Search the Community

Showing results for tags 'turbo'.

-

Turbo Inspection Operation Exhaust gas pressure (drive pressure) and energy drive the turbine, which in turn drives a centrifugal compressor that compresses the inlet air (boost pressure), and forces the air into the engine through the intercooler and plumbing. Since heat is a by-product of this compression, the air must pass through an intercooler to cool the incoming air and maintain power and efficiency. Increasing air flow to the engine provides: Improved engine performance Lower exhaust smoke density Improved operating economy Altitude compensation Noise reduction. The turbocharger also uses a wastegate, which regulates intake manifold air pressure and prevents over boosting at high engine speeds. When the wastegate valve is closed, all of the exhaust gases flow through the turbine wheel. As the intake manifold pressure increases, the wastegate actuator opens the valve, diverting some of the exhaust gases away from the turbine wheel. This limits turbine shaft speed and air output from the impeller. The turbocharger is lubricated by engine oil that is pressurized, cooled, and filtered. The oil is delivered to the turbocharger by a supply line that is tapped into the oil filter head. The oil travels into the bearing housing, where it lubricates the shaft and bearings. A return pipe at the bottom of the bearing housing routes the engine oil back to the crankcase. The most common turbocharger failure is bearing failure related to repeated hot shutdowns with inadequate “cool-down” periods. A sudden engine shutdown after the prolonged operation will result in the transfer of heat from the turbine section of the turbocharger to the bearing housing. This causes the oil to overheat and breaks down, which causes bearing and shaft damage the next time the vehicle is started. Letting the engine idle after extended operation allows the turbine housing to cool to normal operating temperature. Mopar's Notes: You should allow your pyrometer to fall below 300°F before shutdown. If you don't have a pyrometer I highly recommend you purchase a pyrometer gauge and install it. There is also turbo timers that allow the driver to turn off the ignition and lock up the vehicle. The engine will continue to run for set time and then shut down. These add-ons will extend the life of your turbo greatly. Turbo Inspection Procedure Visually inspect the turbocharger and exhaust manifold gasket surfaces. Replace stripped or eroded mounting studs. 1. Visually inspect the turbocharger for cracks. The following cracks are NOT acceptable: Cracks in the turbine and compressor housing that go completely through. Cracks in the mounting flange that are longer than 15 mm (0.6 in.). Cracks in the mounting flange that intersect bolt through-holes. Two (2) Cracks in the mounting flange that are closer than 6.4 mm (0.25 in.) together. 2. Visually inspect the impeller and compressor wheel fins for nicks, cracks, or chips. Note: Some impellers may have a factory placed paint mark which, after normal operation, appears to be a crack. Remove this mark with a suitable solvent to verify that it is not a crack. 3. Visually inspect the turbocharger compressor housing for an impeller rubbing condition (Fig. 25). Replace the turbocharger if the condition exists. 4. Measure the turbocharger axial end play: a. Install a dial indicator as shown in (Fig. 26). Zero the indicator at one end of travel. b. Move the impeller shaft fore and aft and record the measurement. Allowable end play is 0.038 mm (0.0015 in.) MIN. and 0.089 mm (0.0035in.) MAX. If the recorded measurement falls outside these parameters, replace the turbocharger assembly. 5. Measure the turbocharger bearing radial clearance: a. Insert a narrow blade or wire style feeler gauge between the compressor wheel and the housing(Fig. 27). b. Gently push the compressor wheel toward the housing and record the clearance. c. With the feeler gauge in the same location, gently push the compressor wheel away from the housing and again record the clearance. d. Subtract the smaller clearance from the larger clearance. This is the radial bearing clearance. e. Allowable radial bearing clearance is 0.326mm (0.0128 in.) MIN. and 0.496 mm (0.0195 in.) MAX. If the recorded measurement falls outside these specifications, replace the turbocharger assy.

