-

Posts

1,324 -

Joined

-

Last visited

-

Days Won

11

CTcummins24V last won the day on December 24 2017

CTcummins24V had the most liked content!

Reputation

332 TrustworthyPersonal Information

-

Location (City, State)

Back in New England

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Torque Converter Rattle

CTcummins24V replied to CTcummins24V's topic in 2nd Generation Dodge 24 Valve Powertrain

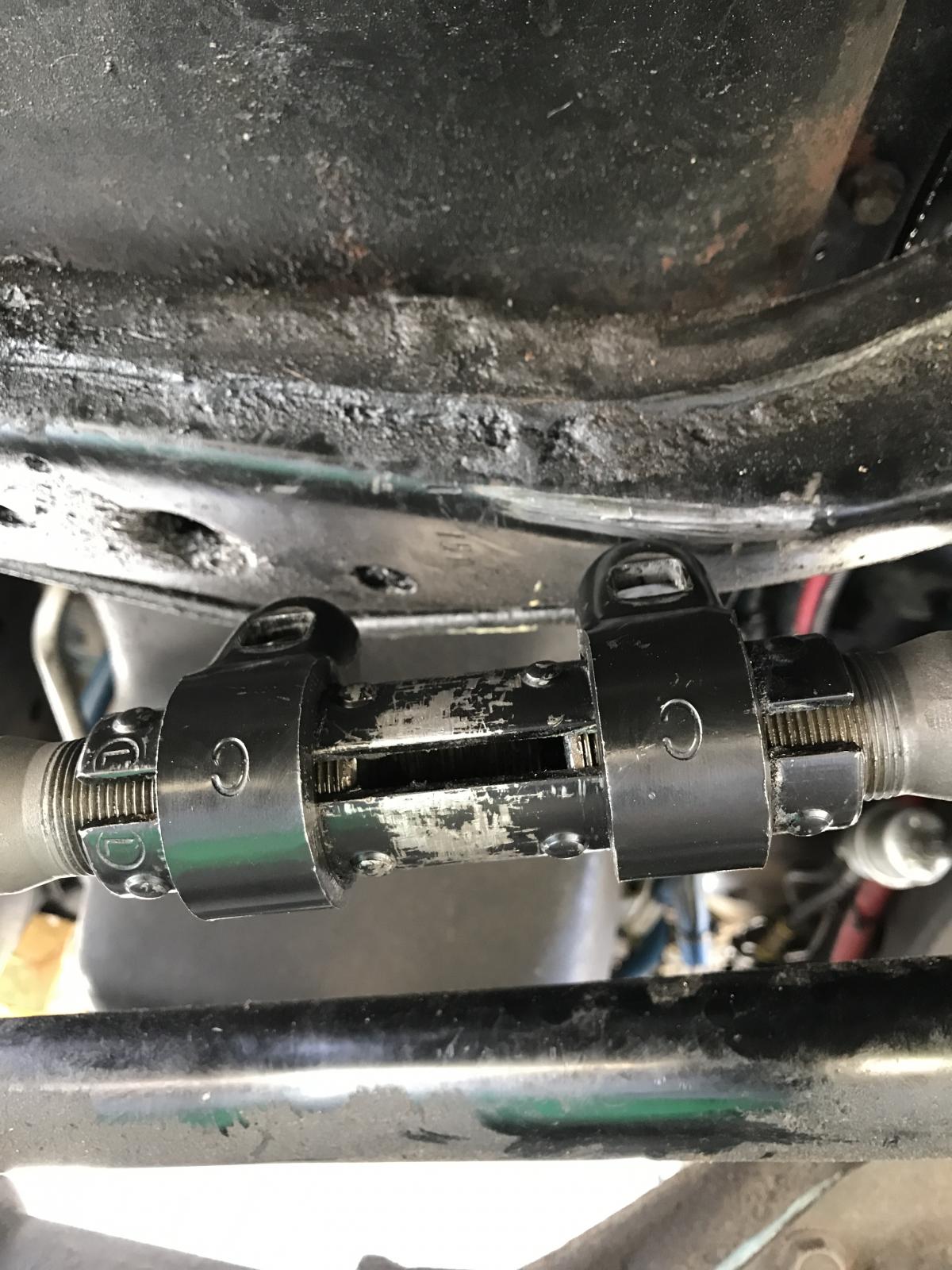

Finally solved, a day before I sold it! front axle, intermediate shaft bushing was all worn out. With the CAD removed, I could lift both the intermediate and right outer shaft 1/4”, so both shafts, shift fork and collar were rattling hard with the torque converter locked. Noise would disappear in 4 Wheel Dr. -

American racing baja 17x8

-

I have a company truck and am expecting kid #3, it was time to say goodbye good news is it’s going to farmer with multiple cummins and they work on trucks

-

Just my experience, I have run 6 different sets of injectors. Stock, DAP 60hp VCO, DFI 100hp VCO, DAP 100hp SAC, Contagious 40-50hp SAC and now Bosch RV275 VCO. All VCOs ran great in every scenario, and both sets of SAC injectors gave a rough/choppy idle when warm in park and a stumble when warm at light throttle. SACs ran great with some throttle, but I couldn’t handle the choppiness. SACs gave me a scare I had engine issues, but new RV275s put that to rest.

-

60 psi Specs for this turbo...

CTcummins24V replied to Stanley's topic in 2nd Generation Dodge 24 Valve Powertrain

Should be a super b/s300g. 57/65/14. Borg warner airwerks everyone has the standard s300 rebuild kits, just a matter of getting upgraded 360 thrust bearing -

What are these rubber grommets that came with the new Fel-Pro gasket for the tappet cover? Existing bolts only have a sealing washer?

-

I took out the heavy duty lift coils and put my stock front coil springs back in. With the lift, the drag link adjusting sleeve was maxed out with the threaded ends butting each other in the sleeve. So I cut 3/4” off each threaded end so they wouldn’t bottom out. Now I have a huge gap between the threaded ends with everything roughly aligned by me. Is this a weak point or don’t worry. This is on my 01 with 2010 T style steering.

