Everything posted by sooxies

-

99 Engine swap - engine year 55 block

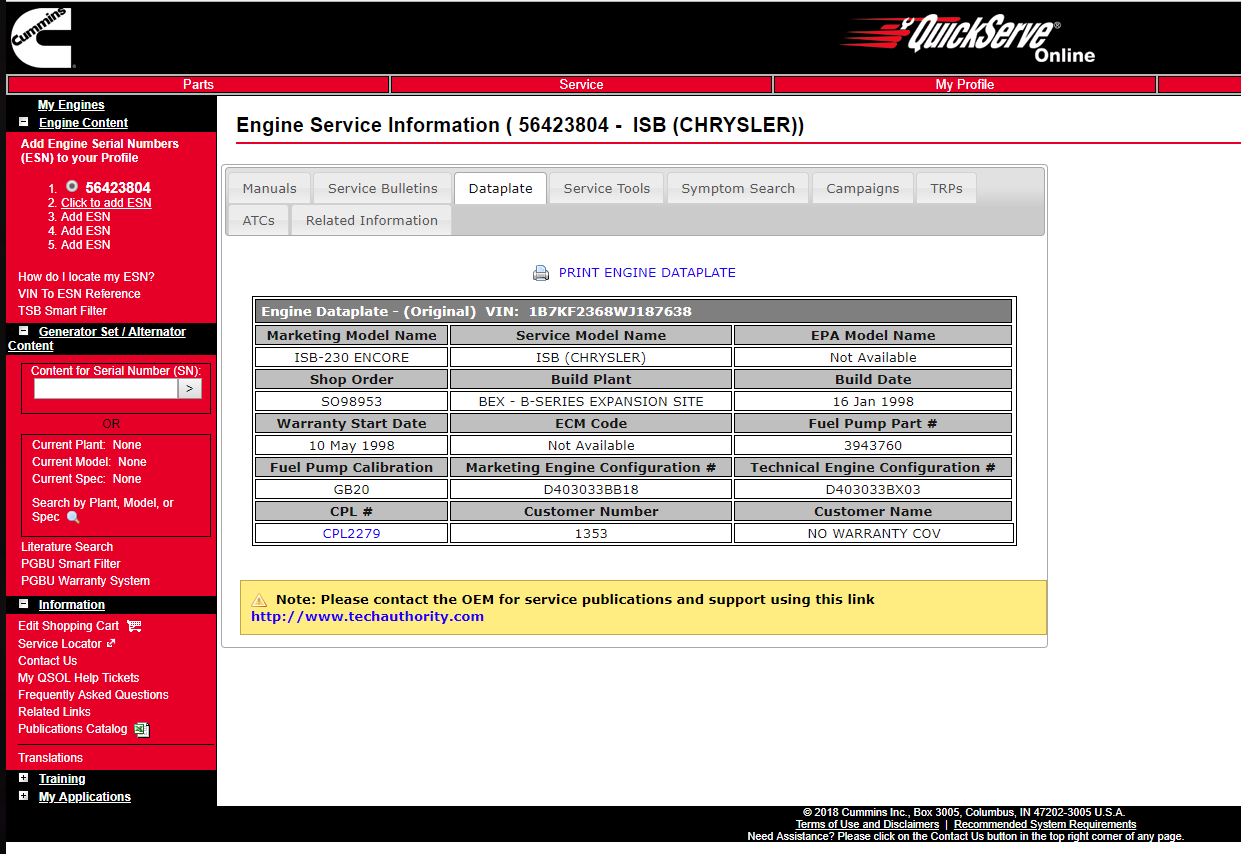

@SavageTusk You can also do it through Cummins QuickServe. https://quickserve.cummins.com Make a free account and add the ESN.

-

**5/6 Speed Owners** Which way are you routing your gauge wires into the engine bay?

@Mopar1973Man Awesome. Thanks! I'll try the main harness grommet this time. Is it a tight fit? I suppose it's not. I think that's what swayed me away from doing it the first time. Was worried I'd be slitting into something and it may not end up working in the long run.