-

- turbo inspection

- turbo

-

(and 2 more)

Tagged with:

-

Description The intercooler system (Fig. 28) consists of the intercooler piping, intercooler and intake air grid heater. The intercooler is a heat exchanger that uses air flow from vehicle motion to dissipate heat from the intake air. As the turbocharger increases air pressure, the air temperature increases. Lowering the intake air temperature increases engine efficiency and power. Operation Intake air is drawn through the air cleaner and into the turbocharger compressor housing. Pressurized air from the turbocharger then flows forward through the intercooler located in front of the radiator. From the intercooler, the air flows back into the intake manifold. Inspection Visually inspect the intercooler for cracks, holes, or damage. Inspect the tubes, fins, and welds for tears, breaks, or other damage. Replace the intercooler if the damage is found. Pressure test the intercooler, using Charge Air Cooler Tester Kit #3824556. This kit is available through Cummins Service Products. Instructions are provided with the kit. You can also use the below to test for boost leaks with turbos with a 4" inlet Mopar's Notes: Many people have created their own air system or intercooler testing equipment from common plumbing part at a hardware store. Basically, you want to cap off the turbo and have an air connection that is regulated to 20-25 PSI maximum. You can spray down the air system with soapy water and look for leaks (bubbles) or see if the pressure falls off. WARNING! Do not use caustic cleaners to clean the charge air cooler. Damage to the intercooler will result. If internal debris cannot be removed from the intercooler, the intercooler MUST be replaced. 1. If the engine experiences a turbocharger failure or any other situation where oil or debris get into the intercooler, the intercooler must be cleaned internally. 2. Position the intercooler so the inlet and outlet tubes are vertical. 3. Flush the intercooler internally with a solvent in the direction opposite of normal air flow. 4. Shake the intercooler and lightly tap on the end tanks with a rubber mallet to dislodge trapped debris. 5. Continue flushing until all debris or oil are removed. 6. Rinse the intercooler with hot soapy water to remove any remaining solvent. 7. Rinse thoroughly with clean water and blow dry with compressed air.

- 1 review

-

- 3

-

-

- intercooler

- turbo

-

(and 2 more)

Tagged with:

