Everything posted by ISX

-

Clutch not disengaging..

The master cylinder had some surface oil on it. So I'm guessing it was part of it. I ordered both of them from napa around $165. I got the entire hydraulics ripped out. Only took 10 min so I'm thinking I did something wrong. I usually have a minimum of half an hour in everything so I don't know what went wrong. I couldn't believe the master just twisted and then it was free to be pulled out. That must be where I lost 20 min. :shrug:Master will be here tomorrow slave they had to order straight from manufacturer so maybe next week.

-

Looking at a first gen CTD to add to the fleet

Regular cab kinda sucks since you can't lean back, but I guess you should be sitting up straight if your driving anyways :lol:The jump from 3rd to 4th really isn't much of an issue really, just hold 3rd up in the RPM's a little longer and your fine. There's people that pull 20-30k with them so that's definitely saying something about how much of an "issue" it is :whistle:I've heard parts are harder to find and more expensive for the NV5600 too, so if we have both heard that then it must be right. Though I wouldn't think much of something like that since you probably won't be changing anything but the clutch.

-

Looking at a first gen CTD to add to the fleet

The NV4500 is definitely more driveable than a NV5600. I drove a 24V 6spd a couple times and I always thought it was just a PITA having to shift so much, not to mention having to get a feel for where 3rd and 5th were since they are both in the middle. As far as which one will hold up more, this is debateble. Statistically the NV5600 is rated for more, but if you talk to truck pullers it just becomes a toss up. However, this is up in the 1000TQ+ range when you even get to either trans' limits, so if 600tq is all the power you want, get whatever one you think you need. There is a little gap between 3rd and 4th on the NV4500 that the NV5600 fills, the NV4500 also has the 5th gear nut issue, which I really don't think is much of an issue. Seems to come off every 100k, though I don't think Mike has ever had his come off as far as I have read. If it were me, I would get the NV4500. For as many times in a year that I pull a *heavy* trailer, I have no need or want, for a 6speed. NV4500 is also 100lbs lighter. So basically it doesn't really matter, just comes down to if you want to have an extra gear or not..

-

Clutch not disengaging..

So today, clutch completely gave out. The pedal anyways. It lets the clutch grip enough to hold engine rpm, therefore it's basically useless to even try to use the clutch. So I got home, took the slave cylinder off, and pushed in the actuator, very easy to do. So I then notice the fluid moves substantially when I let the actuator release all the way, it almost sucks it dry leaving about 1/4" of fluid in the reservoir. When I press it all the way in with my hand, it rises way up. So I put it back into the truck and pushed the clutch all the way in. There is absolutely ZERO movement in the fluid. Nobody has said anything about determining if the slave/master is bad by watching the fluid so maybe this method isn't accurate? I would think it would be a sure-fire sign that it's junk since the fluid has to go somewhere when you press in the clutch, and I am seeing no movement at all. So what's the verdict on this? I'm going to replace the master/slave now but just wanted to know why this method is never talked about..?

-

Looking at a first gen CTD to add to the fleet

I don't know where I read about the slinger thing, something about either bending one that is there or putting one in to get the oil really going. Obviously they need more oil slinging around. I think south bend clutches are all rated for more than what you want so it will be fine. As for mileage, your right foot is what makes or breaks it. Just because you turned it up doesn't mean it takes more fuel to do 60mph.. It has the ability to use more fuel to get to 60, or dump it out the exhaust in the form of black smoke lol, but even that can be controlled, all with your right foot. Mine went from stock to probably around 700-800ftlbs which is almost twice the tq from stock, and my mileage never moved, driving consistently based on seat of pants will keep your mileage rock solid no matter what mods are on it.

-

Looking at a first gen CTD to add to the fleet

Supposedly, if you over fill the getrags a quart and do something with an oil slinger, they end up lasting longer and aren't to bad to have.The 6 speed would last longer and probably be a wiser thing to do. Just have to get a clutch to hold up to the constant backing up and going forward abuse.

-

12v injectors

Well in the name of some articles, I pulled all 6 today. The lugnut trick worked, it was a little loose thread but it was able to thread all the way down and none of the threads were damaged. They were in there GOOD. I had to use a 4ft crow bar that I stuck in the hole of vise grips, and I used one of the longer sockets as a fulcrum right up next to the injector, if you were too far away, it wouldn't get enough leverage. I even got to the point of putting a fence post driver on the end of the crow bar to add weight and leverage and then it worked a little better lol. I started taking a wrench to the flat spots on the injector and turned them side to side the 1/8" that would turn and that did seem to help. I need to look the numbers up to see if they are aftermarket or not. Don't look too bad after 325k though, I put a thin layer of grease all over all of them since they do have a little surface rust, figured it would help them coming out next time too Here's an article I made on it. http://mopar.mopar1973man.com/cummins/2ndgen12v/injectors/injectors.htm

-

oil selection guide

My thoughts exactly. I've seen a lot of threads about people wondering what they all meant, never see a page written as good as that though.

