- Replies 11

- Views 8k

- Created

- Last Reply

Top Posters In This Topic

-

mopartechnician 4 posts

mopartechnician 4 posts -

Dieselfuture 2 posts

Dieselfuture 2 posts -

Ilikeoldfords 1 post

Ilikeoldfords 1 post -

king3500 1 post

Ok, I did this 3 weeks ago so I am just finally getting around to doing my write up. I know people have concerns with the airdog/raptor issues, but hey, somebody has to see if they are fixed. I have no concerns about these pumps, as I have never had any problems getting warranty on customers raptors. Also, I have an electronic gauge as well as a quick release fitting for a mechanical gauge to check pressure whenever I need to.First things first here are the partsAirdog and hardware Here is the sump kit by Bean's diesel

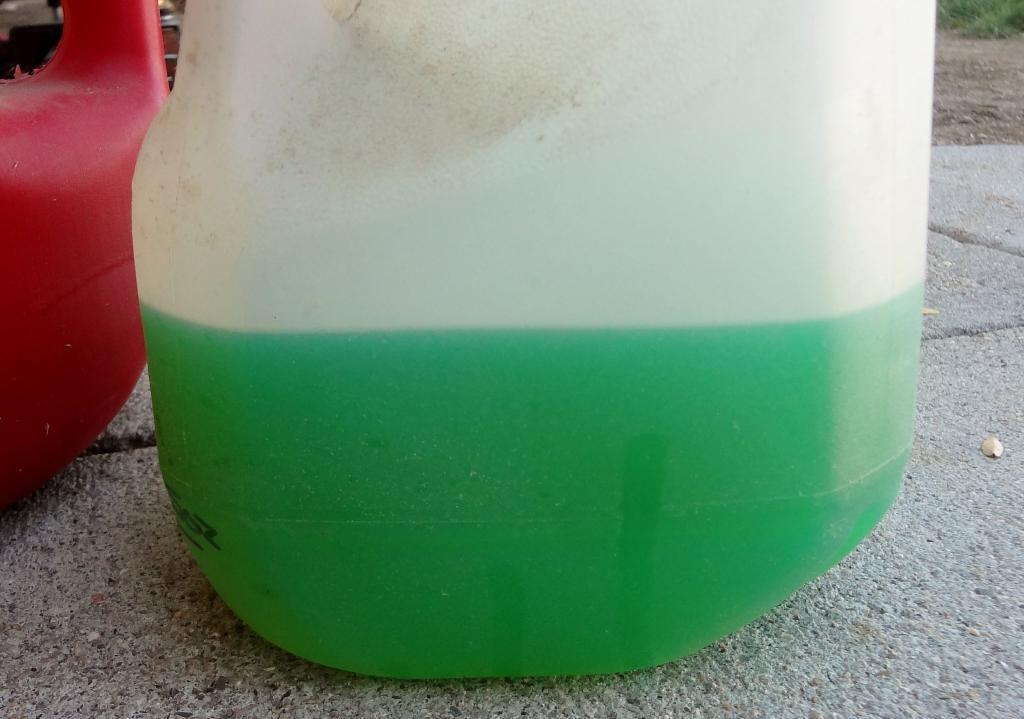

Here is the sump kit by Bean's diesel First thing I did was drain the tank through the fuel filter housing drain into 5 gallon buckets and jumping out the lift pump wires to control the flow.Here is what your fuel looks like when you mix 2-stroke oil at 128/1

