Everything posted by sngsht

-

transmission

Dropping the pan on mine ('06) took about 7 1/4 qts. to refill, you should have a reusable gasket and as long as it's in good shape I'd use it. No leaking or issues after reusing mine. Here's a link to a basic how-to on your bands. http://forum.mopar1973man.com/threads/8025-Replacing-Governor-pressure-solenoid-and-pressure-transducer-adjust-bands-in-a-48RE

-

Possible 5th gear nut fix for the NV4500.

Looks like a pretty good idea..

-

Need to be schooled in Big rig driving...

That's some great advice there! Every time we broke in a new driver, I just went ahead and ordered a clutch brake for his truck:doh: Loved the 9 spd's, I learned to drive in a old Tandem dump with a 534 Ford gas , and a 5X4 trans LOL what a pain that dog was.. My Favorite was a Old White with a strait piped ,big cam Cummins, 9 spd. It was horrible on a tight job-site because the turning radius was about 4 football fields, but the sound of that old Cummins, with the turbo making boost was pure music..

-

Concealed Carry......................Finally

I'll agree , you can cover a 1911 with a very loose fitting shirt, that's left untucked, but for honest every day carry, especially in warm weather, it's going to be pretty difficult to consistently conceal anything in a OWB holster. I actually started out carrying a 1911, but for T-shirts and warm weather ,casual wear, it just didn't work for me . What works great for one , may not work at all for another, everyone's different. Ultimately crafting my dress code around a firearm wasn't my goal . I wanted one that that allowed me to incorporate it into my normal, everyday routine, be accurate and dependable, and have the lethality needed for it's purpose.

-

Concealed Carry......................Finally

That's good to hear! I saw that the Gov. had veto'd the bill, and was impressed when they overrode it:woot:! - - - Updated - - - Open carry definitely has it's plus side, unfortunately in my neck of the wood's ,it can also cause a "disturbance" so even though it's legal it only takes one nervous nellie to get you spanked for inciting panic. I bet the Star would be pretty tough to conceal at though! I carry a Kel-Tec PF-9 7+1 capacity,just put it in a IWB holster and no one ever knows it's there even in a T- shirt.

-

Camper installed and heading out for some fun.

Wow! That's a pretty slick set-up!

-

Possible move to the NW...

Hope it all works out! I'm not sure if it's much help but my son is stationed in the Seattle/Tacoma WA area,and I was shocked at the cost of living there. Everything here in the peoples republic of Ohio seems about half what it is out there,the flip side is their median income (where he lives) is double what ours is too, so it's kind of a wash..I think it's in the high 60's low 70's range? Beautiful country with LOTS of rain...

- From the Northwoods

-

Replacing Governor pressure solenoid and pressure transducer,adjust bands in a 48RE

