Everything posted by Mopar1973Man

-

Merry Christmas everyone!

Good morning all. Day after Christmas... Even with all that is going on with me, I managed to get a friend to hang out with me for Christmas. sadly I ended up being stoned and passing out quickly on him. Best past I was able to get some much-needed sleep. I'm thankful that I didn't spend Christmas alone. As for snow it is dumping snow pretty good this morning here and becoming more like wintertime now. Hopefully, everyone had a wonderful Christmas and got some awesome gifts.

-

Merry Christmas everyone!

-

Help

Again why I said if there is 100k miles just replace them. The solenoid coils can be tested on a test stand. If the injectors have less than 100k just pull all six injectors out and have them tested. This eliminates all the guessing. Then test your gasket wiring and go from there.

-

Help

First question how many mIles on the injectors? If the mileage is over 100k miles time to replace all 6 injectors. Now as the the valve cover electrical I would ohm from pin to injector contact to be sure no opens or shorts. Error codes are showing electrical issues. It even could be bad injector solenoids causing the errors again if over 100k miles I would start with injector replacement first. Now I'd these injectors are less miles I would pull them all out and have them tested I've seen a injector fail from damaged internal parts.

-

I know this is sudden but...

- W-T ground wire mod - Simplified

That's cheap way to do it but still way better to remove all that and ground it directly at the Vp44 and not even have the ground heading to the passenger but to the driver side battery. Then the charge wire goes to the passenger battery with a 150A breaker or fuse.- 35 comments

- 5 reviews

-

-

- 2

-

- I know this is sudden but...

Yesterday was a much better day. I managed to get sleep as well as last night. As for my abilities and function, it is a change in figuring out typical daily activities. Being I've got the two ports in my back I need to keep those dresses dry and clean. What do I do with my bags? Yeah, just a simple task of hopping in the shower has more steps. Then my clients are coming and paying up and picking up vehicles. It is still a mental thing for someone to take over my job and have the trust the job would be done right. Which is timely and needed. So yesterday just headed to McCall for banking and groceries. I welcome the time to leave the house and be out. I've been cooped up for quite a while considering my stay in Boise ugh. Give me a little bit to heal up and I'm going to be busy here. I will admit the ports in my back are sore most of the time from laying on them. Thank Gwad for cannabis which great pain relief without constipation problems. Strange enough even after the scrapping of my bladder there is ZERO pain which is weird to me. My ports are always floating 3-4 just enough to annoy me. As I type I'm sitting Indian style on my bed. There are several of you who reached out to me and checked my mental status. Go for it I'll just have to tell you all I'm just crazy and looking forward to the changes that are coming. Really? Yup, I'm more or less retiring for wrenching. 40 years of turning wrenches I could easily give it up. Will I miss it a little bit but I look forward to developing my coding skills in AlmaLinux and Interworxs. So how did I deal with the stress and anxiety of all this well... there is another side of me some know about and others it's a secret. I started playing with what some call cosplay. Well, I've created a character named Titanium. Titanium is based on the song Titanium. Speaks about being shot down but I never fall. So when stressful things were happening I could whip out my photo and show photos of me dressed up as Tiranium. This created a following just in the hospital. I've been requested to be in full makeup and dressed up. The hospital staff is shocked at how positive and how I'm dealing with the stress of all this but I'm still moving forward and looking forward to my new life that should have 100% survival rate and 0% of cancer return. If I see replies I'll post the photos. Then you all might find out how crazy I am.- Tuning Assistance

