Search the Community

Showing results for tags 'fuel system'.

-

Fuel Pressure Specification For Bosch VP44 Injection Pump

Mopar1973Man posted an Cummins article in Fuel

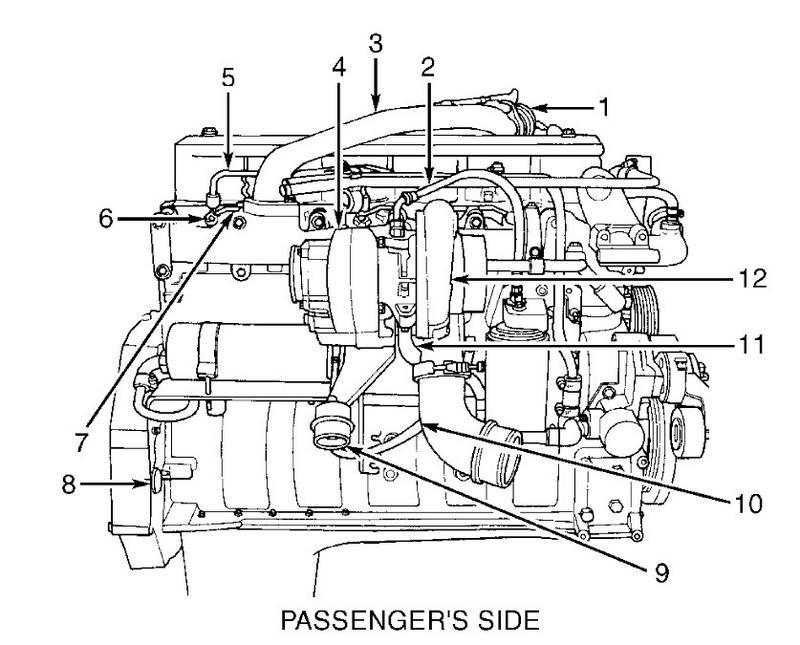

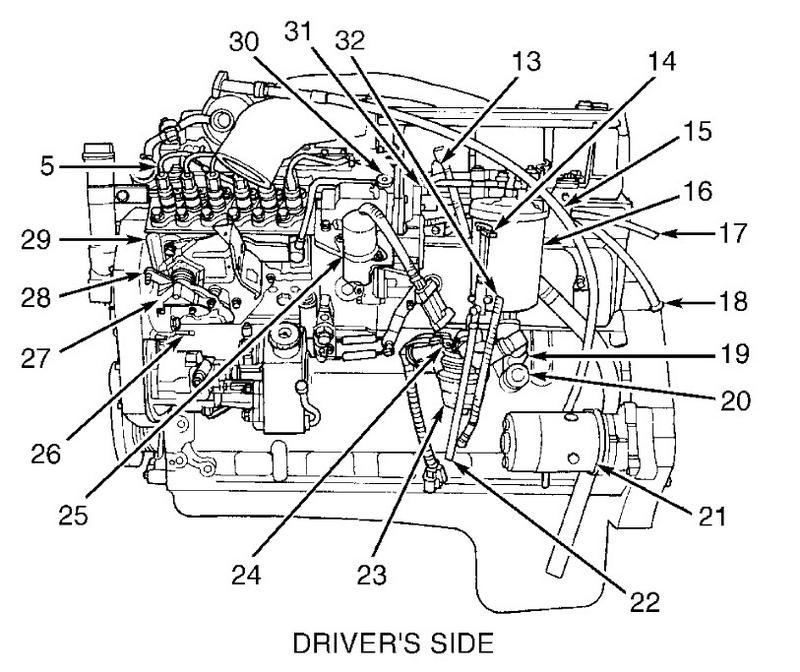

Fuel Pressure Specification For Bosch VP44 Injection Pumps Here is a copy of the fuel system specifications from the Dodge Factory Service Manual. This is for your Dodge Cummins Turbo diesel truck with a Bosch VP44 injection pump. Fuel pressure Normal fuel pressure should float about 14-15 PSI running down the pavement. It should never fall below 10 PSI at all. Here is a colorize fuel pressure gauge to give you a clue of the fuel pressure span you want. You want the needle to stay in the green at all times. Yellow zone is a warning that you should check the fuel filter, lift pump performance, overflow valve, etc. This is undocumented maximum pressure is 20 PSI. Now take notice to the overflow valve is set for 14 PSI so excessive pumping of fuel does nothing for performance except create more heat in the fuel, which in turns reduces the cooling ability of the fuel and adds more stress to the lift pump. So a little extra fuel pressure is a good thing because it ensures the Bosch VP44 injection pump stays cooled and lubricated properly. However, excessive fuel pressure will heat the fuel and reduced the cooling ability of the fuel. Now always remember that the only lubrication the Bosch VP44 injection pump will see is the fuel itself so if you don't have enough fuel pressure it will cause damage to the Bosch VP44 injection pump. It's like the same as running the engine with low oil pressure it will continue to run, but the damage to the engine will occur. On the other hand, the Bosch VP44 injection pumps, which happen to be about $1,200 to replace. Pressure Drop The amount of fuel pressure drop between idle and wide-open throttle. 2-3 PSI drop from idle to WOT is normal. However, 5 PSI or more pressure drop from idle to WOT is pointing out a failed lift pump, plugged filter, and/or plumbing restrictions. 2-3 PSI Is Normal Dropping more than 5 PSI is pointing towards a failed lift pump, plugged filter, or restrictive plumbing. Just to show you the difference in the stock plumbing which is 6mm ID plumbing and most performance pumps come with 1/2" ID plumbing. These pictures will give you an idea... The first picture is a Big Line fitting over the top of the stock plumbing. Then the second picture compares the stock 6mm ID steel lines to a 1/2" ID Big Line hose. The best way to show this example of restrictions is to let's say your house is on fire. You know your garden hose has 80 PSI of pressure, but the garden hose is only 5/8" ID hose. Your wife calls 911 and gets the fire department coming in the meantime you keep fighting the fire with your little 5/8" garden hose and losing the battle. The fire department shows up and pulls a 2 1/2" hose off the truck and charges it at 80 PSI and now winning the battle. Your fire is put out! What is so different? No matter what the size of the fuel line will dictate how much volume can be pushed through the fuel line. Like the story above the water pressure was the same at 80 PSI, but the hose size jumped from 5/8" to 2 1/2" ID hose and the volume changes are the size of hose. So the same thing applies to the stock fuel system. The stock banjo bolts and 6mm ID pipes are just too restrictive and cannot supply enough volume of fuel for that Bosch VP44 injection pump demands. This why I highly suggest you go up to 1/2" ID plumbing. Reasons Why Fuel Pressure Is Critical Let's take a look at a Bosch VP44 injection pump. I've labeled the fuel lines supplying fuel and return line plus the overflow valve. Now I know there is a ton of rumors on the internet of all kinds of minimum pressures for a Bosch VP44 injection pump. I'm going to say stick with the Dodge Factory Service Manual Specifications for fuel pressure. Now let's talk a bit more about the flow of the fuel. The lift pump supplies pressurized fuel to the Bosch VP44 injection pump the overflow valve regulates how much fuel pressure is held. Excessive fuel pressure is returned to the fuel tank. The picture below is of the bleed hole in the overflow valve this image was magnified x10 to show you how small the bleed hole really is. Give you an idea the size of the hole use a single strand of 14 AWG copper wire, and it will NOT fit the hole. The bleed hole is there solely for bleeding air out of the system which air will pass through this tiny hole rather easy but fuel will not. However, if you're looking for long life from a Bosch VP44 injection pump, I would personally suggest you adjust your minimum pressure to 14 PSI this will ensure the overflow valve remain open and a constant fuel flow through the Bosch VP44 injection pump and keep it cool all the time. Let me play out a simple scenario. Let's say my fuel pressure is roughly 10-11 PSI. I'm going to drive up into the back country approximately 40 miles with my Dodge Cummins towing an 8x8 utility trailer. Now the whole trip heading uphill into the mountain towing an empty trailer is going to be enough fuel flowing to the injectors to keep the Bosch VP44 injection pump happy. However, I've spent the day and loaded up with firewood and now coming back down the mountain loaded. I'm using my exhaust brake and coasting most of the way down taking it slow and easy. At this point, the injectors are no longer firing so the Bosch VP44 injection pump is not pumping fuel out to the injectors. Furthermore, the overflow valve closes at about 10-11 PSI so let's say it did close. Now where is the fuel going??? Nowhere! It is pooled up in the injection pump and gaining heat and being broke down. You've also removed the cooling and lubricating of the Bosch VP44 injection pump so now it actually taking on damage. To give you a feel for the fuel flow coming from the injection pump with an AirDog 150 at 17.5 PSI of fuel pressure, I've got a video to explain that quickly. I've heard rumors of some people trying to develop a cool down system for the Bosch VP44 Injection pump but after making the video above, there is just no way to cool down the injection pump using the lift pump of even the AirDog/FASS series. The whole problem is the restrictions inside the Bosch VP44 injection pump and the overflow valve as seen in the video above. So the only way to keep the Bosch VP44 injection pump cool is to keep fuel flowing through it at all times. So to keep the overflow valve open I suggest the 14 PSI minimum pressure. I'm currently at 136K miles on my Bosch VP44 injection pump and still going strong using a 16 PSI minimum pressure and an 18 PSI idle pressure. Here is a short video of stable fuel pressure from 55 MPH to 70 MPH at WOT. Here is another video done with idling, cruising, and WOT operation. Yes. I got a