Everything posted by Mopar1973Man

-

Lower engine noise with bio diesel?

Ah... I'm smart enough to catch fuel delivery trucks and talk to the driver. Like I found out that Maverik Fuels in McCall the delivery driver doubles the dose of PPD (Pour Point Depressant). Typically when he delivers down in Boise ID they only add half of the PPD. I'm always doing my research and talking to people to get facts. Hence why I've never had to use Anti Gel Products.

-

Shock! Unknown order coming?

No. My MPGs will be triple digits. Keep guessing.

-

Lower engine noise with bio diesel?

How about 461k miles (21 years) and never used any antigel products? I don't even have a bottle even in the shop. Seen winter temperatures as low as -40°F and never had any issues.

-

Spring is fast approaching!

You are just as bad as @Honey Badger she blames me for all the snow that is coming. I'm used to seeing at least 2 to 3 feet in my yard but right now I got like 2 inches of snow and more mud. Now at @Honey Badger house in Lake Fork which is about 40 miles from here, they just got another 1.5 feet of snow. She calls it spring storms I call it winter yet. Spring storms here are heavy downpour rain storms. By April I can fire up my water system again. McCall / Lake Fork will be in the freezer till nearly June. Just depends where you live and the elevation you live at. Here is 2,860 feet and Lake Fork is just barely 5,000 feet.

-

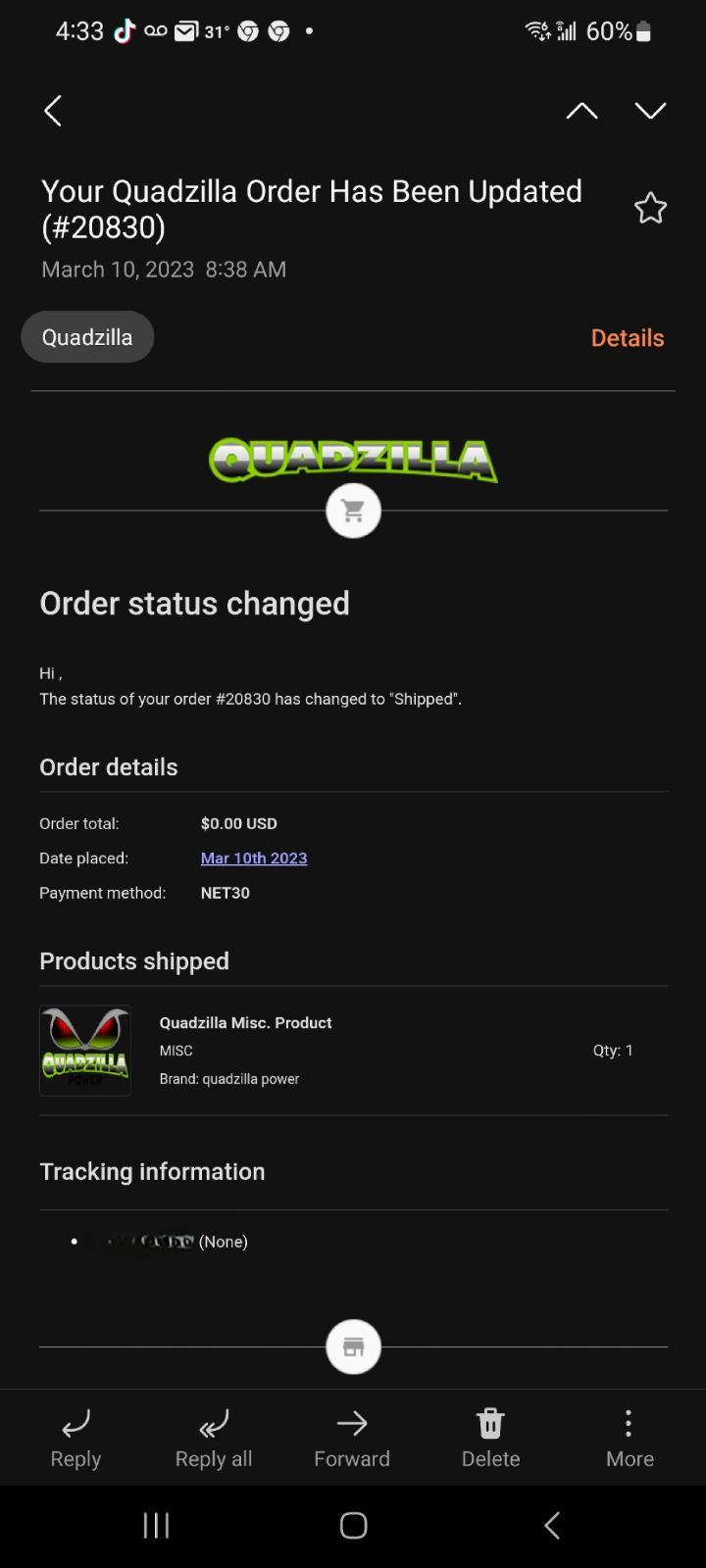

Shock! Unknown order coming?