-

**5/6 Speed Owners** Which way are you routing your gauge wires into the engine bay?

Straight and to the point! Rewiring my three gauges. Just wanted to see/hear what people have setup for getting their sensor wires past the firewall. Thanks!

-

2001 24V charging issues

Absolutely check for high AC noise!

-

98.5 Electrical Issues

@Mopar1973Man @adamey1000 @Nekkedbob Jeez....that wouldn't be a loose ground wire for the PCM could it? I barely touched it and it slipped right out of the crimp. I can only assume this will fix my issue! Thanks for the help fellas! Learned a lot about electronics in a short amount of time. Time to re-check for AC noise and then ground wire mod. I did order these cables from custombatterycables.com and they are very high quality. The crimp sleeve that came with it to splice these wires was a dumb move on me but I needed to get the truck on the road at the time. Time to learn how to solder. I feel they should emphasize to solder these wires only. Why even include a the crimp? Again, I should have known better.

-

98.5 Electrical Issues

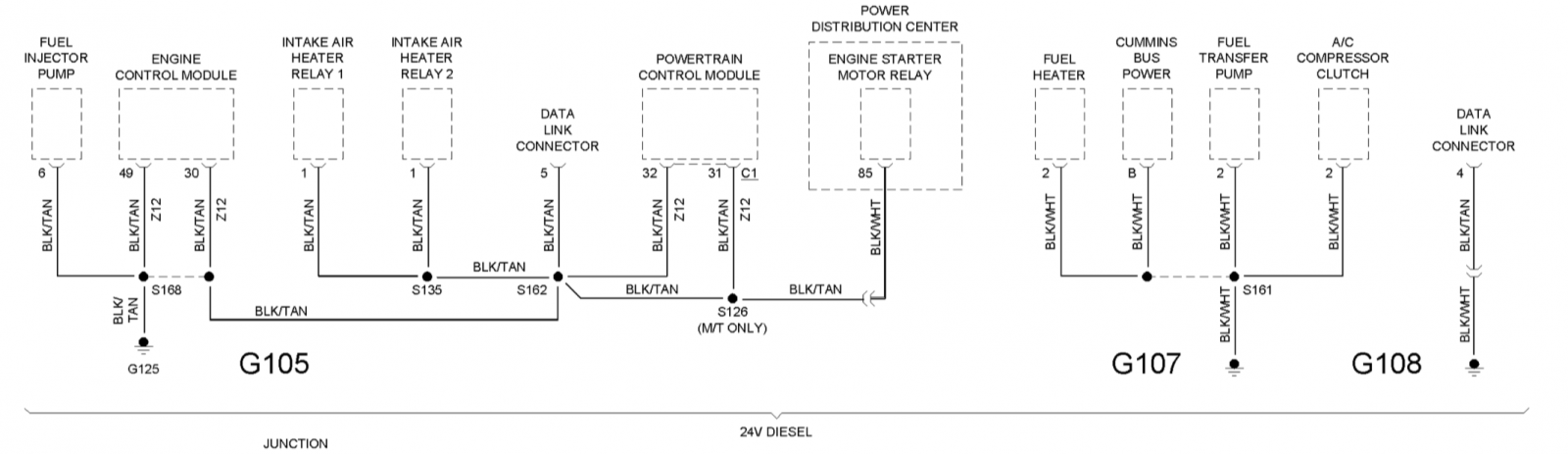

Alrighty. Confirmed the parasitic draw is coming from the OBD2 port. I see only 19 milliamps when i have my scanner plugged in. Getting somewhere slowly! Now onto wire chasing. I went into my 1998 FSM and it states that pin 5 eventually ends up at G105 and pin 4 at G108. I wish the grounds were labelled like yours are MoparMan. Still searching through my FSM. It's obvious wiring changes were made all throughout the 98-02 24-Valves. One day at a time...making progress.

