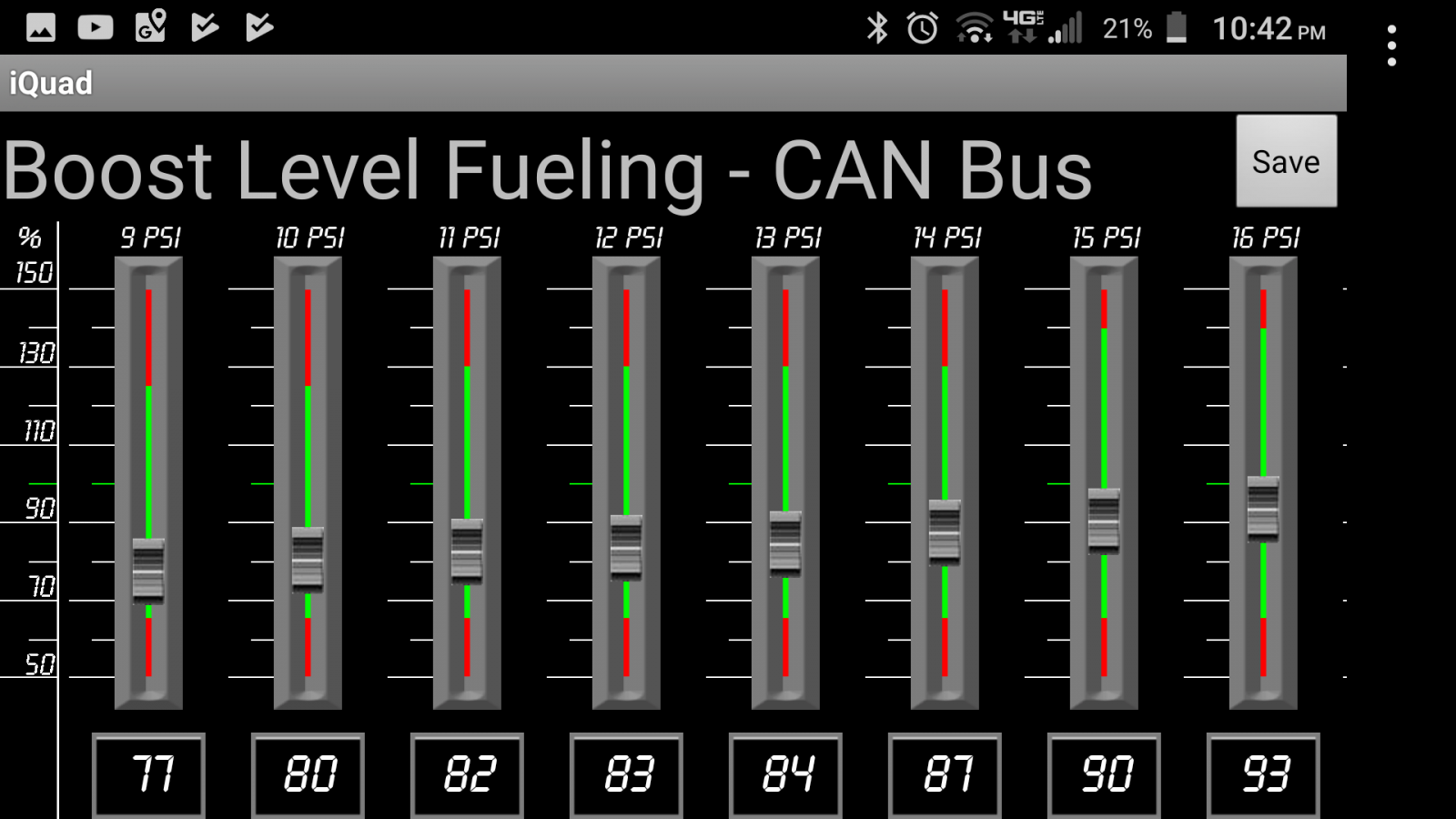

I did some more datalogging as of late and found that a more aggressive timing curve later in the rpm band, say 2500 + rpm, seems to pull harder up top. Previous I was running tunes that maxed timing at 26*. I took 2 tunes copied them and ran them back to back on the same stretch of road, same conditions. I was not using wiretap for this so I will leave those details out

First Tune 29* max

Second Tune 26* max

The interesting thing is the tunes are the same except for the timing above 2500 rpm. If you look on the graph rpms hit that 2500 rpm mark at about line 20-21, each line is ~.3 seconds so 3 lines = 1 second. You can see where timing jumps and also where boost jumps.

Now keep in mind the graphs are not exact so take them with a grain of salt, but everything appears to show that the tune with higher timing up top gives faster time to 50 mph, and a faster ramp up of boost. The higher timing tune appeared to reach 50 mph nearly 1 second faster.

as always studs are a good idea, but I am fairly sure anyone can run this timing above 2500 rpm. If people are not blowing their heads off left and right with other tuners then there is no reason why this type of timing curve will hurt with the Quadzilla.

Food for thought, open to other thoughts.