It's not much of a surprise if I give away all the answers right away is it? Might also be a new product for the store as well. First I've got to give my personal opinion on the product when I get it. Let's say it's an accessory item that some of us will be wanting. Oh, I love keeping you all guess what can it be? Oh, the excitement to find out what goodies Quadzilla happen to send me...

-

Lower engine noise with bio diesel?

Be aware standard petroleum anti-gel will not work for bio-diesel. You have to find a product designed for use for bio-diesel. This is a big problem for guys like in Minnesota that have only bio-diesel and most standard products will not deal with bio-diesel being it's made from animal fats or plant matter. Not the same problem that petroleum is paraffin wax and bio-diesel could be like bacon grease, animal fats, etc that petroleum diesel anti-gels will not handle so be aware of that.

-

Spring is fast approaching!

Yup McCall just got like 20 inches of fresh snow last night. Then we are forecasted for another 3 to 5 inches of snow in the high mountains tonight. Spring is a ways off yet.

-

Shock! Unknown order coming?

Yeah, I got up this morning I've got emails from Quadzilla about a product being shipped to me. Not sure if something went wrong with the store or a hacker. So being smart I called @dieselautopower and talked to Lenny and I guess Jacob Kidd has a new toy he wants me to beta-test for him. So in a few days I'll tell you guys what I got.

-

VP44 replaced, Injectors replaced, now P0112

Wire tap hooks to the fuel solenoid lead. Then the tuner will extend the pulse on the fuel solenoid in microseconds.

-

VP44 replaced, Injectors replaced, now P0112

Yup, there is but the only thing that sensor does is report the cam speed which is the same as the VP44 (half of the crank speed). Then there is a fuel temp sensor that reports the fuel temp in the VP44. The P0112 code is the IAT sensor IIRC is low volt code meaning the sensor line is shorted to ground. Remember the IAT sets timing on the VP44 basically in a nutshell if IAT falls below +80*F then ECM calls for an extra +3 degrees of timing. When it rises above 80*F then it retards the timing. As for things hooked ot the PSG. You have a electronic solenoid to control the fuel pin for throttle. Then you have the hydraulic solenoid to control fuel pressure to advance and retard timing. Then the one sensor that sees the cam speed and the fuel temp that's all there is there is no other magic or witchcraft inside the PSG. You can see that sensor here right of the PSG. Here is the tone wheel... Look at the mainshaft and you can see the tone wheel for the sensor.

-

VP44 replaced, Injectors replaced, now P0112

The ECM provides timing information based on RPM and engine load which is based on throttle position.

-

VP44 replaced, Injectors replaced, now P0112

If you purchase a Bosch Certified pump it should have a NEW PSG module. If so it is sold blank which means it will be ran on a Bosch 815 test stand for 3 hour to calibrate and test. After passing all test then the PSG is flashed. It is policy for all Bosch certified builders to core out the old PSG and replace. One's that reuse the old PSG are not a certified rebuiler and are not test standing the rebuilt pumps.

-

Final Ratios

I know there are a lot of guys out here that love their oversized tires and I will admit they look super cool. Now to make it all come together and make it a rocket ship on rails you need the proper final ratio. Optimal for most daily drivers that are here optimal final ratio to the ground is 3.73:1 after the tires. The problem is any size larger than a factory 265's on 3.55 gears is going to lower the ratio. I created a chart of the final ratio with some tire sizes to see the results. Subscribing members only...

-

Quadzilla Temps

So... 122*F - 40 = 82*F outside temp roughly. Typically the intake and fuel temp will match on a long run. IAT is typically +40*F higher than outside air. You'll find that no cold air intake will change this being the intercooler does all the work. Turbo will create heat when compressing air. Engine oil temp seems pretty good. Just a bit high meaning either the vehicle is heavy or being worked hard. Possibly timing is set up wrong. The lower the engine oil temp the better. I typically float 158*F to 165*F. The coolant is spot on for temperature. Just remember Cummins ECM CANBus can't show temps over 204*F and it will flip over to -40*F. Big questions... What is your cruising RPM's at 65 MPH? What is EGT's at 65 MPH? What is your boost at 65 MPH? What is your timing at 65 MPH? Clues to gaining the best... Stock HX35W and +150 HP injectors... 66 MPH is 2,000 RPM Boost at 65 MPH is 2 PSI EGTs at 65 MPH is 550 to 600*F Timing at cruise state is 23 to 25 degrees at 65 MPH. Going higher to 80 MPH. 80 MPH is 2,450 RPM Boost at 80 MPH is 5 PSI EGT's at 80 MPH is 600*F to 700*F Timing at cruise state is 27 degrees at 80 MPH. Make you think... On working with me to get a solid tune...

