- Replies 44

- Views 9.8k

- Created

- Last Reply

Top Posters In This Topic

-

gsr46r 15 posts

-

dripley 11 posts

-

evan717 6 posts

-

Dieselfuture 5 posts

Most Popular Posts

-

That is your problem. I would first fix that before I did anything with ECM, it's a known fact cummins people are retarded, there are few at each shop that know what they're doing and that's what keep

-

Thank y'all. I'm not sure if the engine has ever been out. Got the ECM back from cummins without an argument. The lady was nice and took the fee off. Will attempt all of the steps this wee

-

It should be solid with crank, this is how computer knows piston is in certain position so it can command to inject fuel at the right time. If this gear rotates then fuel is injected at wrong time and

Hi all,

My 2000 ram 2500 cranked, but would not start. I managed to get it started and it got me home, but the tachometer said 0 for the whole ride.

I scanned it and got p0336 which is a crankshaft position sensor fault. I put a new one in (from rock auto), cleared the code, and when I went to start it, same problem- The starter cranks, but no start. The RPM's stayed at zero when it was cranking.

I haven't had great luck with rock auto, so i bought a CKP sensor from advance auto with a lifetime warranty. Put it in, tried to start it and the same exact problem! it cranks but does not start. At this point, i figured it's an electrical issue, so I ran a whole series of voltage and resistance tests. Appreciate the detailed code information! Each of the 3 parts of the sensor produced voltage or completed a circuit.

