- Replies 12

- Views 5.6k

- Created

- Last Reply

Top Posters In This Topic

-

01cummins4ever 4 posts

-

CUMMINSDIESELPWR 3 posts

-

IBMobile 2 posts

-

Hawkez 1 post

Most Popular Posts

-

got installed today, really happy with the way this performs, going to have to get used to not listening to the raptor at start up, its almost like there's something wrong (LOL) I"m idling at 17 psi.

-

Personally, I would keep the priming lift pump. Say you traveling during the winter time and get a bad batch of fuel requiring a filter change you might be in bad shape if the lift pump isn't there is

-

I left the stock fule return line alone and used the metal fuel feed line that goes from the teak to the location of the factory mounted lift pump as the return line for the Fuel Boss. I used a small

I ve always told myself if the raptor ever gives up I'm going with a mechanical pump, and so the other day it started giving me fits and loosing pressure, I tried to adjust pressure up but the electric motor just barley running and sound sick so I just gave up on it, and ordered a fuel boss from GDP.

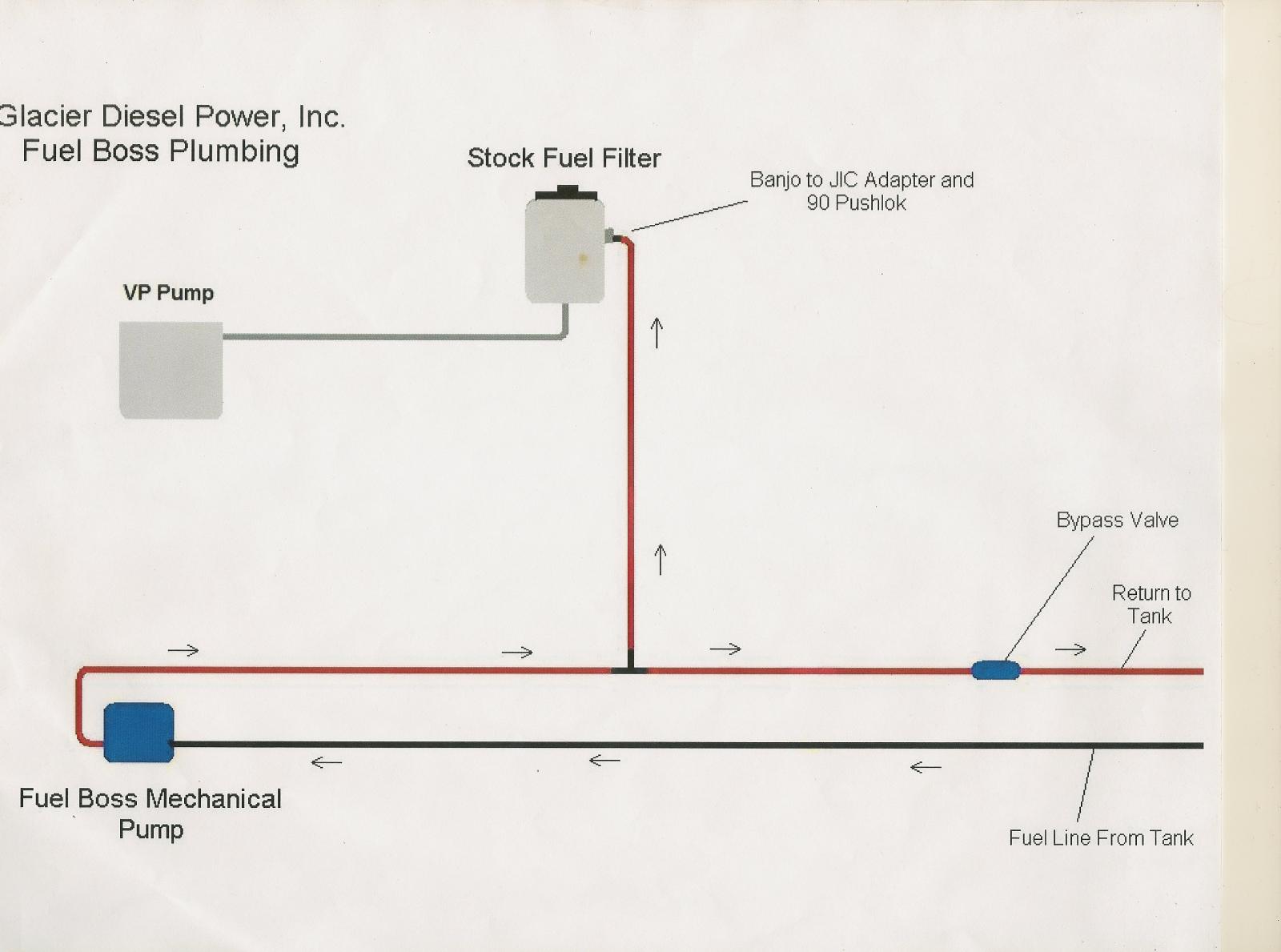

My plan is to keep the plumbing as simple as possible, by eliminating a back up electric pump altogether, just dont see a need for it, and if I ever have to prime I will just use the cordless drill method like on filter changes or something. (also going to stick with the factory block mounted fuel filter for heating purpose) So I plan on tapping in on the 1/2" line from tank right where the raptor was mounted on frame and install a 1/2 npt bulkhead with a shut off valve on inlet side and I have a 1/2 " threaded fuel strainer on the other side then reduced to a 3/8 jic push lock and continue the route with the directions provided, thus excluding the hobs switch and bypass valve since no priming pump will be their anymore, also I plan on installing a tee on the return to tank so it spits going into the fuel module and filler neck and hopefully reduce some of the foaming effect and also keep up with the demand in the module from the suction of the fuel boss, So any input from you guys running the fuel boss, or any input in general if this is a good idea or not