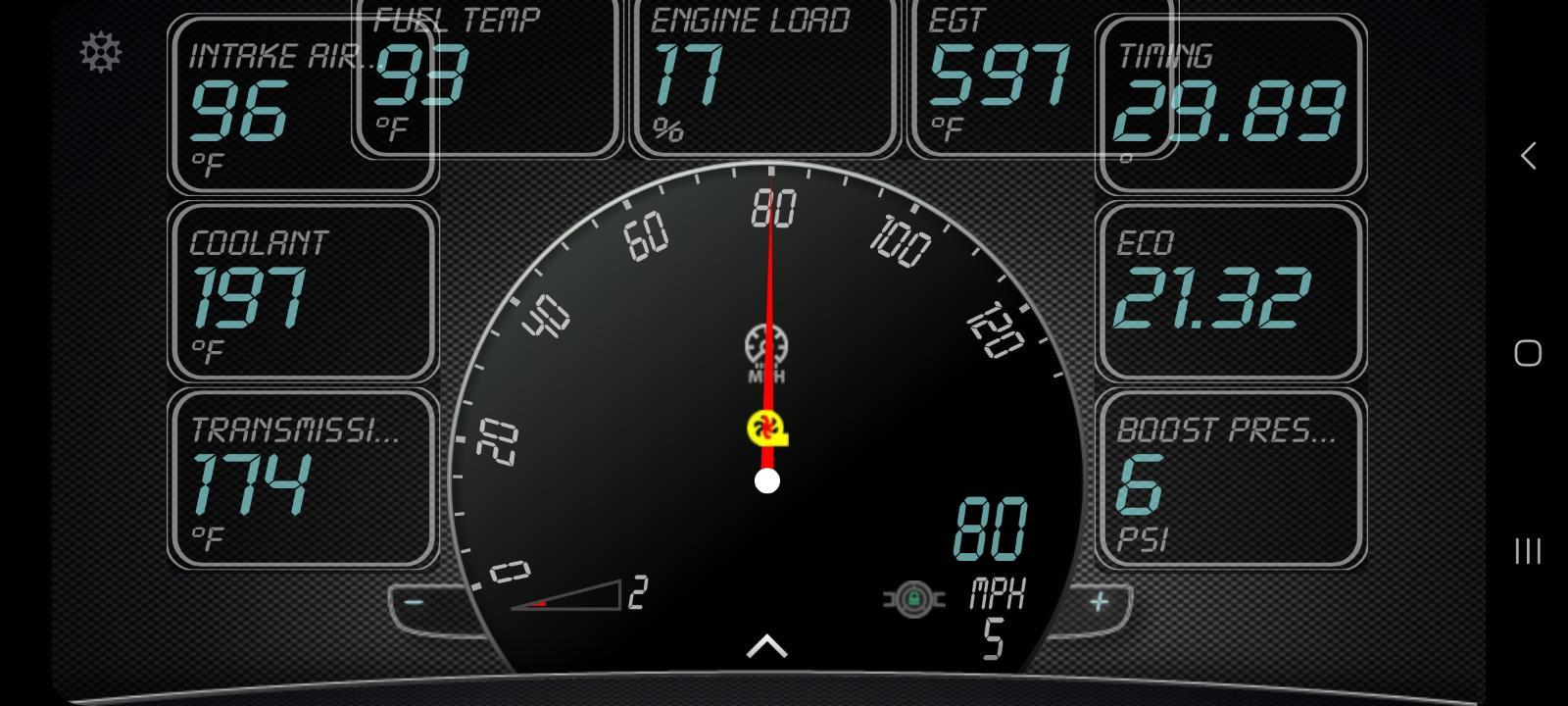

Level 2 caps any fuel table to 100% stock fuel. Then allows the custom timing. Now this points out that the custom tune fuel table it restricted. Now the timing table is going to be the most important thing about the tune. Being able to get a flat engine load at 65 MPH then we set cruise range. So as long as your engine load is low and boost is low you can have 24° to 26° BTDC at 2,000 RPM and do it safely. Another trick is if you have the transmission temp sender plugged into the oil test port on the oil filter housing you can verify you amount of timing by your oil temperature. Proper timing your engine oil temparure should hover about 165 vs 195 coolant. Now if engine oil temperature is great or equal to coolant temperature your timing is too advanced. Any changes that add more to temperatures or increase engine load your going the wrong way. When the tune is done right EGTs should be so low that in the winter I can drive 15 miles and barely get the truck to full temperature.- Tuning Assistance

