- Replies 21

- Views 2.8k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 4 posts

-

JAG1 4 posts

-

Ravewolf 4 posts

-

Andyba20 3 posts

Most Popular Posts

-

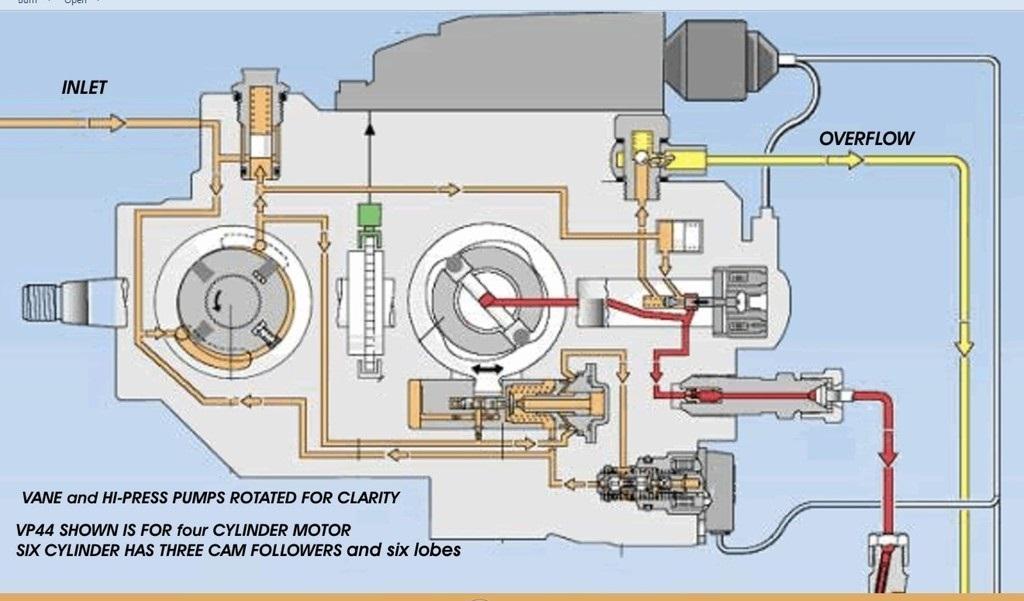

"The lift pump has no say in when the overflow valve is open." I stand behind that statement. Rarely, does anyone talk about the role of the internal vane pump inside the VP44. Its rol

-

@Max Tune, I really appreciate your response. You ask many good questions. The VP44 fuel system is made up of several series and parallel circuits, especially inside the VP44. That's where the comp

-

A certified rebuilder has to have a 250,000 dollar test stand and run the rebuilt units for, I believe 3 hours, and only the ones functioning perfectly are sold to the public.

Well, pretty sure my truck ate it's last injection pump. Left me stranded in my home town. Parked it at my dads house so it's safe, but I'm done with the vp44. And the truck in general. I hated the tan interior on it, and the fact I couldn't find anything other than dash parts for it.

I have a lock on an 86 square body with a junk 350 and axles. As soon as I can get that pile of crap dodge back home, it's getting ripped apart, and parts are going on that Chevy, minus the electric crap.

I'm so over the wires and stuff, just want to p-pump it and never have to worry about it again. And having a truck which I can pretty much build out of a magazine. I always wanted another square, and a cummins one at that. And hopefully the new job I'm getting will make all that possible.

So what's the going rate on a used quadzilla? And a good rebuilt engine pcm? Just had it rebuilt last April at the price of $700. I'm hoping thoroughbred diesel will take a dead vp as a core because they want $1k for a core on top of the $1300 for a mechanical pump.

I'm also selling the transmission and transfer case in lieu of a 4r100 and an np205. With dodge axles. Transmission was rebuilt in 2019 by Super Stick transmission and I babied it because I didn't want to blow it up.