bit carried away and sloshed the fuel in the tank and sucked an air bubble and the pressure fell off. Cranking Pressure Test Here is a simple test on how to do the test for cranking fuel pressure. Pull the fuel pump relay in the PDC and then attempt to start the engine. Pay attention to the fuel pressure gauge during cranking. Be aware this test will trip a P1689 code and light the CHECK ENGINE light. Excessive cranking pressure can lead to difficult starting problems. Suggested Lift Pump Replacement You should replace the stock fuel system completely since it cannot supply enough fuel for even stock requirements without causing damage to the Bosch VP44 injection pump or adding stress to the lift pump. The pumps I suggest are proven and come with a lifetime warranty. These pumps come with a full kit and replace everything from the fuel tank to Bosch VP44 injection pump. AirDog 100, 150, or 165 Raptor 100 or 150 FASS 100 or 150 FASS DDRP (DDRP Ver.2 - 89 GPH) I don't suggest these pumps... Because they don't address the pump location, plumbing restrictions, or come with much of warranty. Stock Carter or Carter Campaign Pump (4090046) Holley Blue or Holley Black FASS DDRP (DDRP Ver.1 - 40 GPH) AirTex Mopar's Notes: That was true for the DDRP Ver.1 However, DDRP-02 is rated at 89 GPH and will hold pressure. It is listed as a Stock replacement pump designed to perform better than the Stock pump, but not for Chips that add fueling. I place a Power Puck on my truck with the DDRP-02 and saw no difference in FP at either idle or WOT, (PP is a timing chip doesn't change the amount of fuel). That said the PP is currently removed from my truck as I overpowered my clutch both loaded and unloaded, back to the stock clutch is fine. Looking for a Valair possible DD organic, or SD Kevlar/Ceramic. It is currently in the stock location and giving 15 psi at idle and 10 at WOT. Information Provided By: rhagfo http://www.cumminsforum.com/forum/98-5-02-powertrain/404412-fass-ddrp-02-a.html#post4197714 Additional Information (About Performance Crowds & Fuel Pressure) I've seen several times where people will link back to performance pump builders and quoting where they say, "(Un-named) proved that 5 PSI, under load, made all the horsepower the VP44 pump could make, even with stock fuel lines, fittings and supply pump." This might be true but there is nothing ever said about the life span of the pump at these conditions. So... Please do not follow these performance crowds into destroying a perfectly good Bosch VP44 injection pump. The fact still remains from Bosch the actual designer of the Bosch VP44 injection pump states that injection pump should return 70% of the fuel back to the fuel tank for cooling and lubrication purpose of the VP44. Being the only way a Bosch VP44 injection pump can do this is to have fuel pressure above 14 PSI to open the overflow valve. Then if the stock Bosch VP44 injection pump with an enhancement box say an Edge Comp on 5x5 can consume 15-20 GPH that means the stock 35 GPH pump cannot keep up with Bosch's design of 70% return volume. So this why products like AirDog, Raptor and FASS was created because they actually meet the demands of the Bosch VP44 injection pump. Then another fact that Bosch will let you know of is that diaphragm damage occurs from operating the Bosch VP44 injection pump at low fuel pressures. Making matters worse is that no Bosch injection re-builder will void warranty a VP44 injection pump with diaphragm damage. Dead give away that you had a bad lift pump or low fuel pressure problems. Please view the Bosch VP44 exploded view page to see there is no diaphragm in the Revision 027 Bosch VP44 Injection Pump Then the other fact is right from the Dodge Factory Service Manual has the minimum fuel pressures (picture at the top of the page). It even states the pressure that the overflow valve requires to open. Refer to the Overflow Valve Testing from the Dodge Factory Service Manual and see that the overflow valve should remain closed at 10 PSI and open by 14 PSI. So if the overflow valve is close by 10 PSI, then you extra cooling and lubrication just disappeared. So ultimately it suggested having a fuel system of no less than 100 GPH supply that can maintain a minimum pressure of 14-15 PSI at WOT. This will great extend the life of the VP44 because it keeps the electronics cooler longer and keeps the rotating parts lubricated properly. So please people let the facts and information from the actual designers of the injection pump (Bosch) and engine (Cummins) provide you proper information for your fuel system for your engine. Don't be swayed by performance shops claim of high horse output with little fuel pressure. As I proved right here doesn't work for the longevity of the VP44 injection pump... Another thing to bring up there are people that are increasing fuel pressures above 20 PSI. Please don't do this. The return port leaving the VP44 pump isn't very big at all. The return port is on the left and supply is on the right. As you can see increasing fuel pressures above 20 PSI put you at risk for shaft seal failure. Increasing the pressure above 20 PSI isn't going to improve the return flow. I say stick with the 14-20 PSI pressure range for seal safety. Additional Information (About Maximum Flow Rates) Here are some calculated flow abilities of the stock fuel system vs. 1/2" big line kits. This is not calculating bend, turns, offices just straight flow for open end plumbing and this is a rough calculation. Pipe Size Gallon Per Hour Flow Rate Gallon Per Minute Flow Rate 6mm ID pipe 75 GPH @ 15 PSI 1.2 GPM @ 15 PSI 1/2" ID pipe 570 GPH @ 15 PSI 9.5 GPM @ 15 PSI Use The banjo bolt Shrader valve to test for fuel pressure, Item 3 in the above diagram. If you have a 98-99 truck the port might be on top of the fuel filter housing. You can see the 90* bend fitting coming out of the top of the fuel filter housing in the below picture. Install a Shrader valve and test from there. I'm hearing of tales of shops, mechanics, or dealers doing the old hook up the fuel pressure gauge and only checking fuel pressure at idle. This is wrong. Because I've seen lots of cases where fuel line restriction, fuel filter plugging, gelling fuel and other thing causing fuel pressure to drop out under load. Like this video from a friend of mine, you'll see he's got awesome fuel pressure at an idle (where most shops gave him the green light). However, what the shops did not test for is WOT at highway speed, and you'll see in the video, he can pull way down to 0 PSI. Anything under 14 PSI is a concern... Anything under 10 PSI is a serious problem. As for having a gauge in the cab all Dodge Cummins trucks should have a fuel pressure gauge in the cab. Because like you seen bench testing with an idle pressure is meaningless if you can't see the WOT pressure at highway speed.- 3 reviews