-

Fass install

Look at the engine where the lift pump should have been. It will be an aluminum bypass block and the wiring has been extended toward the rear.

-

98.5 crank no start

@Auto Computer Specialist would be my first step. Give them a call and see if they can help you... Their list for contacts are in the Vendor list and also in the Vendor forum.

-

Boise Trip

Actually did really good but running CANBus tuning didn't take much get Beast side stepping in 4WD. Instate travel was impressive running 2,450 RPMs and floating 600°F. Engine load was about 22% on the flat. Mo bing through the snow power wasn't an issue it was just keeping a strong hold on the wheel keep Beast heading straight. Being I was running 3rd and 4th most of the way home MPGs are down plus the added drag of the 4WD and deep snow.

-

Boise Trip

Well, yesterday was a heck of a trip. So, @Honey Badger had some shopping to do and help her oldest son with his taxes. I also had a few items to pick up from the stores down there. The evening before we were talking about taking Minnie down but when I looked at the weather reports it said 50‰ chance of snow. We packed up that morning at 9:30 am and headed south. Everything doing good weather was sunny and warm, roads were clear and dry. Fast forward to the evening, we had dinner with Honey Badger's son, her father was there, and @Tatted Hemi and I were discussing web stuff. We left Boise at 8 pm and headed home. By the time I hit Weiser ID it was snowing (2,400 feet), I was thankful we took Beast. It was horrible. I plowed highways 3 to 9 inches deep. By the time I hit Midvale Grade my average speed was 45 MPH. Oh, it gets worse. Hit Council ID and Fort Hall Grade and I was down to 35 MPH chugging along in 4th gear. New Meadows ID last 20 miles I was down to 25 MPH and nearly see 2 truck length at times couldn't see the road edges. Made it home at 1:30 am and got to bed at 3 am and packed in our shopping kinds of stuff. This was so gnarly of a trip my left shoulder and hand are sore from Gorilla Grip on the wheel and fighting deep snow. Beast did extremely good, few times she would sidestep sideways pulling a bit too much power on hills. We are tired and sore this morning be we made the trip safely and no issues.

-

98.5 crank no start

That center bolt you have to be careful not to over torque the bolt. I've seen several that broke the nut assembly inside the PDC. Then the but spins inside and never really tightens.

-

Surging

Just understand dead pedal is part of the safety software to prevent WOT runaway. So when the APPS value goes out of range the ECM ignores the APPS sensor value and uses idle software for safety. I sure would not like it if the throttle went wide open with no way to stop.

-

P1291 No temperature rise seen from intake air heater

We try to help out where we can. He's right it can be difficult some times to understand what is going on. Suggestion is grab some photos with your phone and post them up then we can see what you talking about.

-

boost elbow questions

28.2 MPG hand math. I did another trip from Seattle WA filled the tank drove 300 miles across Washington to the Idaho border and used a touch more than a 1/4 tank across the entire state of Washington last summer. Even this winter with temps as low as -20*F I was still holding close to 22 MPG running 25 degrees of timing at 2,000 RPMs. My current tune is way aggressive timing at a cruise state. Under power, it drops to about 18 degrees at 2k RPMs and flat tucks tall and bails down the pavement. Oh give me some time and I'll be getting the Quadzilla added to the store very soon. https://store.mopar1973man.com/2nd-generation-24-valve/tuners-programmers.html

-

Well, I messed up..

Yeah, you gotta look closely for cracked fuses. I've seen fuses that cracked and look like they are whole and not blown but still don't work. Blown fuses are a little easier to see.

-

Master Cylinder Tip

I've got boxes of stuff either from Beast or Thor I've got piled up on the top shelf. My problem is eventually I find someone that needs that part and it goes bye-bye out the door in someone else's truck.

-

1991 W250 12V, wiring nightmare

Sound like someone needs to go over to the Download section pull up a Dodge FSM for that and look over the wiring maps. The key switch typically turns off both of those unless someone has created a new path by wiring modification. I would look under the dash first for modified wiring.