-

98.5 Electrical Issues

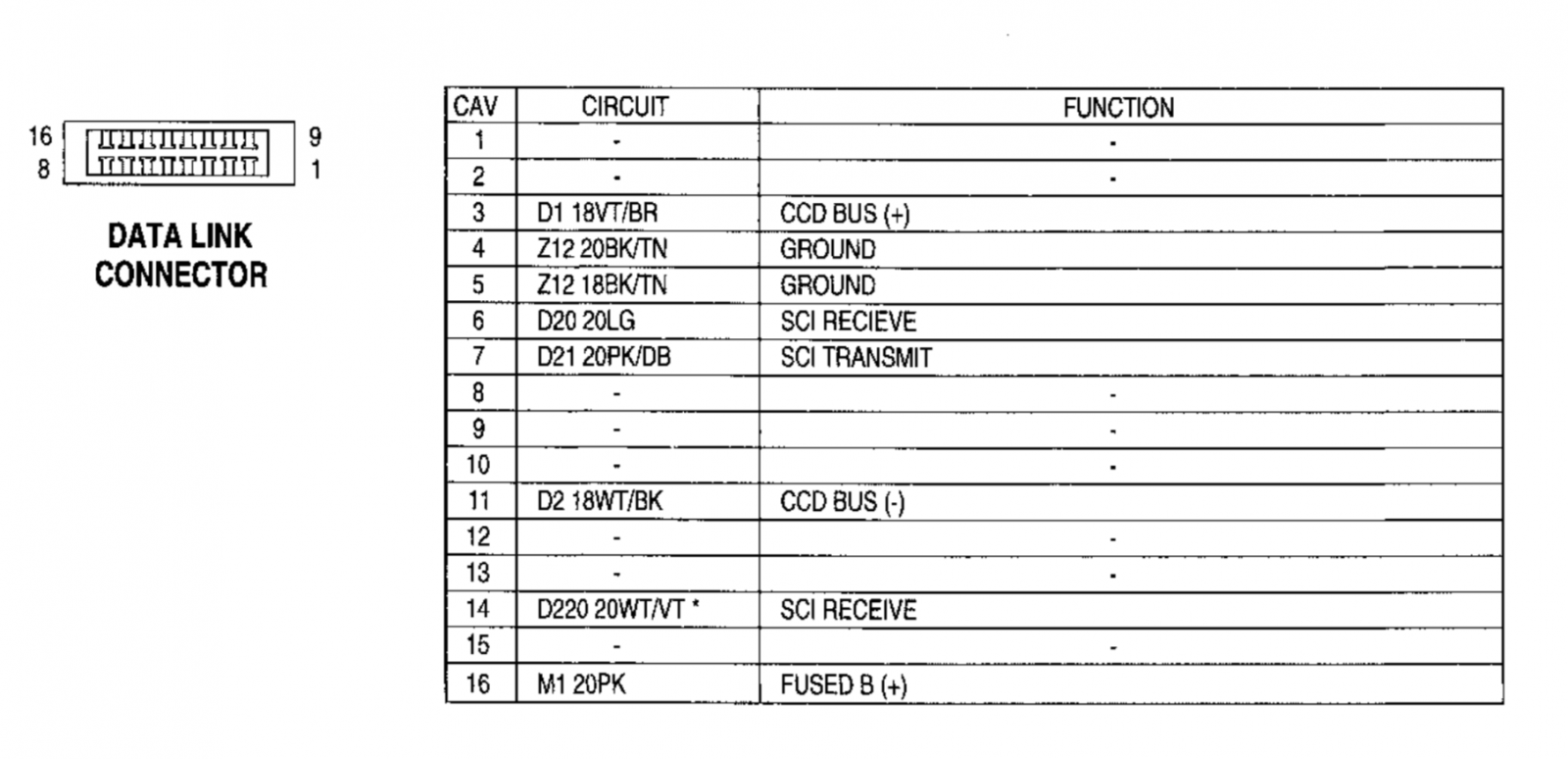

@Nekkedbob Seat belt checked out fine. It did take about half hour but they did lock up as they should. Going to repeat and test for draw after 30 minutes. The clicking noise I was hearing was coming from the AC compressor. I unhooked it and the noise went away. Again, was only hearing this when my scanner was not hooked into the OBD port. @Mopar1973Man I'm getting correct voltage at pin 16 (which I assumed). Not sure if I did this correctly, but for pins 4 and 5 I grounded my meter under the dash and then probed 4/5 on ohm's setting...Pin 4 read -1.9 and Pin 5 I could not get a reading (just read OL). So is pin 5 the wire I should trace?

-

98.5 Electrical Issues

Yes. Thank You! I did run across someone mentioning the seatbelt. I will report back tomorrow. Thank you to all!

-

98.5 Electrical Issues

Update. WTS light functions as normal with OBD2 scanner plugged in (all lights appear to be normal as a matter of fact). So would this be a grounding issue? At least for the OBD port? Check engine is functioning and scanner shows both codes as noted above. So in regards to that, with my multimeter, how do I go about testing the wires on the data port? i.e. AC/DC/volts/amps/ohms?

-

98.5 Electrical Issues

@Mopar1973Man Is it safe to assume the ECM is in need of repair/replacement with the WTS light issue? Or is there any reason a separate electronic issue could cause this?

-

98.5 Electrical Issues

IOD fuse was showing .153 DCA when the interior lights are on and then when i hold down the door sensor (device that turns lights off) it drops down to .023 DCA. PDC Fuses... 40A Tailer .095 50A Battery .378 When I turn to key on engine off I hear a click and then when I take the key back i hear another click. As if something is clicking on then off. Unfortunately not seeing WTS light immediately when key is set to on position. There is no key in the ignition at all and the photo is showing what I am seeing. Doesn't look like it but the WTS light is quite dim and both indicators are just sitting there illuminated.

-

98.5 Electrical Issues