No such thing really. Mileage is all based on how the tune is built and how the truck is driven from there. I can be on any level I wish which with drive the same in every manner but the only thing levels do is just cut the maximum fuel to different limits. Level 2 - Stock Fuel only Level 3 - CANBus fuel only which is about 60 HP jump. Level 4 and up - CanBus + Plus Wire Tap (Level limits the wire tap) In my case, the only time I use level 2 is during the winter to prevent spike of power causing wheel spin. Even with level 3 and up I can still do very well just you have to think more power quicker to destroy the MPG number. All you have to do is go over to the forum for submission for a tune and answer some basic questions. Then I build a tune based on the information given. This base tune will need work and effort. But once the first tune is built and uploaded then you will make your payment for said tune and the forum will keep our notes in order. I will create as many new versions updated based on what is not quite right. All previous versions will saved in your download section so for example 1.0.0 base tune, then we make 1.0.1 and good. Now you request something different I made 1.0.2 and it is a flop that runs poorly with performance problems. We can back up to 1.0.1 and then spur off a new version of 1.0.3 which then we never have to rebuild from the ground up. https://mopar1973man.com/forum/216-custom-quadzilla-tune-request/- I know this is sudden but...

Give me a chance to get that far in my medical then I'll be learning about those right now I can't remember all the medical terms on what that's called. I know I'll figure ways out to protect my bag. Still in all doing things like transmission rebuilds or clutch installs is not going to happen again for me. Yeah doing like my own oil change, sure I know I'll be back to servicing some things in my truck on my own. I still have to remember I've got to keep a sterile field around my port when I get it. Not like in the past when I let diesel fuel run down my arm into my shirt like I've done so many times in the past. But hey... My mind is full of information and different things. I can still support all of you guys out there in the world. Nothing is stopping me now from being here on the website and helping where I can with everyone. Seriously it does help to keep my mind busy with thinking about solutions for problems on these trucks. Even just being on the phone with some of you the phone call helps me settle down and get my mind right. Like I just remembered I was starting this post and got busy so... I'm returning to finish and then realize I need to check on Mark with my injector job in the shop and he already got my front tire tied into the back of Thor to be repaired. It's been really strange to just give orders to people and get stuff done. I'm not the type to do that... But my mini-family here is Jake, Mark and myself.- W-T Ground wire mod - Informational warning

No Raptor Lift Pump tends to run hotter being there is no return leg to the tank so the fuel recirculated from the output to the input will cavitate and then since it never returns to the tank the percentage of recirculated fuel is heated from being pumped over and over within the Raptor pump without returning to the tank. The Full AirDog 100/150/165 resolves all those issues completely. Since there is a return line to the tank any fuel that is being bypassed is returned to the tank. The air entrainment problem is resolved in the AirDog being there is a straw inside the filter so air rises to the top and is returned to the fuel tank. The fuel where the straw pulls from the bottom of the filter is air-free. Since the fuel is recirculated multiple times through the inlet and back out the return the fuel is polished in a multipass setup because of this. AirDog lift pumps will always last longer than a Raptor series, they run cooler being they do return to the fuel tank, fuel is cleaner, and less wear on the pump being there is a prefilter before the pump and the fuel is polished where a Raptor can't do any of the above. Like even on my truck the AirDog is pumping from the main tank area so the fuel is always cooler than stock by nearly 40 to 50 degrees cooler in the summer vs a pump like Raptor and the DDRP is worse being there is no return just like stock. Raptor is just a bigger GPH flow of the stock lift pump with the same issues as a stock lift pump. The Carter stock lift pump was a 60 GPH pump with 7mm banjo lines. Raptor could be 100/150 GPH but depending on the kit and setup it could be just as bad as stock being a lot of people believe in pump from the stock sender basket. This is BAD! All that returned fuel from the injectors is heated to the temperature of the head and returned to the sender basket and then pumped up with a Raptor pump with no return so the Raptor heats the fuel more with its recirculate and now feeds hot fuel to VP44 and wonder why the PSG fries easy. Honestly, for most people, I would never even suggest a Raptor or similar pump because of these issues. Remember I always look at the long-term and longevity of how parts are going to affect the life span of other parts. Sadly Raptor series is missing way too much to make it an option I would even consider.- I know this is sudden but...