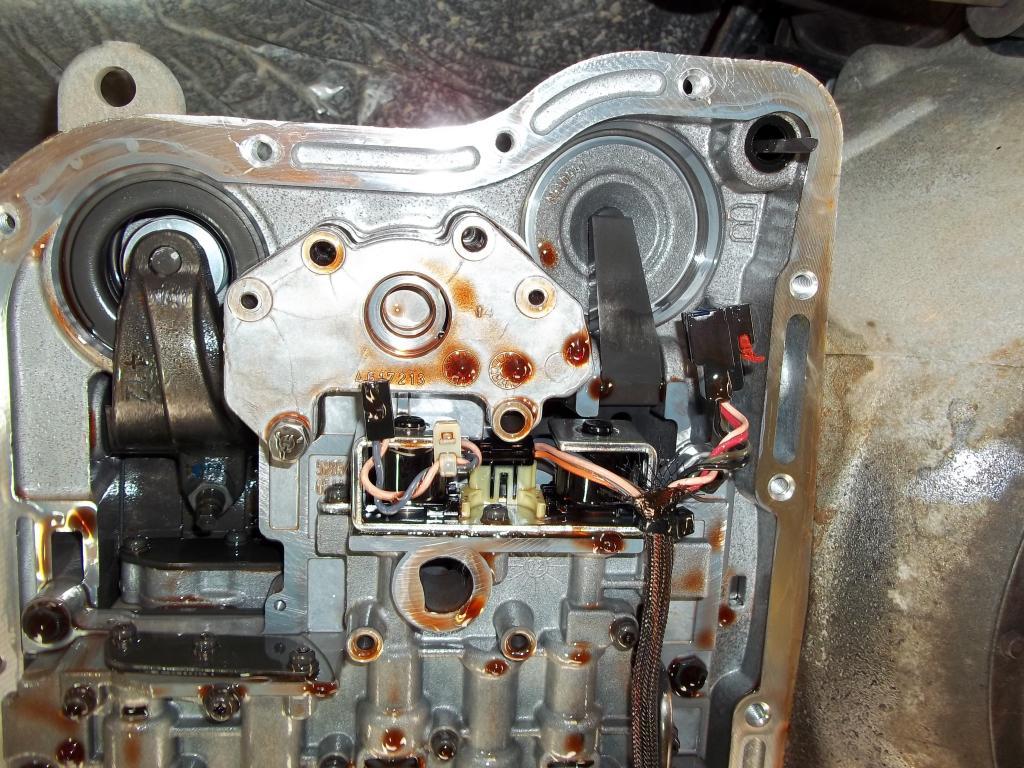

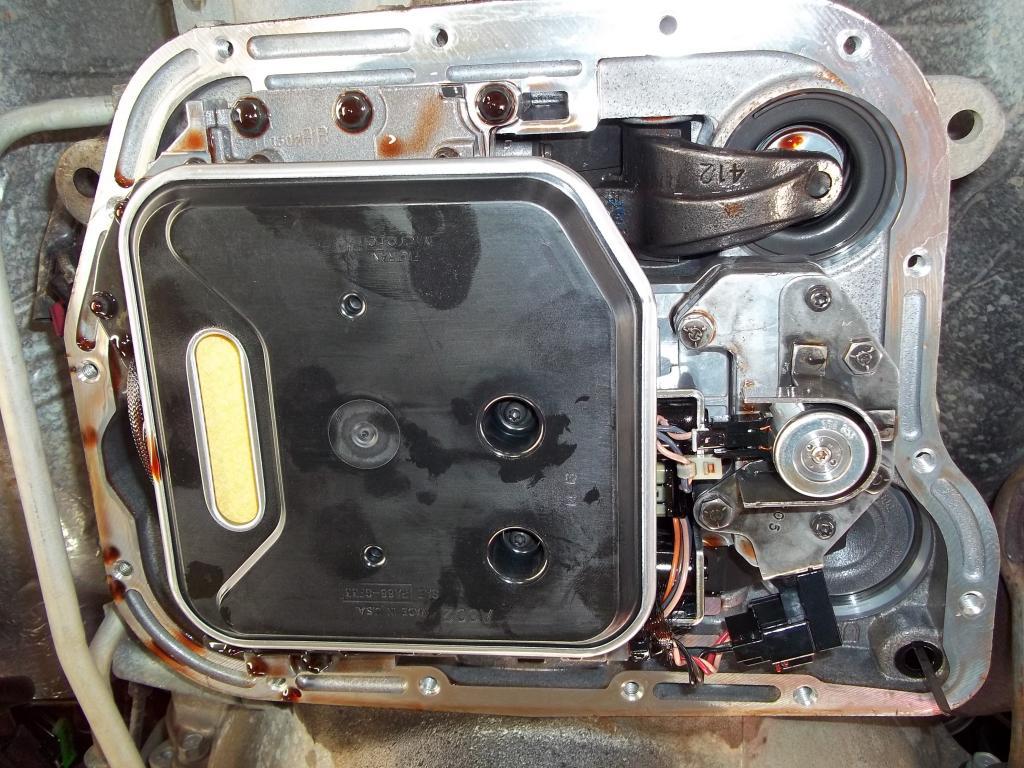

I took some pics as I did mine last week, and thought I'd try making a write up on it. Basic tools etc. you'll need are , approx. 8qts. of ATF+4/filter,Governor press. solenoid and transducer,1/4' drive torque wrench, 1/4" & 3/8" socket sets, basic metric wrench set, a pick or small screwdriver, a drill with a 1/2" bit for the drain plug kit, big catch pan:thumbup2:, and a paint pen or sharpie,plus whatever I forgot:ashamed: 1) Drop pan to drain the fluid, the easiest way is to go around and loosen them all just a turn, then work from one side loosen the bolts in steps. The idea is to get the pan to drop on only one side to minimize spilling and dump the fluid off a corner- easier said than done. I'd recommend putting a drain plug in the pan while it's off ,to make draining the fluid easier. 2)Pic of the Solenoid and transducer, I used the Borg-Warner 50185 Solenoid upgrade instead of the OEM , recommended because of it's larger magnet, and the difference in my shifts is amazing.. 3)Remove the filter and there they are, your going to need a torx bit-T40 I believe and socket to drop it out, but first you'll need unplug the the electrical connectors to the solenoid and transducer, go easy with them ,the hot cold cycles tend to make them brittle. 4)I removed the two torx screws and bolts, leaving the bolt closest to the rear band adjuster in, this will hold the base on the valve body,no risk of gasket damage doing it this way.At this point you can pull gently on the stamped retainer and the governor solenoid will pop out of the base,since its held in a slot in the retainer. The transducer will remain , just make a note of it's orientation and then pull it out as well. If you notice, there is a slot in the retainer that indexes to a groove in the transducer also, thats to hold it in after reassembly Comparison pic old vs. new. 5) Slide the transducer into the spacer after coating the o-rings with some ATF, make sure that it's turned so that the slot will line up properly with the retainer ,oil the o-rings on the solenoid and slide it into the slot in the retainer.Hold it in the bracket ,and reinstall the opposite of how you removed it,just make sure the retainer is lining up with the slot in the transducer as you guide it in. It should go in easily, if you have to force it stop and verify everything's all lined up, before you go primal on it torque all the fasteners, hook up the connectors and your done! Eezy peezy.. 