Going to try and keep this from becoming a long novel...I basically have 2 separate issues in 1 thread (might be related). Long story short, I have been having these intermittent surging issues since late May of this year (happened 4 times I believe). Fast forward to now I am dealing with three things: P1693 P1698 High Parasitic Draw For the longest time I was getting a solo P1693 with my scanner which as I understand cannot exist by itself. I also was having issues erasing/reading codes (sometimes). For whatever reason, I unplugged my only added electronics (gauges) and I finally got the 1698 to show up on 8/22. I'm not sure if unhooking them actually helped me or if I was just lucky to get the 1698 to show. Anyways, truck started fine but idled rough (same symptoms I had in the past). Also, I just so happened unhook my scan tool while the truck was idling and it would die immediately once the OBD port lost connection with the scanner. I come back from a trip (8/26) and my batteries are almost completely flat (just bought a new Fluke multimeter so I was anxious to try it). I'm currently doing a parasitic draw test and I'm finding that unplugging the IOD fuse helps significantly reduce the reading on the meter but is still reading high. Not sure how many milliamps is normal for these trucks when they are just sitting. My dilemma is that I don't even know what to attack first. Would it be logical to go after the parasitic draw issue first before the codes? Or are they related? Any thoughts with the truck dying when a scan tool was unplugged? What other items would be good to check for parasitic draw other then unplugging fuses one at a time? I understand the IOD fuse controls a handful of things including the OBD port so I'm sure something could be said about that. My AC noise was within spec with my former multimeter but I will now retest with my Fluke (once I charge my batteries back up and assuming it will start) So far I have not found any blown fuses. My alternator is new. Batteries/cables/terminals were all replaced not long ago. All ground coming off of the batteries were checked. I have the wiring diagram for the 1998 model year truck. Still trying to understand everything when it comes to electrical but I think I'm learning fast. Detailed instructions are greatly admired once we can figure out a plan of attack. I will respond as fast as I am able to. Thanks!

