Search the Community

Showing results for tags 'injectors'.

-

This article is on how to disassemble a Cummins 24v VP44 injector and thoroughly clean and then reassemble it.For starters, you need to refer back to injector removal and get all 6 Injectors removed from the engine. Once you got all six injectors out you can proceed to clean each injector. But something to be aware of there is small parts and these parts must be put back exactly the way it came apart. WARNING! Only disassemble and clean only 1 injector at a time. All the parts are tuned to that particular body. Don't mix and match parts! Then before you can remove the nut you need to remove your copper washer. This can be done with a putty knife and a hammer just lightly tap the putty knife and it should be able to pry it up enough to using the putty knife or a screwdriver. Now as I set my torque wrench for loosening and kept adding torque to the handle adjustment looking for the click and loosening of the nut. I found it at about 32 foot/pounds so I backed off to 30 foot/pounds and set the wrench. Loosen the nut. Now you need a clean area too. I set up a shop towel and an old ashtray. I filled the ashtray with Coleman fuel (Naphtha). So I would open up the injector carefully and place all the parts in the solvent to soak. Now in the picture above there is a shim that goes in the bottom below the spring. This shim might be stuck inside the body don't sweat it let in soak in the Coleman fuel for about 5 minutes and pick it up and it will fall out. Now that all the parts are soaking take an old scotch bright one that's been used a bit and rather soft. dip it in the solvent and light rub the nozzle clean of soot. Yes, you may rub the tip but be gentle about it. Now look at the pintle (needle) look at the tip for damage or wear... Now check it for smooth sliding action in the nozzle. If it feels rough rub the pintle gently with the scotch bright pad and it will help it out... I was doing a mini-spray test too... Dip the nozzle in the solvent keeping the fuel hole up and holding the nozzle horizontal using a blow gun just a light burst of air will show you your spray pattern somewhat but also ensures the nozzle tip is not plugged. Now just blow all the large parts clean and dry from the solvent. Make sure to blow the fuel passages clear. Once you happy with the clean up and every is clean now reassembly the injector exactly the way it came apart. Put your shim in the body take notice of which side was up. You'll also notice the shim has worn marks from the spring so be sure to put it back in the right way. The shim has to be this side up... Take notice to the side that has the wear mark for the spring... Then place your spring the body. Then there is a cone shaped piece that goes on top of the spring but make sure to place the hollow side up. This is for the pintle to ride in. The mid body goes on top of this take notice to the pins it will only go on one way... Then your nozzle and pintle go on top to look like this... Here is a good video of how I did each injector.