-

FTE resonator eliminated drone on my 5". Still sounds good

-

I left John's $200 garage set up overnight, I woke up the next morning and it was blown across my wood pile, all the framing bent beyond fixing. Make sure you anchor it good.

-

Another seat cushion thread

CTcummins24V replied to 01cummins4ever's topic in 2nd Generation Dodge Non-Powertrain

4-10mm screws underneath holding the seat frame/cushion down, easy. -

Another seat cushion thread

CTcummins24V replied to 01cummins4ever's topic in 2nd Generation Dodge Non-Powertrain

I just did the genos cushion today, huge difference. I must be sitting 4" higher. Had to adjust the steering wheel because it was hitting my legs. So far so good -

Could be band adjustment screw improperly set leaving everything too loose, so the anchor falls out. Are you adjusting the bands regularly? No 2nd gear is definitely a front band/anchor/strut issue. Possibly front servo issue. Drop the valve body, everything is right there.

-

Injector Connector Tube

CTcummins24V replied to JustTommy320's topic in 2nd Generation Dodge 24 Valve Powertrain

Does that wipe off easily? Is that diesel with dirt? If the injection line to connector tube wasn't sealing properly that would explain the hard start(air in the system) and gunk build up. I have had some gunk around the o-ring but that's because I use tube grease on them to keep them from rolling on install. Are the injection line nuts at the head wet or visible leaking from around the nut at the head?

Rate The Author

Please take the time and give the author a 1 to a 5-star rating for the information you have gained from anywhere on the website. All forum threads, articles, etc. If a members post is good information please don't forget to tell them "Thanks" or "Like"

Rate Us On Google

Please take the time and visit our Google Review page and give us a review of our services.

Tip Jar

If Mopar1973Man.Com has helped you with quick and timely information for your repair please consider tossing a tip in the Tip Jar