Everything posted by LorenS

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

Hard to see the pinion, isn't it? I've never seen the insides of a DANA 80.

-

All sorts of problems w/quad download

For reference for anyone who stumbles on this thread, check out this article to learn more. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/59_fuel/bosch-vp44-injection-pump-overflow-valve-r19/

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

Pretty sure you're still at 3.55. https://www.rocky-road.com/calculator.html It's not mobile friendly! Very small. Remember, the MMR is to get us in the vicinity of 66 to 70 MPH at 2,000 RPM. If you had 3.73s, you'd be at 2,000 RPM @ 68 MPH.

-

All sorts of problems w/quad download

The weep hole lets air out after such things as a filter change. Bump starter, lift pump runs and pushes air out to return line to tank. I wouldn't install one without the hole, but for $80 I might also find a way to drill it!

-

Story Time....

One of my old bosses used to say that rig welders were even lower than whale excrement - he was a Navy man, so that's the Reader's Digest version. I would add "many" to that statement, based on my last 15 years of experience with them. Some are really great guys, but seem to be the exception, not the rule. The couple of women I've met in the profession were great. Being dependable, punctual, honest, and sober will go along way in this world!

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

My dad had an Edge EZ on his 01' dually with 6/speed and loved it, even tipping the scales at 35k pounds on a trip to the dump. He drove slow (65 MPH usually) and would regularly get well over 20 MPG, hand calculated. I think his record round-trip to our cabin +100 miles away was upper 20's. It was cool, almost foggy weather. Enough the air felt saturated, but the pavement was dry. He didn't run any gauges, though, so who knows what EGTs would get to be when he refused to downshift and just rode the torque curve all the way down... Otherwise stock truck besides coolers on the tranny.

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

One possible problem with a tuner is California emissions, unless it has a CARB certificate (Gale Banks may have one?). Gears surely wouldn't come in to play.

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

Is that for the front or rear? This isn't really my wheelhouse, but have looked at these enough to know there are questions I would ask an expert before I dismissed it as impossible! I THINK you may be in luck - maybe not. Yukon makes "thick gear" 4.11 gears to fit - I believe - the same carrier as your 3.55s. They also make "thin gear" 3.73s to fit the 4.10 and up carrier. Here's a link: https://www.randysworldwide.com/product/yg-d80-411t/ Now, if you buy these and Randy sends me a 4.5% commission, don't come calling me with any complaints

-

2001 Auto Upgrade Plans - Turbo, Injectors, Quadzilla, Gauges

I think I merged two threads in my head, but here is one of them! I'll see if I can find the other one, though no promises. https://mopar1973man.com/topic/17088-he351w-turbo-upgrade/

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

Okay, so we take (0.75/0.73) = 1.0274 Your final gear is 2.74% higher than Mike's, so instead of 68 MPH it's about 69.9 MPH. That's with the 3.73 gears and your 19.5s. discussed above. That 3.84 'custom gear set' would need to be 3.95 gears (1.0274*3.84) to match the MMR resulting in 66 MPH at 2k RPM. So now you're creeping closer to 4.10s, which would put you at about 63.6 MPH at 2,000 RPM. Be nice if you had a 7 speed, with a "five and a half" gear of about 0.85. Then you could keep your 3.55 gears, and that gear would be like having 4.18 rear gears for uphill, and your 0.73 final gear for flat and downhill. Or drafting semis... Are you a lead-foot, 80 MPH driver with that permanent sail attached? When one factors in drag, you may want the 4.10s for the higher speeds - which seems quite counter-intuitive. Pushing that camper through the air will take some power! Other folks on here would have far more experience with this type of operation than I do, hopefully they will chime in. This might be a good question in the RV/travel trailer forum.

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

Tire Size Diameter 245/75/16 30.5" 265/70/16 30.6" 235/85/16 31.7" 265/70/17 31.6" 265/65/17 30.6" 240/70/19.5 33" The 19.5 option is about 8.2% larger than the stock size (30.5-30.6") for us 2500 owners, which is what Mike's Magic Ratio (MMR) references. Not measles... 3.55 * 1.082 ~ 3.84, which would be a very custom ratio, indeed. From this, it's probably the best choice - if you regear - to go to 3.73. This is 3% difference from the MMR. In the real world, this means you'd be going 68 MPH at 2,000 RPM versus Mike's 66 MPH (assuming that you have same transmission final ratio). I drive an Auto, so my overdrive is even more ridiculous and puts me at 74 MPH with 3.55s and 30.5" tires, according to the math. I have 31.6" tires right now, the 265/65/17's should go on before snow flies. Just what I need, even more torque to the ground in snow and ice!