-

24V fuel filter fittings help

You want to measure your fuel pressure after your filter(s) to know what is going into your VP44. From his pressure tee he runs a 90 degree fitting, a needle valve, and then air brake tubing up to the sensor (unsure if he uses a snubber as well; he can confirm). I did the same thing. I did not bleed the line completely so there is a gap of air which I thought would keep pressure off of the sensor. Gauge read normally. Again, the goal is to monitor fuel pressure, post fuel filtration, while not destroying the sensor in the long run.

-

24V fuel filter fittings help

I'm not sure about FASS but if you had an Airdog all you would need is a Big Line Kit (from a place like Vulcan). If i recall, the Airdog fitting that goes into the injection pump is the same size as the inlet for the fuel filter housing. You would just cut your hose (shorter then normal) to the fuel filter and then run the big line kit from FF to IP as normal. INSTALL A FUEL PRESSURE GAUGE IF YOU HAVEN'T YET. NOW IS THE TIME.

-

Is There Something I'm Missing With These Head Bolts??

24 valves are ISB engines. Interact System B (electronically controlled). Anything labeled QSB is the heavy duty version. 6BT would reference a 12 valve (6 cylinder, B-series, turbocharged). Photo is from the Cummins 3666193 manual.

-

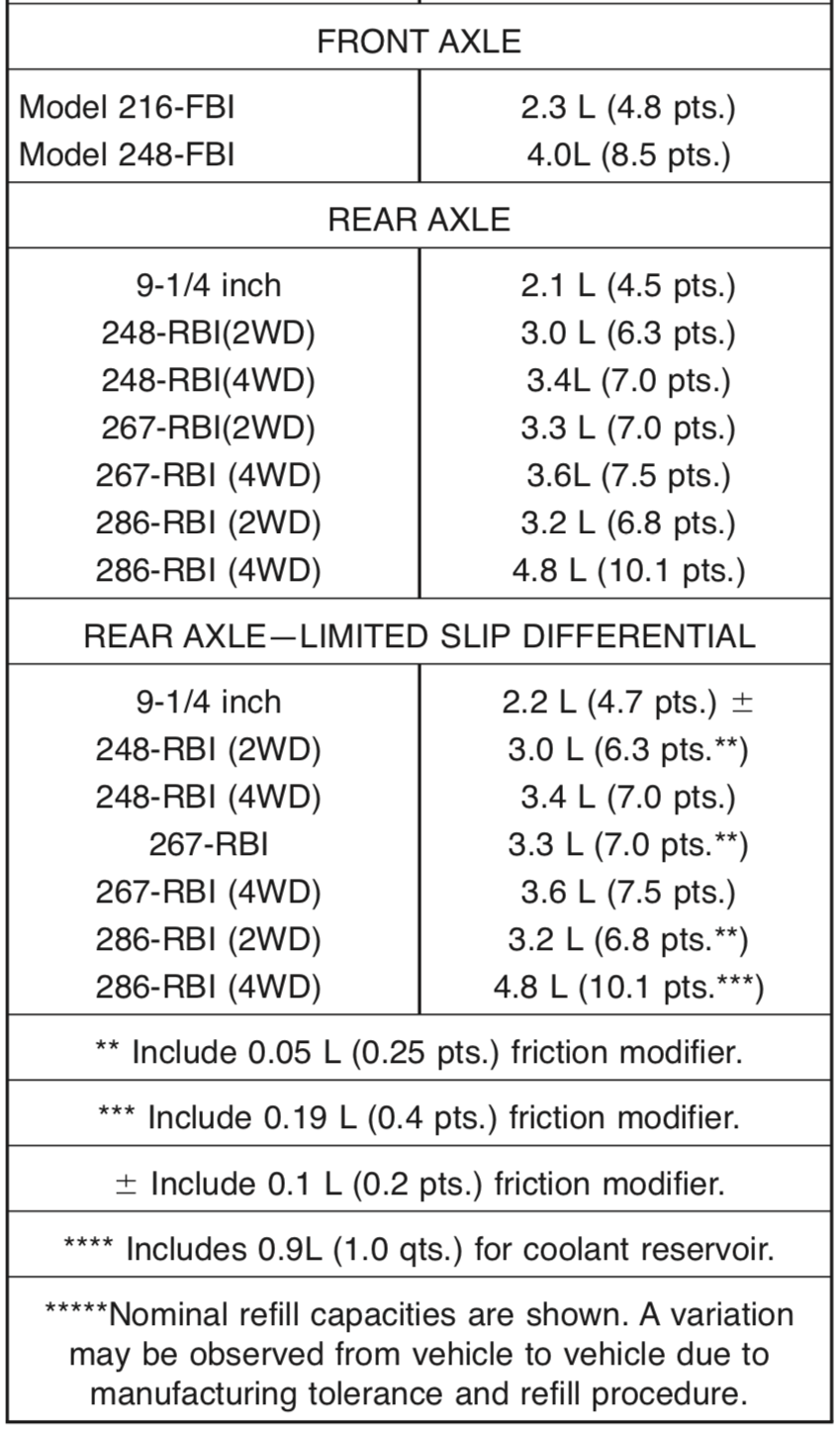

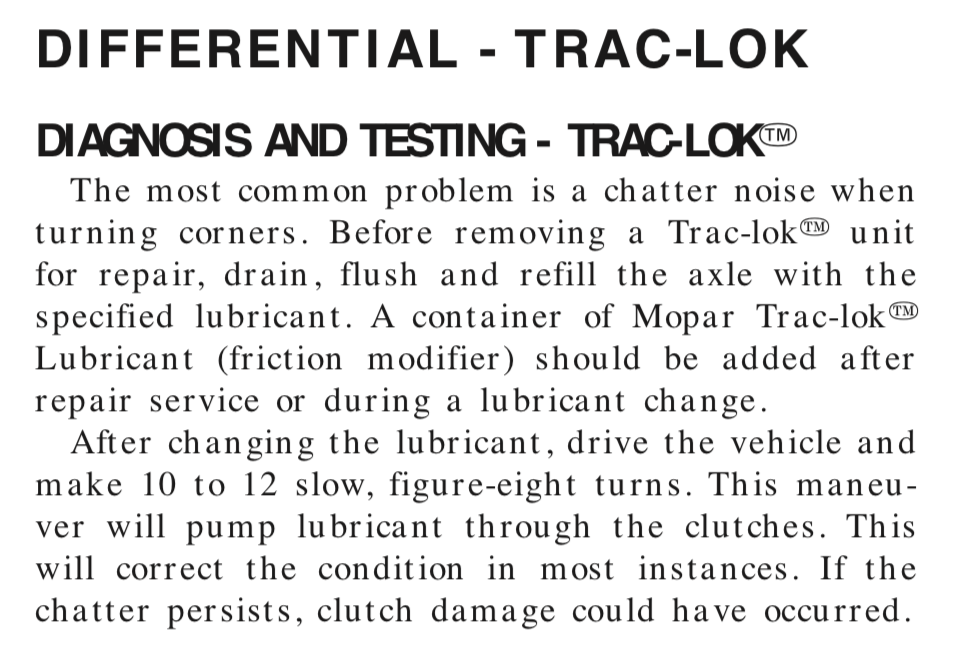

Diff fluid change

286RBI is the Dana 80 Also note the procedure with the figure-eight turns...if you do find you have the limited slip option.

-

Found a twin...

...almost identical. But it is an automatic and a slightly later year based off of the alloy wheels. Small world

-

241DHD T-case rebuild kit

https://torqueking.com/ Has anyone dealt with them? Formally quad4x4.com A lot of people used to recommend them as they carried the original NV4500 fluid.

