Everything posted by Timd32

-

47re Trans Service Tips and Tricks

Pretty sure my filter from Goerend is just a stock mopar filter, for my stock pan I went with the reusable factory one, my Goerend pan came with a simple cork gasket. I have had very good orders from Cascade Transmission, the owner was going thru some health issues last year so he sent some emails explaining that, like an out office reply, it said to just be patient they were short an order picker. I did get an odd bearing in place of a small part, I was letting them know and I sent the bearing back they credited my PayPal and I put a new order in for the part and came in a day or so. I have some of their specialty tools for the OD unit, worked as expected. Saved some money on those. Everyone has a different experience but I just ordered from Cascade 2 weeks ago, that .215 backing plate and a sprag clutch, the quality seemed just fine. Similar to the stuff I got from Rock Auto. RA has good stuff and you can pick your mfg of some stuff. Which is nice.

-

Battery cable re-do

Yeah take away is you need to do this under loaded conditions to get the real numbers.. if you suspect a cable is bad and it looks bad, I would try to clean it up and or repair/replace, no sense trying to prove a nasty looking connection is within specs. FSM is always a great first reference for this stuff.

-

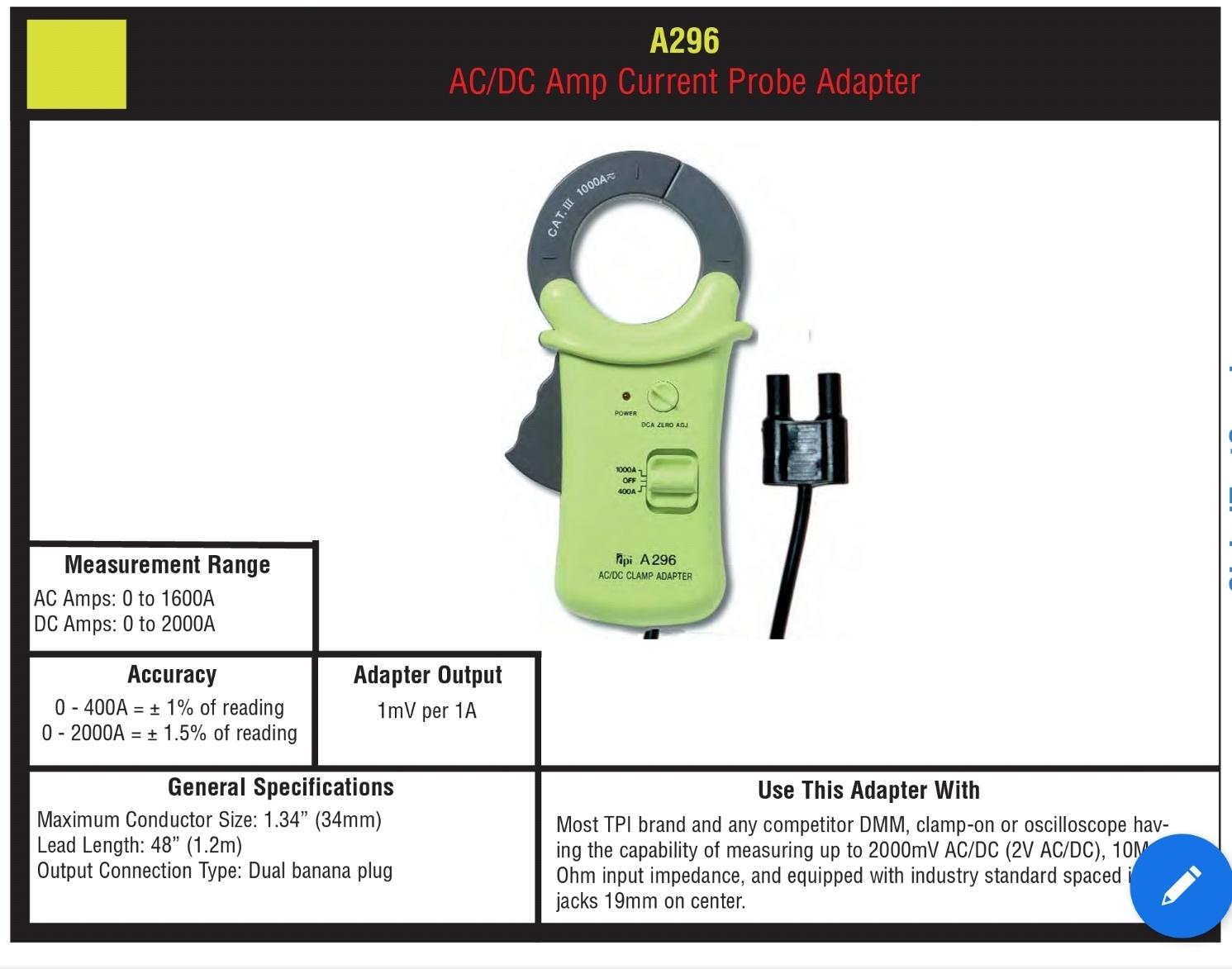

