Everything posted by Tractorman

-

Radiator leak

Rather rude to change the subject like that. What's up with that? Oh, that's right, the subject is Radiator Leak. Good to hear you got your radiator in. - John

-

PS Pump Replacement

I had the same issue with the drive tangs on my OEM pump during the same repair (mine at 176,000 miles) on the vacuum pump. Like you, I thought that kind of wear was excessive and premature. At that time the steering gearbox was a 4 1/4 turn from stop to stop and the tires were stock, so there was no additional stress on the power steering pump. - John

-

rear brakes adjusting to tight

@Nekkedbob, it seems that you have a unique situation. I don't think anyone here is challenging your knowledge - I know that I'm not. But, I also know that when very unusual problems occur, sometimes I have to sit back and rethink things, kind of start over. By starting over, I mean set the brake adjustment as it should be. Then monitor the performance regularly as I mentioned in my previous post. At least then you should be able to find out which is the problem side (if it is only one side). If it turns out to be both sides happening simultaneously, that will be good information to know. This would be another strong reason to start over with diagnosing without changing anything first. You need to know which brake assembly is the problem or if both brake assemblies are having the problem at the same time. That information alone would be of great help to move ahead diagnosing the problem. You have provided a lot of information, but you haven't given much detail. For example, you said, "And yes it has been checked for residual pressure and none has been found." What were the conditions when this residual pressure check was done? If the check was done when the brakes were hanging up, the results of the check would have value. If the check was done hours or days later, then the check would have absolutely no value. Like you, I have done a countless number of rear drum brake repair work. One of the most overlooked things I have observed (even by qualified brake specialists) is the parking brake actuator not being backed off enough to allow both brake shoes on both sides to set firmly against the anchor pin. They may mount the brake shoes correctly on one side, but when the brake shoes are installed and compressed to set on the anchor pin on the other side, energy is transferred through the park brake equalizer, consequently energizing the park brake lever on the previous side which will promptly move the brakes shoes away from the anchor pin. That action usually does not get observed. The park brake cables must be relaxed considerably for this not to happen. I don't think this is contributing to your problem, but it is still worthy of mention. I am really interested to hear what the final fix is going to be. - John

-

rear brakes adjusting to tight

If the cable is removed, there nothing to stop the adjuster from backing off and reducing brake performance. A manual brake adjuster should be used. It has a much coarser, rounded tooth pattern with a spring clip that locks the adjuster in place. I agree. Personally, I don't think it is a self-adjuster issue, but I could be wrong. If it was my truck, I would figure out what is actually causing the problem before making an assumption it is the self-adjusters and then modifying the braking system based on that assumption. I would start by adjusting the rear brakes in a normal manner. Then I would just drive the truck. I would frequently check the brake drum temperature carefully by hand so that I would be aware of the heating of the brake drum / drums before it got out of hand. - John

-

Throttle linkage stuck at idle - cannot accelerate

@01_Cummins_4x4, I have had a Timbo APPS on my truck for over 70,000 miles now. I have also removed the plastic shield. So far, I have not experienced your situation. Plenty cold over here in Baker City but, I haven't started the truck outside in below zero weather, just driven the truck into areas of below zero weather after the engine is warm. I would suspect the throttle cable. It could be that throttle cable housing is shrinking enough in the extreme cold to clamp down on the cable. - John

-

rear brakes adjusting to tight

This is an excellent idea and an easy step that will have informative results. I was going write that in my original post, but I forgot to do so. I seems that I forget many things, but I don't worry too much because shortly I will forget that I forgot. - John