-

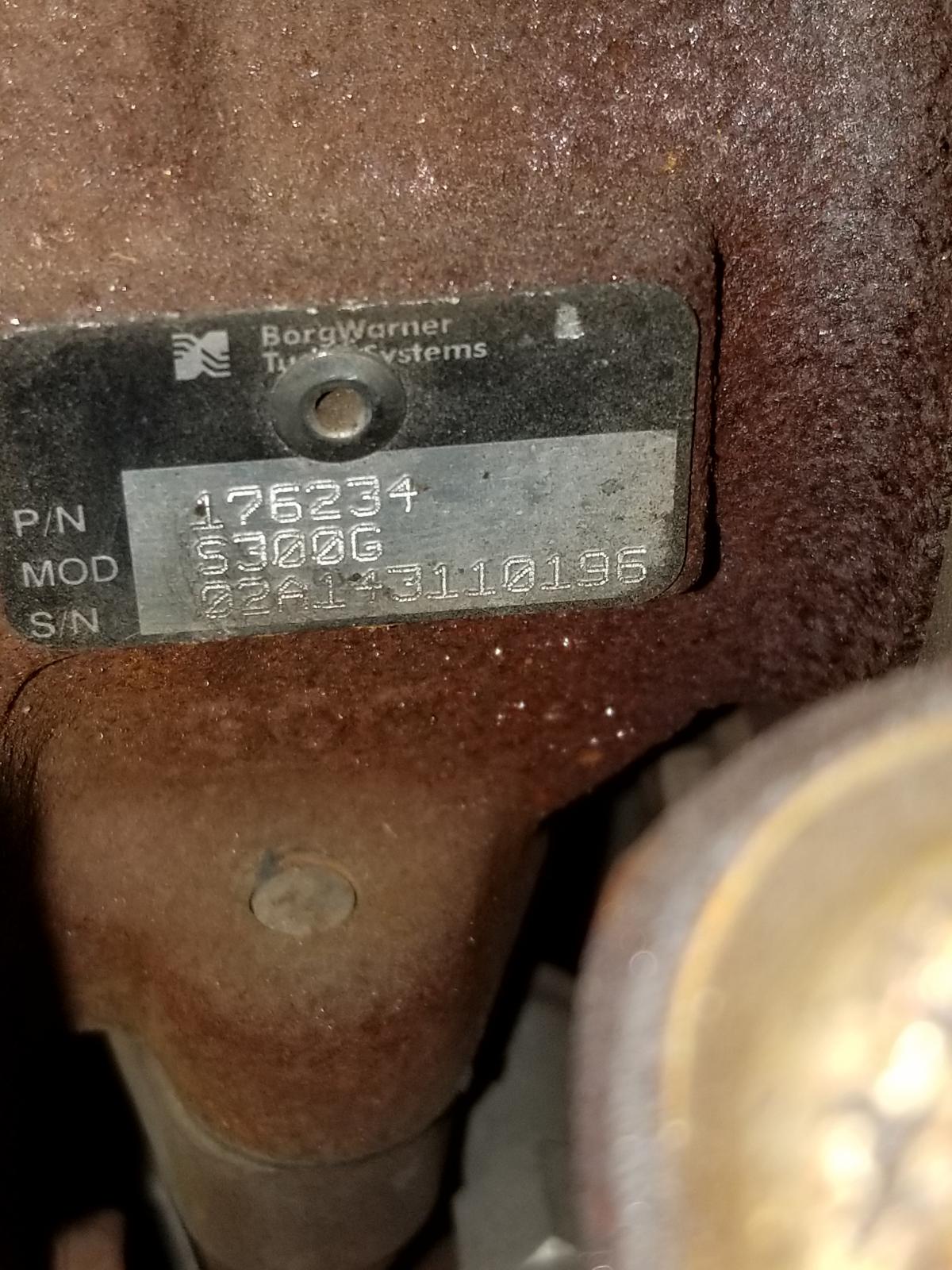

Trying to find specs on this turbo for a guy and I cant find any actual specs on it...(sizes) It needs a rebuild kit also if anyone knows a good place where to get kits Pn 176234 S300g Sn 02A143110196

-

Running standard V2 tuning for now. Wanted to explore the features of the Quad and play around with customized settings. Have boost defuel on at 30 psi, EGT defuel at 1200 °F, high idle kicked on at 30 seconds, warmup mode until 140 °F, MPG offset off, and lastly, turbo timer set for 60 seconds. Shutting the truck off whether I’m at level 0-10, the truck shuts off immediately rather than running the extra 60 seconds after key-off. I set the turbo timer to 300 °F, as well, and have had the same trouble in all levels. Anything I’m missing? Have had the Quad for about 2 weeks now, still trying to figure out the Diagnostics portion of the application, as well as understanding and using the Data Log portion.

- 7 replies

-

- turbo timer

- turbo

-

(and 1 more)

Tagged with:

-

Looking for suggestions. Lots of info here, but hard to find a specific good parts combo for a relatively minor build. My daily driver 2wd 5spd would be a lot more fun with a bit more power. I'm thinking 100hp over stock. Just installed a Valair 13" clutch. Have a wastegate actuator regulator that just showed up in the mail. Truck has a 4" exhaust, gauges, Smarty S04, an air dog factory replacement lift pump (100 gph) mounted to the frame by the tank. Was given a K&N cold air intake but not yet installed. Any thoughts on the least expensive way to reach my power goal? 600 hp would be great, but my budget is very limited at the moment and it is my daily driver. 17.8 1/4 mile times are down right embarrassing. Just looking to spice up my daily commute. If there's an article that covers this, I didn't see it. I have done some research, but most of what I've seen is aimed at heavy towing or all out power. Thanks in advance.

-

So having owned my ‘99 for a little over two months and towing my tractor a few times I think I have decided to see if I can upgrade some things to get some more power. I am as I think that would satisfy my needs. Looking at 7X.009 SAC injectors, a turbo, gauges, and a tuner of some kind to manage smoke and heat. Need some recommendations on a turbo and tuner. Thinking about this Turbo as a direct replacement. For the tuner: either an Edge Comp or the Quadzilla Iquad. Really don’t have the experience to create my own tunes and need more knowledge of diesel theory to be able to get the most out of a tuner so leaning towards something with “canned” tunes. Will run gauges for egt, boost, and trans temp. What range boost gauge should I use, up to 50psi? Already have a fuel gauge. So chime in guys with your ideas and help me choose the right parts to start with.