-

Bored No Work

I have something to confess.. You will all probably think less of me for it too :lol:Last summer when there were absolutely no jobs available, I was asking everyone I knew if they had a job and out of the some 20 people and all their "connections" the only thing I was stuck with was working at a hotel cleaning rooms. I said hmmmmm. Figured it was better than nothing. It actually was probably the best job I ever had, and I've had maybe 8 jobs, most of them were steel work getting so greasy from the oily steel that I would be completely black. So it was nice going somewhere where I could actually get in my truck without charcoaling the tan seats. So they give you about 8-15 rooms a day which you get there at 8 and leave by 1-4 depending on if you got done, so it was paradise really. Go into all the rooms, set the a/c or heat to whatever you want.. I do have a lot more respect for them now, you have to go pretty fast to get everything done in the half hour they give you and also have to get everything on this checklist done, so you end up in pretty good shape, theres also nothing like going in everyones rooms and seeing all the crap they brought with them. I remember one time I watched someone else ask the person in the room if they needed service, instead of room service, so I figured I would try that and see what happened since you can take that a couple ways, as I found out when I did that. 30 year old or so woman comes out and I say do you need any service, she looks me up and down and says what kind of service I said room service after that hahaha

-

Turbo replacment, which one to buy??

Very bottom left of the post you want to thank..

-

old - but so so funny

You know why that movie is so funny? I already did that Brother has an old blazer (not k5, it's the newer POS blazers) and we needed the trans and it was down in the field so I just took tractor and front end loader and did exactly that

-

old - but so so funny

I always wonder just how you guys even find this stuff

-

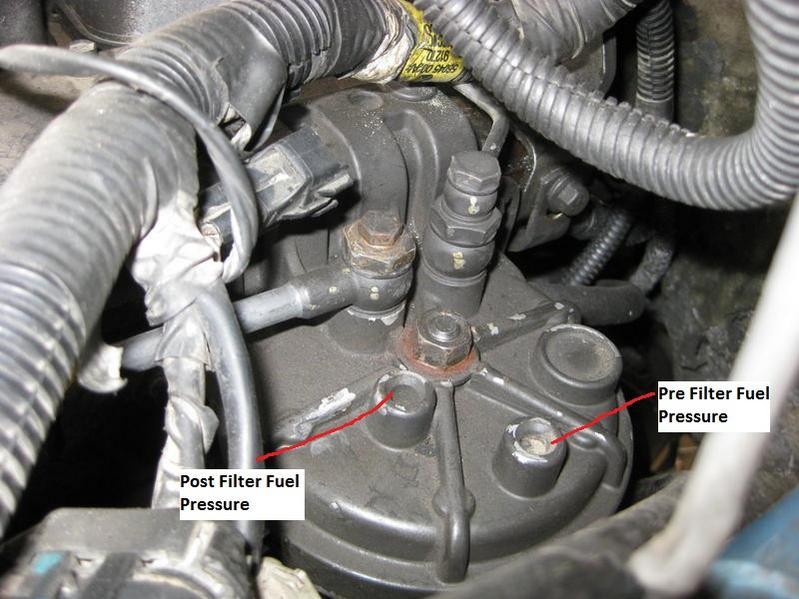

Where to get fuel pressure from on top of fuel filter?

-

Mopar1973Man's Crankcase Vent Modification

Here you go http://mopar.mopar1973man.com/personal/2002/crankcase-vent/crankcase-vent.htm Both links to those service bulletins are on there too, underlined in blue.

-

Replacing the VP44

I traced it back to his static pages http://mopar.mopar1973man.com/cummins/2ndgen24v/vp44-replace/vp44-replace.htm Has pictures on there.

-

12v injectors

I would think it would work. The injector I tried wouldn't come out by hand at all, not being that desperate, I just let it be. If a lugnut has the same thread then that would be perfect, then get some vice grips around the lugnut and rip the injector out. I wouldn't try anything unless I had all the threads of the injector in the lugnut so you aren't pulling on just 1 or 2 threads, don't want to have to buy a new injector just because you pulled so hard that you messed the threads up. I'm sure you could easily make a makeshift hammer like the tool you buy from cummins. I'd say if you spray the injectors with penetrating oil and let it soak for 10 min and then put a nut over the threads and a vise grip on the nut, the injector would come out. Mine was in there pretty good so the hammering method might be the only easy way to do it, but theres a number of methods to get enough force to pull the injector out with the lugnut

-

The Tunnel Ram anyone know about it?

How in the world can a little taper do that! Fluid dynamics you say, hmm, if that works then I might as well throw everything I know out the window. Either way I don't see how when, eh, I'll stay out of this stuff from now on

-

The Tunnel Ram anyone know about it?

