Mopar1973Man

Owner

-

Joined

-

Last visited

-

Currently

Viewing Mopar1973Man.Com Weather

Everything posted by Mopar1973Man

-

Lost brakes while driving

Won't work... Need a DRBIII tool. I've tried the prying the tone ring. Didn't slip in my case. But my right hub would not register speed below 40 MPH. So the ABS assumes the wheel is locked. Even with 3 sets of sensors would not register speed. Had to replace both bearings to fix.

-

Crazy life - Just blogging

Yeah... But weak yet this morning but doing better. I'm way behind. Got the product boxed up and ready for the mail. My truck is down the rear most u-joint failed from salt getting into the bearing. Now got more work than I've got time to do the work. I'm going have to consider shutting down the shop for a span of time till I can catch up. Then like there is several updates needed on the website here. List goes on...

-

Stuck thermostat?

The only spec for a thermostat is opening temp. Nothing else can be changed. As for them falling apart that is a quality issue and nothing is being done about it being that Robertshaw / Mr. Gasket design is failing for all makes Ford, Dodge, and Chevy. Just think Carter fuel pumps have been junk from the start but Dodge still sells them and so does Cummins. They don't hold up period. Never met the minimum standards then and still don't.

-

Stuck thermostat?

Pay triple the price for a thermostat... Again I'll repeat again "Cummins and Mopar do NOT manufacture thermostats". Both of these vendors Mopar and Cummins buy from the CHEAPEST source they can and triple the price because the thermostat box has a Cummins logo or Mopar logo. Being that Mopar and Cummins both have no control on what the manufacture is going to produce.

-

Crazy life - Just blogging

Sorry for the lag in everything gang... Christmas dinner came and gone but @Wet Vette ended up getting the stomach flue even though she had the flue shot. This created a bad deal for her and screwed up her blood chemistry. I've gone down to Boise watch over Eileen and taking care of Mom's dialysis the last 3 days in Boise and Ontario. Eileen is back home and doing fine and gain her strength now. Mom is still doing her dialysis. As for me I'm exhausted from all the driving. Then to top it off managed to eat a u-joint on the rear driveshaft with all the salt on the highway. Just last week I had to change a front driveshaft u-joint because of the salt issue. I've got to do my dialysis run today and I'll be able to get the waiting shipments out tomorrow. For all you that order parts I'm truly sorry but its been a crazy holidays.

-

2 stroke info.

