- Replies 13

- Views 6.7k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 4 posts

-

Marcus2000monster 3 posts

-

dripley 2 posts

-

Nekkedbob 1 post

Popular Days

Most Popular Posts

-

The typical daily driver can be done cold. Normally they don't expand too much. When you talking 900 HP and track stars well there is going to be a lot of heat and expansion on the valves and such. Li

-

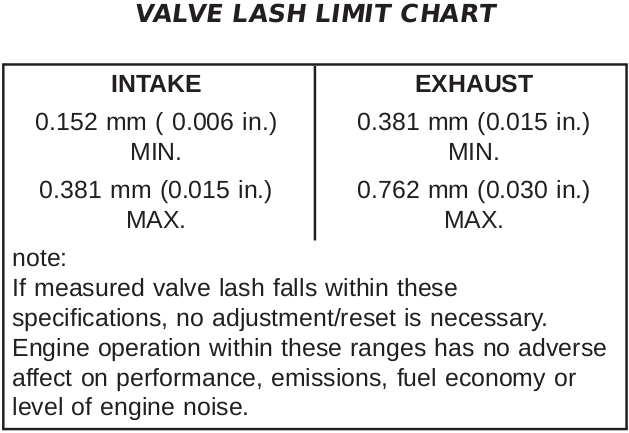

Just for the sake of the topic. I found the specs in the FSM.

-

Ask @hex0rz about the injector change I did on his truck. He ran the 5 hours from Sandpoint, ID show up here at 7pm and I change all 6 injectors in about 1 hour hot. Don't suggest it...

The following is not meant to create an argument just to simply explain my personal results and what I honk is right when doing a valve lash job on my truck.

So everyone here has told me and untold amounts of other members here to do valves on a cold engine. Wrong. Valve lash must be done on a warm engine to get good results. The reason behind this is simple. When the tappets get hot they expand and when they get cold they contract. So if you adjust your valves while cold when you operate your truck the valves are going to expand and not allow proper intake and exhaust valve operation. I personally tried to complete an adjustment 2 times on a cold engine and both times my truck didn’t seem to sound right. Something seemed wrong so after removing the valve cover and checking the lash I found that the valves were to tight! I reset them and still things weren’t right. I asked a friend who owns an 02 900 hp 24 valve what was up and he asked whether I did them hot or cold. I told him cold and he said ahh there’s your problem and proceeded to explain the expand And contract theory and said go home right now and do it right away. I did as he said and today rechecked the lash at approx 2k miles later and the lash is exactly where it needs to be and the truck is running amazing! This is my personal experience and I’m not saying I’m right and your wrong but I know that my truck now runs very well and I’m happy.