- Replies 14

- Views 18.5k

- Created

- Last Reply

Top Posters In This Topic

-

wh82 4 posts

-

Haggar 3 posts

-

Mopar1973Man 2 posts

-

Dieselfuture 2 posts

Most Popular Posts

-

I made a video some time ago showing what the normal amount of blowby (engine venting) should be and what happens when you get a leak in the vacuum lines. Maybe this will help.

-

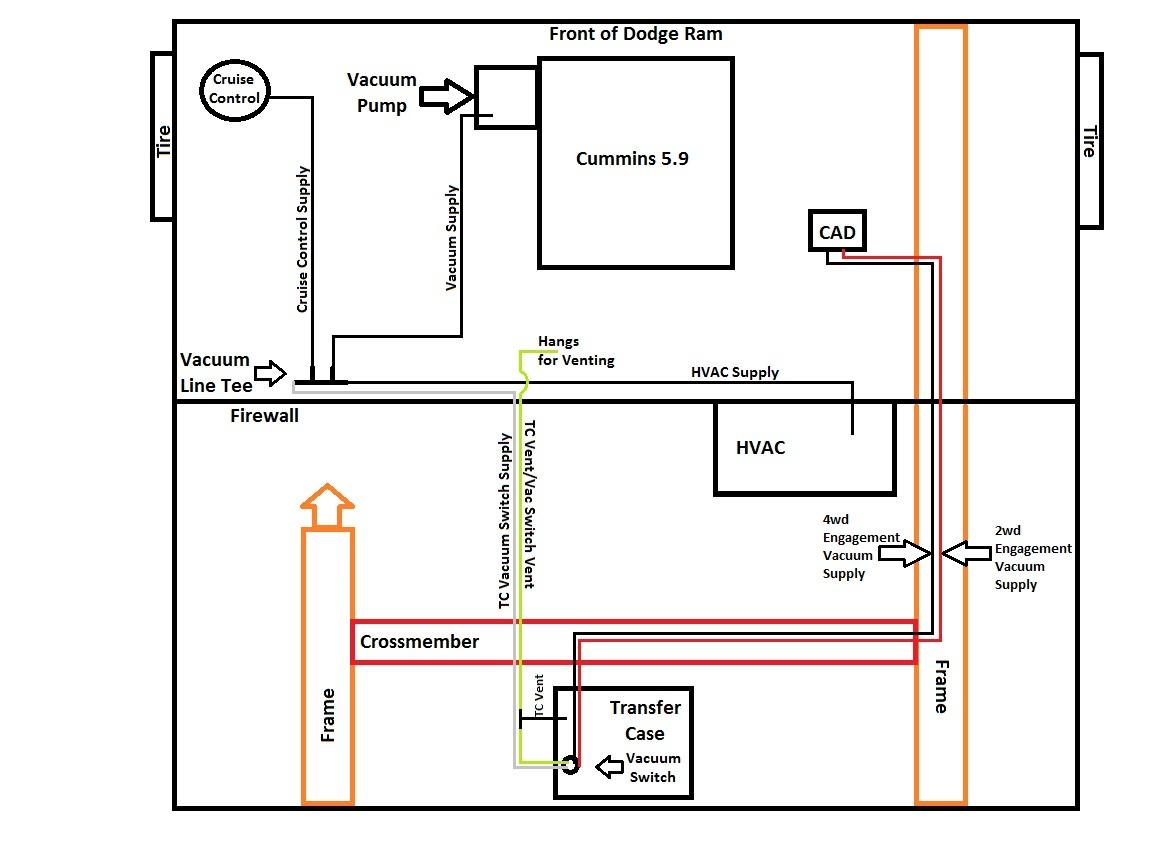

Quote from 2001 FSM Page 24-29 the check valve is not shown in the picture I attached at the end, but basically, the check valve goes in the "vacuum supply" line. This means that when you turn o

-

They really don't hold vacuum at all. Not so much an issue as making sure it creating enough vacuum at the time of operation. In other words making sure there are no vacuum leaks like crack vacuum lin

Hi, very specific vacuum pump question, have not been able to find the answer here or any other site / google. I've read a lot about failing vacuum pumps and re-sealing them, but what I need to know is this..

I do not have the vacuum brake booster, only thing my system feeds is cruise and hvac.

After my supply line fell off the pump the other day (rotted hose) I hooked it back up. I decided to replace some of the hoses and noticed there's a check valve right before the input to the hard line on the firewall... was not working as expected so replaced.

I also grabbed a vacuum gauge and tested. Several sources say the system should hold a vacuum well after the engine is shut down, mine drops fast.

My question is this:

Where should the system hold the vacuum? after this check valve? Or should it also hold a vacuum if i were to hook the gauge straight to the pump? If after the check valve, I'm good, if the pump itself should also hold a vacuum... well then time to move on to those re-seal topics.

Thanks in advance!

Edited by wh82