-

Fuel Injector Operation High-pressure fuel is supplied from the Bosch VP44 injection pump, through a high-pressure fuel line, through a steel connector, and into the fuel injector. When fuel pressure rises to approximately 31,026 kPa (4,500 psi), the needle valve spring tension is overcome. The needle valve rises and fuel flows through the spray holes in the injector nozzle tip into the combustion chamber. The pressure required to lift the needle valve is the nozzle opening pressure. This is sometimes referred to as the “pop” pressure setting. Each fuel injector is connected to each high-pressure fuel line with a steel connector. This steel connector is positioned into the cylinder head and sealed with an o-ring. The connectors are sealed to the high-pressure fuel lines with fittings. The ferrule on the end of the high-pressure fuel line pushes against the steel connector when the fuel line fitting is torqued into the cylinder head. This torquing force provides a sealing pressure between both the fuel line to the connector and the fuel connector-to-fuel injector. The fitting torque is very critical. If the fitting is under-torqued, the mating surfaces will not seal and a high-pressure fuel leak will result. If the fitting is over torqued, the connector and injector will deform and also cause a high-pressure fuel leak. This leak will be inside the cylinder head and will not be visible. The result will be a possible fuel injector miss-fire and low power. The fuel injectors use hole-type nozzles. High-pressure flows into the side of the injector and causes the injector needle to lift and fuel to be injected. The clearances in the nozzle bore are extremely small and any sort of dirt or contaminants will cause the injector to stick. Because of this, it is very important to do a thorough cleaning of any lines before opening up any fuel system component. Always cover or cap any open fuel connections before a fuel system repair is performed. Each fuel injector connector tube contains an edge filter that breaks up small contaminants that enter the injector. The edge filter uses the injectors pulsating high pressure to break up most particles so they are small enough to pass through the injector. The edge filters are not a substitute for proper cleaning and covering of all fuel system components during repair. The bottom of each fuel injector is sealed to the cylinder head with a 1.5mm thick copper shims (gasket). The correct thickness shim must always be re-installed after removing an injector. Fuel pressure in the injector circuit decreases after injection. The injector needle valve is immediately closed by the needle valve spring and fuel flow into the combustion chamber is stopped. Exhaust gasses are prevented from entering the injector nozzle by the needle valve. Fuel Injector Removal The fuel injectors are located in the top of the cylinder head between the intake/exhaust valves. 1. Disconnect both negative battery cables from both batteries. Cover and isolate end of cables. Each fuel injector is connected to each high-pressure fuel line with a steel connector tube. This steel connector is positioned into the cylinder head and sealed with an o-ring. The connectors are connected to high-pressure fuel lines with fittings. 2. If injector at #1 or #2 cylinder is being removed, intake manifold air heater assembly must be removed. 3. If injector at #5 cylinder is being removed, remove engine lifting bracket (2 bolts). 4. Thoroughly clean area around injector and injector high-pressure lines before removal. 5. Remove necessary high-pressure fuel lines. (Refer to - Injection Lines). Do not bend any high-pressure fuel line to gain access to the fuel injector. Cover or cap any open fuel connections. 6. Remove valve cover. Mopar's Notes Most of us will be doing full injector upgrades or replacements. So I know the service manual talks as if replacing 1 or 2 injectors. I highly suggest you remove every as pictured below. APPS Sensor - Removal. Leave the throttle cable attached and lay on the PDC box. Remove the intake and grid heaters by pulling the 4 bolts and the band clamp. Lay the intake and grid heater aside on the PDC box. Remove the valve cover. Remove the injection lines 7. Thread Special Tool 8324 (Fuel Injector Connector Tube Remover) onto the end of injector connector tube. Mopar's Notes You can use a small flat blade screwdriver. Just hook one of the threads on the connector tube and lightly pry out. WARNING! Be aware and not scratch the mating surface of where the tube and high-pressure line and the connector tube meet if you do there will be a fuel leak. 8. Pull injector connector tube from the cylinder head. The injector connector tube must be removed before attempting to remove fuel injector or serious damage to fuel injector and tube will result. 