-

Where is the low power? I've been pondering this. Turbo upgrade? Diff gears? ECM mod? You get to a point when all forms and info get so jumbled you forgot what you are looking for. I don't tow much, some, but not much. I want that tire burning diesel action when I feel the need to use it. I can get about 35 lbs of boost with my setup, which is good, egts climb to the 1500s at Wot( rarely at Wot) . Little worried about that. From what I read my Hx35w (54/60/12) is a good turbo, but a 60/60/12 or 62/68/12 would spool faster. But would that rip the tires loose? If so what is the right turbo internal upgrade? I thought about changing diff gears to 4.11 for low end power with my 285s but my current 3.55 seems to be where I need to be.. I think. I've also heard talk about a Mad catcher ECM mod ripping off the line but don't know how it plays with quadzilla. Once I'm rolling, it's on, but from a dead stop what's the magic ingredient to rip loose? What am I missing?

-

I'm trying to decide between the S200GX-E faster spool or the Super B Special SX-E S363 more top end. I don't tow. Can any turbo gurus help me decide? Anyone have experience with these? Thanks! Oh, and of course open to other recommendations, but these are what I've narrowed it to with my lack of skill. ?

-

Well I’m thinking about doin a turbo swap. I would like to have around 400 450 hp. I will be purchasing a qaud v2 before too long. I’m thinking I will do injectors too. What size would you do with the HE351 and v2? And now for the turbo... do I want the variable geometry or the cw model? I would also like an exhaust brake which I believe is built into these turbos? Has anyone else done this swap? What was your experience? Anyone please chip in with questions comments or concerns. Mods should be in signature. Fass 150 is alsonin the books before long! And just to clarify the truck is running well now. No issues besides the fact it snowed 6 inches yesterday and I hit the ditch! Took out the neighbors mailbox with deer guard! Thanks guys!!

-

So I'm installing a new exhaust manifold (you'd be surprised how many issues you can run into doing this simple job) and this is what I find. Is this enough oil for me to be concerned?

-

Starting a new thread so we don't clutter up other threads with this talk and we can have it in one dedicated thread. So @jlbayes you're the second person now I've seen post in the last couple days saying that the lower stall speed was terrible. Seems weird that builders like @Dynamic are using the slightly lower stalls, but the end user isn't happy. Is it just a preference on your end or is it actually performing bad? @Dynamic you said that the slightly lower stall speed was good up to around a 62mm sized turbo right? @jlbayes what size charger and stall speed where you running?! Tagging for sa purposes: @CSM @Silverdodge @Me78569 @JAG1

- 32 replies

-

- torque converter

- stall speed

-

(and 1 more)

Tagged with:

-

Hey everyone I have been doing a ton of research lately trying to figure out what upgrade I want to do on my truck. I have looked over many different threads regarding injectors however these threads are almost 8 years old now. I have also been following the Quadzilla V2 threads very closely and recently purchased the iQuadBT. Like most guys I have gotten the thirst for more horsepower. I am on a limited budget and I am still looking for a reliable daily driver. So my question to you is, if you guys could go back and start with a truck that only had 63,000 miles on it what would you upgrade next? Here is my list of upgrades(for now): 1. 5 inch Turbo back exhaust 2. BHAF 3. FASS 150 4. Quadzilla V2 5. Bean Sump For some reason I cannot figure out my signature but my truck is a 99, 53 block five speed with only 63,000 miles.

- 45 replies

-

- horsepower

- injectors

-

(and 3 more)

Tagged with:

-

I was thinking of getting a new turbo to run on my truck. Has anyone ran one the Bladerunners. here is the website link for the turbo I was looking at. http://www.xtremediesel.com/afebladerunnerturbocharger46-60061.aspx

-

Im seeing a lot of guys switching to these, a few on here.. Do they really work & perform that well on the 2nd GEN trucks compared to S300 and others out there ????

