- Replies 32

- Views 7.4k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 9 posts

Mopar1973Man 9 posts -

eddielee 9 posts

-

CSM 5 posts

CSM 5 posts -

JAG1 2 posts

Most Popular Posts

-

I went through electrical engineering in 1969 and we were taught that they were functionally the same as a regular diode but with much lower voltage drop and much faster switching time, ideally suited

-

It won't stop a spike. If you have AC of some waveform coming out of your alternator, a single diode will make it a half wave. A half wave is still AC. Beyond that, the minor voltage ripples are ba

-

CSM is right. Diodes won't work. I've seen several ideas for large Capacitors, coils and noise filter circuits. You'll still need to get back to the problem. Fix the damaged alternator. &

I have been considering installing a blocking diode for Alternative energy production to prevent AC Noise from screwing things up.

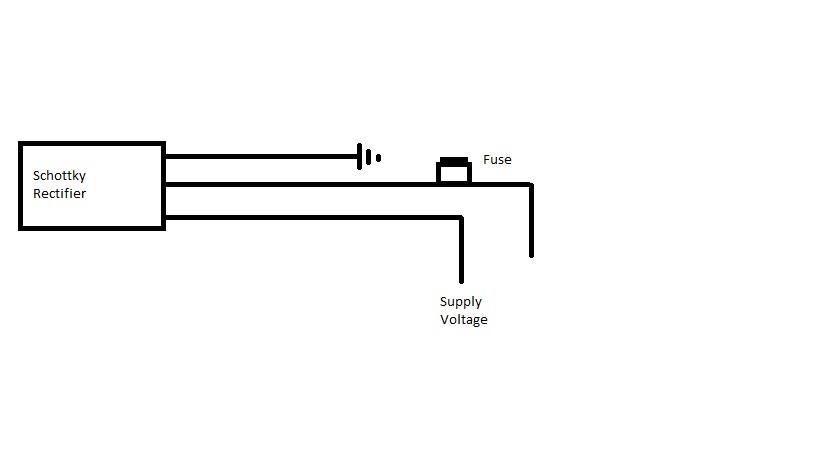

1600V*100A=160kW which is far more than our trucks output. This means that I could install it between the alternator and the power block to protect all electrical components easily and cost effectively. Installing a diode eliminates the possibility of AC current because it only allows current to flow one way. I would install it between the power block and the alternator then heat shrink to prevent electrical hazards.

Another option I have thought of is creating a diode bridge, however, it is difficult to find diodes with the capability of handling the current output. The only benefit to a bridge is that it would eliminate spikes due to having half of the AC wave. I don't think the average 1 max 2 volt spike will effect the electrical so much.

Have a look at what I am talking about

http://www.ebay.com/itm/1600V-Volt-100A-Amp-Wind-Turbine-Generator-Solar-Panel-PV-Stud-Blocking-Diode-/201025568109