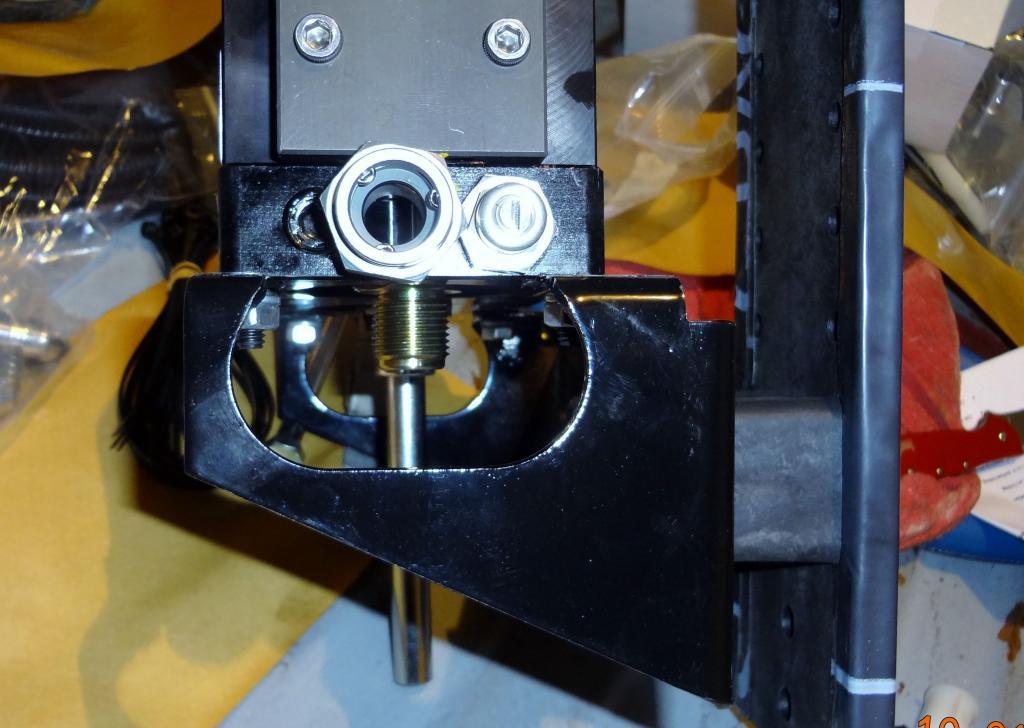

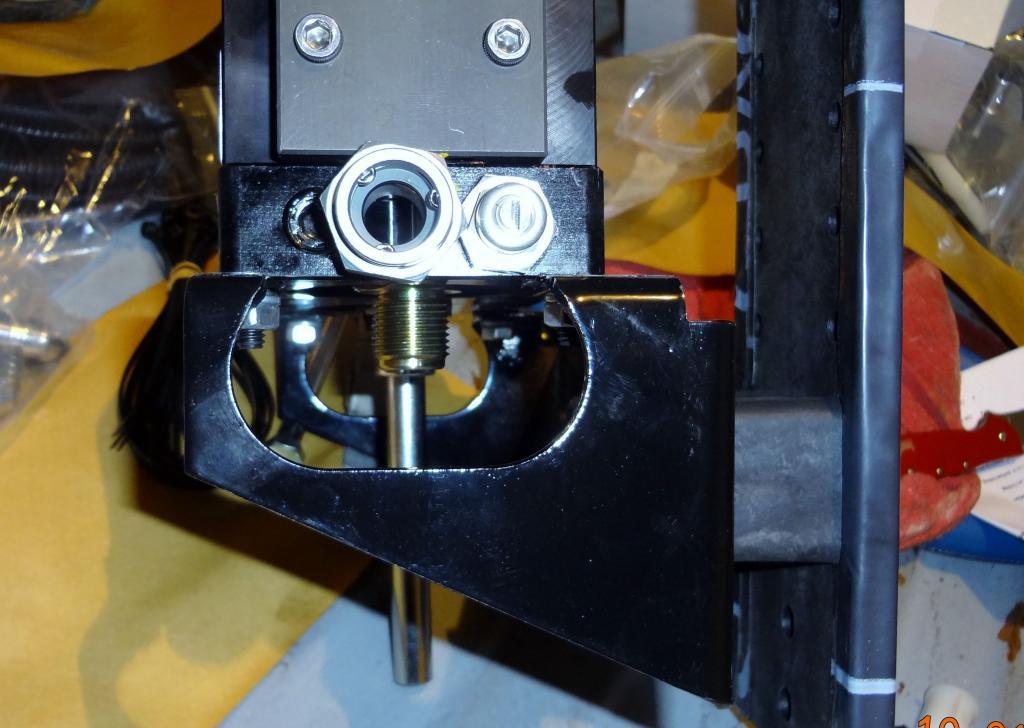

First thing I did was drain the tank through the fuel filter housing drain into 5 gallon buckets and jumping out the lift pump wires to control the flow.Here is what your fuel looks like when you mix 2-stroke oil at 128/1 Now time to put together the Airdog pump and fittings, I used some bituthene around the plates that mount to the frame and also between the actual pump and its mounting bracket to dampen any vibrations/noise.