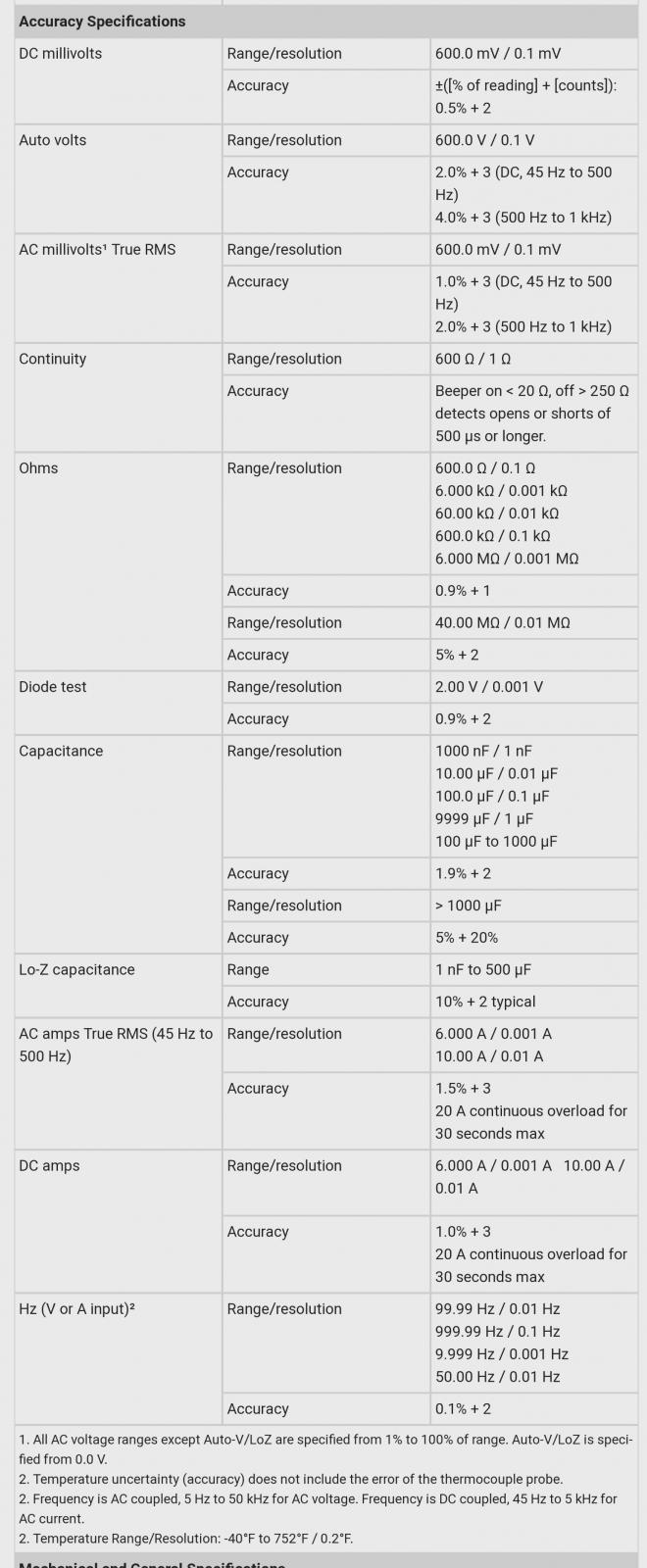

Battery cable re-do

No DVMM has high amps. Need a separate Amp Clamp. Most cost effective use an adapter for your 117. They put out 1mv per amp so adaper plugs into the volt slot. Your meter has the following resolution so look up the ones that would fit nice with your meter and what you think your going to measure, so the cable fits thru the clamp. Or get a dedicated amp clamp, which when you go to DC Amps the price kicks up a bit for a Fluke. Like double the price of your 117. But ebay fixes that lots of stolen good quality meters up there, we have had atleast 8 amp clamps stolen over the years high quality stuff sold for pennies on the dollar. 4 were brand new in the box never made it to us......

-

Battery cable re-do

This was a good article I dug up a while back. https://www.fluke.com/en-us/learn/blog/automotive/electrical-automotive-troubleshooting

-

47re Trans Service Tips and Tricks

Thanks for the added info. Turns out my new (few months) caliper does not auto shut off,,,, well it does when the battery dies.. Need a new battery, I usually have a cheap dial caliper but thats at my work shop. Add that to the list the the "tips" list... keep a spare caliper battery... kinda like a DVMM fuse good like finding one of those local... I will measure my old parts as I know I put new ones of the same size and have all my old parts.