-

rear brakes adjusting to tight

In the first quote you mention "brakes" as in plural. In the second quote you mention "they", which indicates plural again. So, I am understanding that both brakes on the rear axles are overheating. It is highly unlikely that a self-adjuster will cause this - especially in both drums simultaneously. By nature, a self-adjuster can only move the adjuster when there is enough movement in the brake shoes. Even if the brakes are initially adjusted too tight, the self-adjuster cannot grab a tooth on the star wheel until the brake lining has worn enough to allow for enough brake shoe travel for the self-adjuster to grab the next tooth on the star wheel. I highly recommend to not do this. There is something wrong with the brake system. The problem needs to be resolved, not skirted around. When I have situations that are very difficult to resolve, I go back to fundamentals to help arrive at good conclusions. I seek help from people who understand and can explain the fundamentals well. Unfortunately, there are fewer and fewer people around who know drum brake systems well, since the drum brake system is becoming obsolete. That being said, the thing that I see being repeated in your posts is that both rear brakes are overheating at the same time. You also mentioned, "and the pedal has moved up to the top of the travel". This could indicate a hydraulic problem - specifically, brake fluid is not making its way back to the reservoir when the brake pedal is released. A possible source could be brake master cylinder. The first 1/8" forward movement of the dual piston in the master cylinder covers up the compensating port of each piston bore. These compensating ports allow for thermal expansion and contraction of brake fluid when brakes are not applied. If the pistons do not return to their home positions, then brake fluid can be trapped in the brake lines which would not allow for the full return travel of the brake shoes. Over time the brake shoes creep toward the drum surfaces and finally begin to drag. If the hydroboost unit has been replaced at some point in the past, then the pushrod length adjustment could cause this anomaly. Also, there should be some sort of a proportioning valve in the rear brake hydraulic system as well as the anti-lock brakes for the rear axle. These are potential sources of the problem. I am not saying that these things are the cause of your problem, but a possible hydraulic lock would match the symptoms you are having, including the inconsistent time intervals between events. Backing off the brake adjustment and starting over would just mask the problem. - John

-

Replaced batteries, Quadzilla no longer works.

A trickle charger is going to void the warranty!? If I would have bought a programmer that stated that in the manual, I wouldn't install the programmer. I would put it back into the box, send it back, and get a refund. If I were in your shoes, I would challenge the manufacturer regarding that statement. By the way (just my opinion), but you are much more likely to damage an electronic component when operating the said component during an abnormally low voltage condition, such as when you were trying to start your truck with low batteries, which everybody in the world has done at one time or another. Also, the normal large voltage fluctuations from using the starter motor and / or grid heaters are far more disruptive than the fluctuations that could ever come from a trickle charger. Really..., a trickle charger will void the warranty?! - John

-

Grid Heater Delete

Here's my theory for here in the United States. Sometime back in the '70's, the big wigs of the Big Three (Ford, GM, and Chrlysler/Dodge) were having trouble deciding which direction to go - "metric" or "imperial". First one says, "Let's go with metric. It is much simpler and actually makes sense." The second one says, "I think we should stay with imperial. Everyone already knows it and to change tooling would cost a lot of money." After much discussion, the third one says, "Let's do both!" They all agreed unanimously, and it became law. - John

-

True HX35

If everything is working normal, I would think well over 20 psi boost should easily be attained at wide open throttle with a loaded truck on a Smarty tune. My truck has an HX35 with a blocked wastegate and I could easily attain 30 psi boost by 1800 rpm's on a mild Smarty tune when I had 300,000 miles on the OEM injectors. Something is amiss. - John

-

Borgeson steering shaft

Yes. Calling it a telescoping part is better terminology. A slip yoke or a telescoping part serve the same purpose - in this case to allow for axial movement of two joined steering shafts. Normally one would not think of movement between the cab and the truck frame, but there is because the cab is not rigidly fixed to the frame. This minor movement will cause varying degrees of axial movement at the telescoping point of the intersecting steering shafts. I think that others who use the Borgeson steering shaft may have or have had this same problem to a varying degree. It can be difficult to diagnose. You and one other that I have heard from have observed this particular problem. However, I have read of a few others that have had set screws that keep coming loose. I think that the friction in the telescoping part was likely the cause. It does make sense to me. The set screw would remain tight when rotational force is applied because there is a key or splines that absorb the rotational load. But when an axial force is applied (even a small one) it is the set screw that absorbs the load, thus working its way loose. Also, any axial force would negatively impact steering wheel operation. In my opinion, using multiple set screws to hold various steering shaft parts together is not a failsafe design for a steering mechanism. Most other designs incorporate a flexible joint fixed by hardware that can't allow for an unintentional disconnect of the any part of the steering shaft. - John

