Everything posted by ISX

-

Old vs. New, whats the difference?

This has been on my mind ever since AH64 mentioned it. He said the P7100 can do 18,855psi and the vp44 can do 17,400psi and the cp3 can do 23,106psi. I can't find the chart he just posted somewhere but it showed that the rail pressure in the CR engines is highly variable. Seemed to go up with RPM and load, which I think the same happens with the ppump and vp trucks and I don't see those pressures being that different. I mean 23,000 is 5,000 more but can that much have that big of difference? And when it is not at peak load/rpm, is it possible that the pressures of all 3 trucks could be the same? This makes me think how emissions is accomplished. I have heard a lot about the pressures and how the new trucks inject up to whatever number of injections per cycle, but now I don't see how thats any different from any other truck. I realize the newer CR's have multiple injection "events" which allow for a smoother powerband and quieter engine, but if you took that away, what would the difference between the trucks be? I know timing is a big factor.. But if you somehow got the map for the CR trucks on timing into the VP trucks, and canceled the multiple injection events on the CR, would the 2 trucks then sound identical? Now one other thing is that the CR has whatever pressure in the rail for the duration, whereas the VP and PPump would increase pressure quickly as the plunger rammed the fuel out. I am not sure if this makes any difference or not in performance though. And do you have any info on the VE pump?

-

throttle linkage rod end clip???

Well there you go, get the dealer to do it for free Here's the reason for the other hard spot. Uh let me expand on it now that I've watched my crappy explanation. That easy part that I show when the governor spring is in at the beginning, or the first half of the pedal, is actually the only usable part of the throttle. Even during operation. The difference is that during operation, that spot advances. What makes it hard is the governor spring resistance as you can see in the video there is no resistance when I take the spring out. So the half inch gives you full rack travel and then your just pressing against springs and stuff and basically doing nothing. As engine RPM increases, so does the flyweight resistance. This in turn pushes the spot that you "hit" (when it gets hard) back as RPM goes up. But going past that hard spot does nothing.. Eventually the hard spot is on the floor and at that point you will be at redline. I have no fuel plate or AFC whatsoever and when I pass someone I can either hold it to the floor or I can push down till I feel it hit that hard spot and then easily push down riding that hard spot. The power is exactly the same either way. It is a little different when you have the AFC and fuel plate to complicate things but it basically works the same way with them involved since that hard spot means you are just pressing against springs and doing nothing. It's really just a safety feature for the pump since us being humans would rather floor it than ride along the pumps capabilities (ride the hard spot) http://youtu.be/7NH34VIPWY0

-

throttle linkage rod end clip???

Yeah first 3 was throttle cable. Does it get firmer when the truck is off after the pedal goes in maybe 1/2"? Like it hits something...? If that's the case then it's normal, I'll show you why in a bit.

-

I think I just found Heaven

I'd like to hear more of your results. I can get B20 but its an hour away. I thought I had a loss with it but not convinced. I know its an excellent lube and cleaner but I thought it also grew algae. I'd analyze the fuel filter once you change it to make sure nothing weird is going on. Sounds like you go through fuel too fast to matter though. I also don't get the higher price. The B20 is 20 cents higher than regular diesel. Yet E85 is cheaper, hmmmmmmmmmm

-

throttle linkage rod end clip???

Forgot about the rod, sounded a little more like what you are referring to. If its this then yeah I think you have to get a new end. I don't think you can get the ball into the socket without a special process of some sort that us DIY's can't do. I can't do it anyway

-

throttle linkage rod end clip???

There was a recall on the early 12V's, I think just the 94-95' but that was just a sticking issue. I took pics of everything since it seems like maybe something fell off and you are trying to figure out what. Let me know if you need any more pics or vids or anything at all.

-

Homemade Intake Horn

You just had to do this didn't you :banghead: Now I want to relocate mine completely out of the way. I do like what you have done though

-

Nv 4500

1 gallon.