-

Tire Size / Final Drive Ratio - Reality Check (More-fun-with-math!)

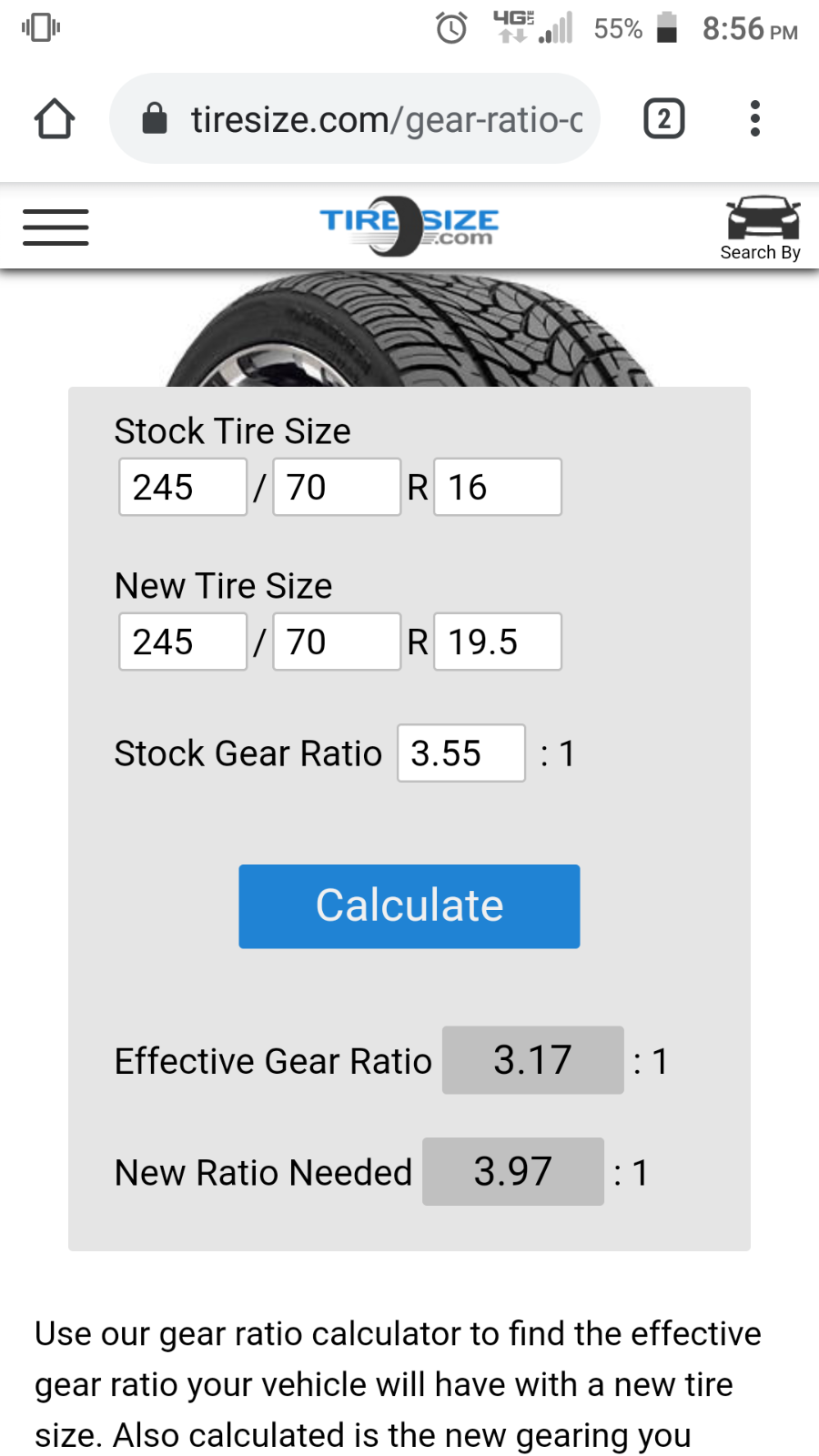

You're actually at 3.41, right? You ran the calculator with 19.9" wheels. And @Mopar1973Man's magic numbers for ratio is based on 245/70/16 tires, I believe. That yields a need for 3.97 gears; the jump to 4.10 makes sense at that point. EDIT: it's 245/75/16. So, it'll be 3.85; I don't know what makes sense from there!

