- Replies 39

- Views 12.8k

- Created

- Last Reply

Top Posters In This Topic

-

01dodge24v5.9 9 posts

-

dripley 8 posts

-

GSP7 7 posts

-

Mopar1973Man 5 posts

Most Popular Posts

-

You aren't going to do anything for the gauge bounce with the overflow valve. That is not what it is there for. Looks like the ball and spring in the fass is worn out.

-

It doesn't matter how old fass is, when I got mine brand new it had same issue they ended up sending me a new ball and spring that fixed the issue. You can try mortifying spring a little bit and see i

-

I think he's thinking 3rd Gen track bar. Typically the ball stud fails on 2nd Gen track bars.

Okay I've got something going on with my truck and I'm in need of ideas. My truck sounds different (more tinney rattle) in the top end, less power, less boost higher EGT's. I pulled the valve cover off and re-torqued everything. I was worried something vibrated loose. Everything was tight. I did start the truck while the valve cover was off, and I could hear what was I think was the injectors. Not sure what they are suppose to sound like?

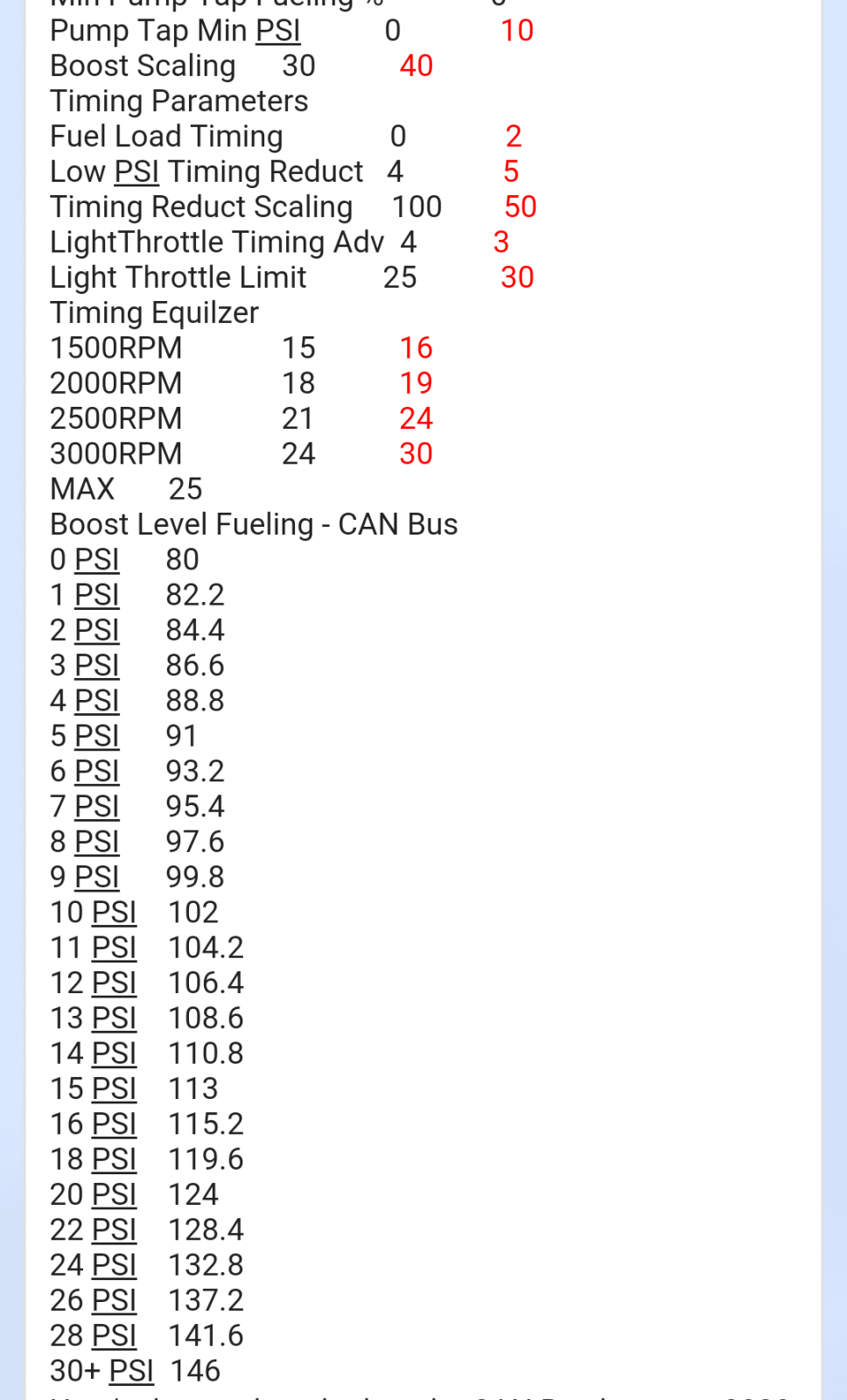

I haven't changed a thing with any settings in the Quad tuning. I'm running the edge tune, (I can post them if anyone wants to look them over). Only thing that I found was the set screw on the boost elbow backed out and was gone. I replaced it (screwed all the in) built a "boost tester" pressurized the system, zero boost leaks. I'll add the data logs, the one in green is from January, red one is from yesterday.

Today I adjusted the valves ( they were a little loose), while running the truck after the valve lash adjustment I noticed the fuel pressure was running between 12-13 psi at idle. I put a mechanical gauge on it and I've got a crazy surging going on. It will stay at 12ish - psi for a second or two, then surge up to 22ish, then drop back to 12ish again(I'll try and add a short video). I did the bucket test on the fass 150 everything is flowing great no surge, Next, I put everything back except pulled the fuel line off the vp44 and ran it into the fuel tank via main fill hose (used the key bump flowed great). Last, I powered the pump with a constant power source independent of the trucks electrical system flowed great no surge.

What I need ideals with is I think I have possible two problems aggravating each other.

First is the loss of power, boost with higher EGT. I'm not sure on this one bc I haven't changed anything with the power out put in my tune. Just showed up along with the change in engine sound...

Re-recap: boost test= no leaks, replaced the boost elbow set screw(I found it missing), adjusted valves, no blow by, waste gate functioning normal with compressed air test.

Second is the fuel surging issue... It only seems to surge when the fuel lines are hooked up to the vp44. I'm wondering if there is a fuel return regulator or valve that's malfunctioning ?

Re-cap: Fass 150 bucket test= no surge, in-tank pick up used to feed the fass 150 and pressure line flowing into tank fill = no surge, out side power source = no surge, all the lines back in the places they came from(pick-up, pressure, return) truck running with out side power source= surge, same as test before truck power source= surge

Video file is to big, it won't let me upload it. I can email it to anyone that wants to take a look.

Thanks guys any input or ideas will help!!