Everything posted by Leaky88

-

New Isspro R5604R Mechanical FP Gauge/R7798 Snubber- Slow Response

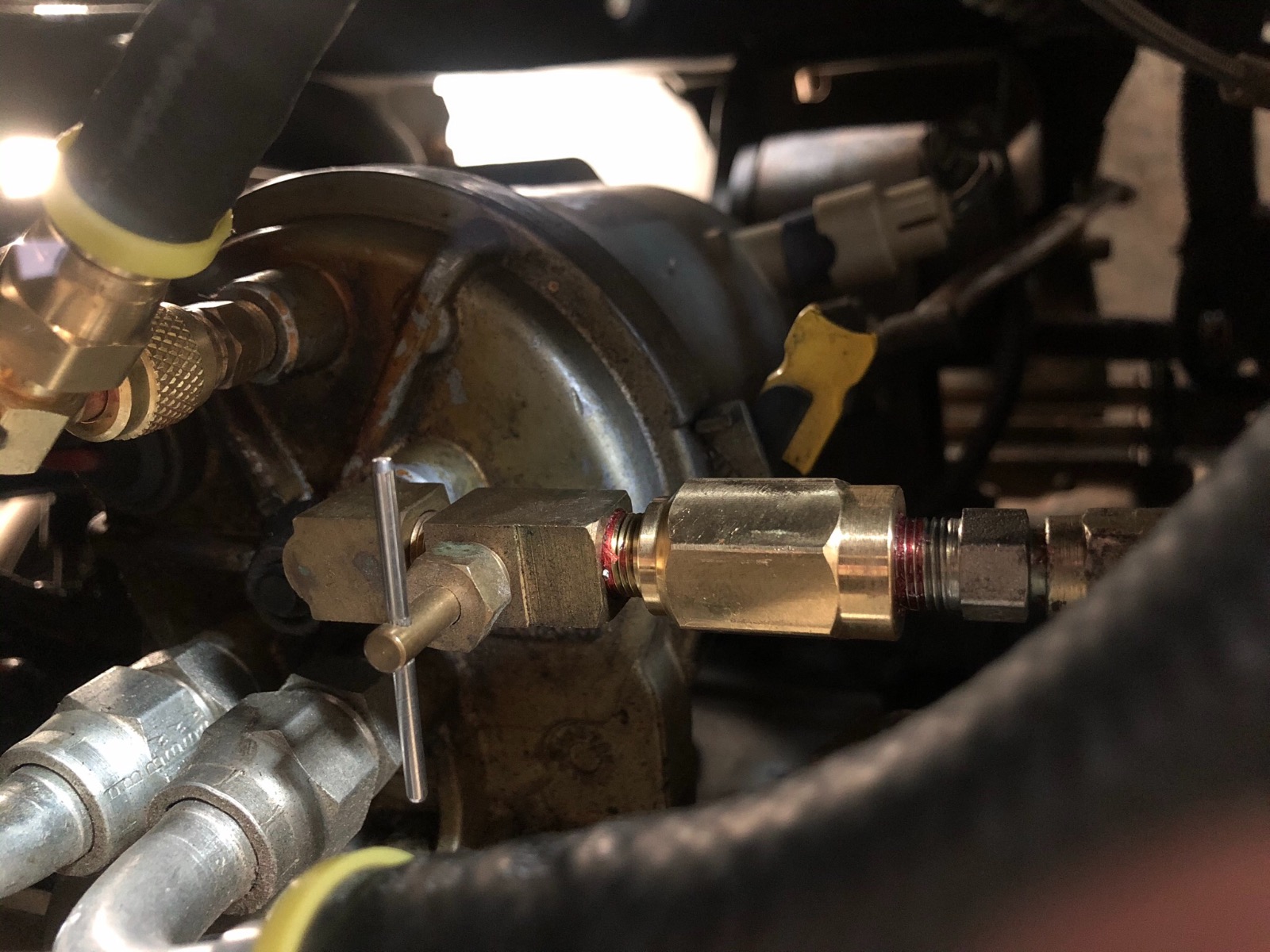

Thanks for all the Feedback. Update: Changed the piston in Isspro R7798 Snubber to the #02 (for Oil) and gauge now responds really good. Believe the Standard #2 piston (that comes installed with Snubber)would have worked fine, however I have Needle Valve/Snubber combo which put addition restriction on flow to Snubber on to the gauge. But I have to have a shut off valve just in case. I DO think the R7798 is a very good Snubber. Just curious if anyone has checked the accuracy of the permanent Cab gauge with a portable Diesel Fuel Pressure tester. If so, was there any disparity in the readings. I have found 1.5-2.1 deviations. Readings taken from top of OEM Fuel Filter Housing. Thanks again, Leaky

-

New Isspro R5604R Mechanical FP Gauge/R7798 Snubber- Slow Response

Yep. Needle valve is wide open. Pretty certain you could put on a pot of coffee on after start/up and it would be ready before gauge was at full swing. I guess plus of this is there is no danger of damage to internal gears of gauge. 😏 Talked with ISSPRO today and was told I might need to change out the Snubber piston to the one for Oil (#02) since it’s less restrictive than the Diesel #2 piston that gauge comes installed with.

-