9. Remove and discard old o-ring from injector connector tube. 10. Remove fuel injector hold down clamp bolt at the front end of the clamp. Do not loosen or remove special (2 shouldered) bolt at the rear end of the clamp. Remove injector clamp by sliding it from shoulders on rear clamp bolt. 11. Thread rod from Special Tool number 8318 (Fuel Injector Remover) into the top of the fuel injector. Mopar's Notes Take one of your short intake bolts and thread it into the head of the injector. 12. Tighten nut on 8318 tool to pull (remove) fuel injector from the cylinder head. Mopar's Notes Use a screwdriver and pry the injector straight up carefully. 13. Remove and discard old o-ring from the fuel injector. 14. Remove and discard copper sealing washer (shim) from the bottom of the injector. If copper sealing washer has remained in the cylinder head, it must be removed. Fuel Injector Installation The fuel injectors are located in the top of the cylinder head between the intake/exhaust valves. 1. Inspect fuel injector. a. If necessary, perform a pressure test of the injector. b. Look for burrs on injector inlet. c. Check nozzle holes for hole erosion or plugging. d. Inspect end of the nozzle for burrs or rough machine marks. e. Look for cracks at the nozzle end. f. Check nozzle color for signs of overheating. Overheating will cause the nozzle to turn a dark yellow/ tan or blue (depending on overheating temperature). g. If any of these conditions occur, replace the injector. 2. Thoroughly clean fuel injector cylinder head bore with special Cummins wire brush tool or equivalent. Blow out bore hole with compressed air. 3. The bottom of the fuel injector is sealed to cylinder head bore with a copper sealing washer (shim) of a certain thickness. A new shim with correct thickness must always be re-installed after removing injector. Measure thickness of injector shim. Shim Thickness: 1.5 mm (.060”) 4. Install new shim (washer) to the bottom of the injector. Apply a light coating of clean engine oil to the washer. This will keep washer in place during installation. 5. Install new o-ring to fuel injector. Apply a small amount of clean engine oil to o-ring. 6. Note fuel inlet hole on the side of the fuel injector. This hole must be positioned towards injector connector tube. Position injector into cylinder head bore being extremely careful not to allow injector tip to touch sides of the bore. Press fuel injector into cylinder head with finger pressure only. Do not use any tools to press fuel injector into position. Damage to machined surfaces may result. 7. Position fuel injector hold down clamp into shouldered bolt while aligning slot in the top of the injector into the groove in the bottom of the clamp. Tighten opposite clamp bolt to 10 N·m (89 in. lbs.) torque. 8. Install new o-ring to fuel injector connector tube. Apply a small amount of clean engine oil to o-ring. 9. Press injector connector tube into cylinder head with finger pressure only. Do not use any tools to press tube into position. Damage to machined surfaces may result. 10. Connect high-pressure fuel lines. Refer to High-Pressure Fuel Lines Removal/Installation. The fuel line fitting torque is very critical. If the fitting is under-torqued, the mating surfaces will not seal and a high-pressure fuel leak will result. If the fitting is over torqued, the connector and injector will deform and also cause a high-pressure fuel leak. This leak will be inside cylinder head and will not be visible resulting in a possible fuel injector miss and low power. (28 ft. lbs.) 11. Install valve cover. 12. (If necessary) install intake manifold air heater assembly. Refer to Intake Manifold Air Heater Removal/Installation. 13. (If necessary) install engine lifting bracket. Tighten 2 bolts to 77 N·m (57 ft. lbs.) torque. 14. Connect negative battery cables to both batteries. 15. Bleed air from high-pressure lines. Refer to Reprime fuel system procedure.