6) Now's the time to adjust the rear band, it's a easy job but it has to be done right,if you don't do it properly, bad (expensive) things are probably coming your way. That being said, crack loose the lock nut, and back it off 4-5 turns so it doesn't bottom out as you tighten the band. Get yourself a 1/4" torque wrench and 5.5mm socket.Tighten the band to 72 INCH lbs then back off 3 full turns ,hold the adjuster (very important) so it doesn't turn as you tighten the locknut-25ft lbs. Here's a couple of tips, use the paint marker on the adjuster to make a reference mark, AFTER you've reached your final torque.Then carefully take note of it's location and back it off the 3 turns. Then after you tighten the locknut, this mark also gives you a positive verification that it hasn't turned, as you tightened it. It's much better to err on the loose side band adjustments, too tight is probably gonna break some parts. I personally like using a beam type wrench so that I can see it coming up on it's final torque, and I also back off the torque values by 10% since it's a worn in band- right or wrong that's my opinion only. I don't have any pics but,the front band is essentially the same procedure. Its a little difficult to get to and if you have one, a crow foot wrench will come in handy! Back off the lock nut a few turns ,use a torx bit to tighten the adjuster to 72 INCH lbs. then mark it and back it off 1 3/4 turns ( I went 2 turns because of my err a bit on the looser side opinion) then hold firmly as you tighten the lock nut- if you can torque it great! your a better man than I,there's just not enough room in there for my pudgy hands :shrug:a wrench and a torque wrench, just wing it ,it will be fine.. 7) Install the filter 8) Pick a spot on the pan where your sure the drain plug wont interfere with anything, drill a 1/2" hole ( at least in my kit) and install per instructions.This kit had a o-ring for the plug seal, only no groove to retain the o-ring when you tightened it, so I replaced it with a fiber washer.Install the pan, tighten the fasteners in a criss -cross pattern and fill with fluid. 9) I started with 5qts. of fluid ,fired her up and let it idle in neutral , and then added more fluid, while checking for leaks, as needed to bring the level up to full. Your done! Take her for a drive and recheck for leaks , and fluid level.. -

-

Gut convertor?

Your preaching to the choir ,when it comes to the 2 stroke oil! After reading all the charts ,I'm sold on it's long term benefits, even if they aren't something I can "feel" performance wise..It's affect on the convertor was just something that hit me the other day when I was under it doing the trans service. I assumed given the nature of a diesel, that the Cat's. on them would have to be more tolerant of fuel/oil in the exhaust than the gasoline version,but still was curious. Thats the great thing about this forum that i think sets it apart,there is almost always a a definition as to why something works or doesn't work..Not to mention, quite a bit of factual detail in the explanation or even opinion concerning the issue..Kudo's to you guy's ,that's for sure!