New Isspro R5604R Mechanical FP Gauge/R7798 Snubber- Slow Response

Yep, I’ve incrementally open Needle Valve to its max opening.

-

New Isspro R5604R Mechanical FP Gauge/R7798 Snubber- Slow Response

By slow I mean it takes 5 plus minutes to reach maximum sweep.

-

New Isspro R5604R Mechanical FP Gauge/R7798 Snubber- Slow Response

Replaced 5YO Isspro Gauge due to it reading 3.5 PSI higher - when compared to VPMAX liquid filled gauge from Vulcan. Both readings were taken at top of OEM Fuel Filter housing. I have a direct custom made 1000# tested line with JIC fittings between Cab Gauge and OEM Fuel Filter housing via a New Isspro R7798 Snubber connected to Needle Valve, going into Fuel Filter housing. No Isolator. Only thing different in new arrangement is the new Isspro R7798 Snubber - with pistons. (Correct Diesel Piston is installed) Previous Set up had the simple brass small hole Snubber and Needle valve, needle valve set so gauge responded exactly like Moparmans video. New setup works, but Gauge is “very” slow to respond. I switched back to old gauge, same slow response. Anyone using this Isspro R7798 Snubber with similar experience? Thanks

-

FASS 150 - FLOW-THRU REGULATOR UPGRADE

Oh I agree. Hindsight is always 20/20.

-

FASS 150 - FLOW-THRU REGULATOR UPGRADE

Hello, Curious if anyone has done this FASS 150 upgrade, and if so, your results/comments please. Thanks