-

New to this forum, seems like a knowledgeable group of guys (shout out to y'all) However I'm having issues with my 2001 5 speed. She has a quadzilla adrenaline tuner, scheid diesel 100hp injectors, and an edge boost elbow. After installing the injectors she has a slight white haze coming from both the exhaust and the engine compartment. Both are very light. The exhaust gets denser when accelerating, and sometimes turns black. It seems to smell normal (not sweet like coolant, or like burnt oil). What could cause these symptoms if of concern at all? It also is is jerky/studdery at around 1200 rpm, but smoothes out at higher rpm, or harder throttle input. Also I have a stock clutch, with very low mileage on it. It seems to rattle under harder acceleration, is that just due to the clutch not liking the torque?

-

Looking for suggestions. Lots of info here, but hard to find a specific good parts combo for a relatively minor build. My daily driver 2wd 5spd would be a lot more fun with a bit more power. I'm thinking 100hp over stock. Just installed a Valair 13" clutch. Have a wastegate actuator regulator that just showed up in the mail. Truck has a 4" exhaust, gauges, Smarty S04, an air dog factory replacement lift pump (100 gph) mounted to the frame by the tank. Was given a K&N cold air intake but not yet installed. Any thoughts on the least expensive way to reach my power goal? 600 hp would be great, but my budget is very limited at the moment and it is my daily driver. 17.8 1/4 mile times are down right embarrassing. Just looking to spice up my daily commute. If there's an article that covers this, I didn't see it. I have done some research, but most of what I've seen is aimed at heavy towing or all out power. Thanks in advance.