-

Gut convertor?

I was running 1oz per, but cut it back to 1/2 oz per gallon as several had suggested..I personally think mine was a bit quieter at the 1oz level,but warm starts may (or may simply be my imagination) be just a bit quicker..

-

Gut convertor?

I'm running 2 stroke oil at approx 1/2 + oz per gallon, think this will have any long term affect to the convertor? I know oil in the exhaust on a gas engine, will mess one up,how about long term on a diesel?

-

Gut convertor?

Testing isn't a issue, but the truck is all stock.. Just wanting to get as much air flowing as possible, with as little drone as possible..

-

Gut convertor?

I've been bouncing the idea of gutting my Catalytic convertor around in my head for awhile. The theory is to increase exhaust flow obviously, but I've been reading all sorts of conflicting theories. Anyone have any experience with this? Pro's/Cons??

-

How can you not,love this...Diesel power S.A. style...

Love the full tandem burnouts

-

How can you not,love this...Diesel power S.A. style...

https://www.facebook.com/photo.php?v=432382420202774

-

Cab lights installed

Nice write up!

-

Tires: Treadwright

They must use that new math..

-

Chicken Pluckers anyone?

Wow,that thing works pretty slick, can't get much easier than that! I'm thinking the music might need a bit of tweaking though, I kept waiting for Ron Popeil to jump in from the side and, want to sell me two for one low price:hyper:

-

Governor pressure solenoid,band adjustment?

Thanks for the Video,can't get any more descriptive than that!

-

Governor pressure solenoid,band adjustment?

I'm going to change my 48RE trans filter and fluid next week (65,000mi) and while the pan's off do the bands as well. I occasionally get a shuttle shift at very light acceleration, and after doing some reading I'm also going to replace the Governor press solenoid with a Borg-Warner one, and the pressure transducer also. I figured the cost of those wasn't alot more than the fluid will be, so might as well do it while the pan is off.A couple questions, approximately how much fluid am I going to need to pick up for this? Replacing the solenoid and transducer look pretty straightforward, but is there anything I need to look out for? Been a while since I've done bands, I was planning on using my beam type torque wrench for the torque but, I have a clicker type also (I just never trust 'em:pray:) do you think it would work better for this? Thanks!

-

Squeak - Rotational high pitch

A wear indicator on a worn brake pad will sound similar also, and a caliper that's binding will cause a vibration at lower speeds also. That's a easy thing to check , and eliminate .

-

Replaced one wire on the starter. Now truck will not start, no click at key turn.

I'm learning A LOT I didn't know! Just a thought ,since the other starter wasn't hitting the ring gear,do you think the spacer might have been stuck to the nose of the starter that was returned? Or are there different starters, and it's a crap shoot which one you get when purchasing a Reman?

-

Replaced one wire on the starter. Now truck will not start, no click at key turn.

Now that, would get the old ticker going!!!

-

Tires: Treadwright

Cooper still puts the dot on their domestically produced tires (at least at our plant) The tires come out of the presses,go thru inspection,then on to the balancer's that grind the white letters, and give them a finish grind if needed. Then mark they mark the heavy spot before kicking them down the line..The Chinese manufactured tires I've seen don't have that mark, and have a lot of runout and balance issues - we rework A LOT of our China made tires. - - - Updated - - - Two things come to mind here, I know airing up is the right thing to do when hauling ,but anytime there's daylight showing on the sides there's some sort of issue. The first obvious thing to me is the pressure is too high ( sidewall composition will affect this,so regardless of what pressure used on the last set,this set may be different) , in order to wear properly they must have the proper (full) contact patch. This may be why some have found they seem to drive better after the carcass wears in, it will absolutely affect handling and wear, probably causing it to run hotter as well? Perhaps the tread package has to much of a crown built into it to allow running the proper PSI, without running on the centers?? The other is ,have you tried rotating them? I've always went by the old school adage, that you never switch the rotational direction of a radial, I don't think it's a critical now as back in the day, but it never hurts. Perhaps the belts were "broke in" with a different rotation, and maybe rotating to a different side might help?