-

96 Ford Ranger 2WD 2.3 5sp. Rear Leaf Spring Bushing( Forward) replacement.

Thanks

-

96 Ford Ranger 2WD 2.3 5sp. Rear Leaf Spring Bushing( Forward) replacement.

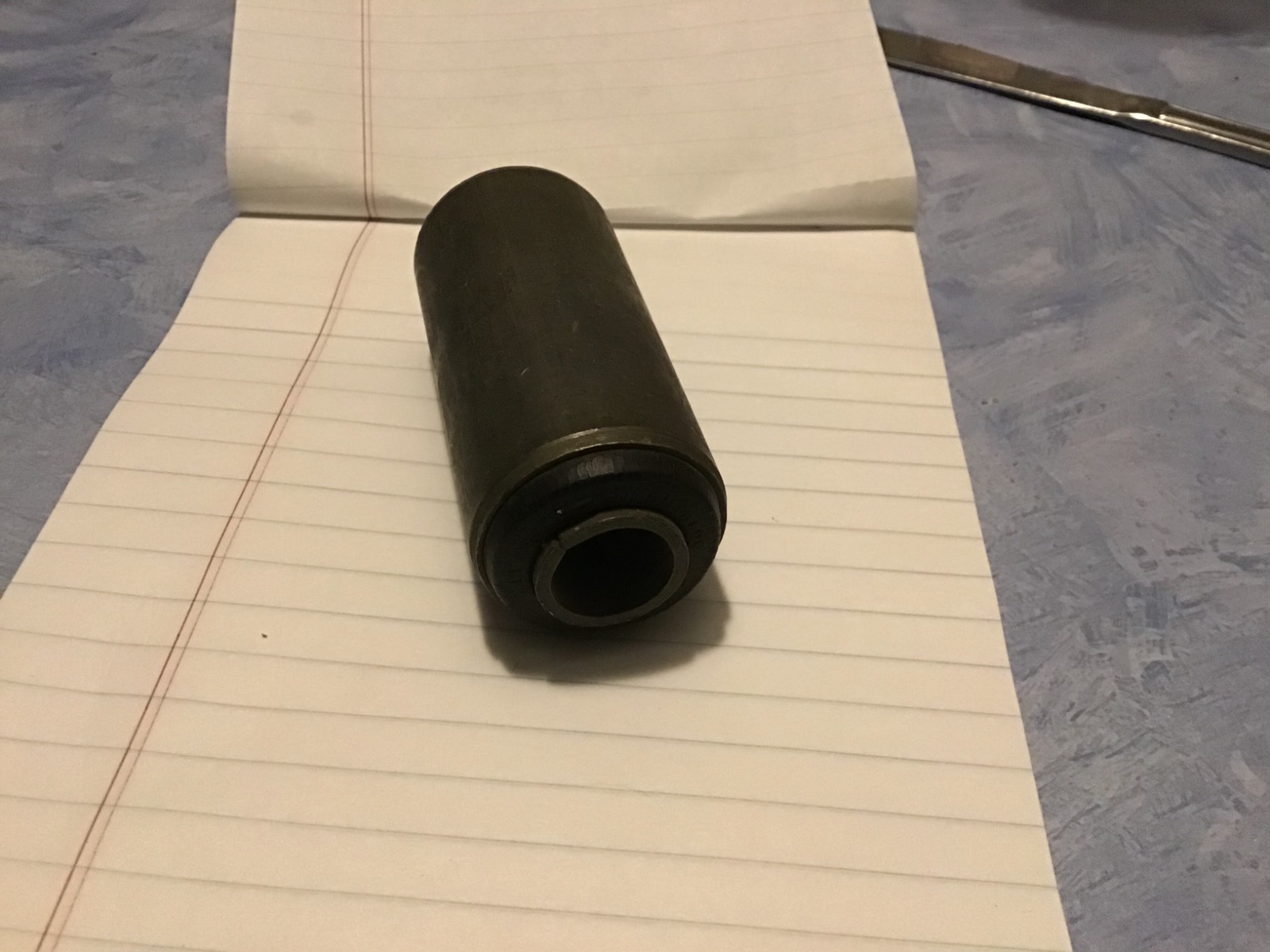

Diesel future, Thanks. Could very well be the issue. I bought it second hand, so I’m not sure of prior abuse. I took some measurements and it’s not a true eye hole. The Bushing has 1.625 OD and there’s a .075 difference between it and bore. It’s a great truck, but 25 winters of salt has done a number to the undercarriage. But, it runs good and not owned by a lending institution, so I keep patching it up. Time to improvise. Thanks again. Leaky

-

96 Ford Ranger 2WD 2.3 5sp. Rear Leaf Spring Bushing( Forward) replacement.

It’s not the part. I’ve investigated this for a week now. Used MOOG, NAPA, Centric, all purported to be a fit for my truck. OD is 1-5/8; ID is 9/16”, Length 3” on all three. Yet, each brand slides into the “clean” eye with zero effort. I don’t know if it’s the age, rust or what has changed the original dimensions of the eye. As I understand, the rubber bushing needs to fit tight in the eye to perform correctly and should not rotate. I suppose I could insert a metal shim to reduce sloppiness, to lock it in place