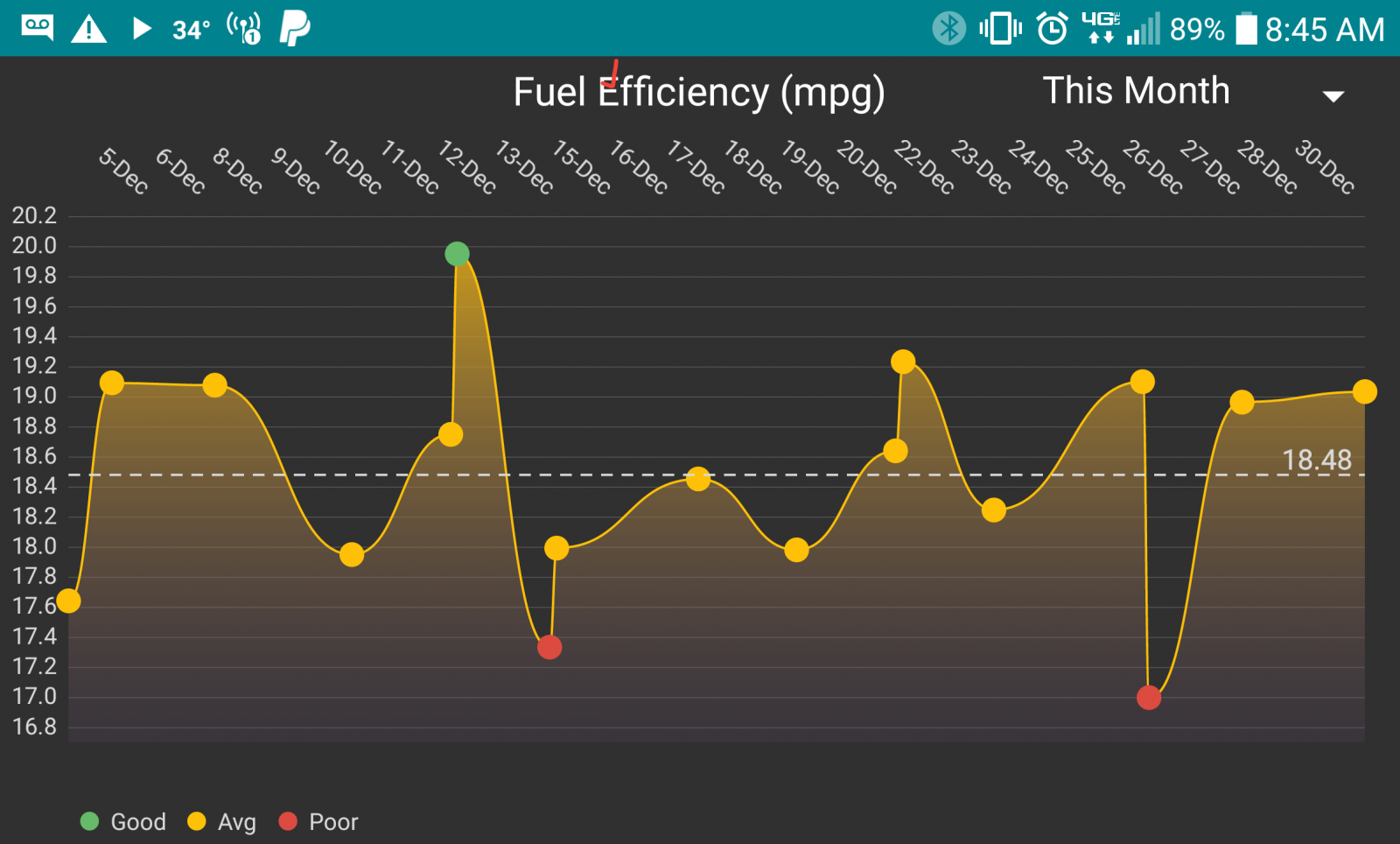

Oh even with my Emergency run to McCall hospital for @Wet Vette and quickly packing up and chasing her to Boise, ID St. Lukes Hospital and driving hard and using full power of my Quadzilla I still pulled 19.03 MPG with my foot in the throttle. But, there again I'm tuned for Petroleum diesel fuel not Biodiesel.

-

Trip odometer self resets!

Ever since I did the W-T ground wire mod and the PCM protection fuse mod I've stopped all the alternator failure issues now on my truck.

-

Few new to cummins questions

Just like there is the washable oil filter... Just too risky to use any washable filter. Every time you wash the filter the media is being broke down and then possibly putting dirt and debris on the wrong side of the filter causing engine damage. Like most of use toss dirt filters in the trash and install a fresh filter and filter media. My turbo right now is spotless after 250k miles of driving. My BHAF cost about 50 dollars and last over 150k miles and never needs to be washed. 405k miles and still clocking miles... 1,200 a week.

-

Stuck thermostat?

Lets say I've never had a NAPA fail yet, in my truck and hundreds of customers I've do work on, including all makes Dodge, Ram, Chevy, or Ford yet. Remember I'm counting all my customers and vehicles I've worked on or serviced. Now Cummins thermostat I replaced plenty of them so far. Short life span, physical failed as I've documented (attachments above) etc. Also Cummins has changed providers several times being I've documented several different designs and manufactures sold by Cummins. Like example Robertshaw, Mr. Gasket, Motorrad, etc. Very unsettling when Cummins has to change manufactures over 4 different times. As for Robertshaw and Mr. Gasket failures they cover all name brands Dodge, Chevy and Ford... As for Mr. Gasket... So being Cummins is currently using Mr. Gasket since Robertshaw no long manufactures engine thermostats. I've already called Robertshaw and and asked for more info.

