- Replies 20

- Views 3.6k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 6 posts

Mopar1973Man 6 posts -

Andyba20 4 posts

Andyba20 4 posts -

YeaImDylan 4 posts

YeaImDylan 4 posts -

Sycostang67 2 posts

Sycostang67 2 posts

Most Popular Posts

-

Much less issues with... Track bar Ball joints Tie rod ends Drag link Steering box Power steering pump Brakes Wheel bearings Wheel joints The l

-

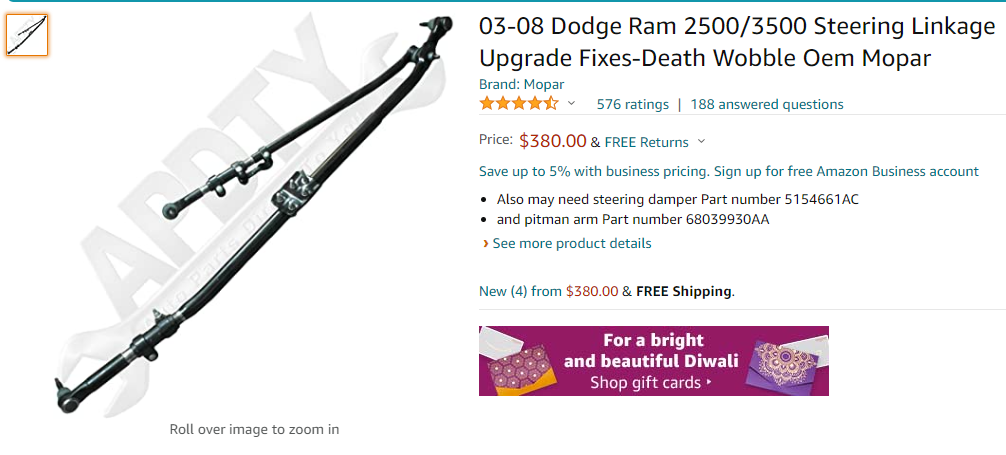

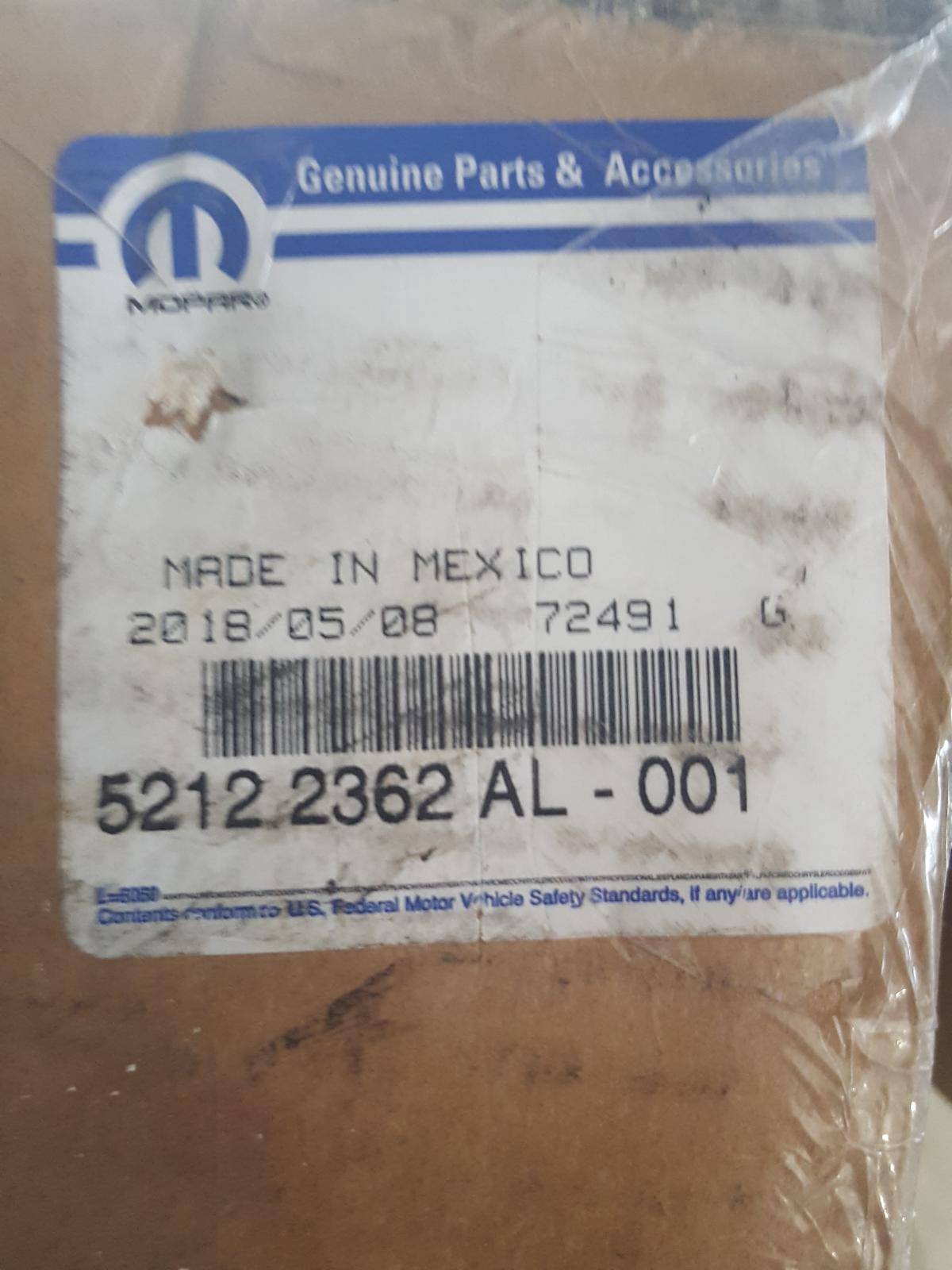

If you are staying factory, there isn't a "bar" like heim joint setups. Each piece is the tie rod end 08.5+ upgrade (t-style) on top, normal 2nd gen (y-style) on bottom. On b

Hey all! Back again with more questions lol.

So I am wanting to replace the the 2 bars for steering (I get confused with what to call them my bad, tie rods I'm assuming?), steering box (planning to go with a blue top), sway bar, track bar, and possibly ball joints, alignment shop told me one or both had a little bit of play but told me I wouldn't have issues with tire wear. If there are parts I'm missing that I should replace, please tell me below! Tire wear has been fine I believe and its been about 5k miles. Need to rotate soon. I have a LOT of slop in the steering, possibly kind of dangerous at this point lol.

Biggest question is what brand to go with for these components. I keep hearing on forums these days that Moog is sadly not what they used to be... I just don't want to spend a bunch of money and have parts go out in a year or less. I also do not want to spend a fortune. I also see talk about changing to the "Y" steering I believe and I'm open to that suggestion if its truly worth it and I don't have to make any holes bigger on components to upgrade and/or spend a lot more than what the stock steering setup replacement would cost.

Also, when doing the steering box, how can I make sure the pump is clear of debris? It's a new pump and I'd like to re use it but I want to assure there isn't any debris in there so I don't damage the blue top. Will be buying new power steering lines as well.

Planning to do it all on my own to save money and use the hobby shop on base here. If any of you know anyone semi close to Camp Lejeune, NC and they'd be willing to help, I'd love the help if I'm able to get it lol. Will definitely bring a 6 pack (or more) for that person. Also, how far can I safely drive after replacing these components to get it aligned? We have a firestone on base which would be a mile or 2 drive, off base location would be a minimum of probably 8-10 miles.

Open to ANY and ALL suggestions!

Thank you.