Good morning all. It has been a big mental thing for me the last day. Processing that my life will change from here on forth. Like simple things like taking a shower, you have to figure out what to do with two drain bags? How about getting dressed where do you put the bags just so not everyone has to see them? The fact I'm now going down to Mark's place to explain how I do injector installs so he can finish my job for me. The fact I've got to get up every 3 hours or so to drain my bags. All these are just things I have to learn to handle in different ways. When I was in the hospital and the nurse did it all for me, then when I got home you are redeveloping your method of life to work with your medical issues. So yesterday was full of phone calls contacting clients to inform them I'll no longer be doing the wrench work on their vehicles but I have Mark that will be filling my shoes. Now sitting down with Mark and redeveloping a system where he is taking care of the shop jobs and how and when I need to go down and talk to him in regards to jobs/tasks so he can keep jobs flowing for me. No, I'm not getting depressed or worried about what has happened to me. This is the change of life I'm going to go through. I've still got plans to do many things yet. Just some of the stuff I want to do won't be done by my hands any longer. I see my life getting simpler in a way. Consider it was always me out in the front lines doing the grunt work, figuring out problems. Yes, this is true. Now I've got a full crew that all came together to aid during this time and some are willing to take over some of my tasks and responsibilities. Way less stress for me. The more I've been talking to friends (local and website) and adopted family I'm learning quite a bit very rapidly. Then like today I know that Mark is going to pull the front tire off of Beast and run it in for me to fix the slow leak. Simple things like that are just out of my reach right now. My medical problems right now have me very limited in what I can do and where I can go. This will not last forever either. I do have to move forward and get my next step of medical treatment planned out so I can get to the final healing stage. I appreciate all the love and kind words from all of you guys and gals out there. I'm going to make it and live on and still be you Cummins Guru. I've just got a rough patch to 4x4 through but Mopar1973Man doesn't know the word quit. I'm going to get through this rough patch and move on.- Tuning Assistance

That's all timing based then. The only clue I can give is make sure your retarding properly during acceleration. That will allow for building boost. Transmission wise with the torque converter lock / unlock at 45 is AC noise issue from bad grounds. I highly suggest you do the W-T ground wire mod.- W-T Ground wire mod - Informational warning

Dude!?!? Really?? Yeah I've done that a time or two being my ignition lock the key can be pulled out in any position. So yo end up sometime hitting ACC and pulling the key out. As for the Raptor being its not typically prefiltered before the pump and the pressure regulator is re-directed back to the inlet makes a good way to create caviatation.- PCM role

Ok PCM controls the ability to start/run and the central timer handles locking and unlocking doors and receiving the fob commands.- W-T Ground wire mod - Informational warning

I have to admit I bought the typical ring terminal to fit. Mine was more of a thin plated copper. Then solder the ring terminal on. The issue was being thin copper it just tore. The replacement is much thicker which is automotive style either crimp on or solder on. So then like the saying Dodge makes it and Cummins shakes it. The thin copper ring gave up.- I know this is sudden but...

I'm back home. I've got much more to do yet. I've got to make phone calls to get started on chemo treatments. Then I'll have my final operation to remove the bladder and prostate. I was shocked tonight by a friend down the road when he told me you are now officially retired from being a mechanic. True. I am no longer going to be crawling under trucks doing dual disc clutches like I did just days before. This is NOT the end of Mopar1973Man... I now transforming into a whole new person and going to have to change the way I work. Simple. I now have the time to do the website and get the store back up and working. Yeah, I gotta balance between what I'm doing medically until the end. Then I need to have purpose too so the Good Lord shuts the door of the shop to me but now I can go back to schooling people on how to build a badass street machine that does the jobs you need done without sucking the fuel tank dry. I see so many positive things coming soon just because of my health issue. Then I finally ended up a retired mechanic, but transformed into a business owner and will be of the management level and will end up having to bring in a crew to do the dirty work. Still, even with everything that's happening to me, I can't stop being part of the Cummins Community. Never going to happen.- I know this is sudden but...