-

Buying a Quad soon

I've seen that too. The other I hate is touch the screen to raise or lower the power it will dump the app, then restart the on its own and refuse to connect till I shut down fully including the engine. Funny my Bluetooth head stereo will drop and reconnect to my phone every time no problem. iQuad will be stuck till full shutdown. Which happened last night in Boise at a fuel station.

-

Bad ECM/PCM?

Remember the PCM is the master computer to start the network, then the ECM is second in line to fire up.

-

Electrical Nightmare!

ECM appears to be damaged did you get a warranty?

-

Few new to cummins questions

Junk... Any washable filter is junk. That is DIRT that is on your finger and it is entering your engine wiping out the rings. Now take it all off and toss it in the trash. Go buy a BHAF. Problem solved.

-

Lost brakes while driving

Don't bother with Timken... Waste of money. I've been getting 180k to 200k+ miles from SKF unit bearing from NAPA.

-

Lost brakes while driving

Go to Dodge Dealer and spend the money for labor for a dealer tech to pull out DRBIII tool and measure the front axle speeds while driving. There is no cheap tools for the public Snap-on is expensive tool as well. Even my Innova tool won't do ABS on these trucks.

-

Track Bar Keeps Coming Loose

Still after 405k miles still using the factory style track bar. I would look at the tapered hole for damage. Typically get about 150k miles from a track bar. With your 3 inch lift could be causing your issues pulling on the track bar excessively.

-

Lost brakes while driving

INSIDE the bearing and un-repairable... You have to replace the unit bearing.

-

2 stroke info.

Yup @IBMobile is right on the BTU values... But I've got the last key though... Stock truck with stock ECM tune is going to be deeply retard in timing. With ECM running retarded then the timing is right on mark. Now someone like me that is tuned to petroluem fuel (summer) with lots of added timing is going to take a hit to MPG performance. Now if I keep my current winter tune in the summer (which is retarded per good) then it should work out just fine. Since my summer tune is about 21 to 22 degrees at 2,000 RPM's then it would be igniting too early. But a retarded tune would fix this and get you fairly close to right. Since Idaho fuel is petroleum based and about 30 to 40 cents cheaper not worth the trouble. Using ASTM testing labs cetane scale. Using Material data scales for diesel fuel information. Take note biodiesel is below the scales ability... 118k BTU's

-

Stuck thermostat?

When the score board is NAPA ZERO failure, and Cummins 3 failed (2 body splits and on fell apart) and Gate 1 failed (stuck open). Not good... Replaced another Cummins that slit apart again. (Robertshaw design).

-

Buying a Quad soon

I've tried a LG G3 phone, LG G4 Phone, LG G5 phone, and a Azpen Tablet. All had the same problem with the Quadzilla. Relocated the BT head into the cab still having connection issues.

-

Few new to cummins questions

Radiator has to come out first then the intercooler can be removed. The radiator lower neck won't pass IIRC.

-

Newer hvac conversion

You'll need the newer electronics in the cab. Most of that stuff is CANBus controlled. Like the fan speed switch is not like ours. It CANBus signal to the TIPM for control of the blower. Take note newer truck don't even have a relay for blower motor or the A/C compressor it's all controlled by the TIPM.

-

Few new to cummins questions

As long as your not venting oil your fine... Nothing is wrong the engine is in good condition. Little soot coming past the rings and good long drain periods can net clean oil for quite a while. Would be a good suggestion to wash out the intercooler so it doesn't cake up in time. Also consider rebuilding the turbo. Turbo rebuild kits are super cheap like 50 to 70 bucks and fairly easy to do.

-

Crappy Mileage No Matter What Tune

NO TAPE or SEALANT the sensor needs a good ground contact. Tape or sealant will foul the signal or make it not read at all. Brass is typically self sealing. Passing though too. Is never use any sealant or tape on any oil fittings. The other problem is if any tape or sealant go into the oil system it could plug oil cooling jet(s) or mess up the bearings very quickly.

-

Morimoto HIDs Headlights in a 2nd Generation Dodge

I've been researching the LED angle too for my 1996 Dodge. Trying to find a good quality LED bulb that holds a good pattern.