Rear Wheel Bearing Torque

- Replies 4

- Views 1.3k

- Created

- Last Reply

Top Posters In This Topic

-

pepsi71ocean 1 post

-

Haggar 1 post

-

Dieselfuture 1 post

-

wil440 1 post

Popular Days

Most Popular Posts

-

If these are opposing taper bearings instead of unit bearings then the way to do them IF you have no instructions whatsoever Make sure outer races have been bottomed out correctly and the

-

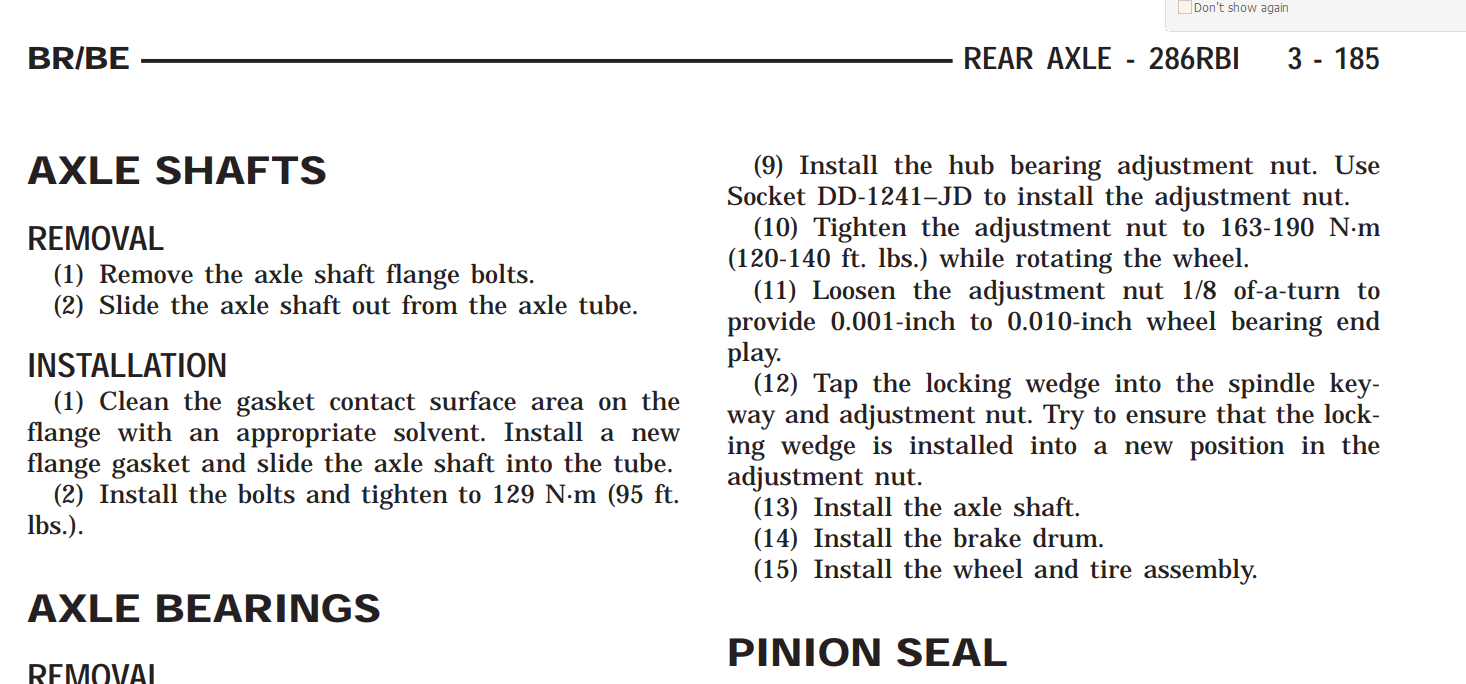

Here is what the 01 manual has for that. Step 8 is install the outer bearing, so this is the tightening process. Merry Christmas! Hag

I looked under axles and couldnt find torque for rear wheel bearings.They werent just real tight coming off, is it just snugged up?