-

So having owned my ‘99 for a little over two months and towing my tractor a few times I think I have decided to see if I can upgrade some things to get some more power. I am as I think that would satisfy my needs. Looking at 7X.009 SAC injectors, a turbo, gauges, and a tuner of some kind to manage smoke and heat. Need some recommendations on a turbo and tuner. Thinking about this Turbo as a direct replacement. For the tuner: either an Edge Comp or the Quadzilla Iquad. Really don’t have the experience to create my own tunes and need more knowledge of diesel theory to be able to get the most out of a tuner so leaning towards something with “canned” tunes. Will run gauges for egt, boost, and trans temp. What range boost gauge should I use, up to 50psi? Already have a fuel gauge. So chime in guys with your ideas and help me choose the right parts to start with.

-

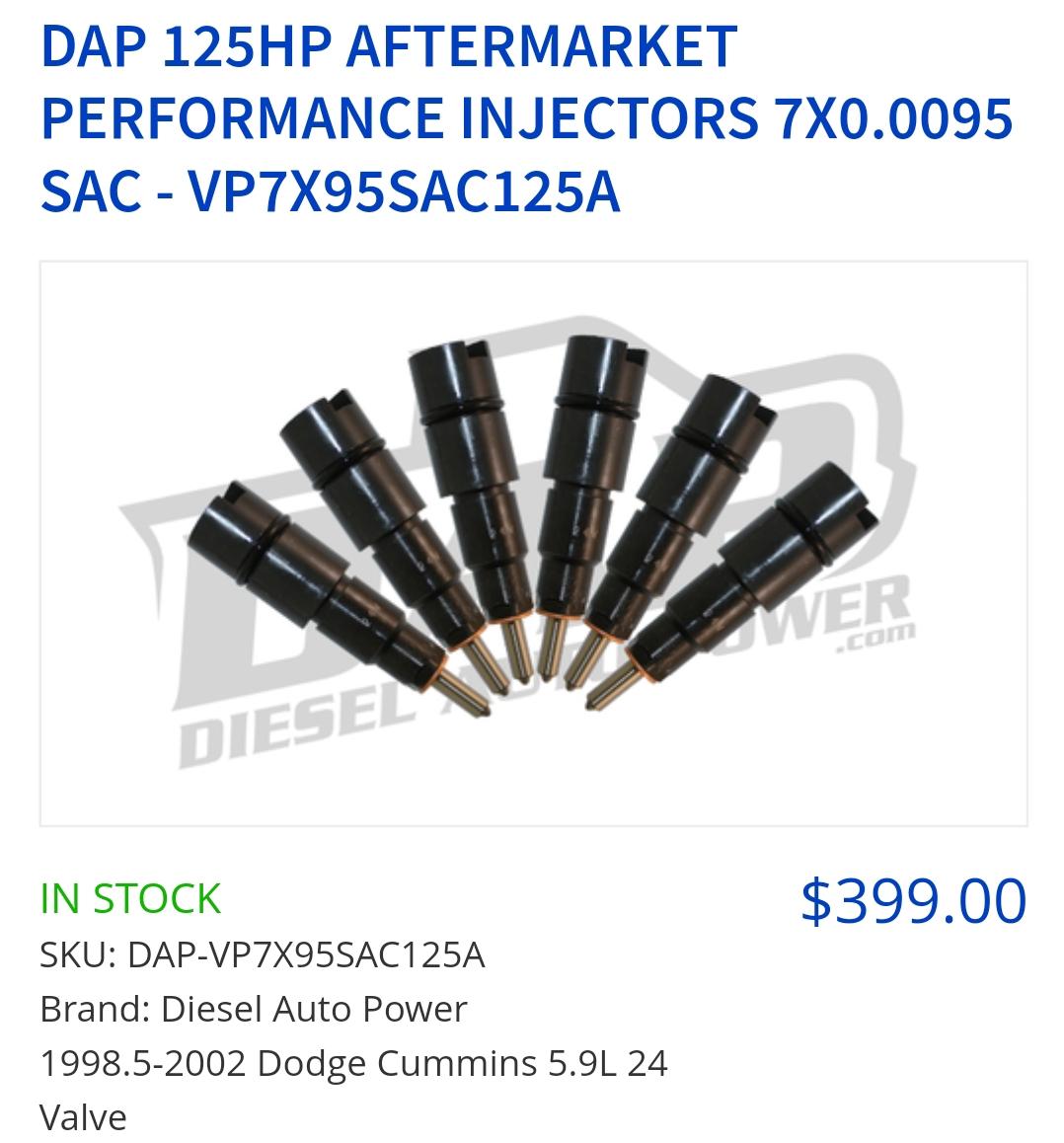

I am thinking about picking up some injectors. Anyone have experience with DAP Aftermarket injectors? Here's what I'm looking at. Obviously I'm looking for a lower cost Injectors, I have stock now. I'm running a 150gph pump, turbo upgrade is after the injectors. Set of 6 Diesel Auto Power 125HP Aftermarket Performance Injectors for Dodge 24 valve Cummins. 7 hole (0.0095 inch holes) SAC style. Compatible for years 1998.5-2002. Installation kit included: (Injector connecting tube removal tool/nut, copper sealing washers, and o-rings for connector tube). new copper washers

-

So if your running a junky edge comp or juice and want just a little more fun, this is what smoke out put you can expect with a 90hp 7x.0085 VCO injector from DAP. Clean burning and sensible injector for a well balanced rig. Pop pressure on this truck is 300bar. Truck setup: 99 model year, fass 95, edge juice (same program as comp), 4” exhaust, HX35W, garbage jasper trans, triple disc, 4.10 gear. this specific truck doesn’t have the pump tap installed due to a new VP44 installed so this is just stock, level 1/sub 1 and level 2/sub 1 for low smoke and smooth acceleration to keep traction under control. With levels 3-4-5-6 with the pump tap of course expect smoke and hard torque and acceleration. This truck is a fleet tow rig and they don’t run the pump tap because employees drive the truck and they don’t want it hotrodded but wanted a little more pull without the pump tap being installed. stock: level 1/sub 1: level 2/sub 1: Good setup for daily drivers and tow rigs. You can hit 1300-1350* on wide open runs on all levels so make sure you have a good set of gauges (not glow shi(f)t, there garbage, slow and your gonna melt a piston)... would work well with S03 users also. Levels 1-4 or if you use REVO settings (actual level is irrelevant then).

- 22 replies

-

- 2

-

-

- edge comp

- edge juice

-

(and 3 more)

Tagged with:

-

I'm getting ready for a 5200+ mile trip and with just over 100K miles on the clock I've been thinking about replacing my injectors when I do the valve adjustment before I go. I was looking at Bosch 275's when I came across these on E-bay. https://www.ebay.com/itm/Brand-New-Dodge-Cummins-RV275-Performance-Injectors-for-98-5-02-24-VALVE-5-9L/161397044745?hash=item2594037609:g:KBQAAOSwxH1T8Kjl&vxp=mtr They're made/supplied by Sundieselsystems http://sundieselsystems.com/performance-products/performance-injectors/ Has anyone had any experience with this brand of injectors?

-

I just had to replace #5 injector line due to it breaking of at the head. Something that surprised me is that it would appear that the injector line appears to to be double walled with a very small line inside of the outer line separated by what appears to be nylon. I don't know that be an absolute fact but this is what I see from the damaged parts. Here is a pic of the knob that broke off at the head. I have not been able to cut the old line open to see. Is the entire line of this same construction? If so that would explain why I could not fold the line over to crimp it off. I will cut the old line open tomorrow and see what is there.