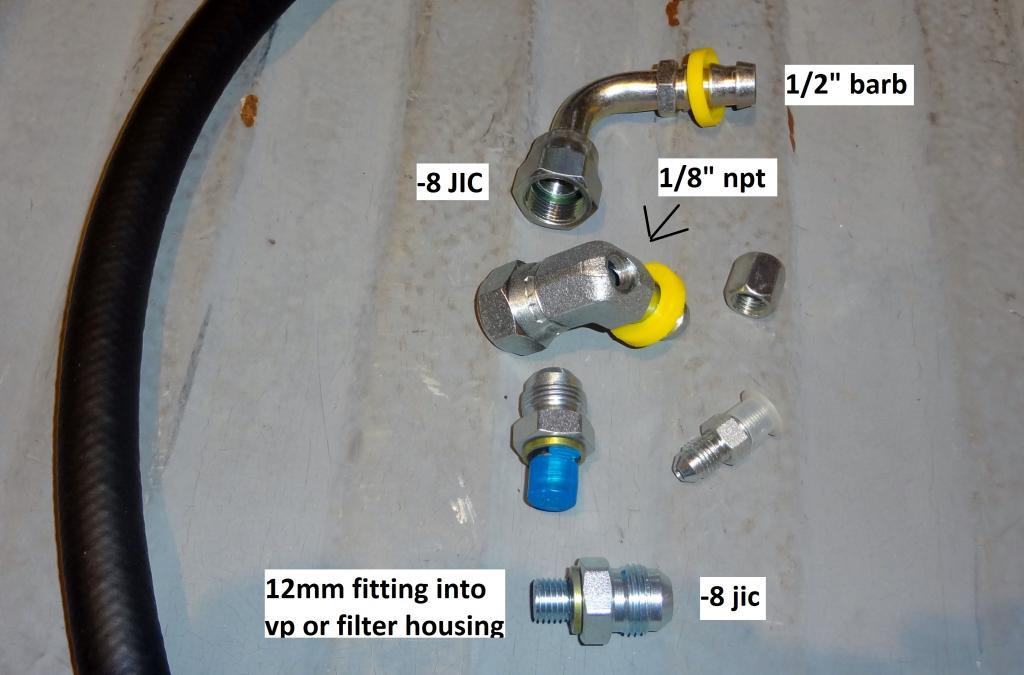

Now time to put together the Airdog pump and fittings, I used some bituthene around the plates that mount to the frame and also between the actual pump and its mounting bracket to dampen any vibrations/noise. I ran all hoses and wiring, that ran up to the engine bay, through the frame rail to clean up and protect them. I also ran the fuel line into the stock filter housing to keep the extra filtration as well as the water separation. (I don't believe the fuel heater does much good)Next I installed the Vulcan big line kit, here are all the fittings and sizes to help clear up anything

I ran all hoses and wiring, that ran up to the engine bay, through the frame rail to clean up and protect them. I also ran the fuel line into the stock filter housing to keep the extra filtration as well as the water separation. (I don't believe the fuel heater does much good)Next I installed the Vulcan big line kit, here are all the fittings and sizes to help clear up anything This is the fitting that will go into the vp44 and the bottom of the filter housing.

This is the fitting that will go into the vp44 and the bottom of the filter housing. These are the elbows that will hook into the previous fittings. The one with the 1/8 fitting should go on the vp44 fitting.

These are the elbows that will hook into the previous fittings. The one with the 1/8 fitting should go on the vp44 fitting. Here is the glowshift maxtow gauge I got, its an analog as well as having the digital number readout. I am not to happy with the gauge as the needle looks like a windshield wiper when you are driving and have the throttle on anything off idle. I think the sensor is way to sensitive because with a mechanical gauge, the gauge only drops 1 psi at WOT

Here is the glowshift maxtow gauge I got, its an analog as well as having the digital number readout. I am not to happy with the gauge as the needle looks like a windshield wiper when you are driving and have the throttle on anything off idle. I think the sensor is way to sensitive because with a mechanical gauge, the gauge only drops 1 psi at WOT Here is the fuel snubber that came with the fuel pressure gauge, this or a needle valve is a must to keep your pressure sensor safe from the hammering the vp44 does.

Here is the fuel snubber that came with the fuel pressure gauge, this or a needle valve is a must to keep your pressure sensor safe from the hammering the vp44 does. Elbow with adapter and snubber

Elbow with adapter and snubber Now onto the fuel sump. They say to drill it right below the stock fuel module, so I cleaned up the tank really well. After drilling the pilot hole with the provided hole saw, I let any fuel drain out that was still in the tank. After it stopped dripping, I finished drilling the hole and cleaned up all the shavings. After I drilled the hole I think drilling under the stock sender is not the best as it interferes with the installation of the sump.