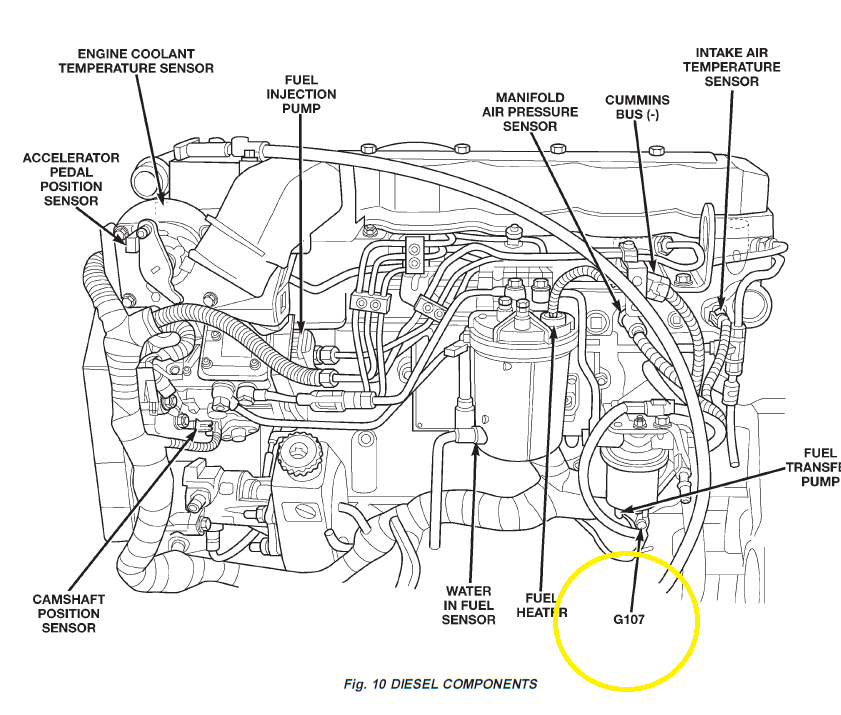

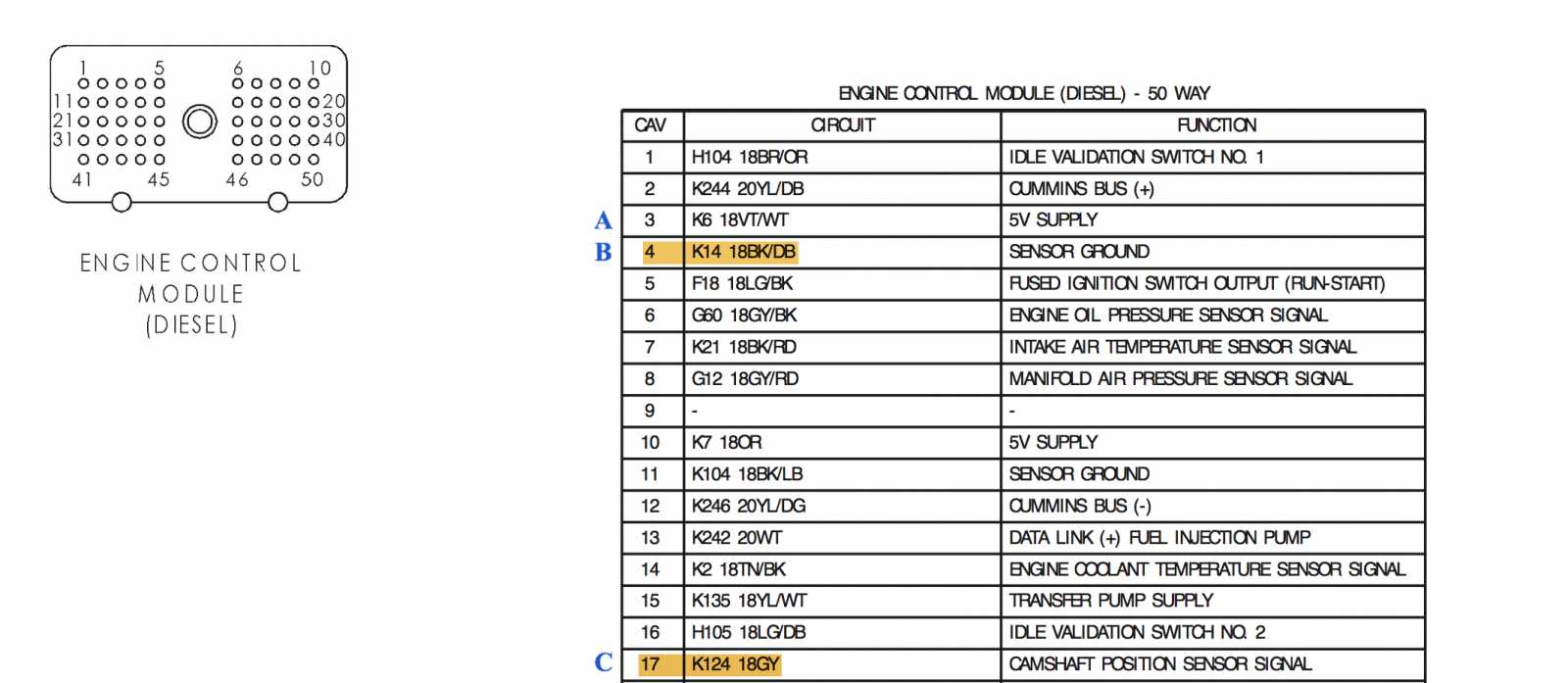

When i connected A to C (sensor to ecm signal wire), the lift pump turned on. The middle wire B on the connector (on a hall effect sensor) had a lot of resistance from the CKP sensor connector to ECM connector, so I replaced it, and again, the same issue! It cranks but doesn't start.

I just got the batteries a couple weeks ago- I've tested them and know they're good. I am stuck and can't figure out what else the issue could be.

I am wondering if:

-for some crazy reason, i got 2 bad brand new sensors?

-maybe one of the female connectors doesn't meet the male pins? they sell a part at autozone i can buy to replace the CKP sensor connector

-let's say it's not an electrical issue, maybe an issue with the lift pump not sucking enough fuel? when the sensor is disconnected, i can turn the lift pump on manually by connecting A and C from the hall effect sensor. But, when the sensor is in there, i hear the lift pump turn on intermittently, like there is a reset period. but it's not loud like my 3rd gen. in my 3rd gen, any time i turn the key to run, i hear the fuel pump humming loudly from the tank

I've read about this issue and see most people have their issue fixed after replacing a CKP sensor or two. I haven't been so lucky lol.

Please give me your opinion. Could it be an issue in the fuel system? While it ran, the truck drove fine- nothing felt erratic

Thanks!