Going to kill the KDP soon - advice

- Replies 23

- Views 4.7k

- Created

- Last Reply

Top Posters In This Topic

-

Ironforger 9 posts

-

klcammie 5 posts

-

mopartechnician 3 posts

-

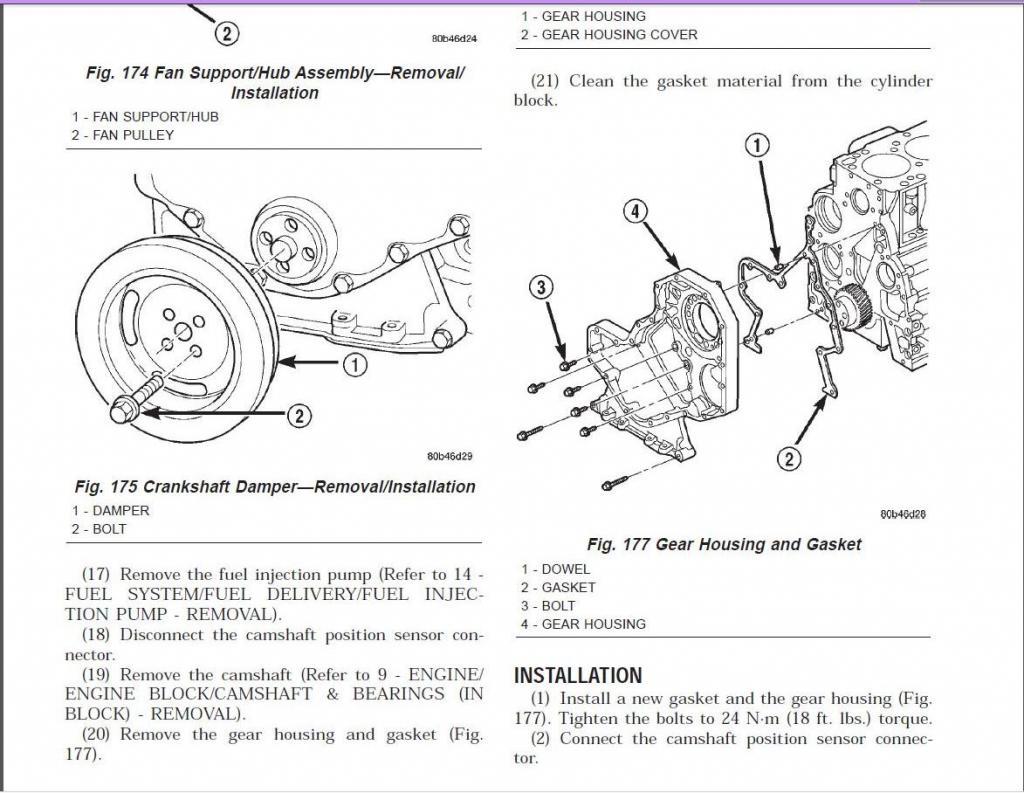

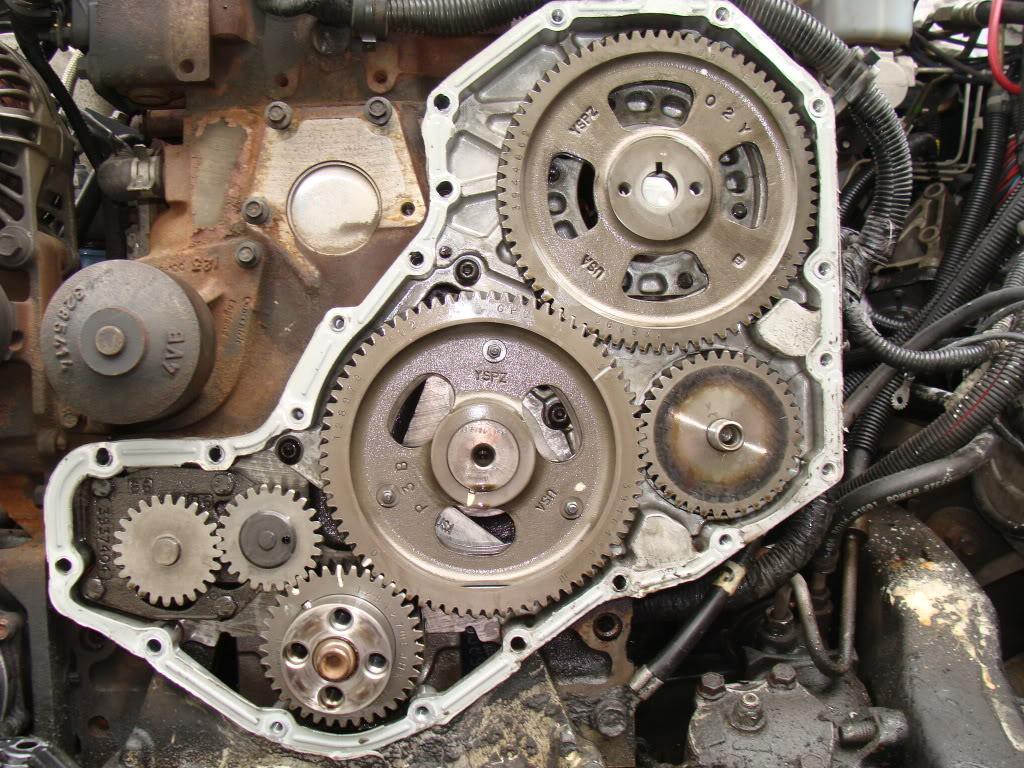

MnTom 2 posts

Getting ready to address the kdp soon. At the same time I'm going to clean the radiator, degrease the engine & delete the puke bottle & add a fuel boss. Want to try and get all this done before it get's to cold outside.Questions: I've decided to just unbolt the pulley assy from the block instead of using the custom wrenches to take the fan apart. Is there a gasket between the pulley assy & block? Or can I put it back together with the high quality grey rtv stuff? Same goes for the timing cover. Can I just use grey rtv on the re-assy?I've done the kdp on my first gen years ago, and I recall it was pretty easy but I used a new gasket for the timing cover. Any other pointers or step by steps for the 2nd gen?Thanks