- Replies 23

- Views 3.3k

- Created

- Last Reply

Most Popular Posts

-

No experience here with either mechanical pumps but plenty with a gallon of most any beer, UK or USA. Either will tend to delay or slow down a repair. Keep a stiff upper my friend.

-

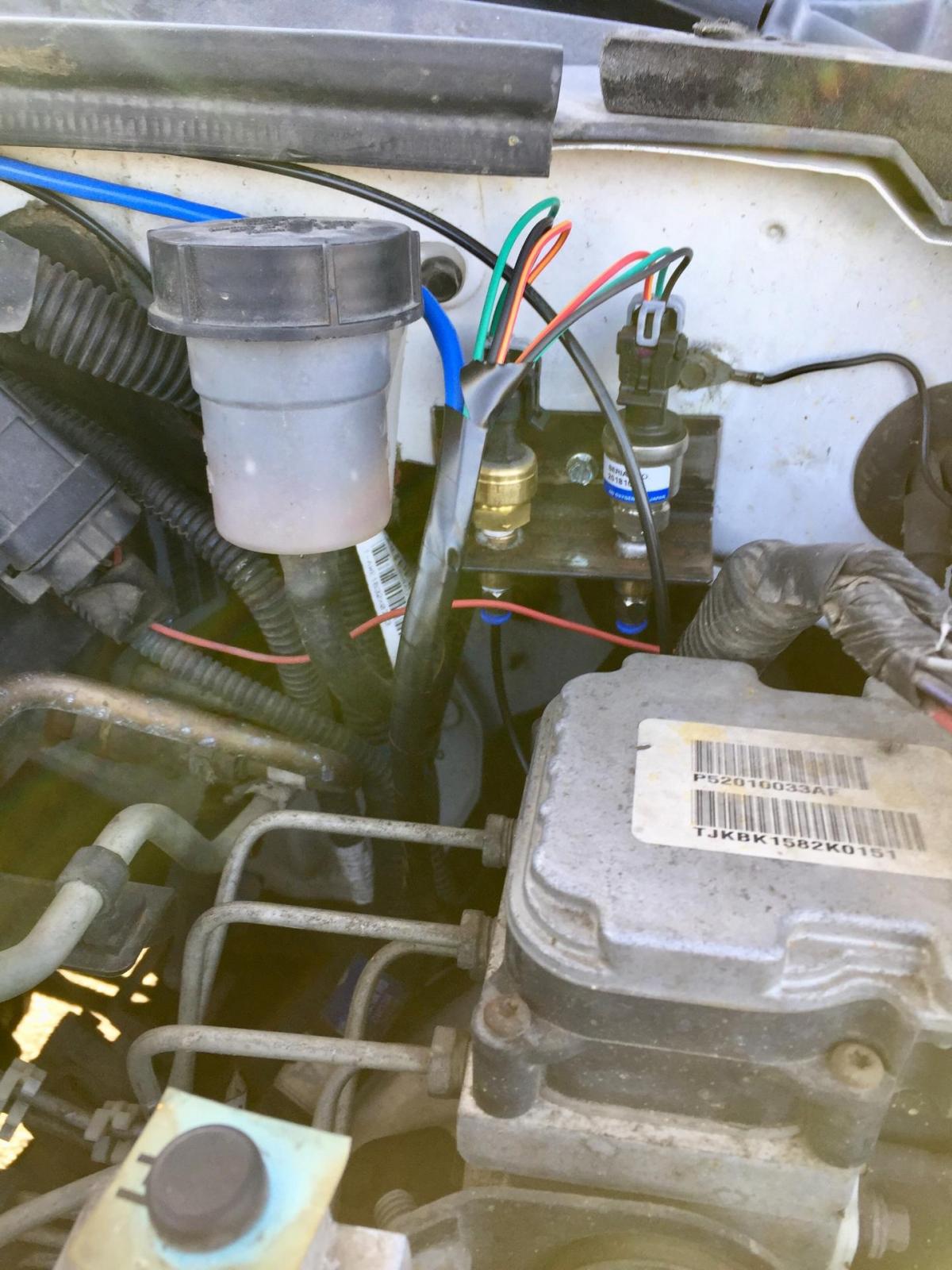

Fuel Boss mounted. You would have to rip the bumper off to hit the fuel pump.

-

The way I look fuel pressure...it takes 14psi to open up the overflow back to the tank which means that the VP is full of fuel. Since fuel lubricates and cools the VP then having the overflow open me

.jpg.17662a3a3b3375c2079abacd0d5bdc64.jpg)

Just finished fitting a Isspro mechanical fuel pressure gauge, this took 1 1/2hrs, removed the factory ash tray and the two top small bolts/screws behind were the same width apart as a cheap gauge mount I had so easy mounting and away from the pillar which I want to keep free for 3 other gauges I also slipped some Cat fuel line hose over the small plastic line for added protection in the engine bay and under the dash all the way from gauge to FP, still got to Zip Tie it all up but had to run it to check for leaks.

FP sits at 15 to 16psi at idle, I haven't driven it yet as it's behind my work van, to swap them around my work van has to go onto the road for a minute or two so seeing as I'd had well over a UK gallon of American IPA in a craft pub last night I'll do that tomorrow.

I did a torque stall and FP drops to 7 or 8 psi, now I think thats too low but last week when towing 9k + I did check temps of the VP and it was what I'd call warm but no where near hot. In hindsight I should have checked the tank temps and I had a DMM that has a laser temp deal on it with me DOH

I think I have two options here.

1. Truck has a Fass stock replacement that is in the stock position with stock lines, I could 1/2" line kit it and relocate LP to the frame next to the tank and it be not much better

OR

2. DTT Assassin which removes the LPFP from the ECM and adds reliability, this kit from DAP comes with a big line kit and draw straw

I am leaning towards a mechanical LPFP anyway but I'd want to be looking at the whole fuel system to figure out how to get more fuel going back to tank whilst keeping good FP and also route this through fuel coolers IF the tank was getting warm, I have a Cat fuel filter complete on the truck and I can't remember if any fuel returns go back to FF housing or tank or both but intend checking tomorrow, It's too hot here at the moment, my garden temp sensor say 44C in full sun... mad dogs might but this Englishman won't

The only downside of option 2 I can see is It hangs off of the front of the engine low down so deep water/mud etc might be a problem but then again here in the uk would I be offroading a 21 year old truck made in another country thats the size of a small house and at best parts take a while to get here.... most likely not

Is anyone using a DTT ???