-

CHEAP EBAY APPS?????

Just read this entire thread to only to read this. That's a shame.

-

Aaxle slop

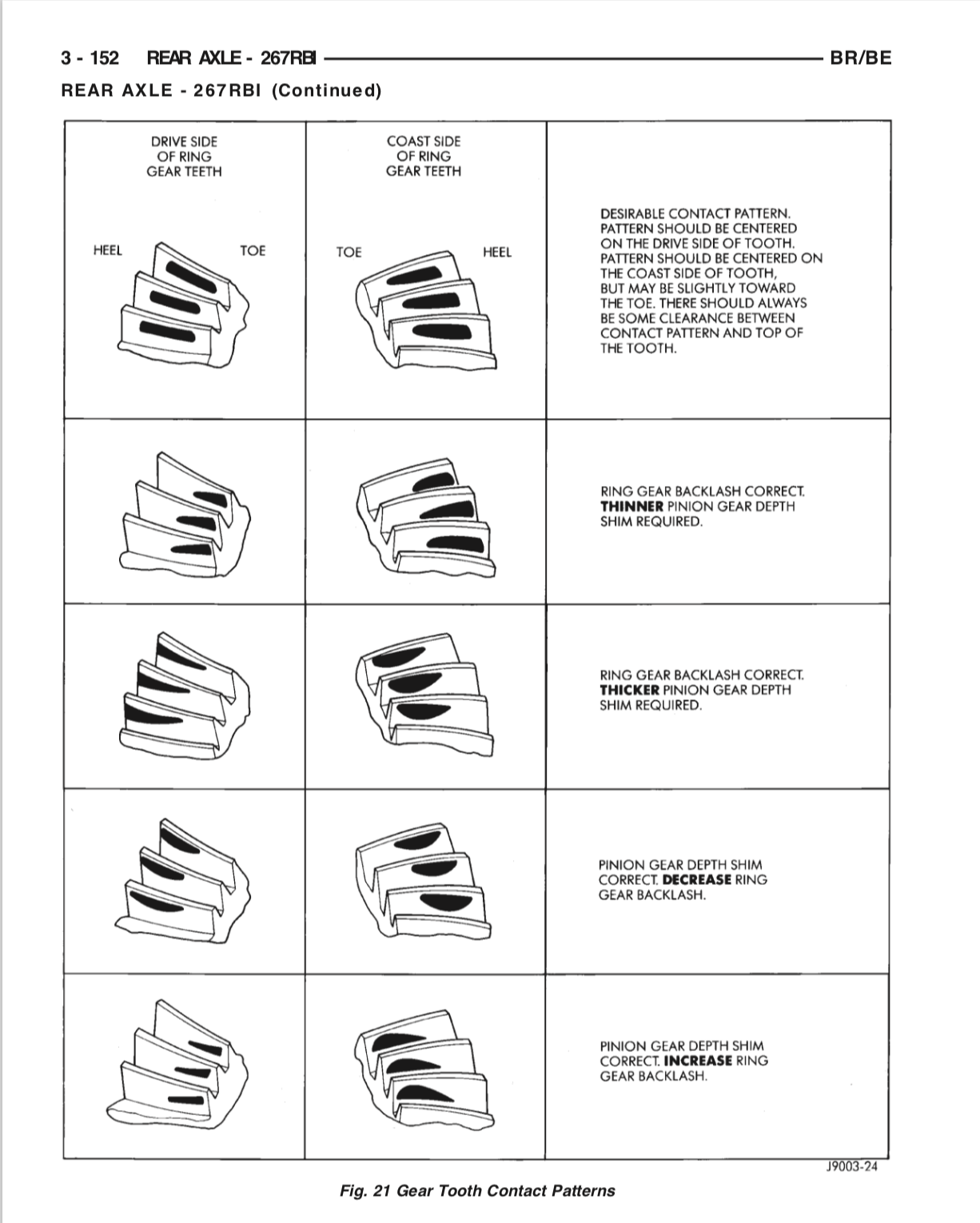

I attached a service manual for the Dana 70 (PDF). Also in the Dodge FSM... (267RBI is the Dana 70) For info, any of the Dodge factory service manuals go into great detail as well in regards to disassembly/install (as one would expect). Dana 70 FSM.pdf