-

- 2

-

-

-

- lift pump

- injection pump

-

(and 3 more)

Tagged with:

-

How To Install an AirDog 150 Fuel System The AirDog 150 fuel pump is a good design kit. It comes complete with all hardware, mountings, fitting, hoses etc. to hook up to your Dodge Cummins Truck. It was rather easy to install on my truck since I already had a Vulcan Big line Kit and Carter campaign lift pump. Mounting suggestion (for 4WD trucks) is that you push the pump forward towards the transfer case so the skid plate can protect the pump and filters from road debris. But make sure you leave enough room to access the transfer case for fluid checks and drain and fill service. As for doing plumbing it rather straight forward. Route the hose and cut to size. But I'll make another suggestion. Look your routing over very carefully for a place to protect the fuel line from damages (sharp body edges, tight spots that could pinch, or get snagged by road debris, etc) Also remember to include enough room for your connectors. Below is the return fuel setup. As for doing the electrical is also very straight forward too. It was designed rather good too. Looks just like stock wire harness. Suggestion for routing of wiring. The pump power leg should be routed with the taillight harness on the truck then you can zip-tie to the existing wiring and it look rather factory looking. The relay and fuse can be mounted on the firewall by the ABS controller. There is an existing ground wire in this location and I utilized the screw to mount both the fuse and relay on this ground screw. Draw straws Install (Old School) Now for the draw straw kit took some time and consideration. You got to ways of installing the draw straw by pulling the bed of the frame or to drop the tank. Since I've got a topper on my bed and lots of stuff in the bed of my truck it would be best to drop the tank. Here is a picture of the tank removed and I did prop it up on wood so the bottom of the tank didn't get flattened. Now you got to drill your hole for the draw straw. I use a 1¼" I drilled it on a high spot of the tank towards the front. After a period of time has passed now I found out that the hole should be smaller like 1 1/8" hole. Basically, now all you got to do is assemble the draw straw part and install it into the tank. But you'll find out that the straw is a bit too long and needs to be trimmed. I pushed the straw into place and measured the amount that it was sticking out of the grommet then trimmed it off. I did add some grooves to the bottom of the straw to keep it from sucking flat to the bottom. Now I get asked a lot about how much gap to the bottom of the tank you need for the draw straw. This is an easy answer you want to place a quarter (coin) on the bottom of the tank and the tip of the draw straw should just touch that. Seem tight, right? Well think about the weight of diesel at roughly 6.6 pounds per gallon there will be 60 pounds of diesel pressing down on the tank bottom at a quarter tank so this measurement will widen with more fuel and less as the tank empties. I lightly notched the tip of the draw straw to keep if from ever sucking flat to the bottom. As for performance I've managed to run down below 1/8 tank warning light several different times now with no problems. So now you should be complete. The Draw Straw should be all assembled and installed in the tank. So now re-install the fuel tank and hook up fuel line going to the AirDog 150. All you need to do now is re-prime your fuel system. My results were great. I've got awesome fuel pressure now.

-

- airdog 150

- lift pump

-

(and 1 more)

Tagged with:

-

Fuel Pressure Specification For Bosch VP44 Injection Pumps Here is a copy of the fuel system specifications from the Dodge Factory Service Manual. This is for your Dodge Cummins Turbo diesel truck with a Bosch VP44 injection pump. Fuel pressure Normal fuel pressure should float about 14-15 PSI running down the pavement. It should never fall below 10 PSI at all. Here is a colorize fuel pressure gauge to give you a clue of the fuel pressure span you want. You want the needle to stay in the green at all times. Yellow zone is a warning that you should check the fuel filter, lift pump performance, overflow valve, etc. This is undocumented maximum pressure is 20 PSI. Now take notice to the overflow valve is set for 14 PSI so excessive pumping of fuel does nothing for performance except create more heat in the fuel, which in turns reduces the cooling ability of the fuel and adds more stress to the lift pump. So a little extra fuel pressure is a good thing because it ensures the Bosch VP44 injection pump stays cooled and lubricated properly. However, excessive fuel pressure will heat the fuel and reduced the cooling ability of the fuel. Now always remember that the only lubrication the Bosch VP44 injection pump will see is the fuel itself so if you don't have enough fuel pressure it will cause damage to the Bosch VP44 injection pump. It's like the same as running the engine with low oil pressure it will continue to run, but the damage to the engine will occur. On the other hand, the Bosch VP44 injection pumps, which happen to be about $1,200 to replace. Pressure Drop The amount of fuel pressure drop between idle and wide-open throttle. 2-3 PSI drop from idle to WOT is normal. However, 5 PSI or more pressure drop from idle to WOT is pointing out a failed lift pump, plugged filter, and/or plumbing restrictions. 2-3 PSI Is Normal Dropping more than 5 PSI is pointing towards a failed lift pump, plugged filter, or restrictive plumbing. Just to show you the difference in the stock plumbing which is 6mm ID plumbing and most performance pumps come with 1/2" ID plumbing. These pictures will give you an idea... The first picture is a Big Line fitting over the top of the stock plumbing. Then the second picture compares the stock 6mm ID steel lines to a 1/2" ID Big Line hose. The best way to show this example of restrictions is to let's say your house is on fire. You know your garden hose has 80 PSI of pressure, but the garden hose is only 5/8" ID hose. Your wife calls 911 and gets the fire department coming in the meantime you keep fighting the fire with your little 5/8" garden hose and losing the battle. The fire department shows up and pulls a 2 1/2" hose off the truck and charges it at 80 PSI and now winning the battle. Your fire is put out! What is so different? No matter what the size of the fuel line will dictate how much volume can be pushed through the fuel line. Like the story above the water pressure was the same at 80 PSI, but the hose size jumped from 5/8" to 2 1/2" ID hose and the volume changes are the size of hose. So the same thing applies to the stock fuel system. The stock banjo bolts and 6mm ID pipes are just too restrictive and cannot supply enough volume of fuel for that Bosch VP44 injection pump demands. This why I highly suggest you go up to 1/2" ID plumbing. Reasons Why Fuel Pressure Is Critical Let's take a look at a Bosch VP44 injection pump. I've labeled the fuel lines supplying fuel and return line plus the overflow valve. Now I know there is a ton of rumors on the internet of all kinds of minimum pressures for a Bosch VP44 injection pump. I'm going to say stick with the Dodge Factory Service Manual Specifications for fuel pressure. Now let's talk a bit more about the flow of the fuel. The lift pump supplies pressurized fuel to the Bosch VP44 injection pump the overflow valve regulates how much fuel pressure is held. Excessive fuel pressure is returned to the fuel tank. The picture below is of the bleed hole in the overflow valve this image was magnified x10 to show you how small the bleed hole really is. Give you an idea the size of the hole use a single strand of 14 AWG copper wire, and it will NOT fit the hole. The bleed hole is there solely for bleeding air out of the system which air will pass through this tiny hole rather easy but fuel will not. However, if you're looking for long life from a Bosch VP44 injection pump, I would personally suggest you adjust your minimum pressure to 14 PSI this will ensure the overflow valve remain open and a constant fuel flow through the Bosch VP44 injection pump and keep it cool all the time. Let me play out a simple scenario. Let's say my fuel pressure is roughly 10-11 PSI. I'm going to drive up into the back country approximately 40 miles with my Dodge Cummins towing an 8x8 utility trailer. Now the whole trip heading uphill into the mountain towing an empty trailer is going to be enough fuel flowing to the injectors to keep the Bosch VP44 injection pump happy. However, I've spent the day and loaded up with firewood and now coming back down the mountain loaded. I'm using my exhaust brake and coasting most of the way down taking it slow and easy. At this point, the injectors are no longer firing so the Bosch VP44 injection pump is not pumping fuel out to the injectors. Furthermore, the overflow valve closes at about 10-11 PSI so let's say it did close. Now where is the fuel going??? Nowhere! It is pooled up in the injection pump and gaining heat and being broke down. You've also removed the cooling and lubricating of the Bosch VP44 injection pump so now it actually taking on damage. To give you a feel for the fuel flow coming from the injection pump with an AirDog 150 at 17.5 PSI of fuel pressure, I've got a video to explain that quickly. I've heard rumors of some people trying to develop a cool down system for the Bosch VP44 Injection pump but after making the video above, there is just no way to cool down the injection pump using the lift pump of even the AirDog/FASS series. The whole problem is the restrictions inside the Bosch VP44 injection pump and the overflow valve as seen in the video above. So the only way to keep the Bosch VP44 injection pump cool is to keep fuel flowing through it at all times. So to keep the overflow valve open I suggest the 14 PSI minimum pressure. I'm currently at 136K miles on my Bosch VP44 injection pump and still going strong using a 16 PSI minimum pressure and an 18 PSI idle pressure. Here is a short video of stable fuel pressure from 55 MPH to 70 MPH at WOT. Here is another video done with idling, cruising, and WOT operation. Yes. I got a bit carried away and sloshed the fuel in the tank and sucked an air bubble and the pressure fell off. Cranking Pressure Test Here is a simple test on how to do the test for cranking fuel pressure. Pull the fuel pump relay in the PDC and then attempt to start the engine. Pay attention to the fuel pressure gauge during cranking. Be aware this test will trip a P1689 code and light the CHECK ENGINE light. Excessive cranking pressure can lead to difficult starting problems. Suggested Lift Pump Replacement You should replace the stock fuel system completely since it cannot supply enough fuel for even stock requirements without causing damage to the Bosch VP44 injection pump or adding stress to the lift pump. The pumps I suggest are proven and come with a lifetime warranty. These pumps come with a full kit and replace everything from the fuel tank to Bosch VP44 injection pump. AirDog 100, 150, or 165 Raptor 100 or 150 FASS 100 or 150 FASS DDRP (DDRP Ver.2 - 89 GPH) I don't suggest these pumps... Because they don't address the pump location, plumbing restrictions, or come with much of warranty. Stock Carter or Carter Campaign Pump (4090046) Holley Blue or Holley Black FASS DDRP (DDRP Ver.1 - 40 GPH) AirTex Mopar's Notes: That was true for the DDRP Ver.1 However, DDRP-02 is rated at 89 GPH and will hold pressure. It is listed as a Stock replacement pump designed to perform better than the Stock pump, but not for Chips that add fueling. I place a Power Puck on my truck with the DDRP-02 and saw no difference in FP at either idle or WOT, (PP is a timing chip doesn't change the amount of fuel). That said the PP is currently removed from my truck as I overpowered my clutch both loaded and unloaded, back to the stock clutch is fine. Looking for a Valair possible DD organic, or SD Kevlar/Ceramic. It is currently in the stock location and giving 15 psi at idle and 10 at WOT. Information Provided By: rhagfo http://www.cumminsforum.com/forum/98-5-02-powertrain/404412-fass-ddrp-02-a.html#post4197714 Additional Information (About Performance Crowds & Fuel Pressure) I've seen several times where people will link back to performance pump builders and quoting where they say, "(Un-named) proved that 5 PSI, under load, made all the horsepower the VP44 pump could make, even with stock fuel lines, fittings and supply pump." This might be true but there is nothing ever said about the life span of the pump at these conditions. So... Please do not follow these performance crowds into destroying a perfectly good Bosch VP44 injection pump. The fact still remains from Bosch the actual designer of the Bosch VP44 injection pump states that injection pump should return 70% of the fuel back to the fuel tank for cooling and lubrication purpose of the VP44. Being the only way a Bosch VP44 injection pump can do this is to have fuel pressure above 14 PSI to open the overflow valve. Then if the stock Bosch VP44 injection pump with an enhancement box say an Edge Comp on 5x5 can consume 15-20 GPH that means the stock 35 GPH pump cannot keep up with Bosch's design of 70% return volume. So this why products like AirDog, Raptor and FASS was created because they actually meet the demands of the Bosch VP44 injection pump. Then another fact that Bosch will let you know of is that diaphragm damage occurs from operating the Bosch VP44 injection pump at low fuel pressures. Making matters worse is that no Bosch injection re-builder will void warranty a VP44 injection pump with diaphragm damage. Dead give away that you had a bad lift pump or low fuel pressure problems. Please view the Bosch VP44 exploded view page to see there is no diaphragm in the Revision 027 Bosch VP44 Injection Pump Then the other fact is right from the Dodge Factory Service Manual has the minimum fuel pressures (picture at the top of the page). It even states the pressure that the overflow valve requires to open. Refer to the Overflow Valve Testing from the Dodge Factory Service Manual and see that the overflow valve should remain closed at 10 PSI and open by 14 PSI. So if the overflow valve is close by 10 PSI, then you extra cooling and lubrication just disappeared. So ultimately it suggested having a fuel system of no less than 100 GPH supply that can maintain a minimum pressure of 14-15 PSI at WOT. This will great extend the life of the VP44 because it keeps the electronics cooler longer and keeps the rotating parts lubricated properly. So please people let the facts and information from the actual designers of the injection pump (Bosch) and engine (Cummins) provide you proper information for your fuel system for your engine. Don't be swayed by performance shops claim of high horse output with little fuel pressure. As I proved right here doesn't work for the longevity of the VP44 injection pump... Another thing to bring up there are people that are increasing fuel pressures above 20 PSI. Please don't do this. The return port leaving the VP44 pump isn't very big at all. The return port is on the left and supply is on the right. As you can see increasing fuel pressures above 20 PSI put you at risk for shaft seal failure. Increasing the pressure above 20 PSI isn't going to improve the return flow. I say stick with the 14-20 PSI pressure range for seal safety. Additional Information (About Maximum Flow Rates) Here are some calculated flow abilities of the stock fuel system vs. 1/2" big line kits. This is not calculating bend, turns, offices just straight flow for open end plumbing and this is a rough calculation. Pipe Size Gallon Per Hour Flow Rate Gallon Per Minute Flow Rate 6mm ID pipe 75 GPH @ 15 PSI 1.2 GPM @ 15 PSI 1/2" ID pipe 570 GPH @ 15 PSI 9.5 GPM @ 15 PSI Use The banjo bolt Shrader valve to test for fuel pressure, Item 3 in the above diagram. If you have a 98-99 truck the port might be on top of the fuel filter housing. You can see the 90* bend fitting coming out of the top of the fuel filter housing in the below picture. Install a Shrader valve and test from there. I'm hearing of tales of shops, mechanics, or dealers doing the old hook up the fuel pressure gauge and only checking fuel pressure at idle. This is wrong. Because I've seen lots of cases where fuel line restriction, fuel filter plugging, gelling fuel and other thing causing fuel pressure to drop out under load. Like this video from a friend of mine, you'll see he's got awesome fuel pressure at an idle (where most shops gave him the green light). However, what the shops did not test for is WOT at highway speed, and you'll see in the video, he can pull way down to 0 PSI. Anything under 14 PSI is a concern... Anything under 10 PSI is a serious problem. As for having a gauge in the cab all Dodge Cummins trucks should have a fuel pressure gauge in the cab. Because like you seen bench testing with an idle pressure is meaningless if you can't see the WOT pressure at highway speed. View full Cummins article

