- Replies 35

- Views 4.7k

- Created

- Last Reply

Top Posters In This Topic

-

dripley 16 posts

dripley 16 posts -

Mopar1973Man 6 posts

Mopar1973Man 6 posts -

Haggar 4 posts

Haggar 4 posts -

JAG1 3 posts

Most Popular Posts

-

That was me in Cally. Now being ticket free for nearly 25 years. I know when its safe to wind the old Cummins to a C note. Rare but I've done it a few times.

-

ahhh, but those voltages were in reference to battery ground. they need to be to sensor ground. lets try that first. Hag

-

Sounds like the o-rings need replacing for sure. I've got to ask how many miles on the injectors? It might be time to consider re-popping or replacing if close to 100k miles. MAP sensor c

Well I notice after changing my oil 2 weeks go that I had not had to add any which is unusual since I have a leaky rear main seal. Today I check the oil and sure enough now I have more oil. Took the valve cover off and ran engine. Sure enough there is fuel sitting around no 2 and when shut it off and look back there is nothing there. What ever is there has gone back down the between the injector and the bore and I think I see air bubbles around no 3.. So I restarted the engine and sure enough there is air bubbles and fuel around no 3 and 4. The best I can see no 1, 5, and 6 are fine. I stuck a q tip at the bore of all of them and came back with oil on 1,5,6 and fuel around 2,3,4. since daylight short that is the only 3 I changed along with draining the oil. So the only o rings I have are off a set of rv 275s with 100k on them, nothing else available Sunday evening around here. They have also been sitting in a plastic bag for 3 or more years. I go to pull the injectors and they just lift right out, hardly had to apply any pressure. The o rings on the injectors are somewhat hard and when I took a pic to get them off the broke broke and hardly stretched. The ones on the rv s were stiff but still flexable enough to get off and back on the the other injector and reinstalling the injectors required some force to get them to seat; So for now I think I am ok but hope the other 3 hold until the head comes in a month or so. I will be keeping a close on the oil level looking for some drop.

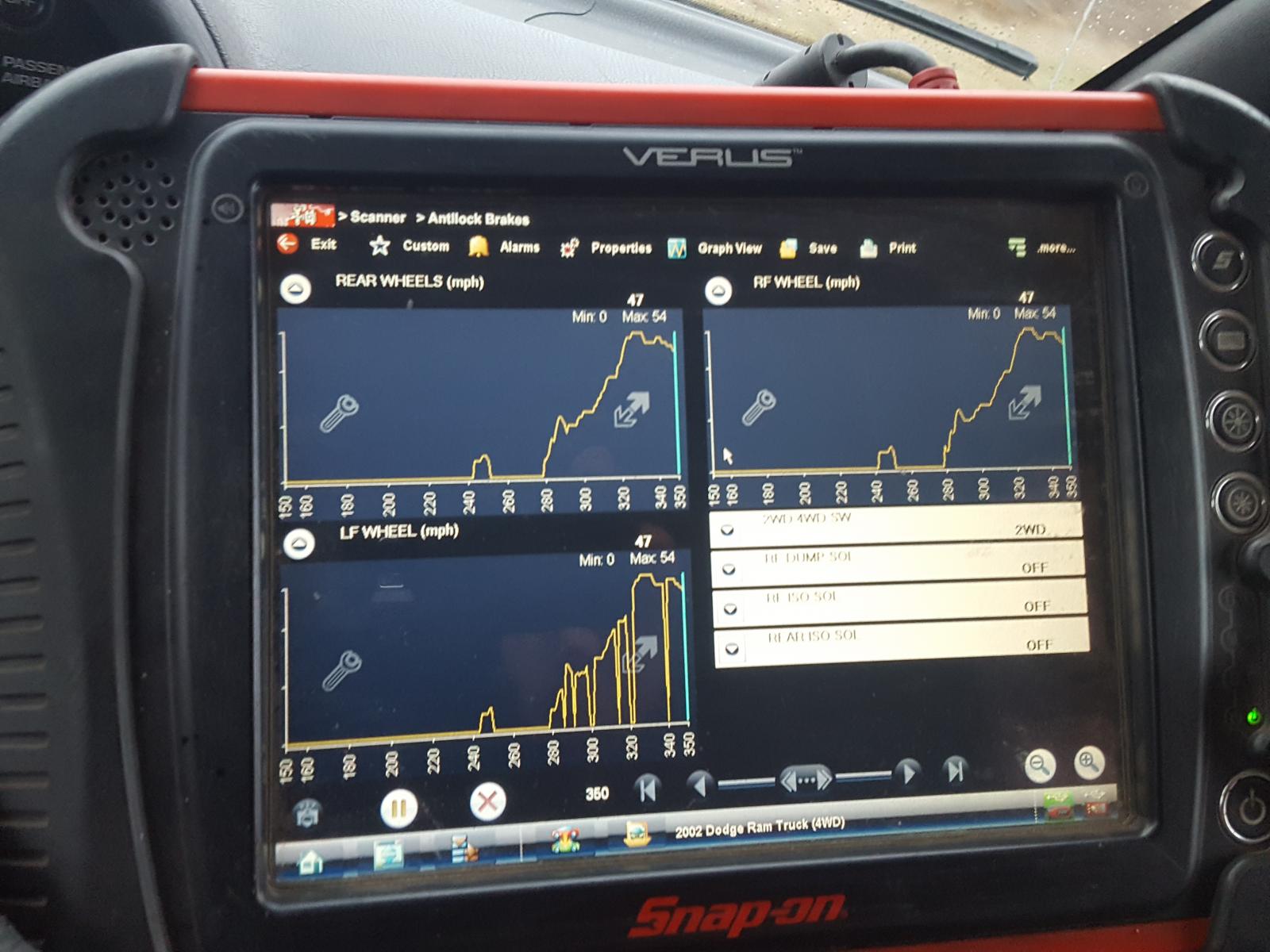

Now for the double whammy. I go for a test drive and have a CEL lit. I have been getting an odd CEL with a 237 code for the past weeks, but the light would go out and everything ran fine. I have planned on going thru the engine harness while the head was off but now on the test I get another CEL and now have a 237 and 238. The scan gauge is not seeing the map and she is defueling as she was a few months ago. Not enough daylight for that one so I will have to do some checking next week.

The end of this job cant come soon enough for me,