- Replies 125

- Views 17.7k

- Created

- Last Reply

Top Posters In This Topic

-

Ilikeoldfords 36 posts

Ilikeoldfords 36 posts -

Mopar1973Man 16 posts

Mopar1973Man 16 posts -

TFaoro 15 posts

TFaoro 15 posts -

CUMMINSDIESELPWR 11 posts

CUMMINSDIESELPWR 11 posts

Most Popular Posts

-

you could get an old ford.

-

I have had this happen with a couple vehicles over the years and one just needs to realize when its time to cut the cord and move on especially when the repairs are going to equal or exceed the vehicl

-

OK fellas. The moment you have all been waiting for!! Just had the reman'd motor stuck back in my truck last weekend. I have to say it is fantastic to have my truck back. This motor is way quieter tha

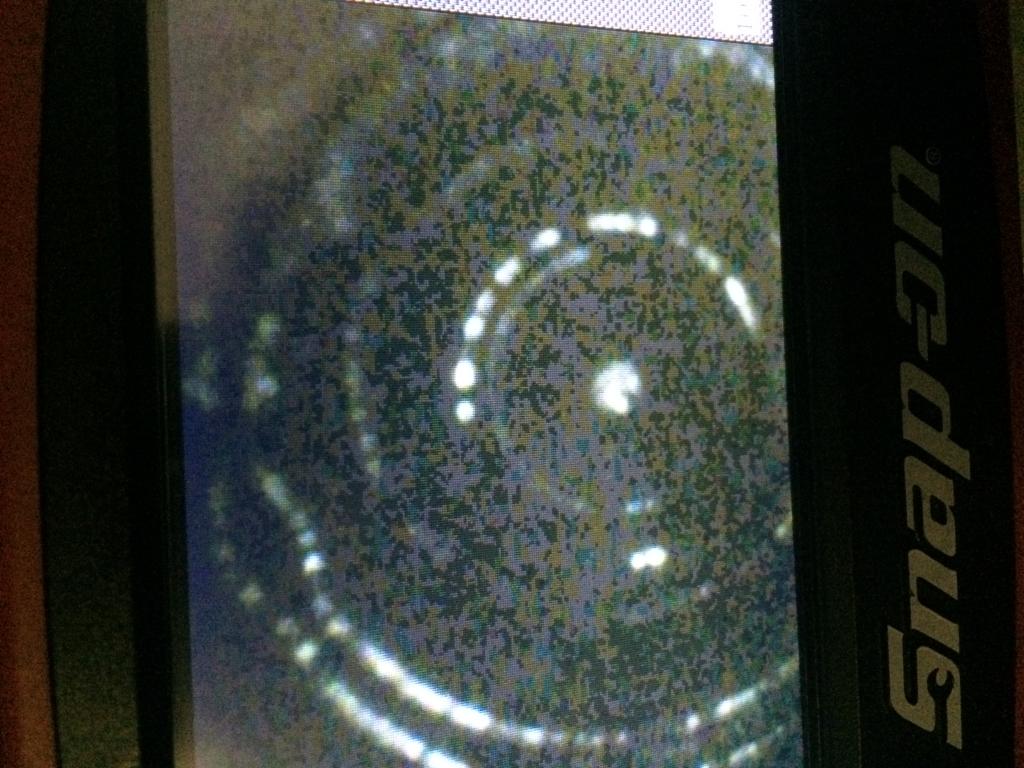

Hey guys. I got a pretty loud knock happening with the old Cummins and could use some help identifying it. My alternator went out on a business trip this week. In an attempt to limp the truck to the next town I ran it dead. I had a new alternator put in it and got it all charged back up.

When I fired it back up it was smoking a lot I had a miss and knocked real bad. I put about 20 miles on it and the miss/smoke went away but the knock is still there.

It changes up and down with engine speed. I have checked under the hood or tools left over belt issues and anything obvious. Boost fuel pressure and exhaust temp are all normal.

No check engine light but I will pull codes next time I get a moment.

Any help would be greatly appreciated!!