-

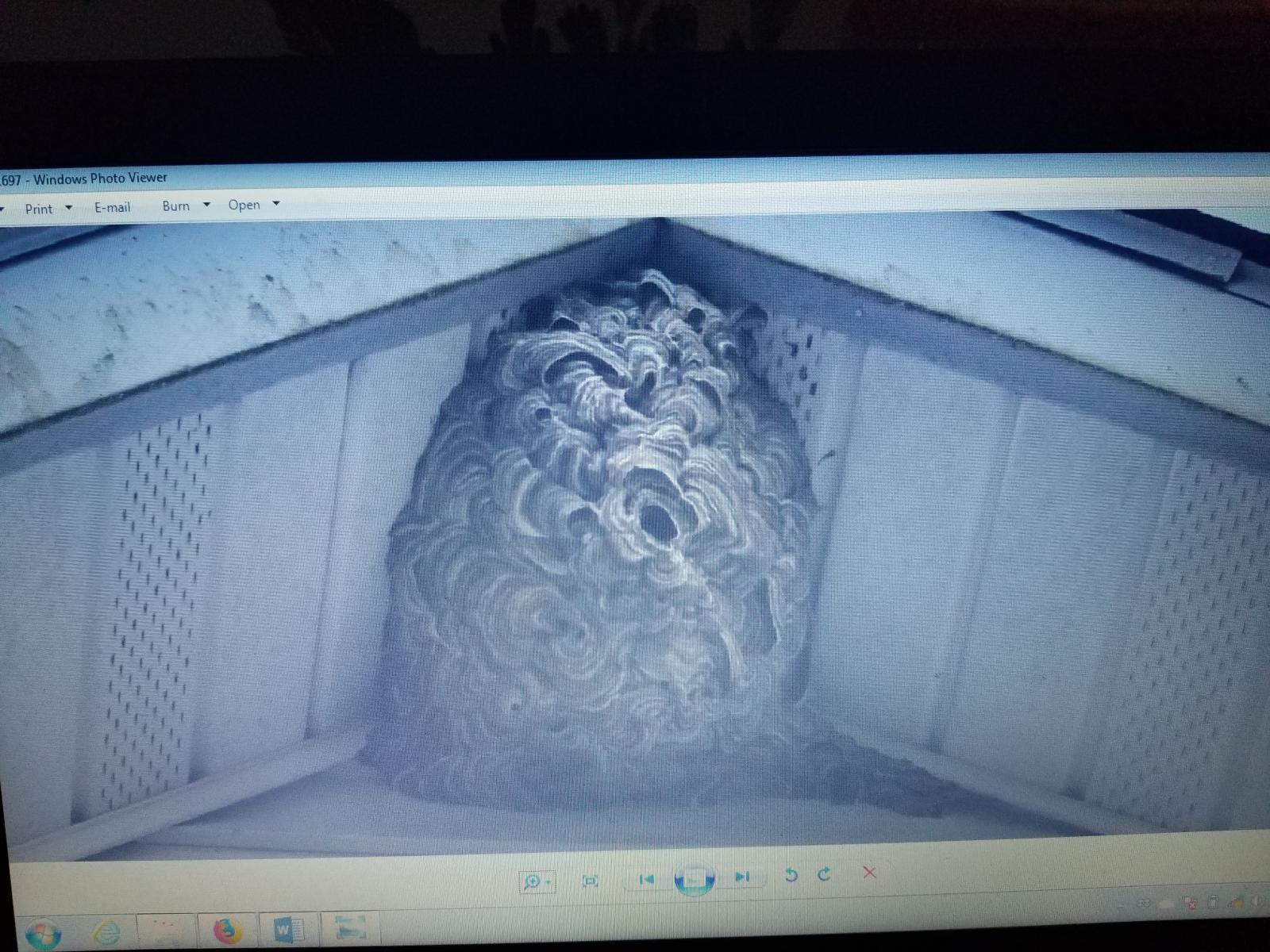

Damn yellow jackets

Im 8 cans into that nest, my latest IR scan shows a pretty dark spot at that roof point, so its saturated really well now, they were pretty bent last night. I like the videos where folks use no chemicals and just a low powered vacuum. I would try that meathod had they not been so far up on the house. On the chemical side.... What I have learned is you have maybe 6s-8s of spray time and if you are going to use multiple cans, pull and hold till empty. If you stop near the end of the can and restart it atomizes (if thats a word) pretty bad and it will no longer spray a stream, so in my case being 26+ feet you need all you can get out of the can. The foam stuff works really well, coats the nest, the stream stuff is longer more direct spray, I always buy more then I need and can always return the unused, it goes fast. But thay nest is really thick so it takes a lot to saturate the thing.