-

So I posted a thread a little while ago about my turbo and it throwing a p0234 code. Got no respose. So, I decided I would try and dig a little deeper into the issue. I thought about making a leak tester to see if I can figure out what was going.So I went to the local stores and parted together a tester. Got a 4" rubber coupling and a 4" adapter with a cap. Put an air regulator on the end and called it good.So I put the tester on the inlet of the turbo and put the pressure to it. If I apply more than 10psi, the tester wants to slide off the turbo from the pressure. The rubber will also balloon out. I was getting a little nervous about a catastrophic failure but I managed to get it up to 23psi I think the wife said.I'm not sure if its normal or not, but I think my boost elbow is an edge boost elbow for one, but then also I dunno if the little hole on the side of it is normal or not? I may of not had the engine turned at the right point to keep the pressure up either but I was loosing pressure.My intent with the tester was to actually see if I could get the wastegate to actuate to see if the wastegate was indeed stuck. I dunno at what psi its supposed to open?So instead, I stuck the air hose up to the wastegate line with an air nozzle and applied air that way. It made the arm move and the wastegate actuated...So, I'm wondering now, if I have the boost elbow on is if thats whats causing me to throw the code? I took the truck out after and floored it. The highest the boost got was 27psi. With my injectors and boost elbow, should'nt I be making moe boost then that? Is 27psi also enough to throw the p0234 code as well?

- 11 replies

-

- boost

- boost pressure

-

(and 1 more)

Tagged with:

-

So I think I am burning oil from the turbo... I am going through about a quart every 600-700 miles. I am not leaking anything on the ground except a few drops here and there. I have checked my blowby while the engine is cold right after start-up, and after being on the freeway for a couple hours. Either way, i have hardly any blowby, a puff every now and then. The only other thing I could think of is maybe the seals in the turbo are shot. It is the stock turbo, never been touched and it has 193,xxx miles on it. The head was rebuilt last summer so I dont think it could be in there. Any ideas? thanks everyone!

-

After removing the stock air box and K&N filter:nono: and installing the BHAF, I decided to take a look at the turbo. It does not look damaged but it is filthy. At the risk of sounding stupid, what would be the best thing to clean it with? Or would it be best to just leave it alone? Remember I am new to the diesel world! Just don't want to make any costly mistakes or slack on maintenance.

-

Hey Guys, I am fresh to the site - have dug around on some of the tests that can be provided, did those and after running thru that and replacing the MAP sensor we are still at a loss so I am reaching out to you guys for some help if you would....The truck is a 2001 Dually, 3500 4x4, has the HO engine in it with about 83,000 miles on it. Fuel system has a Raptor 150 Pump with a Draw straw and bigger lines to support more fuel not only to the filter, but past it and direct to the VP. I run a pressure gauge that reads pressure just previous to the VP to monitor the pressure right before the VP to keep an eye on lift pump pressure and filter condition. It's been holding steady at 19 pounds while truckin' down the road. When fueling, I use Wallyworld 2 Stroke TC3w Oil to keep the VP lubed at 1oz to one gallon of diesel.Here is what has been happening:Acts like dead pedal once in a bit, won't get out of it's own way sometimes and even floored truck will not accelerate hardly at all - will exhibit lean smoke at the top of the rpms while trying to get 'er moving to the next gear. Then after some time, it just jumps back into life and away we go - sometimes it runs like there is no issue and sometimes it takes a while - this is both warmed up and cold. Turbo response during this "episode" is basically gone. Even when things are operational, the EGT's seem higher than they used to be. One second it's running like its new, the next, it won't get out of it's own way. Sometimes when I start out in second (it's a 6 spd manual) it wants to almost stall and that is when I know that things are not starting out so well... The problem is random like I said - you can have it floored and there is no response and then 4 seconds later - hey!, it's alive!We've reset the apps and on the OBII Snap On test, it's reading %'s as far as foot pedal movement-We are attempting on getting to the root of the problem and I have two quick questions before I give you the War and Peace size story that backs the history on this-1 - On a VP44 Inj Pump, can it "come and go" timimg wise to advance great one round and then not the next?I guess in other words, can the non-response be caused by a pump that is failing advance-wise and then the pump get back into time and it'll run fine? 2- On the MAP Voltage Low test, the MAPS did not seem up to par voltage wise on the OBDII Snap On test so I replaced it - here is the question:The Maps that I took off the engine is twice the size of the one that was sold to me, inlet hole is for pressure reading is half the size as well - It was however the harder one to find and about $166 my cost - it does have the right plug in for the harness three-pin oval, not the round plug in - part number on the new one is EC1854 made by BWD - the stock Mopar one has a 10702 on one side (i think that is a 2 on the end) and a 3417030 on the other. That seem right that they are different sizes? I can't find anywhere that has the bigger one....? it took a socket that was an 1" 1/4 to get it out and the new one took an 1" 1/16....Doesn't seem right?That is a place to start as I don't want this to be 7 pages long to start with as I know that you have things to do other than read a novel from me...Thanks for the help - I'll have more as we go and please feel free to ask questions as I am sure more info is helpful.Thanks all, have a great Sunday!!