-

96 Ford Ranger 2WD 2.3 5sp. Rear Leaf Spring Bushing( Forward) replacement.

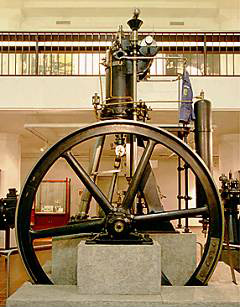

Left Rear Support Bracket, beside fuel tank, rusted out and was replaced. Removed the old front bushing, on Forward Eye, cleaned it up. When I went to replace with new bushing, it fits, but it just slides in, there is no interference fit, and it requires no press. Is this normal? I’ve checked the part number and it’s correct. O.D. Is 1-5/8. When I did the rear smaller bushing, I needed a bolt and stack of washers to draw it in. Picture is an “example” of the type of one piece bushing replacement I’m using. It smaller size used on rear end of leaf spring. Any assistance would be appreciated. Thanks Leaky

-

Center Armrest 99 Quad Cab

Thanks for Feedback. Must need lubed since there are no obstacles hindering movement. To be clear, I need to: remove both Driver and PAX seats. remove both L&R covers (pictured) clean, lubricate, and work mechanism.

-

Center Armrest 99 Quad Cab

Arm rest is locked in vertical/up position. I’ve tried lifting, moving to R and L, and repeated normal release action, with no joy. Any advice would be appreciated. Thanks

-

Grid heater bypass question.

Thanks ALL. Appreciate everyone’s input.

-

Grid heater bypass question.

Mike, Thank you very much for a valid response to my question. Appreciate it!

-

Grid heater bypass question.

I did my Grid Heater By-Pass using a SS581. (It's a great modification that will reduce unnecessary demands on the electrical system and I don't have to disconnect my Grid Heaters in the Spring). Mine works great, but I want to change my SS581 to a "protected" relay. Call me gun shy but anything that threatens the electrical system is a no-go with me. Is there another "Protected" relay besides the SS598 that can be used? The reviews on the SS598 are horrible. Thanks. Leaky

-

DRB III Emulator

Bump

-

DRB III Emulator

Per Connected Automotive Systems there is a Interface with Laptop based S/W that performs and does what the DRB III does. Does anyone have experience with this Emulator? Thanks Leaky

-

Windshield Washer Reservoir Leak at Sensor.

it’s all good. If something is not dripping from these diesels, the engine should not be turned over. I have not timed the duration, but it appears to be a drip, a pause, a drip, vice drip,drip, drip. I just want the fluid level to drip below sensor so I can examine/replace the grommet. If I pull the sensor now, it will go gush, gush, gush, and Ill go cuss, cuss, cuss.

-

Windshield Washer Reservoir Leak at Sensor.

dripley, That's good! Should have known that was coming.

-

Windshield Washer Reservoir Leak at Sensor.

NIsaacs, Where did you buy the bottle? Thanks. Leaky

-

Windshield Washer Reservoir Leak at Sensor.

Mine leaks where barb enters tank. Can the grommet be replaced, if so where might I find replacement. Any feedback would be appreciated. Thanks Leaky

-

ECM - And so the search begins

Need an ECM repaired. I looked at Pepsi's Chart. Think I will pass on Auto Computer Specialist. So moving down the list, has anyone dealt with dieselsystemservices? If so, I'd like to hear about it. Thanks. Leaky

-

New VP44 - Engine requires excessive cranking when hot

01cummins4ever, Thanks. It's driving me nuts. And, the stress on the Starter has always been a concern to me.

-

New VP44 - Engine requires excessive cranking when hot

01cummins4ever, Thanks. No. it will NOT fire off instantly - when HOT- with the FASS 150 Lift Pump disabled. However, if I use a FASS DP02 Lift Pump, it starts HOT all the time/everytime.