- Replies 148

- Views 23.4k

- Created

- Last Reply

Top Posters In This Topic

-

RAD 62 posts

-

dripley 31 posts

-

Mopar1973Man 18 posts

-

Marcus2000monster 10 posts

Most Popular Posts

-

Don't feel bad... I can't tell whether its a girl or a guy anymore.

-

I did not know an airtex came ready to plug into the stock pig tail. Or did you make something to do that with? Is set up thru a relay or is the pig tail the power source for the pump? The reason I as

-

Agreed. I was thinking lift pump relay. I believe you meant NOT best for the ECM

MM suggested I post up after speaking with him on the telephone yesterday afternoon.

this all started after some cold weather here. leaving work one day and just died on me a few times, hard to start and then finally nothing.

here goes

working on a 1999 2500 5.9 l . it is hi-line w/auto transmission. key fobs never worked for me.

trouble is it is very very hard to start. finally got it to run yesterday, let it run for about 5 minutes and turned it off. it didn’t want to start again.

then when turning the key to start and run position, no lift pump noise.

i waited 30 minutes and cycled the key again and heard the lift pump running.

wait to start light come on immediately for about 2 seconds then goes off. grid heater are not hooked up at this time

before I have let it run till it warmed and shifted the gears and/or gave it some fuel and just dies.

batteries are at full charge, 13.9v from alternator. I did have the alt. checked. checked out fine. mm suggested to take it out and have it checked again for bad diodes

new rebuilt starter

refreshed/rebuilt ecm

new tpps

IP been in it just at two years (blue chip diesel - stock)