- 23 replies

-

- 1

-

-

- fuel

- injector lines

-

(and 1 more)

Tagged with:

-

Hey everyone I have been doing a ton of research lately trying to figure out what upgrade I want to do on my truck. I have looked over many different threads regarding injectors however these threads are almost 8 years old now. I have also been following the Quadzilla V2 threads very closely and recently purchased the iQuadBT. Like most guys I have gotten the thirst for more horsepower. I am on a limited budget and I am still looking for a reliable daily driver. So my question to you is, if you guys could go back and start with a truck that only had 63,000 miles on it what would you upgrade next? Here is my list of upgrades(for now): 1. 5 inch Turbo back exhaust 2. BHAF 3. FASS 150 4. Quadzilla V2 5. Bean Sump For some reason I cannot figure out my signature but my truck is a 99, 53 block five speed with only 63,000 miles.

- 45 replies

-

- horsepower

- injectors

-

(and 3 more)

Tagged with:

-

Well I just got thru installing a new set of DAP 50hp Injectors. The whole process went well. The most fun was dealing #6 and to a lesser degree #5. I did go the extra mile on cleaning up the ends of the fuel lines after reading all that @hex0rz went thru. Used scotch brite pads to polish them up real good before re installing them. So far I have a little weeping, just enough to dampen the head at the injectors, but no leaks beyond that. I figure I am going to ride that out a little and see it goes away as in the past. As far as the injectors go, they run quieter and deliver a little more power than the RV's they replace. They are however smokier and a little hotter than the RV's. The only way to keep them from smoking is to turn the fuel level down on the comp to level 1. Thats on level 3 or 5 on the power setting. Not happy with that part. I have not had a chance to talk with DAP about that as of yet. Will do some time next week. I did replace my valve cover gasket as I suspected it was leaking on the rear of the head. It seems to have been the case since I let the truck idle for 20 minute or so with little oil hitting the ground. I will know better after going to work tomorrow. The old gasket had oil all over the outside of it at the back. One thing to add to this is if anyone is worried about running 2 stroke or bio fuel the old ones were just about as clean as the new ones except for the shiny metal on the new ones. The RV's had 150k on them. I will take some better pictures of them tomorrow. Cant get the camera to focus on them good tonight. v's

-

Who is Big Bang Injection ? New information recently released ! Big Bang Injection (BBi ) is an Austrian company that was founded in 2012. What started as a part time venture, evolved into a full time enterprise manufacturing High Performance Common Rail Injectors. We, the owners of Big Bang Injection (Martin Schöppl and Jürgen Tanzer), bring to the table a combined 25 years of HANDS ON Common Rail Injector experience. We both parted ways with our full time employer Robert Bosch GmbH on January 31st 2016. Our departure allows the release of information regarding our experience which has previously been kept under a cloak of secrecy, required by contractual restrictions with our former employer. We were employed at the Robert Bosch GmbH Common Rail Injector Lead Development Facility for commercial vehicles, located in Linz, Austria. Lead Development Facility. This is where the magic happens. Design, development, proto typing, assembly, testing…. This link will provide the details for you: http://smartyresource.com/downloads/BBI_Introduction.pdf Thank you! For some reason the link in the above post doesn't work from here. Try this instead! Thank you! http://smartyresource.net/forum/showthread.php?1013-Who-is-Big-Bang-Injection&p=5065#post5065

-

- 1

-

-

- bosch

- common rail

-

(and 3 more)

Tagged with:

-

Well first off I would like to thank Cajflynn for the wonderful donation of his used RV275 injectors, which happen to show up in todays mail. i'll get some pics up soon... In the mean time I'm going to gather up a few supplies for installing them. Does anyone know where I can get copper shims and fresh O-rings for these??? Holy Cow!!! :eek: I looked up the numbers on the injector and... 0432193635 / 4183 Comes back as either a RV275 or a 300 HP injector...:confused: Still much better than stock! :thumbsup: http://forum.mopar1973man.com/attachment.php?attachmentid=60&stc=1&d=1260397958 http://forum.mopar1973man.com/attachment.php?attachmentid=61&stc=1&d=1260397958 http://forum.mopar1973man.com/attachment.php?attachmentid=62&stc=1&d=1260397958