-

- lift pump

- injection pump

-

(and 3 more)

Tagged with:

-

Okay guys I'm new to the forum here and I need some help. I have a 1999 24v and on my way to work the other day my truck died on me and completely shut off in the middle of the road. It didnt have any weird symptoms before this happened it just died and now will not restart. Any ideas as to what this could be or where I could begin trouble shooting this?

- 6 replies

-

- engine shut off

- wiring

-

(and 2 more)

Tagged with:

-

Having an issue and just starting to look for the cause. Have a 1999 24v with a 5 speed transmission that will shut down after you let off the accelerator when you accelerate hard. After it dies you have to crank the engine excessively to get it to restart. At times it won't restart unless you pull/coast start it or bleed the injector lines.

-

(Copied From TDG.com) For the 89-93's (Bosch rotary pump)there's a screw behind a tin access cover about the size of a nickel. It takes a 1/2"(13mm) to break the jamb nut loose, then take the screw out. It'll have a metal band welded on it that needs to come off. Once that's off you can run the jamb nut farther out(towards the outside of the pump, about 2 turns). Then put it back in and test, some smoke more than others(especially with Lucas POD injectors!). The pre boost power adjustment is under a cover that looks like a vacuum diaphragm, and it is one. It has a torx bit with a jamb nut. Loosen the torx for more low end & tighten for higher. The governor spring is different than in the later 12 valves, and is not adjustable. The other adjustment is to rotate the diaphram, under the top cover with 4 screws. Use the picture at right as reference. Turn the diaphram clockwise 90-120 degrees, this is like sliding the fuel plate on a 94-98. Now put it back in & test. The best bang for the buck, is to get a gov spring, most of the time they are under $20, and let it rev up to 3200 rpm. If you plan on a gov spring, hold off on doing the fuel screw shown above, it needs to be close to stock setting. Might take a look over here for more information... http://mopar.mopar1973man.com/cummins/1stgen/inc-pump/inc-pump.htm

-

Well I would like to personally thank GOS Performance for providing me with a quality product. It took me a little over 3 hours to get it all installed to my specs that I wanted. I did some changes during my install to hopefully protect the pump and filter from damages this summer when I'm out cutting firewood. The when the box showed up from the "Brown Man" I was kind of shock to see how big the box was. I didn't relize that is came with all new fuel ine, fittings, electrical, etc. Right On! Instructions are really easy to understand. Once I got the pump all hooked up I was expecting this loud pump to buzz on the frame below. I turned the key and didn't hear nothing! UH OH! So I bumped the starter and listened. Wow! It really quiet running pump... Got it fire up (without priming!) and I was seeing 17-18 PSI Wow! This truck has never seen over 14-15 PSI in its life till now! Even stomped on the throttle I never got below 15 PSI. I know why too. I still got to put in the draw straw kit. I scarficed my old Vulcan Big Line Kit to make a pickup line temporary till I get back from my trip I got to make next week... I'm going to head out and grab my camera from the shop and post a few pics... Well here we are... Here is the old little carter Campaign pump (4090046) from Cummins... (Looking a bit sad and tried...) Then there is the installed AirDog 150... (Mount towards the transfer case to allow the skid plate to protect the filters for being hit.) With a solid 16.5 PSI shown on the gauge! I've seen up to 18 PSI now... Then the rest is in my write up on my BOMB listing now... http://mopar.mopar1973man.com/personal/2002/airdog-150/airdog-150.htm

-

Carter Campaign Pump 4090046 Cummins Part Number $63.00 Dodge OEM Pump BSAAL6429X Mopar Part Number $209.00 Napa OEM Pump NFPP74213 Napa Part Number $179.99 Carter Fuel Pump (Generic) P4601HP $99.50 Carter Campaign Lift Pump This is a redesigned lift pump for the Cummins engines. From what I heard it was design for the Buses more than anything. But I found that the Campaign pump is exactly identical as the Dodge OEM pump that was supplied at manufacture. Just much cheaper in price! UPDATE - November 24, 2006 The campaign pump is doing fair with a stock engine configuration. My fuel pressure have slid a bit and now it idles at 13.5 PSI, Cruise at 12.5 PSI, and WOT 11.0 PSI. It's starting to get marginal. It might get even worse with the addition of the Edge COMP that is coming soon. Update - December 25, 2006 I have been notified by Cummins in Boise ID that the Campaign pump is no longer available. If you attempt to order 4090046 you find that the price jumped from $65 to $202. So it time to research the next new pump for replacement. Dodge OEM Lift Pump The OEM lift pump that Dodge use to supply for replacement is no longer. They now are converting over to a in-tank fuel pump. Basically the module has the pick up screen, fuel sender, and lift pump as a package. The problem is the pump is weaker in pressure compared to the old version and requires you to lift the bed of the truck to replace. In other words if you have a lift pump problem now your going to be stuck on the side of the road. Carter Fuel Pump - P4601HP I got one of these from Summit Racing. What I found out is the fuel pressure is much weaker. I got roughly 8 PSI at idle and 4-5 PSI at WOT. The other problem is the fuel fittings are 3/8" NPT. So it can not be used a replacement pump. The electrical connections are for ring terminals. So once again it will not work on the truck unless to change your plumbing and electrical connection. But why bother when the pressure is to low to use... Fuel System Pressures - UPDATE! I'm hearing a lot of people saying that it's OK to let it slide down below 10 PSI... Cummins set the pressure limit for a reason. This reason includes proper cooling and lubrication of the fuel system components under extreme loads (WOT). I highly suggest you stick the recommended pressure listing. You cannot have any fuel volume without pressure! Something has to PUSH it! http://mopar.mopar1973man.com/personal/2002/campaign-pump/campiagn-pump.htm