-

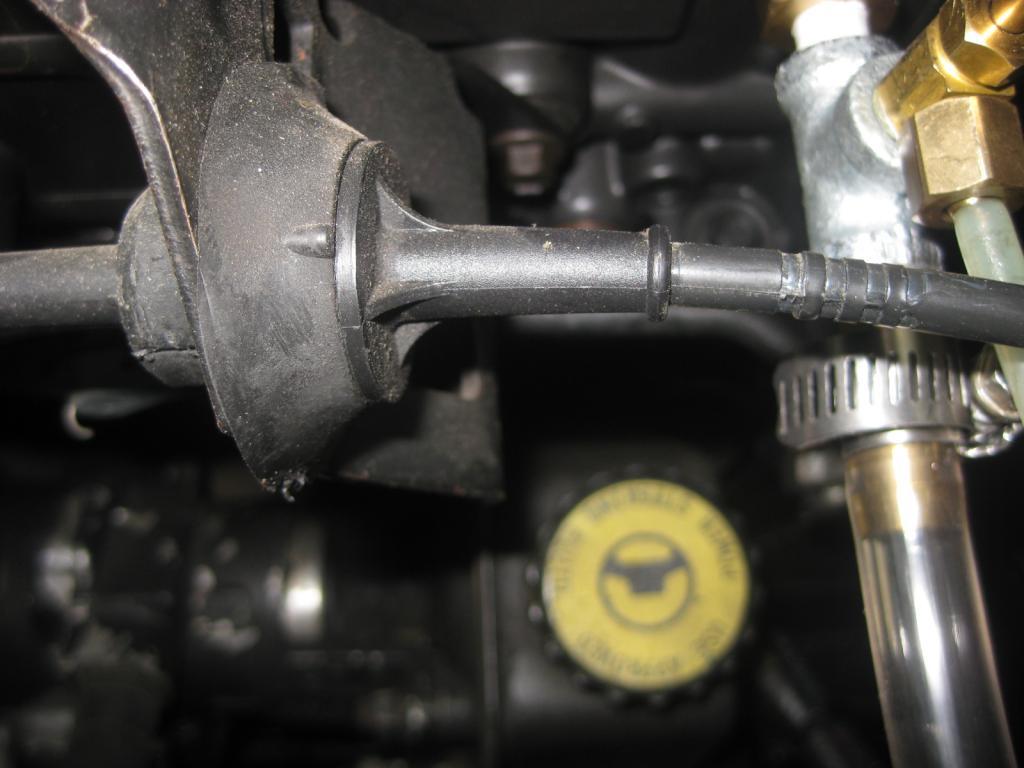

Mopar1973Man's Crankcase Vent Modification

The blowby will find a way out... Be it the crank seal, dipstick tube (yes it will shoot the dipstick out) or other means. That pressure cannot be contained and IF all things are somehow sealed with cement, it will push the oil out of the blowby tube until it can breathe. If you happen to be pointing straight down, it will push every last drop of oil out. Though there are usually easier routes.. Mine has a habit of pushing the dipstick out an inch since it's easy to push out and with however many miles I have, there is a good amount of blowby.

-

What do the Family members here do for a living

Technically I'm an electrician. In actuality I do everything but. Not sure what the deal is. Lately I have been installing conveyor. It's a brand new boiler repair company for powerplants and whatever other crap they do but we are still trying to get our foot in the door. Going to college this fall for mechanical engineering and probably all the aerospace classes to get me that emphasis, so I can possibly design things in my future.

-

1st I've heard using STP in diesel fuel

You can't judge by how thick it is. It makes sense but it just doesn't live up to it's thick properties sometimes. For instance, looking here http://articles.mopar1973man.com/general-cummins/36-fuel-system/68-hfrr-testing-of-common-diesel-fuel-additives we see that motor oil does basically nothing for lube. It is 2 better than regular diesel. I don't know how much thicker you can get than motor oil. Kinda scary though since we rely on that to lube the engine. But whatever it does in the fuel makes it a crappy additive. Then we have biodiesel, best lube out there, yet it's also a solvent However, we have no data on the STP so who knows, other than it has stuff we don't want in it. Shoulda asked him how many VPs hes been through.

-

Hanging tube.

http://www.cumminsforum.com/forum/94-98-engine/232657-checking-blowby.html

-

Hanging tube.

Mine is clear too The compression that blows past the rings goes into the crankcase and has to be vented somewhere so it goes out that tube. That is why it is used to measure engine wear. There is a certain test you do with a manometer (water column) and if it has too much pressure then the engine needs a rebuild.

-

I noticed a flaw...

After thinking about this, we could just have a list like a phone book. Put the states in alphabetical order though it would just be a list. Like: [*]Alaska [*=1]That one guy - 555-5123 - somewhere cold [*=1]His sister - 5594204 - close to me [*=1]Possibly his mom - 58549 - in the vicinity [*=1]Eh not before his other sister - 94930204 - in range Then you could just print it out or something. I would make it a word document so I know it would all fit on one page. Other than that I don't know what other way to do it.