- 57 replies

-

- 1

-

-

- +40 hp

- 0432193635

-

(and 2 more)

Tagged with:

-

http://www.dieselpowerproducts.com/p-7531-budget-rv275-24-valve-cummins-fuel-injector.aspx if no one has seen this yet I wanted to let everyone know that dieselpowerproducts.com is offering a cheaper version of bosch's RV275 injectors. They say it offers all the same benefits as bosch's product. Right now they are running a sale and are only 49.99 a piece and free shipping on orders over 100.00. So if you have been looking to get these injectors but are on a budget check out this alternative product. I just ordered mine the other day, I will let you know how I like them.

-

Yea. As of today I had to drop my sub-level again. Getting to smokey as summer time started coming on and noticing more and more smoke as I would be towing and/or launching with a heavy foot. I'm wondering if others have notices anything like this with warmer weather? No ill-effect to MPG's at all but the smoke level is slightly higher now than was during the winter time. I'm also wondering is the injectors changing for like a break in process and flowing more?

-

hey yall need some help here. Had to replace my injectors due to multiple bad injectors (shop did return flow test). Ordered injectors from diesel care and when I installed them the truck idled fine for about 5 minutes then i pulled out of drive and gave it a little bit of gas and heard a ting sound and truck started dumping white smoke with rough idle. Got back in garage, figured injector wasnt seated properly and pulled all injectors and tubes. One of them had a clean tip so i figured that was the injector that unseated. reinstalled everything, started it up and once again dumping white smoke with rough idle and a knock. Called diesel care and they suggested caping off each fuel line at the rail and see which one stops the smoking. they think that the system wasnt primed properly and air made injector stick open. Could this be the case? should i cap rail and see or should i pull all injectors and send all back (already not happy cus injectors i ordered were backordered and they sent me 40 overs instead of the 50's like I wanted)? Thanks for any help! 03 Cummins common rail Video of truck idling: http://www.youtube.com/watch?v=AfDbbNmhbHs&feature=youtu.be

- 5 replies

-

- injectors

- white smoke

-

(and 1 more)

Tagged with:

-

This is for the old '99 that the parents have now. It's got a "miss" at idle............but only after the engine has gotten up to operating temp. Cold idle is normal with no miss. It's a miss, but the computer adjusts by increasing the idle speed slightly after warm up.. Running up and down the road, she runs as good as ever. Dad says she's been averaging 19mpg most every fill up. What should I look for and check to diagnose this??? Thanks guys!!

-

Here is what it is doing: 1) Takes 1 to 1.5 secs to start... prior to injectrs/V adj... as soon as it turned over it would start.. 2) Rpm is around 740-750 with ever so slight bump to it... like its out of time or missing... it was very smooth prior to the install and had 780-800rpm. 3) I put it in reverse and it stalled (twice) when a bumped the throttle never done that before. 4) Noticeably more smoke (puff) at start up... and when i bump the throttle just sitting there it will puff smoke. Did not really do that before... 5) I was very careful installing injectors and crossover tubes they came with protective covers and i was very cautious when i put them in... injectors and tubes all snapped in and went together like they are suppose to... 6) When I was adjusting the valve clearance I used the alternator pulley to turn the engine over... I had the injectors out. The eng would not turn in direction it turns when running... the belt would just slip on pulley... So I was able to turn it in the other direction. Could I have hurt something by doing that? I did hear some clicking sounds coming from the lower engine back by the tranny it sounded to me... I need some expertise on this one! - - - Updated - - - After wise counseling from this site and others I did some trouble shooting... APPS voltage reading and fuel system bleeding, CORRECT torque on High pressure fuel lines at the head and lift pump pressure adjustment. Results: 1) hard start has gone away for now... 2) rpm more consistent and steady @ 750rpm... 3) no more stall in reverse now... 4) normal smoke puff at start up... 5) rechecked valve lash on all of them and they are within limits... The video is after all of your recommendations... turn sound up at the start of the vid (then down as the truck accels... air over cam get noisy) and when I am sitting there and later in the vid when i start it up you can here the idle pretty good... thanks for all your help! http://www.youtube.com/watch?v=05bnRloNC7M