-

So I got my HX35 swapped on tonight and what a difference!!! I thank all you guys that told me to swap off the old HY before buying injectors. I got my new glowshift pillar gauges on last night so I thought I would see how much boost I was getting with the HY35. The max I could get was around 17psi. Tonight I swapped on the HX35 and installed the pyro probe. The turbo already has a boost elbow in it. On my test drive I was seeing 25 psi and that was on a flat section of road full throttle. My pyro was climbing to around 950 when pinned to the floor. Does that sound about right? I'm running a Superchips D box will it fool the ECM and allow the 25 psi+ boost or will I throw a code eventually? How high can I get the boost with the elbow before I run into issues? I don't need ridiculous boost just want to keep my EGTs low when towing. Lastly I know you guys like to run your trans temp on the outlet to the cooler, but that isn't an option for me right now. I'm going to put it in the test port on the right side of the trans. I saw something about using an extender on the probe. Can't I just thread the sender right into the trans? I will use the center port not the servo ports. Thanks guys.

-

I have been running without a boost elbow for some time and I installed the adjustable elbow today and there is no increase in boost pressure, 27-28 lbs and I am still getting over boost code. Also, if I get into it hard, as soon as I let off there is a poping noise, like a backfire in the area of the turbo. The poping noise just started last week and has only done it about 5 times and is intermittant.When I installed the boost elbow, I turned the screw down all the way, then back it out about 1-2 turns, still get the code and same boost numbers. Then cranked the screw down all the way, same results.Any ideas?

-

Not quite sure what the problem is, but here's what happened. I had cruise set at 75 and everything was fine, tuck ran fine, good oil pressure, plenty of power, no warning lights, etc. All of the sudden there was a clicking sounding type of a knock, for lack of a better description and a lot of bluish smoke I think, it was dark but I could see smoke in the mirrors. It would increase as the RPM's did. I got off the turnpike and called a wrecker. Checked the oil it was full and no puddles or leaks. I had my OBD II scanner with me and it read P0234 with no check engine light. As far as I can tell I think the engine sounds fine but the knock/click is so loud it's difficult to isolate. I don't have a fuel pressure gauge so I don't know what the pressure is but I have replaced the VP and the lift pump. Never had that noise before, nor have I had a blown turbo. Is it possible the turbo and or waste gate could be making the sound?

-

Hi guys. I have a couple questions on what is going on with my truck. I noticed I am shifting too early where the RPM's are low and it surges or jerks until the RPM's get higher. It is shifting into 4th gear with OD off at 25mph and it happens also about 45mph where its shifting into high gear and doing the same thing with OD on. Tonight I was doing a couple road tests and I got on it alittle more than usual and when I got home because of how it was acting, I used my scangauge and I had a p0234 code. So I have been doing alittle reading about the wastegate etc which I do not understand and wonder how the code is related to what is going on with my truck. Is it something else with these symptoms??? The only thing I have done different recently is have an Airdog 100 installed and hooked my Quadzilla XZT up a month ago. Any suggestions or answers are appreciated!!

- 20 replies

-

- automatic transmission

- p0234

-

(and 2 more)

Tagged with:

-

While changing the oil today I had my filter off and noticed something odd. I cant remember if I have noticed this before but there are no nicks in the blades and it has no in and out movement and very little side to side. It spins freely fine and builds boost as it should but as you can see there is a chunk of metal missing right behind the nut.

Rate The Author

Please take the time and give the author a 1 to a 5-star rating for the information you have gained from anywhere on the website. All forum threads, articles, etc. If a members post is good information please don't forget to tell them "Thanks" or "Like"

Rate Us On Google

Please take the time and visit our Google Review page and give us a review of our services.

Tip Jar

If Mopar1973Man.Com has helped you with quick and timely information for your repair please consider tossing a tip in the Tip Jar