-

2001 Auto Upgrade Plans - Turbo, Injectors, Quadzilla, Gauges

There is also the HE351W with a 12cm housing. I believe this is the one that @Blueox01 installed this spring, and IIRC in that thread it was given a thumbs up by DAP and @Me78569 for value. I don't remember horsepower goals for that build, but was compatible with exhaust brake. Just food for thought! https://www.benzforce.com/collections/holset-hx35-he351-accessories/products/new-genuine-holset-he351w-4043980-4043982-he351

-

Lift pump control guidance

I was going to go the ASD route, but the idea of tapping into a perfectly good wire while my ECM still has a working lift pump circuit didn't appeal to me. Just tripping a relay, there's no real risk of taxing the ECM.

-

Winter Front For Dodge Cummins

When I got sent to MN for winter, this article inspired me to make the same sort of winter front for my truck - out of rubber commercial stair treads ?. Not near as pretty, but cheap and effective!

-

LED lighting - Interior Courtesy Lighting

Thanks to this article I was able to not only upgrade the bulbs without breaking the overhead console, but actually fixed one of the map light switch mechanisms!

-

Better headlights for your 2nd Gen Dodge Ram

This article, coupled with some forum posts on this site, led me through the process of installing Projector headlights in my Ram. I couldn't be happier with the results!

-

Rusted Bolt Removal Tips Needed

I didn't know that's how it is attached, that's great news! Maybe next weekend I can tackle this project.

-

Rusted Bolt Removal Tips Needed

I agree with the impact, it's one reason I tried the air hammer with the "Shake and Break", or whatever it's called. It the device you put in the air hammer with a 1/2" socket drive on the other end, then can rotate with a standard wrench. Since those are flanged bolts, I really thought it might work. I've been spraying those bolts for weeks with Aerokroil penetrant. However, on the outboard bolt the rust has - for lack of a better term - welded itself solid. As in, I can't see the gap between the thread and the flange! It's like I used rust brazing material. Maybe if I had borrowed a bigger air hammer it would've worked better, I could only find my wimpy, rapid-firing one. I think the next step is to work on the oil drain bolt so I can remove the entire turbo from the truck. I haven't made any headway with @Threadzy's HX35 he sent to me (other than getting it all taken apart), so I need to be able to reuse the HY35 the same day it comes out of the truck. Since I'm still stuck at home recovering/quarantining from the Commie Cold, I have time on my side but it also means I can't get any help!

-

Rusted Bolt Removal Tips Needed

It sure would be a cool tool to have! I'd have to get creative to get near the bolt. I think those bolts are even worse!

-

Rusted Bolt Removal Tips Needed

It sure is, and they are possibly even worse. I bought a used 5 bolt elbow so that if I install a different turbo I don't have to worry about this one. All the turbo to manifold nuts came loose okay, so are now Anti-siezed. However, one of the oil drain line bolts is stuck, too!

-

Donaldson upstream spin on screen

I added this today while home recovering from Wuhans. The filter is rated 95%, 140 microns, per SAE J1985 test. Pretty cheap off of Amazon and a bunch of filters cross over, so shouldn't pose a problem traveling. https://shop.donaldson.com/store/en-us/product/P552203/1553# The base is a standard cheap WIX 24770 universal unit. I drilled and tapped the frame 5/16" NF. I wanted to put a shut-off valve on the tank side, but decided I can just pinch off the hose when the time comes. Since I removed the "sock" in the tank when the Draw Straw went in, I needed some protection for the lift pump. I searched a 100 micron filter that would fit this filter base, but couldn't find one. Originally I had purchased 25 micron filters for this base, but decided that was too fine - I'd rather change the under hood filter more often!

-

Rusted Bolt Removal Tips Needed

Considering how difficult it is to reach the other bolt with a torch - and my experience level with a torch - this will be an out of vehicle repair!

-

Rusted Bolt Removal Tips Needed

I'm putting this here because it doesn't apply to any limited Generation of truck. Am attempting to remove the exhaust flange bolts from my turbo "about" so that I can in stall my new exhaust. I have been spraying it off and on for weeks, both cool and hot, with AeroKroil. Today I've laid into it both from above and below with my wimpy air hammer in an attempt to jostle the rust. My guess is that from the top was a mistake, as it could swell the bolt like a river. However, the other attempt from below didn't make much difference. Any further in-truck ideas?

-

Fuel pressure loss after sump install

If this pressure drop happened immediately after the sump install, I would start with a filter check, no matter how much you cleaned the tank. Any and all remnants now have gravity assisting them in their quest to enter your fuel system versus settling on the tank bottom.