- 1 reply

-

- fuel system

- injectors

-

(and 1 more)

Tagged with:

-

So I have a 2001 dodge cummins with the 6 speed manual, it has 50 horse injectors (50k on them) new vp44 (20k on that) the batteries are fairly new. It also has a pacbrake, air dog 150 which was installed before the new VP44 and a holset turbo that pushes a little more boost than stock and it also has a 4 in straight pipe. The issue with this truck is I have a miss and I called the kid tonight and he bought the APPS sensor from dieselsource.com and HE DID NOT CALIBRATE it. He told me he was getting his dead pedal in the same area I said it was missing at. I have cleaned the IAT sensor, probed the ECT and it all checked out good the only codes are a P0500 ( speed sensor signal ) and P0118 ( self created high voltage in ECT sensor while testing it). So tonight I pulled the battery cables followed the steps exactly and after I turned the KEY back off after calibrating it, I started it and idled it up and the miss started at 1200 RPM and went through 1700 and then in a few mins it only isolated to around 1500-1700.So my main question is what can happen if you DO NOT calibrate the APPS, and any advice on this situation would be very helpful. I am about to sell this truck and I NEED TO FIX THIS!Thanks, Corey

- 4 replies

-

- fuel system

- injectors

-

(and 2 more)

Tagged with:

-

thinking this is the next upgrade i mostly take trips up to the hills tow the 20 foot seaox here and there maybe a trip tp canada to visit cousins.

-

I am looking at upgrading my 99. I have gauges(egt, fuel and boost), boost fooler and a boost elbow. I am thinking that one of the next things to install are injectors. I know everyone likes the RV275's, but looking around I am wondering if 75 hp injectors are also a good option. I do not tow heavy loads a lot, but there are times that I do load the truck down and would like to have some extra umph. I know that I will also need to upgrade my fuel pump as I still have a stock type in the tank, but for now I am just looking at different options. The truck has around 350,000 miles thus far and runs down the road without missing a tick. Thanks for any input.

-

I know this has been hashed about before but I gotta ask. I'm thinking about a set of RV275's for my mostly stock '02 with 118,000 miles, see other stuff in my signature. I do haul a pretty heavy camper and tow a boat. The truck has a Quad ZXT+ chip thingy (pretty mild by most standards). My question is...amd I just wasting my $'s or will I see a REAL difference?Second question: Can I install them myself? I not a total idiot with a wrench and can follow directions. I was thinking it's also about time to adjust the valves too. Thanks to all for opinions.

-

I have a 01 Automatic. I replaced the auto and upgraded. I want to stick 80 to 100 Dap Injectors but i am worried about the turbo. The hy is a pos. Will a hx40 give me the boost i need?

- 32 replies

-

- injectors

- performance

-

(and 1 more)

Tagged with:

-

hello, newbie and first posti took my injectors out and sent them in and had them pop tested 3 came back good and the other 3 came back bad sticking nozzels,,,Can nozzels stick?i pulled the three bad ones apart just as one of your post shows and nothing was sticking so what do they mean?can this be true?

Rate The Author

Please take the time and give the author a 1 to a 5-star rating for the information you have gained from anywhere on the website. All forum threads, articles, etc. If a members post is good information please don't forget to tell them "Thanks" or "Like"

Rate Us On Google

Please take the time and visit our Google Review page and give us a review of our services.

Tip Jar

If Mopar1973Man.Com has helped you with quick and timely information for your repair please consider tossing a tip in the Tip Jar