YES!!! I've got a green light to head home. I've got most all tubes and wires off me. I've still got the two bags coming out my back. Yes I'll be heading home at about noon. I've got to get my discharge papers and then I can split. Yeah those are my scrubs from home. No I didn't steal them from the hospital. But alot of nurses thought I was part of the staff.- Tuning Assistance

@Tractorman is right on the money. Tire size Gear ratio Transmission type Turbo Injectors (size and pop pressure) Towing you want RPMs between 2,000 to 2,500 for optimal power. So if you are running oversized tires on 3.55 will make your EGTs high. Example of Beast at 82 MPH. So optimally you want a final ratio of 3.73 for towing and highway. Like myself I'm running 245/75 R16 tires on 3.55 gears which nets me a 3.69 final ratio. Screenshot is about is my Beta test of going for high MPGs during winter and experimenting with higher coolant temps to gain a little more power and lossless some of the waste into the coolant jacket. Another view of running I84 at 80 to 82 MPH. Oh just keep in mind I'm running 2,450 to 2,500 RPMs at 80 MPH so as you can see good eco numbers.- I know this is sudden but...

First step I've got to get released from the hospital to get home for even a short time. This bed sucks, mattress I've got caved in. I'm seriously hoping they pull the catheter out today and get me ready to head home. Then I can work on food and more rest my style. Being stuck in a bed and allowed to get up and move without a nurse really kind of sucks.- I know this is sudden but...

Good news. I might get to go home soon. My first doctor from back in 19 looked me over and is going to see about getting me out of here. I've got to put in some walks today to gain my strength and I'll get to go home for awhile and schedule other procedures like I've gotta do chemo. Make sure we shrink it all down then have it all removed.- I know this is sudden but...

Thanks. I'm going to make it. Managed to get breakfast this morning and then walked the halls with 2 nurses. I'm more sore around the ports they put into my kidneys than my bladder being scrapped out. That's the weird part I never had any serious pain in my bladder area after the first surgery. It's nice I'm sitting on my bed right now and looking out the window at Boise Idaho which is hazy today here in downtown Boise. Just got a shot at getting my face shaved and washed up some and feeling more human after being pinned in bed for the last 2 days. Even got my laptop out so I can type a response to you all.- I know this is sudden but...

Update for everyone. I'm alive doctor did his first exploration surgery for scraping my bladder out. Sadly I'm going to lose my bladder and prostate. I'm all good with that. Right now they are trying to save my right kidney. Strange enough there isn't any pain even the whole week before just a normal day. So what happened is since I've got a super high pain tolerance I did even know that my bladder was cancer loaded again till the bleeding started. My life will change. I'll no longer be laying on the shop floor doing clutches like my last 2 Tiktok videos I posted. Don't worry guys and gals I'll continue to support the Cummins Community from my website. Might have to find a apprentice to replace me and teach my knowledge too. Even with my health issues I'm going to keep trucking. I've got a great crew already covering me from home and down here in Boise. Mark Hall and Jakob Jackson is watching over my home. Mark is dealing with my last two jobs back home easy stuff doing injectors and the other truck rebuild the front and change fluids. Tianne Blynn (and family) my bookkeeper is down watching over me in the Boise valley. She going to take care of the hospital bills and such. So when it done I'll be peeing in a bag but I will be 100% cancer free and alive. I appreciate all the get well wishes and love all of you. I might get discharged here in a few days possibly. We will see. I'm like a Cummins engine I can take a beating and putting down the miles. Promise to keep you all up to date. I've got my laptop so when I get freed up to walk again I'll get sat up and get busy on the laptop.- I know this is sudden but...