-

My tires and speed...

You have to go by RPM's to really check, when the TC is locked up. So in overdrive if you have 3.55 gears at 1600RPM, the stock tires will be at 59.2mph, but you will really be going 63.8 because the nonstock 285's are bigger.In other words, if the speedo says 59 at 1600RPM, then you know its set up for those other tires. If it says 63.8 at 1600, its calibrated for the bigger tires.

-

Broken smoke screw!!

Ah that screw. I have 2 complete AFC's if you need parts off it.. --- Update to the previous post... It's M6 x 1.0 and 1" long. I think you can get something like that at ace. Call around, if you can't find one you can have mine. Send me 45 cents

-

Broken smoke screw!!

Where exactly is this smoke screw? There is a fuel plate and AFC stuff and yeah I cannot think of any smoke screw. The starwheel sure isn't 10mm. Give me some clues to where this thing is and I can figure it out.

-

vp44 fears

Any codes? What is the fuel pressure like?

-

Up close and personal with a 94...

I bet they took that pump off and couldn't get that nut either so just said screw it. It just takes a little finesse. You gotta think of it the same way I do, nothing is ever harder, things just take more time. It's not even that hard, you must have big hands You can take the injection lines off and that might make it easier, if you haven't already. Just loosen all the nuts and take the 2 10mm mounting bracket bolts out and they are off. Guess I don't know which one you are having issues with. There is one that you can get from the bottom and one you can get from the top, both suck. The one farther in there really sucks and yeah try it from the bottom of the pump reaching around. Do I gotta make a video showing how its done lol.

-

Up close and personal with a 94...

15mm socket, M10 x 1.5. That one IS a PITA. There are only a few bolts that I know of that are a pain, that is one of them, lift pump bolt is another. Everything about piston #6 sucks as well lol. Anyway I use a couple extensions and a ujoint socket thinger until its past the back of the pump to get that one.

-

Up close and personal with a 94...

Take the fan off, batteries out, shroud off, radiator reservoir out, windshield fluid reservoir out, put all the wires inside the body and the fuse box pcm and relays on the bottom of the hood, and then you have something easy to work with Latest thing I did was moved the fuel filter to right above the cruise control module where the drivers side battery used to be. That is actually very easy (2 bolts) and that might be what you have to do to get at whatever bolt there is that is leaking oil. The filter mount goes over the intake manifold and those 2 bolts actually double as part of the intake plenum cover thinger. You take the 2 banjo bolts out so nothing is connected to the filter housing and then unplug the WIF sensor then I think you can wiggle it out from under the fuel lines. You might have to take the one going to the P7100 off to be able to slide it out that way. I have never done it with all the lines hooked up. If you can get a pic of the nut or something I can get you sizes. Or tell me which one. That pump I cut in half is always on my desk lol.

-

Bleeding air from fuel lines

Yeah if the nuts are barely cracked then it kinda holds back all the pressure and you end up with just a dribble. As you loosen them the pressure begins to escape and it will shoot out like an aerosol can. When the engine is running it will shoot a lot further, just cranking doesn't give it as much quantity since the pump isn't turning it as much. You can see here in the first 30 seconds how much mine shoots when I loosen it a good amount with the engine running, but it will just dribble while cranking. http://www.youtube.com/watch?v=M0ZZowFzTzA

-

Water pump

Those links don't work. NAPA uses a setup that works on your computer only as you go through the selection process. Nevertheless, I don't know what else it could be. If the cap doesn't vent then it wouldn't regulate pressure. I have no idea what they mean.

-

Bleeding air from fuel lines

Depends on how loose you get the nuts. If they are just cracked then they will dribble, if you crack them a good amount they will eventually simulate a sprinkler system. Just let it dribble a good amount watching for air bubbles and tighten when it seems like a constant flow of just fuel with no air bubbles. The fuel pressure gauge shouldn't have air in it, you will just have to bleed that out by cracking the line behind the gauge slightly and letting it drain into a jar or something.

-

Water pump

I think the vented ones are the ones with the lever on them that allow you to vent it manually. This is so when the engine is hot you can lift the lever and it blows the pressure into the reservoir until it has no pressure and then you can safely take the cap off. Radiator caps seal off the radiator with the rubber thing on the bottom with a spring that gets pushed back at 15lbs or whatever the pressure is. So when the pressure gets to 15lbs the water can push the seal out of the way and move out to the reservoir. The lever works by simply pulling the seal up, simulating high pressure relief.