-

Borgeson steering shaft

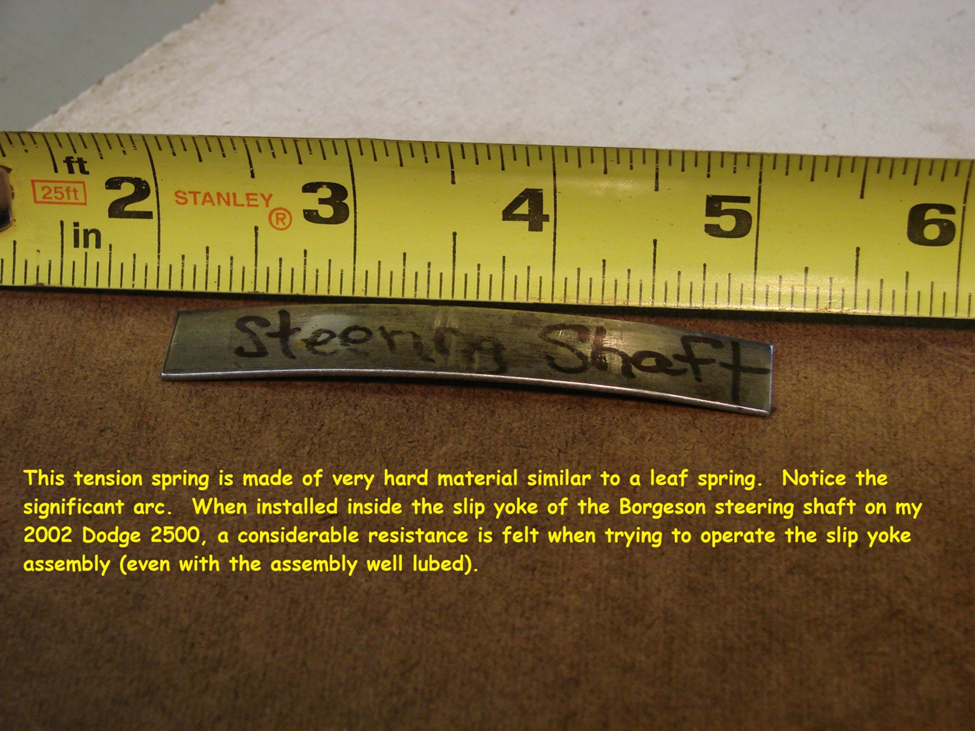

Even keeping it lubed did not help me. I have had the Borgeson steering shaft for about 150,000 miles now. The first thirty thousand miles almost drove me nuts. It took 30,000 miles of driving to figure out that the slip yoke was binding - but not all of the time. When it did bind, you could hear a click and feel something in the steering wheel. When the symptoms occurred, the truck steered poorly. Also, set screws would come loose on the upper end of the upper steering shaft. I kept thinking other things were wrong with the steering. Finally, I disassembled the slip yoke. Each time thereafter when I disassembled the slip yoke, I would see a couple of places where the grease was completely wiped clean. I also noted that there was more friction than I thought there should to operate the slip yoke. The photo below shows a tension spring used in the slip yoke assembly. I even reduced the arc in the tension spring, but I still thought there was too much tension. I finally just removed the tension spring. From that time forward the steering completely changed. No noises, steering operation very smooth, and no more loose set screws ever, for the last 120,000 miles. After going through all of this, I am now fine with the Borgeson steering shaft. But, one needs to be diligent about checking the tightness of the set screws. The set screws will not loosen unless there is an underlying problem. In my case, the underlying problem was the random heavy axial load placed on both pieces of the steering shaft due to the high resistance in the slip yoke. Once I removed the resistance, all was well. - John 12-16-2021 Borgeson Steering Shaft.docx

-

Disappearing Brake Fluid

When the master cylinder is low, the fluid will be split into two separate reservoirs. One should have been empty and the other should have remained at the top level of the dividing wall. If you observed which one is empty, it would help you diagnose the problem. Be sure to check the rear brake line between the frame rail and the fuel tank. Since you live in the rust belt, your truck is a candidate for a brake line rusting through from the outside. - John

-

Suddenly didn't want to start.

That is the classic signature of air leaking into the fuel system while parked. Park the truck with nose facing uphill again with a 1/4 tank of fuel for a day or two. I will bet the problem will be back. With the truck parked on level ground or nose downhill with a relatively full fuel tank, the symptoms go away..., until the leak worsens. - John

-

Another radiator leak thread, this the season

Yes, you can do that. I did it when my OEM radiator began leaking at the plastic seam. You will lose coolant until the radiator seeks its own level - kind like old vertical flow radiators did before coolant overflow bottles. The top two rows will not have coolant flowing through them, but that is okay for an emergency. @Mopar1973Man's method is much better. No loss of coolant and 100% capacity of the radiator. - John

-

Melted battery terminal

@IBMobile and @Mopar1973Mancouldn't have said it better. I would disassemble, inspect and clean all of your battery connections and battery grounds. - John

-

Another radiator leak thread, this the season

As far as altering this valve permanently, this would not allow pressure to build in the cooling system. It is the high limit of the of the pressure relief valve in the radiator cap that allows coolant to reach a boiling point of approximately 245°. Cutting the valve for @Doubletrouble's situation is a good idea, especially since he wants to drive the truck while waiting for his new radiator. The coolant will pass back and forth to and from the overflow bottle without building pressure. T If he marks that cap and keeps it in the boonie box, then he will have a cap on hand in case it is needed again under a similar situation. I edited my post because I didn't like what I wrote the first time. - John