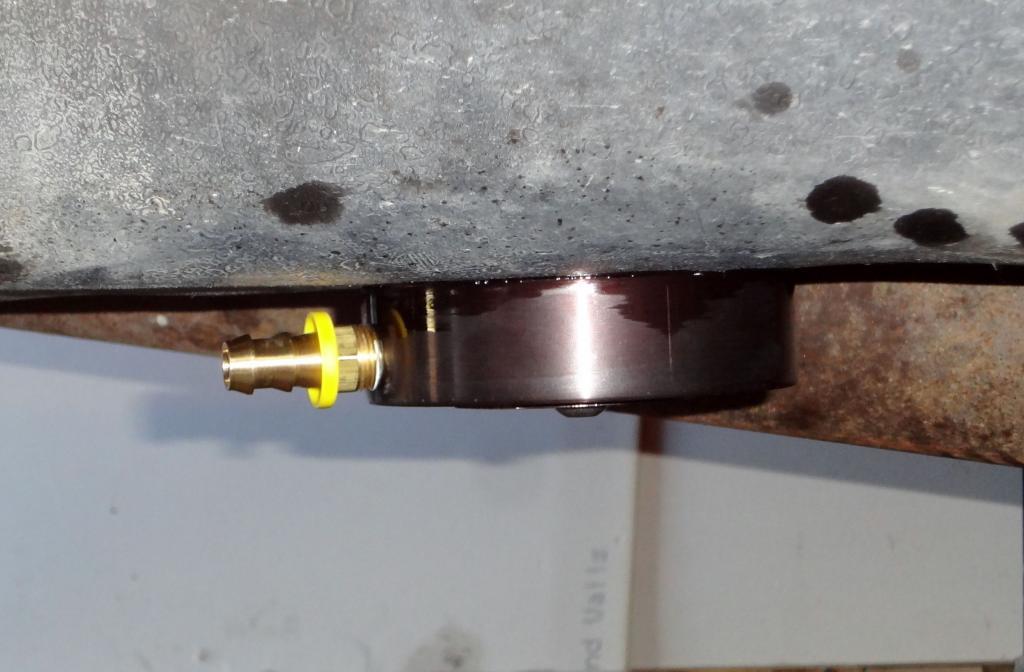

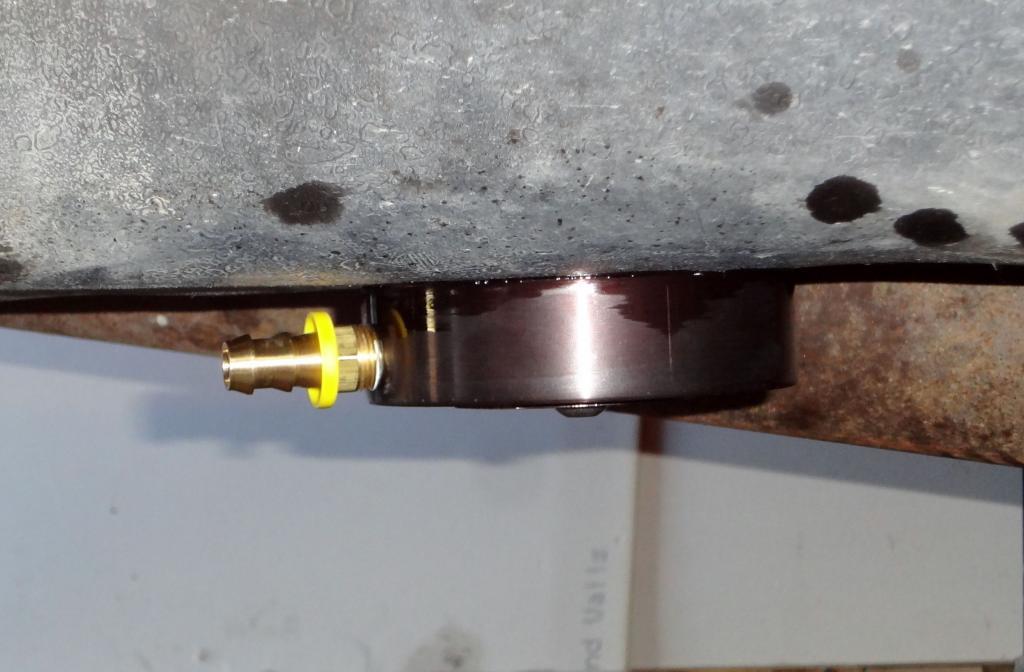

Now onto the fuel sump. They say to drill it right below the stock fuel module, so I cleaned up the tank really well. After drilling the pilot hole with the provided hole saw, I let any fuel drain out that was still in the tank. After it stopped dripping, I finished drilling the hole and cleaned up all the shavings. After I drilled the hole I think drilling under the stock sender is not the best as it interferes with the installation of the sump. Sump all installed

Sump all installed Sump is roughly 1" tall and sits above the frame rail. Yes something could hit it and tear it off but I rarely go offroad so I won't be worried about it.

Sump is roughly 1" tall and sits above the frame rail. Yes something could hit it and tear it off but I rarely go offroad so I won't be worried about it. And finally, its installed. This is my attempt to show how far everything hangs under the truck and the protection it has.

And finally, its installed. This is my attempt to show how far everything hangs under the truck and the protection it has. Final thoughts, so far so good. As I said earlier, with the mechanical gauge, I only drop 1 psi at WOT with my setup and chip on highest setting. Don't believe there will be any gains in mileage, but I now know I have great fuel pressure (19-20psi) and great filtration.

Final thoughts, so far so good. As I said earlier, with the mechanical gauge, I only drop 1 psi at WOT with my setup and chip on highest setting. Don't believe there will be any gains in mileage, but I now know I have great fuel pressure (19-20psi) and great filtration.