Here is how I see it. The intake manifold is an air tank, there is not individual ports like the exhaust manifold, otherwise the intake manifold would have 6 ports instead of one big chamber. Pressure is equal everywhere in a tank, when you open the valve on an air tank, the rest of the tank accommodates for it, while the valve is open, you could have a million pressure sensors in the the tank and they would all have the same reading, this the tank relieves pressure at a constant rate, having every spot inside it reducing pressure equally. CFM is the other factor, if you have an 80 gallon air tank, your still restricted by your 1/2" air hose.. On the same token, the tank can only be filled as fast as the line from the compressor can fill it and the pressure difference that is there, and since all pressure in a tank is equal, the pressure difference quickly if not instantly, equalizes.Now, how this relates.. The turbo is the compressor, the plumbing running to the intake manifold is the line from the compressor to the tank, so that is one factor. Remember that the Tunnel Ram Intake has the same opening rectangle size as stock, so you gain no flow there, even if it was bigger, you still have the plumbing from the turbo to the intake that would all have to be upgraded as well, as well as a bigger turbo to actually need the bigger plumbing.Now the intake manifold is the tank, filled with the amount of boost you build which we will say is 20psi. Being a tank, it is obvious that the only restriction is the 1/2" line going to your air tools, or in this case, the amount your valves open or the size of them. The air tank or intake manifold has plenty of capacity to flow through a valve, it is just waiting to let out it's 20psi, and being fed by a 3" intake to a tiny little valve opening...yeah it has more than enough flow/capacity. If you were running 100psi, were a sled puller, and running 5000rpm, then your valves will be using the air tank like crazy and you might notice a negligible gain in flow to your #6 piston from the fancy intake and I do mean negligible. If you are running that kind of stuff, why not just get the banks dual ram intake..which still is restricted by intake-to-turbo plumbing :lol:Lastly, if your not blowing black smoke and your EGT's are not through the roof, I think you are flowing plenty. Your turbo CFM is the main issue. I only have 6 intake valves and when I made a thread about what EGT does your truck seem to level out at, the results between 24v and 12v were also negligible, so I think only sled pullers see the benefits of 24v's since they would be able to easily "outflow" a 12v's head, but for those who are 350HP/35psi and under, I don't think there is any inadequacy in having only 6 intake valves.

-

80,000 Miles......No Full Oil Change

http://mopar.mopar1973man.com/personal/2002/frantz-filter/frantz-filter.htm There's all your info Just a roll of TP.. Think they use the dense 1 ply stuff like they got in factory bathrooms.

-

So, My vp44 died. Now what..

Answers in shades of green Dang that didn't work, here's 2 stroke link http://mopar.mopar1973man.com/cummins/general/2-cycle-oil/2-cycle-oil.htm

-

VP44 problems ?????

Not sure on the second half of your question but as for the first half, your basically just saying can I make it to town 30 miles away on the gallon of gas I have in my tank... It might go another 10,000miles, it might go to the end of the driveway. The electronics seem to be the determining factor and are cooled by the fuel which needs 14psi to cycle through the lift pump adequately enough to be flowing cool fuel the entire time. There is some good reading on it here http://forum.mopar1973man.com/showthread.php/1656-VP44-Write-Up-Minimum-pressure-suggested... You might not have hurt it yet, but 10psi is the bare minimum, with 14psi being the preferred minimum, and your saying that you have dipped below even 10psi.. Either way, your lift pump is not doing it's job any more.

-

12v injectors

1. Take off injection line2. Take off fuel return line, make sure you don't drop the copper washer that "U's" around both sides of the return line3. Unscrew hold down nut, 15/16".4. It will pull out if you are extremely lucky, otherwise, you need to screw something over the top of the injector threads so you have something to pull the injector with, pulling on any part of the injector may damage it. There is a special tool you can get that screws onto the threads of the injector (where the injector lines go) which is connected to a rod with a slider weight on it, you slide it up really fast and it hammers the injector out. There is a copper washer on the injector around the tip, make sure you don't leave that in the hole if it doesn't come out with the injector. If you are putting new injectors in and you use their copper washers, it will end up 2 washers thick and mess up the fuel spray in the combustion chamber. Make sure you clean the area really good before you do anything, and make sure nothing gets in the top of the injector where the injection lines screw onto, if anything gets in there, it will go through the injector :badidea:When putting back together, injector hold down nut is 44 ft/lbs and injector line nuts are 22 ft/lbs. Use some antiseize on hold down nut.

-

VP44 problems ?????

Your lift pump is the only thing creating the pressure, and unless you have fuel spraying out of a line somewhere, it is the only cause. Your problem is one of the most common problems for any 24V owner, and it all falls back to the crappy OEM lift pump. If you still have doubts, test your lift pump. http://mopar.mopar1973man.com/cummins/2ndgen24v/lift-pump-diag/lift-pump-diag.htm

-

OK no laughing guys but my truck doesn't have owners manual, sooooo

Flman is right on the money. Water can come from a number of things, diesel fuel attracts it for 1. This is hardly an issue if you drive your truck regularly, if you get your diesel at a place that doesn't have much turn around, their tanks could be forming water inside them, try using the station you see all the semi trucks running through. The only silly question are those not asked

-

The Tunnel Ram anyone know about it?

I am having doubts. Pressure is pressure, if it says 20psi, that doesn't mean 20psi to cylinder 2, it means that whole intake manifold chamber is filled with 20psi of air, and since the square that the intake horn bolts to is the same size, I see no CFM addition. It looks nice, but I don't think you would notice anything at all.