-

True HX35

It is going to take a long time to answer all those questions. Good questions, though. - John

-

True HX35

@Mopar1973Manprobably banned you from the site as a practical joke. Then he forgot to tell you..., - John

-

True HX35

There is something wrong here. You should easily see 30 psi boost with the Smarty S03 and stock injectors with an HX35. If I was in your shoes, I would be finding out what is wrong before I went to larger injectors or a different tuner. My truck has the original HX35 and I have blocked the wastegate. I have run the Smarty S03 for over 100,000 miles with 60,000 of those miles on the original stock injectors which I changed out to RV275's at 303,000 miles on the truck. 30 psi boost was easily attained even with the high mileage stock injectors. On another note - your signature says automatic transmission. Shouldn't there be an HY35 on the engine? Has the HX35 been modified in some way that maybe you don't know about? - John

-

Another new guy from Mtn Home

I am the original owner of my truck. The VP44 injection pump failed around year 2005 and Dodge warrantied the injection pump and also installed an in-tank lift pump to replace the block mounted lift pump. They installed a lift pump relay. All repairs were done under warranty. This was Dodge's fix for problem lift pumps and problem VP44's back then. I have since installed a frame mounted FASS lift pump, probably the same lift pump you mentioned. I used the existing relay for the lift pump operation. The main point is to reduce the electrical load through the ECM to extend the reliability and life of the ECM. So, whether or not you keep the old lift pump location or frame mount a different lift pump, it is important to wire in a relay for the lift pump. It is not as hard as you may think to properly wire in a frame mounted lift pump. I see that @IBMobilehas directed you to the appropriate article. - John

-

Another new guy from Mtn Home

@Bob the Builder, if the lift pump is still located in the factory position by the fuel filter housing, this means that the power supply for the lift pump is probably provided directly from the ECM. The FASS lift pump you are installing should be relayed and the coil portion of the relay triggered by the ECM. This will remove a considerable electrical load from the ECM. The switched portion of the relay should have a fuse between the relay and an unswitched power source. Also, the coil portion of the relay should be protected by an internal diode. - John

-

Radiator leak

Wow!! What lot of hassle to get something that should be easy to get! I would try to hold off using stop leak if you can. I used it once early in the life of my truck for about three years because of a leaking heater core. The heater core still leaked and slowly got worse. When I replaced the heater core, I could not get the coolant to clear up - even flushing and changing it out three times. I finally installed an external coolant filter system which cleaned it up in 3 weeks. My original radiator started leaking at the driver side tank seam at 309,000 miles. I replaced it with a NAPA radiator and it now has 50,000 on the new radiator and is doing fine. No issues with pulling 20,000 lbs combined weight over 6% grade mountain passes during the summer. - John

-

Who likes Bilsteins?

I have had Bilsteins 4600's for about 130,000 miles now (since 2015). They have worked out fine for me. The truck rides and handles good. I have heard that the 5100's are stiffer than the 4100's. You did not mention which shocks you have. - John

-

Fan Clutch Unscrewed Itself

My brother-in-law moved his 2003 2500 4wd NV5600 truck yesterday. While he was moving it, I noticed a ticking sound coming from under the hood. Upon investigation we found the whole clutch fan assembly laying in the bottom of the radiator shroud. Not what I expected. The unit had unscrewed itself from the threaded pulley hub. The interesting part is that there is hardly any damage. The large clutch fan nut shows witness marks where the outside of the crank pulley was rubbing and two fan blades show similar wear from rubbing on the crank pulley hub. The fan blades never contacted the radiator or anything else (including the fan clutch thermal switch and wiring harness), which was amazing. So, I am thinking that maybe the fan clutch was locked and the assembly came off when the engine was shut off; otherwise, I think the damage would have been much more severe. Anybody ever had this happen to them? We replaced the fan hub bearing in December, 2018, just over 20,000 miles ago. I used the proper wrenches to remove and reinstall the fan clutch. Most of my life I was a mechanic by trade and I have been around Dodge trucks and many other similarly equipped vehicles and I have never witnessed or heard of this happening. A new Mopar fan clutch and a new Dorman fan have been ordered. - John I just realized I posted in the wrong forum. Should be in the third generation powertrain forum. Maybe someone could move this post. Thank you, - John