Rebuilding a Holset HX35/40W turbo

- Replies 38

- Views 10k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 8 posts

-

Silverdodge 7 posts

-

CSM 5 posts

-

notlimah 4 posts

Most Popular Posts

-

Funny point that is totally against common truck thought. I totally agree with you. The auto trucks tend to be significantly faster throughout the curve as the exhaust gas energy stays h

-

Wonder who is actually making them. Ran into this with my secondary. Not all 360* bearings are created equal. A compressor wheel, turbine wheel and rebuild kit. A buddy in Indiana builds

-

I disagree with that statement. Response would be worse generally due to the effect of manual trans and clutch. Torque converters are heck of a tool to stay on turbos and loading the engine.

No, I don't have a write up for this but I will post the PDF document for the service manual.

http://www.myholsetturbo.com/manuals/HX30_32_35_38_40_GW.pdf

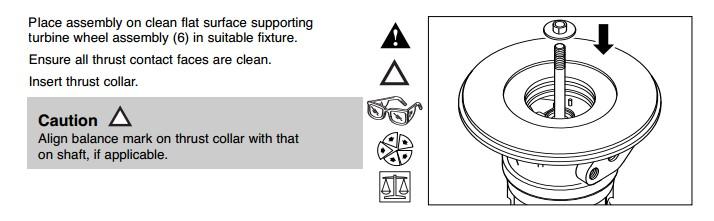

I'll admit it's fairly easy to do. You will need a very good pair of snap ring pliers. Everything else is a standard tools wrench and such. I did run into a snag and created a bind in the shaft. Make sure to put your thrust washer back in. Once I grab the manual and seen the exploded view of the turbo I knew right away what I missed. Sure enough dug into the ashtray I put all the old parts into and there it was. Slipped it on the shaft and it spins good. The 2 end are 12 points the turbine is 19mm 12 point socket and the compressor nut is 10mm 12 point nut left-hand thread. You torque to 124 inch pounds.

Once I grab the manual and seen the exploded view of the turbo I knew right away what I missed. Sure enough dug into the ashtray I put all the old parts into and there it was. Slipped it on the shaft and it spins good. The 2 end are 12 points the turbine is 19mm 12 point socket and the compressor nut is 10mm 12 point nut left-hand thread. You torque to 124 inch pounds.

For the smaller snap ring, I created my own tips for my snap ring pliers from nails. trim a nail to length and then carefully ground the tip into a point for the small snap rings holding the bearings. The larger snap ring for the compressor side I trimmed down two Allen wrenches that fit the holes and they were plenty strong to pull that snap ring.

My truck is slightly torn apart and without injectors right now. So might as well get the turbo done and ready since the bearing kit came first.

Edited by Mopar1973Man