I'm alive still after the surgery but this one is going to be tougher to handle. This time the cancer has obstructed both of my kidneys so this is like second day of my no food or water diet. Sometime today I'm going to have drain out of both sides of my back for my kidneys. They have to clear up my plumbing so my kidneys can drain. Strange enough that I was working on a clutch job for 3 days and did a trip to Lewiston. Next day I started to bleed light, by Wednesday it was really bleeding. I'm finding out I've got a super high pain tolerance. Which this is getting me in trouble. Never even knew I was having issues till the bleed. Update seems this is going to be a long road. I'm going to have to do chemo this time. Being the cancer tore up my bladder pretty bad the doctor is opting to removing my bladder and prostate. Yup I'll be on a bag but I'll continue with life. This might slow me down for wrenching but I might finally get back to doing web work doing what I wanted to do. Doctor assured me I will survive but I'm going to be missing parts.- 2nd Gen Cummins heater temp differences between trucks

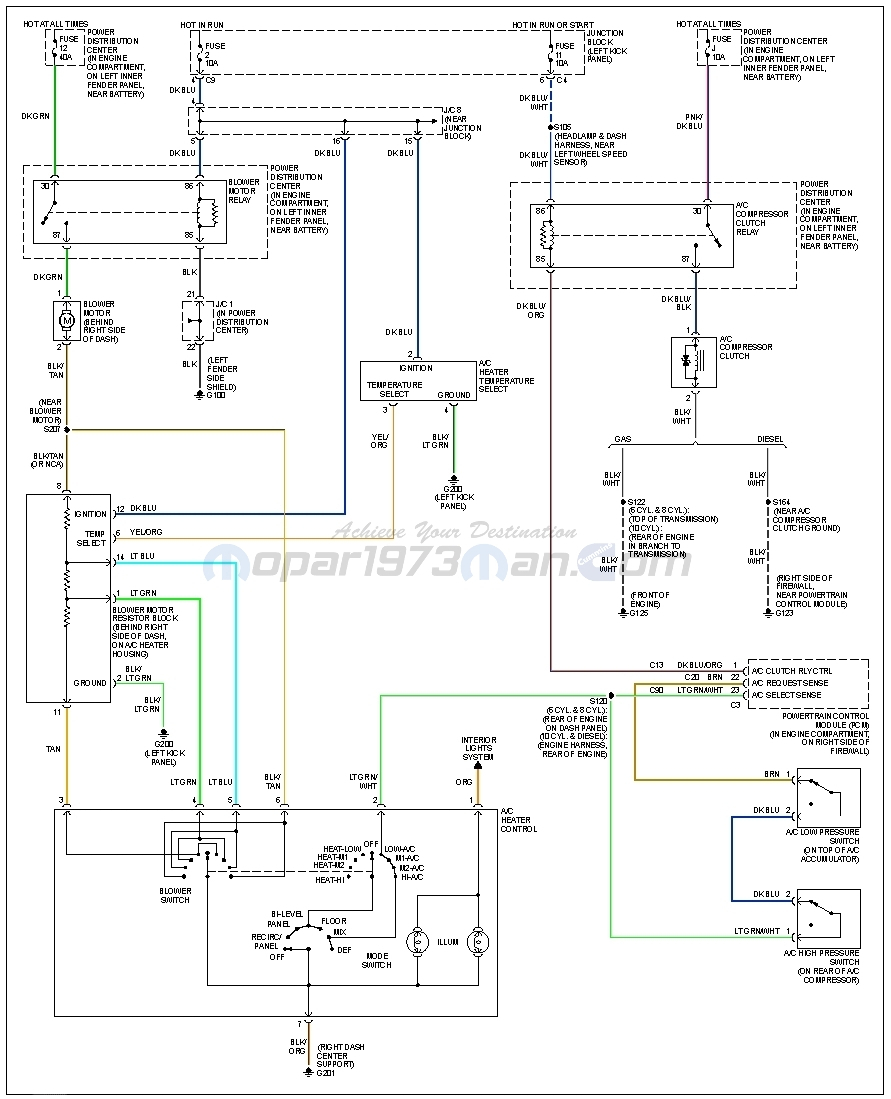

I know this has the old school fan switch but the wiring is the same for later 24v truck. There is nothing different to the early and late blower motor wise. I think there is less restriction on the Max A/C setting more so than power difference at the motor. Recir air will always warm faster as long as your A/C compressor is not over whelping the HVAC like my truck likes to do most days. I tend to use the bi-level setting while driving but even that will possibly pull the temp down more with my A/C compressor going. - W-T ground wire mod - Simplified