-

ECM OR VP ISSUE

Do you have a fuel pressure gauge installed? If not, now is the time to make an investment in one. I've just been going through the p0122 code. Installed a Timbo APPS and code has not come back...for now at least (confident the sensor was toast and was not a ground issue).

-

VP/ECM Issues?

Let me rephrase a little from my second post... While driving 55-60 on the freeway, the RPM's started to drop almost to the point of the engine dying. Almost instantaneously, the RPM's jump back up to normal which in my feeling caused the truck to lunge forward. This is all within half of a second approximately. You felt it as if you were slowing down then immediately felt that lunge forward once it regained it's normalcy. I'm confident that the metal-like clunk I heard the first time was something in the drivetrain as a result of the truck jerking forward. I inspected everything visually and felt for anything loose (all was normal). I've been recently wondering if it is possibly a fuel-related issue. I'm thinking I will warranty my fuel pump. I supposed it wouldn't hurt assuming I can make it happen. Sadly the sending unit went out for my fuel pressure gauge. Fuel pressure was within the normal range when the gauge was last working (which was before this happened). Due for a new fuel filter so I have another one on the way and Autometer said that the sending unit is serviceable so I need to get it sent out.

-

VP/ECM Issues?

This is just a little update... Today was my first issue since this thread was started. Was driving 55-60 on the freeway and the truck bucked/surged. This happened within a matter of half a second I'd say; it was really quick (just one single jolt forward). The motor did not die (might have come close...not sure) and it came back to normal within this very quick moment. Once again...no CEL. I did hear the door chime ping once (as if there was a dashboard warning). Zero codes on the scanner.

-

VP/ECM Issues?

Finally I have something to post about. I haven't had any issues so I've been lurking. Sadly this could be an expensive one? Let us discuss... Today I'm out driving to an appointment, all is well. Take a right hand turn and hear a loud bang, more-so a metal clunk (almost sounded like a u-joint snapped on the driveshaft). I immediately notice a slightly odd idle at the next stop light. Go about another block after I make the turn and the truck starts bucking/limping, practically no power. I noticed a little bit of white smoke out the exhaust when under load (but not idling). Made it off the road into a parking lot and I'm thinking textbook bad VP44. During this entire time I never got, and still do not have, a CEL on the dash. I turn the engine off. Next, I turn it back on and the vehicle is now running normally and has been ever since. Only getting a 1683 DTC with my scanner and nothing else, which I find odd. I am not sure in which module the DTC is in because my scanner has odd labels for the ECM/PCM. But I will soon confirm which one it is in. My past DTC's in the month of May were: (These DTC's below are not currently showing just thought it would be worth mentioning): P1682 -Replaced alternator and code has not come back. Confirmed bad alternator by bench testing it. P0122 -Code came back 1 week later after clearing it. Cleared it once more and did an APPS reset simultaneously and the code has not returned. Pretty puzzled at the moment. I can go out right now, crank it up, and it runs normal. No bucking, smoke, rough idle, loss of power, and no CEL. I'm starting to think ECM but we'll see. Thanks Fellas UPDATE: Getting no codes now. Not one.

-

17” 3rd Gen Wheels

I could possibly be the only one here who's powdercoated third/fourth generation wheels. I'm very pleased with how they turned out. I really wanted to keep the original finish but this was the easiest option. $60/wheel to blast and coat. Fast turnaround. An establishment who specializes in it should be able to do any color you desire.