-

Here you go gang 12V layout of both sides of the engine... :thumbsup: http://forum.mopar1973man.com/attachment.php?attachmentid=68&stc=1&d=1260576366 http://forum.mopar1973man.com/attachment.php?attachmentid=69&stc=1&d=1260576366 http://forum.mopar1973man.com/attachment.php?attachmentid=70&stc=1&d=1260576366

-

- 2

-

-

- 12v engine layout

- fuel system

-

(and 1 more)

Tagged with:

-

Ok so Hello everyone.....Yes I am a Newbie. I just bought a 2002 one ton Dodge ram from my company. It has 240k miles on it. Tranny needs some work one of the guys popped a cooler line and drove her dry. I fixed the line and filled her back up and she still rolls down the road just not as strong as she should be. My problem is I know the tank is dirty so the filters get plugged pretty quick which is why she will start to kind of cut out every so often, I try to keep the water drained, but the other day I was rolling home from NC and she chugged a couple of times then she just quit on me. Now this has happened before while the company owned it and I know it was a quick fix at the shop I just dont know what they did. I assumed they put in a new filter and she was back up and running. Ive been out of town a lot and have not had the chance to put a new filter in it and try but I was wondering about priming it when I do?? Thanks fella's. Have a great evening Jeffrey

-

I have never had a fuel leak, but low and behold... When I power down, I get a drip off the bottom of the transmission.... I put a cup under it and collected a small amount, but enough to realize it sucks... Seems to be related to pressure in the lines as it stops after 10-minutes or so. Any ideas where to check for the most common fuel drips? :confused::confused:

-

I am trying to find an OEM replacement kit for the fuel heater element on the fuel filter cannister for my and my wife's truck. I am getting reading that these are getting very difficult to get and are no longer in production??? Is this true??? :confused: Anyone know where they can be purchased? I understand they are a Cummins Filtration item and the part number is: 3928013-S Can anyone verify this or provide the correct part number? Thanks.

-

The 2kreeks hauler has been missing at hiway speeds 'cruise 50/65 mph' every other speed is ok. If truck is acelerating no problem, pulling hard 10k up everything nornmal. The lift pump was replaced approx 3500 miles with a generic AIRTEX BRAND. This was replaced during a oil change when I found out the new carter was starting to fail. Now with new instruments the fuel pressure at idle is 21.5lbs and wot is 16lbs. My basic idle time is approx 5mins and some time more depending on how long of pull and how heavy..Does this high of fuel pressure hurt the vp44?Could this high of fuel pressure cause the missing?Only codes showing with key trip, is 1693 which was left over from a p0122, which is gone now after replacing the apps.larry

-

I installed a airdog 100 and I finally install a glowshift fuel pressure gauge. I noticed the when I first ran the truck the gauge would read between 18 and 20 psi, then at times it would read between 16 and 20 lbs. Is the gauge the problem or the airdog...thanks :confused:

-

Ok guys here it is I got this code after I plug the OBD II scanner tool on this truck I just bought. The previous owner told me about this problem , when the truck is running at speeds of 60 o 70 the pedal wont respond and the speed goes down and I have to lower the speed by braking or putting it on neutral and then it will respond. What do you guys think?

- 6 replies

-

- fuel pressure

- fuel system

-

(and 2 more)

Tagged with:

-

I was just wondering if anybody has taken the box off of one of the newer style Dodge Pickups 94 and up? When I was installing propane and natural gas systems and the tanks on vehicles many years ago we found it alot easier to install the fuel systems with the box off. I didn't do a newer style Dodge at that time. At that time 4 guys would pick it up and another would push the truck forward and put two saw horses under the box where we would set it down. I need to do the sending unit and new fuel lift pump system so that is why I was wondering how easy these boxes come off. It's so much easier to work standing up.

-

What's the difference between a truck vp and a midrange vp? can we use the midrange pump on our trucks??:confused:

- 10 replies

-

- difference

- fuel system

-

(and 2 more)

Tagged with:

-

I'll have to check at the dealer in Canada to see if they have the heaters since we have Canadian warehouses that supply the dealers here. You might contact Mancini Racing in Detroit, www.manciniracing.com ? I think might be their website. From what I heard Chrysler is emptying some warehouses and Mancini had a bunch of that stuff for sale as they always have in the past for Chrysler. They have this pump on their site:http://ep.yimg.com/ca/I/chucker54_2084_9531548 CARTER - 14-16 psi 100 gph Get the fuel flow you need. These universal rotary vane electric fuel pumps from Carter operate using leaded and unleaded gasoline, gasohol, and fuel boosters. They have an internal pressure regulating valve, and feature free-flow fuel delivery. These pumps have no points to burn out, and no shaft seals to leak or deteriorate. Easy to install, these universal fuel pumps come with a complete installation package and instructions. $122.95 CARP4601HP

- 1 reply

-

- carter fuel pump

- fuel system

-

(and 1 more)

Tagged with:

-

Well, here I am. !st. post for a newbie. Right off the bat, I apologize for any dumb questions that have probably been asked before. I have a 2001 I picked up a few months back from the original owner with 154,000 miles on it. I am told that it has had the lift pump replaced twice and the vp44 replaced once. The truck is all stock. It also had a dealer replaced trans at 127,000 miles as I have been told. I want to install an after market lift pump and stay as close to stock equipment as possible. After reading here and on the other forum I am thinking that the Raptor 100 in front of the stock fuel filter/fuel heater would be the way to go. I guess what I would like to know is about the relibility of this particular pump and or any pump that would allow me to keep the stock filter/heater. I will probably never hot rod this truck with any increase power mods. I would also like some suggestions as to a good quality (proven) fuel pressure gauge. Thank's for puttin up with a new guy, and thank's for your time and attention..........Hood Latch