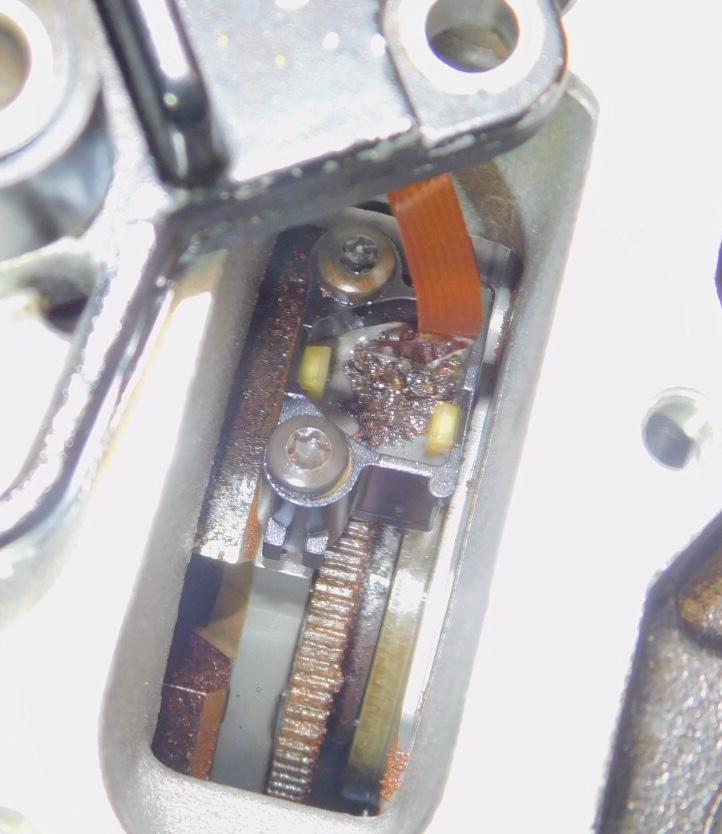

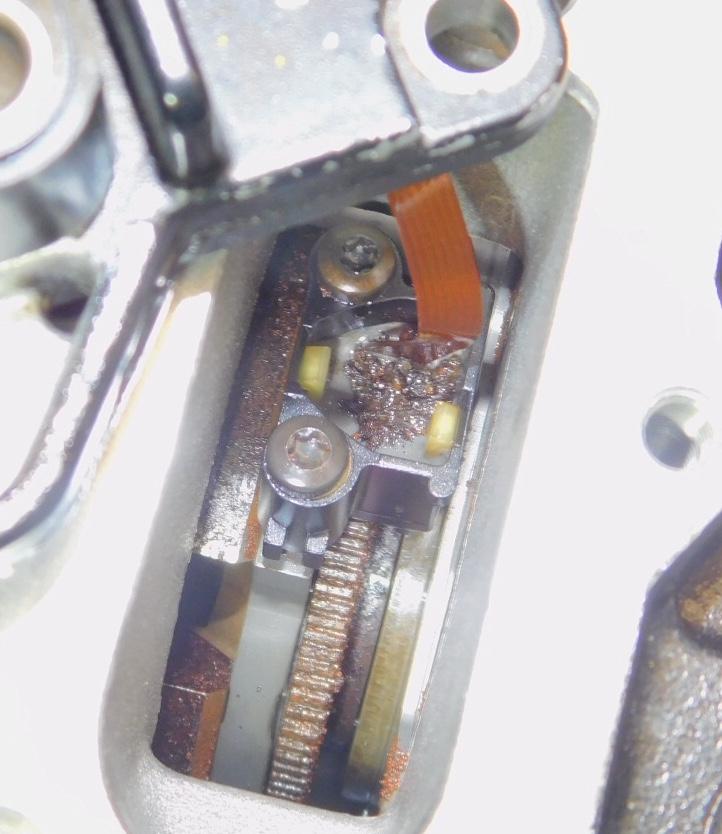

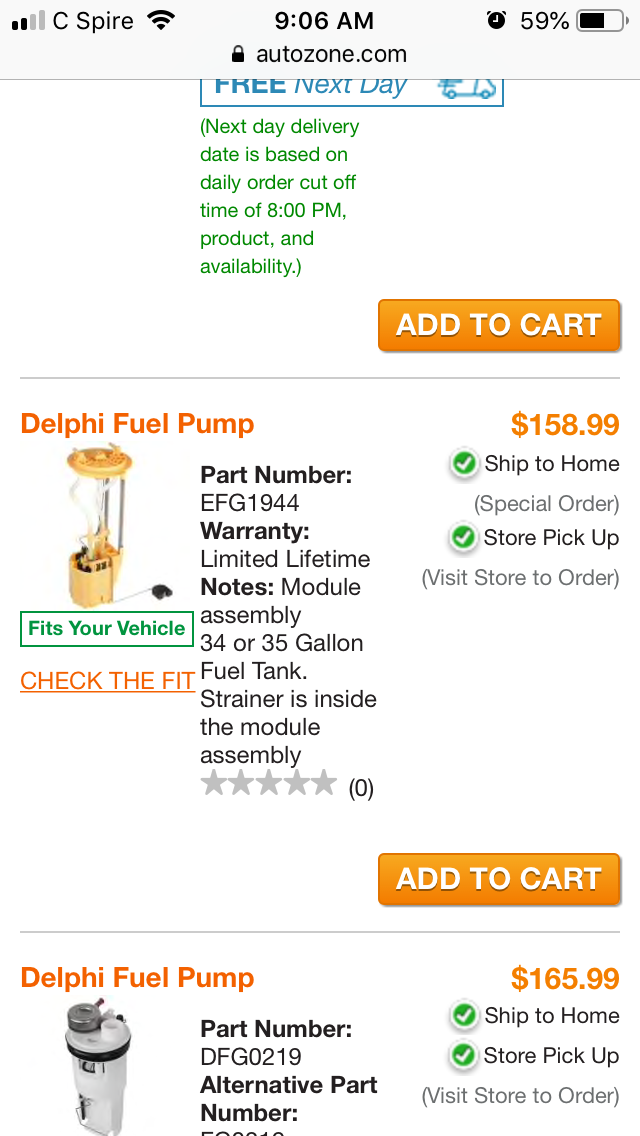

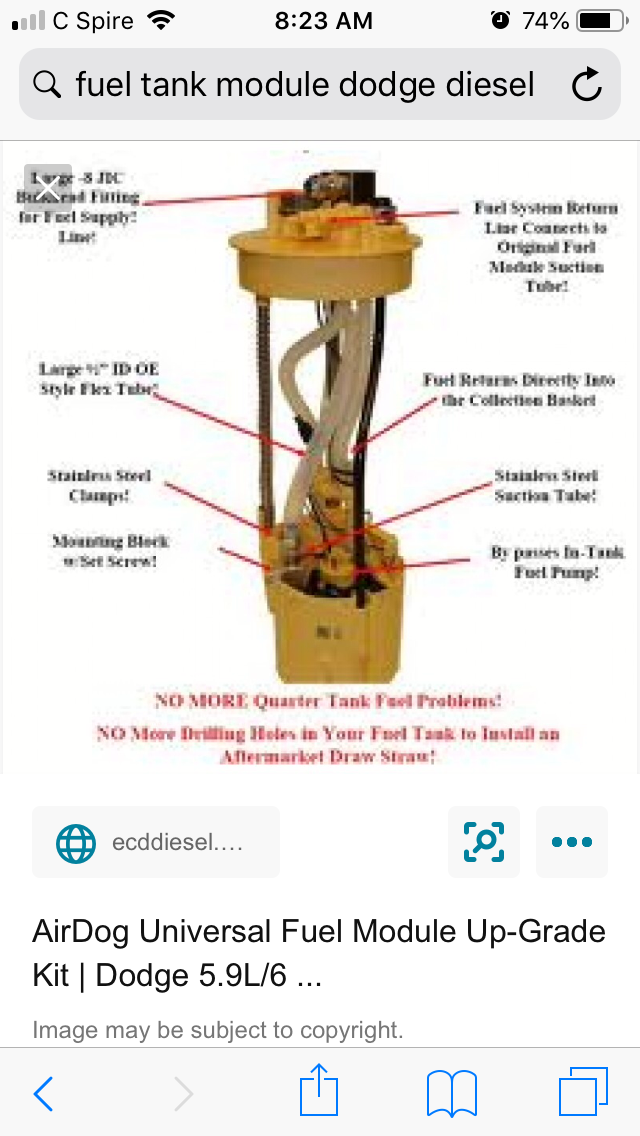

lift pump in it just at 2.5 years (airtex)

have not replaced sealing washers at back of the head. going to do that later today as long as Michael doesn’t dump water on me.

going to get a better fuel pressure gauge today and check that, again. was checking it with a HF pressure testing kit.

all cable ends have been replaced, new military style battery clamps. have not combined grounds to block, yet.

Edited by RAD