- Replies 42

- Views 7.2k

- Created

- Last Reply

Top Posters In This Topic

-

Remington92 14 posts

-

Me78569 9 posts

-

dripley 7 posts

-

kzimmer 4 posts

Most Popular Posts

-

I get it. My fuel pressure is on the A pillar still. Going to move it one day. There other options and I like this better.

-

Well, no wonder you blew the intake manifold gasket!! - John

-

I want to see my gauges up close so I don't miss anything old pictures but still same.

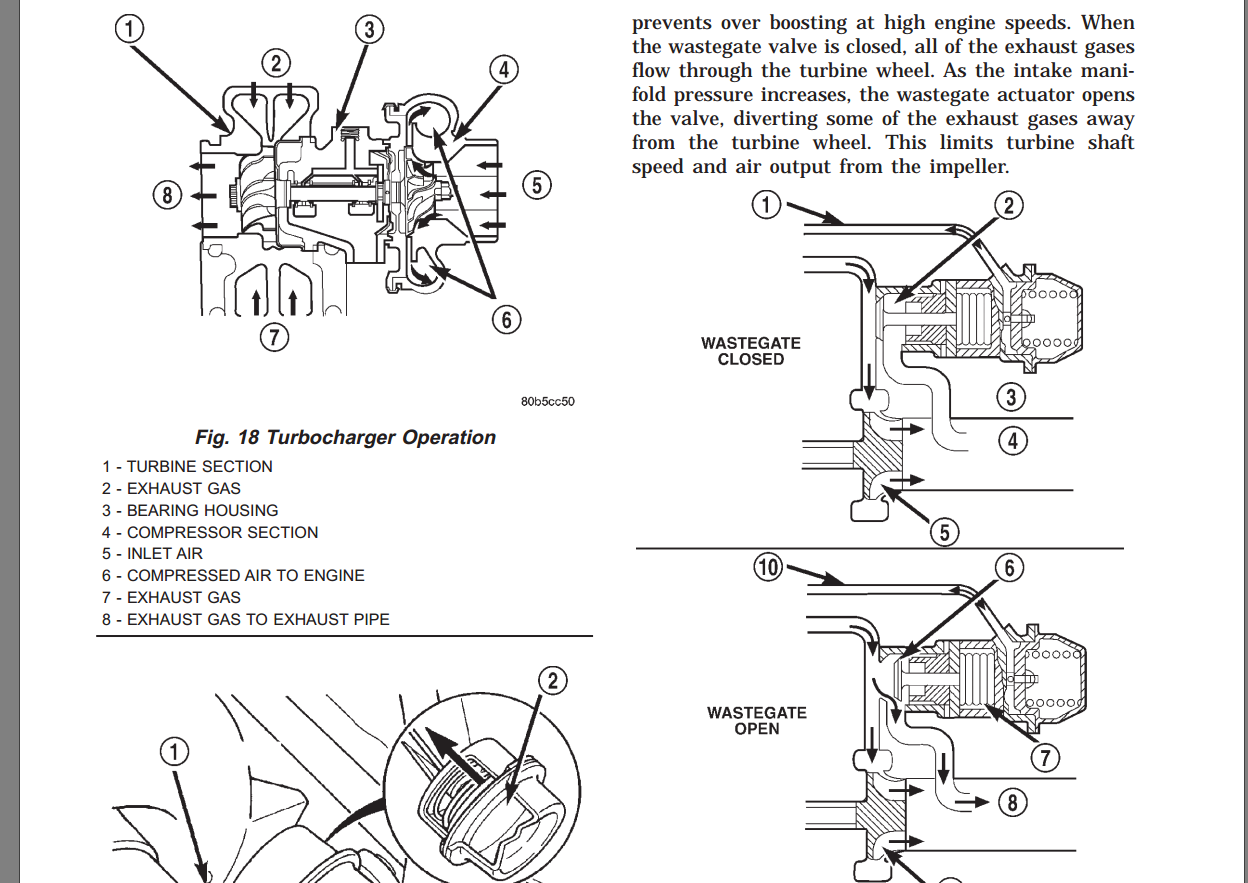

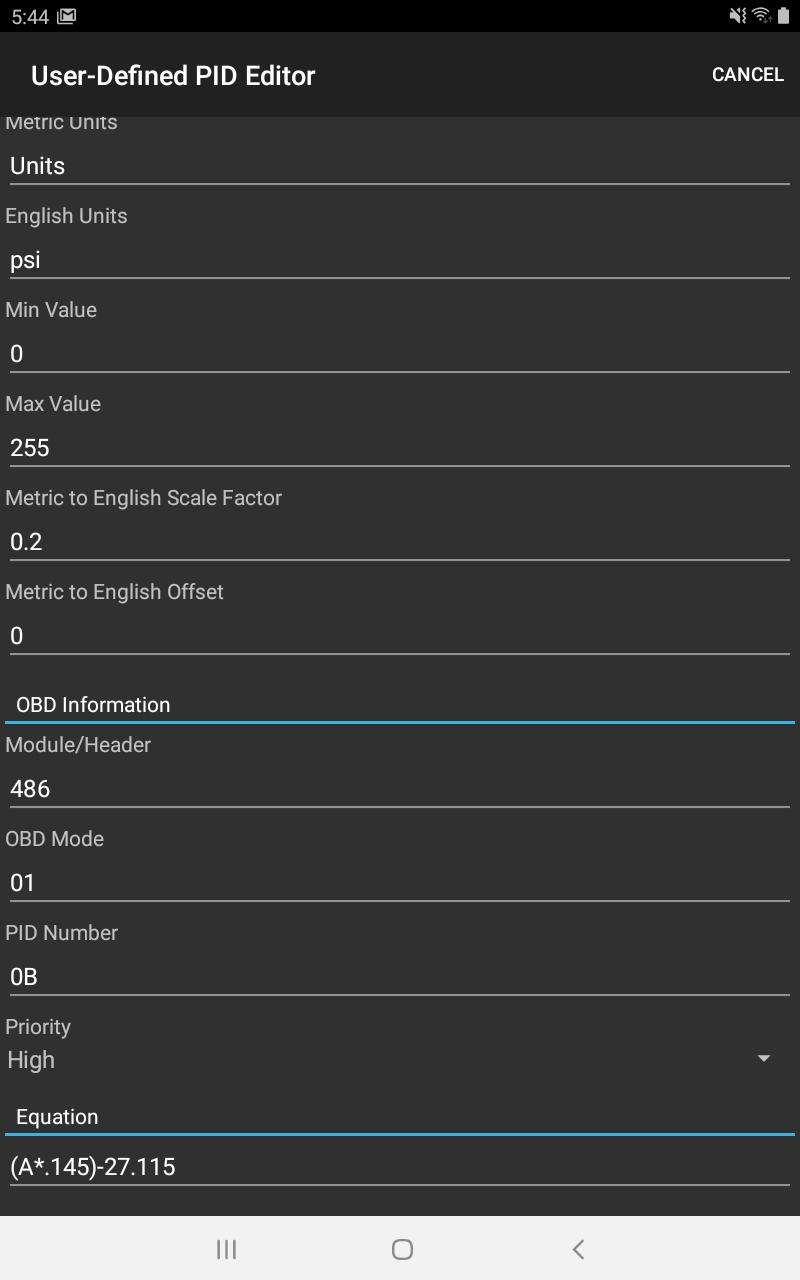

Hey there I just hooked up an OBDLink to my 24v and noticed some strange boost readings. At idle I’m getting 12.4 and at full throttle about 22.4. Is this the app not reading boost correctly or should I be checking my map and wastegate? It’s an 01 HO