-

Ok, for those of you who dont know me and my truck observe. I will start by saying my truck is cursed, some here would agree some will tell you he's not a good enough mechanic. My fuel pump is a Airdog 100 when new it ran about 15lbs of pressure at idle, wot it was 14.50, one year later it drops to 13lbs at idle and 12.50 wot. Ok I have other problems other than that but we wont go there yet. So I just accepted that was normal, so while trying to fix other issues one step at a time ( replacing everythink one peace at a time till I fix it or it will be stock again ) I started with fuel pressure hose from pump to isolater. No leaks no cracks in line no slite fuel on fittings or anything.No sharp bends in line,straight shot all the way.And I said to my self this is a waste of time but here gose. So why do I now have 15lbs at idle again and 14.50 a wot? I will throw this at you to, old vp44 needed to be replaced no dout it had little issues and stuff such as dieing for a split second then pick right back up and run, you know the little things in life that make you day. Oh yes I allmost forgot it has never thrown a code excepted the first vp44 about 50k miles ago. Fuel mileage with old vp was 15mpg new vp jumped to 18mpg, today I am at 14.75mpg again. What the !!!!? I will also say the only thing that has not been replaced is the map sensor and the ait everything has been replaced when I say everything thats just it all of it has either been swaped with another truck or bought new, turbo and ecm have been swaped ran for a day then put back the next day. Turbo one day ecm the next day. Cam sensor you name it.Michael, I am thinking if I dont fix this truck I will take a road trip to see you, I now we laughed about it but it is starting to be a reality. If we dont fix it we can make a new Dodge commercial, I am sure you know of some good mountains aroud there. lol

-

Ok today i was in a hurry and while my truck was warming up in the driveway I notice a puddle under the truck. It was Diesel and it looked like it was coming from the bottom of the lift pump. About evey 5 second there was a drip while it was running only. I took another vehicle and didn't get back intime to look into it futher. Question will these leak at the bottom? It looked dry above it. Anyone had this happen to them? Thanks in advance for any input.:confused:

-

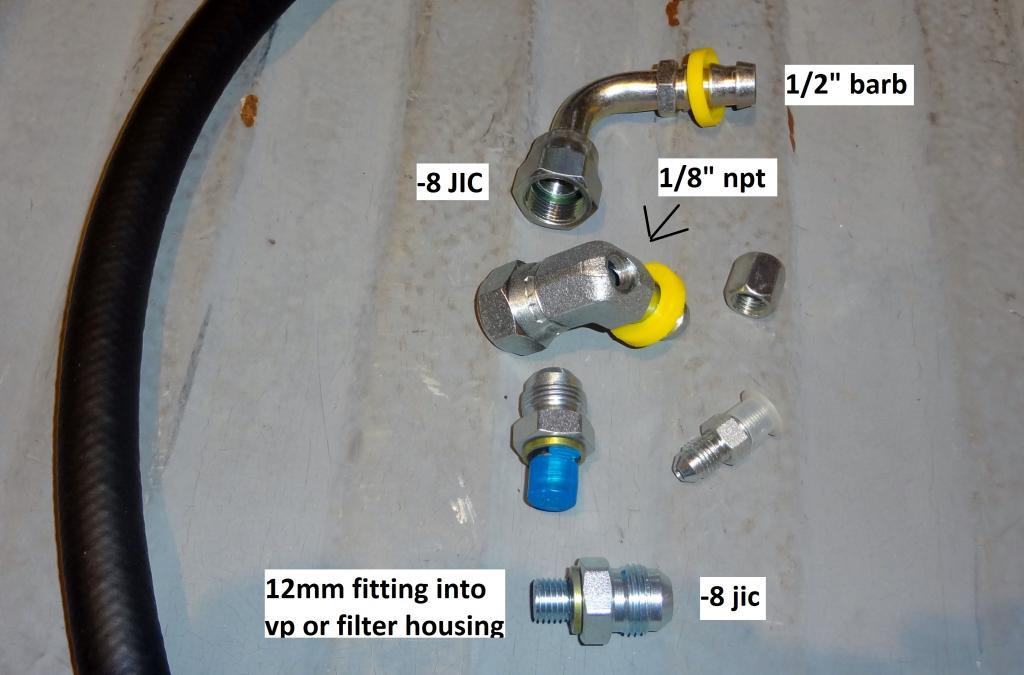

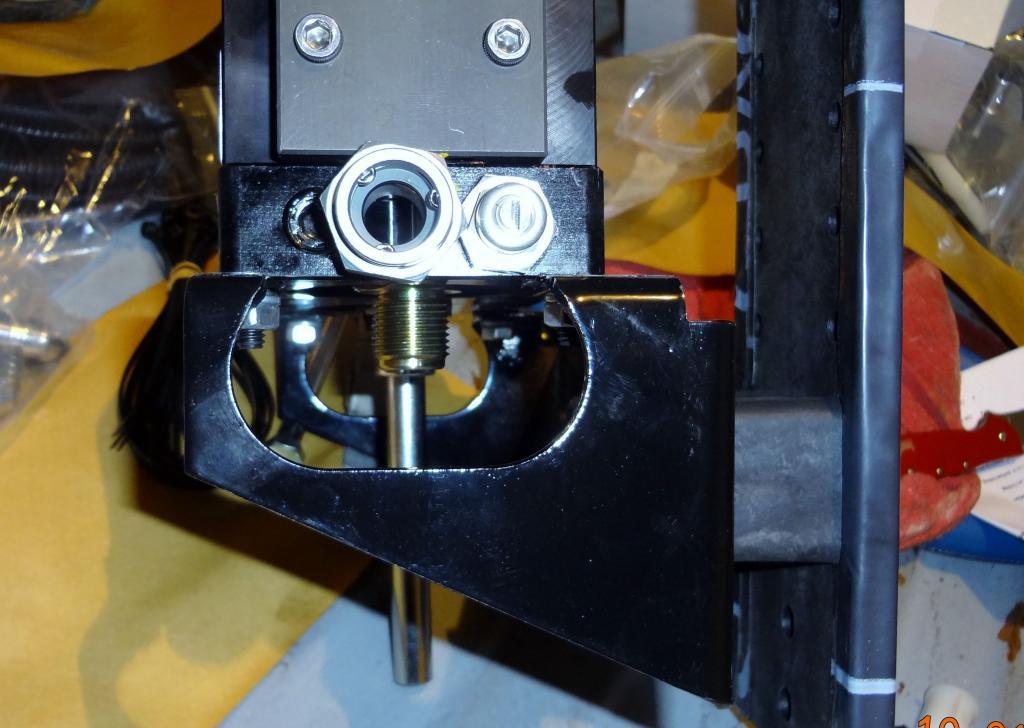

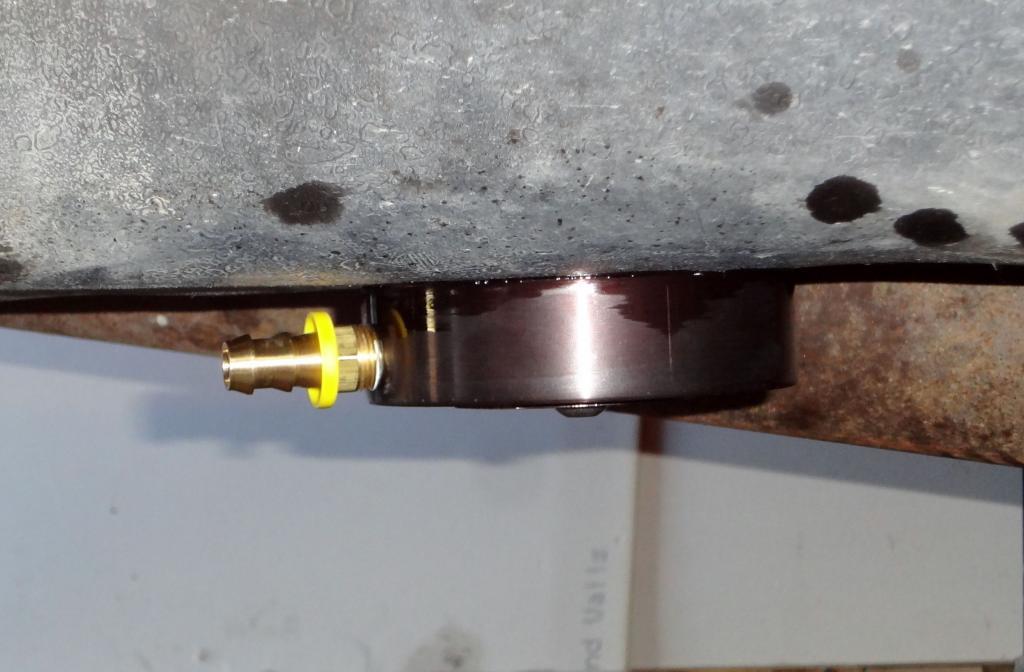

Ok, I did this 3 weeks ago so I am just finally getting around to doing my write up. I know people have concerns with the airdog/raptor issues, but hey, somebody has to see if they are fixed. I have no concerns about these pumps, as I have never had any problems getting warranty on customers raptors. Also, I have an electronic gauge as well as a quick release fitting for a mechanical gauge to check pressure whenever I need to.First things first here are the partsAirdog and hardwareHere is the sump kit by Bean's dieselFirst thing I did was drain the tank through the fuel filter housing drain into 5 gallon buckets and jumping out the lift pump wires to control the flow.Here is what your fuel looks like when you mix 2-stroke oil at 128/1Now time to put together the Airdog pump and fittings, I used some bituthene around the plates that mount to the frame and also between the actual pump and its mounting bracket to dampen any vibrations/noise.I ran all hoses and wiring, that ran up to the engine bay, through the frame rail to clean up and protect them. I also ran the fuel line into the stock filter housing to keep the extra filtration as well as the water separation. (I don't believe the fuel heater does much good)Next I installed the Vulcan big line kit, here are all the fittings and sizes to help clear up anythingThis is the fitting that will go into the vp44 and the bottom of the filter housing.These are the elbows that will hook into the previous fittings. The one with the 1/8 fitting should go on the vp44 fitting.Here is the glowshift maxtow gauge I got, its an analog as well as having the digital number readout. I am not to happy with the gauge as the needle looks like a windshield wiper when you are driving and have the throttle on anything off idle. I think the sensor is way to sensitive because with a mechanical gauge, the gauge only drops 1 psi at WOTHere is the fuel snubber that came with the fuel pressure gauge, this or a needle valve is a must to keep your pressure sensor safe from the hammering the vp44 does.Elbow with adapter and snubberNow onto the fuel sump. They say to drill it right below the stock fuel module, so I cleaned up the tank really well. After drilling the pilot hole with the provided hole saw, I let any fuel drain out that was still in the tank. After it stopped dripping, I finished drilling the hole and cleaned up all the shavings. After I drilled the hole I think drilling under the stock sender is not the best as it interferes with the installation of the sump.Sump all installedSump is roughly 1" tall and sits above the frame rail. Yes something could hit it and tear it off but I rarely go offroad so I won't be worried about it.And finally, its installed. This is my attempt to show how far everything hangs under the truck and the protection it has.Final thoughts, so far so good. As I said earlier, with the mechanical gauge, I only drop 1 psi at WOT with my setup and chip on highest setting. Don't believe there will be any gains in mileage, but I now know I have great fuel pressure (19-20psi) and great filtration.

- 11 replies

-

- 3

-

-

- airdog 165

- lift pump

-

(and 1 more)

Tagged with:

-

Hello everyone. Iam in the middle of driving from Idaho to North Dakota and am having issues in Glendive, MT. I turned off o!f the interstate and slowed to ~15 mph before merging on to a different highway. My truck accelerated fine and at ~45 mph a check engine light came on and I lost all of my accelerator function. I am 770+ miles into the trip and everything else has been fine until now. It is about 10 degrees out so i am afraid to shut off and attempt a restart/check codes via key trick in fear of freezing to a pop sickle overnight. Any suggestions would be greatly appreciated. Thank you!P.s. I am running anti-gel in the fuel so plugged filter shouldn't be an issue and I do not have a pressure gauge to check fuel psi. Engine is idling smoothly, temp is good, oil pressure is good and my fuel filter is 2 months old.

- 11 replies

-

- check engine light

- cold weather

-

(and 2 more)

Tagged with:

-

Here is what it is doing: 1) Takes 1 to 1.5 secs to start... prior to injectrs/V adj... as soon as it turned over it would start.. 2) Rpm is around 740-750 with ever so slight bump to it... like its out of time or missing... it was very smooth prior to the install and had 780-800rpm. 3) I put it in reverse and it stalled (twice) when a bumped the throttle never done that before. 4) Noticeably more smoke (puff) at start up... and when i bump the throttle just sitting there it will puff smoke. Did not really do that before... 5) I was very careful installing injectors and crossover tubes they came with protective covers and i was very cautious when i put them in... injectors and tubes all snapped in and went together like they are suppose to... 6) When I was adjusting the valve clearance I used the alternator pulley to turn the engine over... I had the injectors out. The eng would not turn in direction it turns when running... the belt would just slip on pulley... So I was able to turn it in the other direction. Could I have hurt something by doing that? I did hear some clicking sounds coming from the lower engine back by the tranny it sounded to me... I need some expertise on this one! - - - Updated - - - After wise counseling from this site and others I did some trouble shooting... APPS voltage reading and fuel system bleeding, CORRECT torque on High pressure fuel lines at the head and lift pump pressure adjustment. Results: 1) hard start has gone away for now... 2) rpm more consistent and steady @ 750rpm... 3) no more stall in reverse now... 4) normal smoke puff at start up... 5) rechecked valve lash on all of them and they are within limits... The video is after all of your recommendations... turn sound up at the start of the vid (then down as the truck accels... air over cam get noisy) and when I am sitting there and later in the vid when i start it up you can here the idle pretty good... thanks for all your help! http://www.youtube.com/watch?v=05bnRloNC7M

- 1 reply

-

- fuel system

- injectors

-

(and 1 more)

Tagged with:

-

Hey everyone, I just bought my first CTD. It is a 2001 2500 x-cab, long bed 4x4. Has a 4" BDS suspension lift, and air ride. 145k miles. I am loving it so far. I have bought and installed a BHAF already, but other than that it is all bone stock. This is my first diesel so I will probably be posting lots of questions on here. I will be driving this truck daily and eventually will be towing a 5th wheel camper with it. I would like some input on what fuel system setup, and other mods would be the best for what I intend on using it for. Thanks

Rate The Author

Please take the time and give the author a 1 to a 5-star rating for the information you have gained from anywhere on the website. All forum threads, articles, etc. If a members post is good information please don't forget to tell them "Thanks" or "Like"

Rate Us On Google

Please take the time and visit our Google Review page and give us a review of our services.

Tip Jar

If Mopar1973Man.Com has helped you with quick and timely information for your repair please consider tossing a tip in the Tip Jar