-

47re Trans Service Tips and Tricks

I don't think I have extra plates and fibers in the OD it, as I had one set left over they give you enough for a 48RE, I do have the stepped front clutch with the added plate and fiber, (I'm saying that location wrong, but the one backing plate was modified by Goerend) I think its a 3.8 front band apply lever. I've had it so long forget, bought most of my parts in March of 2018, yeah that ends in an 18.....? Just going by the part number and description on their site.. Gorend: D73-LSA 3.8 On the end play yeah I have been thinking that one out, they suggest to only mess with 3 specific items if it's off, they just say no end play, will roll with that suggested .020" ATSG Reference #, my commentary.. Part #70, #1 Selective Thrust Washer on the back of the pump. (Mine was maybe a fiber washer) Part #105, #3 Selective Thrust Washer (odd triangle one on the back of the Rear (Forward) clutch.) Part #179, Intermediate Shaft Selective Spacer. (Back of shaft between OD unit and main Transmission) My guess here is the last one would be the only one to change as by this point the other two are going to require some "getting into", also I guess at this point I should have wrote down and measured those others prior of that last one does not work, too late for that, but thats a good idea for a tip for someone else. I measured and matched what was in there for the second one, the one behind the pump might have just reused that one? Can check my pile of parts. Maybe: "Measure your installed selective thrust washers and write those down, just in case." Unless that might be overkill, since I did the other mesaurements along the way maybe thats all accounted for... I have a Goerend Valve Body. I think there is a paper in the box. Has the better GM kit on there, they tuned it for around a 10k or less pull weight, they had a small list of questions and I thought there was a bench test sheet, but might be confused with the TC test sheet. Again been a while going from memory of a phone call had with them. But yeah Im going to try to get the basic air checks done maybe by Tuesday, I really rely on that ATSG book and Goerend has a nice supplement correcting the issues with that book, then folks like your self who help us common folks out with a wealth of info, it is appreciated for sure..

-

Damn yellow jackets

Yeah I'm battling a Bald Faced Hornets nest on the house last two nights. Its 26' up kind a PITA to get to it. Used pole saw to pop a hole in it tonight they were pretty bent by that. I rigged up a line marker thing to adapt to the cans then put on my pole saw, consept was better then execution. It worked pretty well, but those cans only last like 5-6s then empty, a nest that big needed more then just one can, still dont think I got them all. Had a bat in the house the other night, no clue whats going on cant see how that damn thing got in, I did a pretty detailed review and still dont see the entry point....... Even tried my thermal camera no signs of a mass infestation. Bottom right are my footprints on the carpet.

-

47re Trans Service Tips and Tricks

Yeah, I get it for sure was over kill to do all those, that OD snapring takes some serious heat for my .215 backing plate to be that blue. For a while I was not finding much wrong as I was tearing it down, till I found that broken Belleville. I also had the whole OD unit out of sight out of mind for a while while I did the other parts. Thats were all the bad stuff was going on. Made some good progress today. Got most of my main assemblies back in the case, pump back on and torqued down.

-

47re Trans Service Tips and Tricks

I gave it my best attempt. I ordered every snap ring available on Rock Auto for the 47RE, some were duplicated in that they had a OD kit. So I have quite a few left over, then the master kit had some duplicates to that Rock Auto stuff, then I destroyed one of the seals so I had to reorder another $65 Transgo rebuild kit, so that has some extra stuff in it. There are a few others but here are some. I think there was one wire ring on the outside of the OD direct clutch housing, needs 2 the kit only had one, it did not appear to have any weight bearing on that surface was just holding the 2 parts together was very thin wire type retainer so I reused that one. The rear forward clutch with large Belleville return spring was broken, that came from Goerend they give you 2 sizes and you send one back. Thats why it looks like a "C" I think it was under $100 for all the extra snap rings, wish they had a master kit for those, but there are a bunch of different types. Its alot for sure but I did not need the truck. Did a bunch of research, I have a decent work shop at home, figure why not give it a shot, it sure is NOT the less expensive way to do it. Would have been a ton easier to have one built, but it will be mine when done, good or bad, no intention to sugar coat it if it goes south. So far have not cut corners on the build. Then,,,, I have all the stuff to do my 241LD transfer case, that was also in the cards, but need to get the trans together first. Time is never on my side... I have a 2yr old, one on the way end of Oct, run my own business with 3 partners and 15 employees, do a bunch of volunteer stuff for Habitat, don't think I knew how little time I had to take this on. So little bits at a time it will come together.

-

47re Trans Service Tips and Tricks

Nope thats my garage at home. I have a 96' 12v, little over 200k on those. I pulled out what seemed like handfulls of fiber material, decent chunks on my first attempt to change the fluid, so from there I knew it was just shot. The previous owner said the trans needed work.... basically the truck was max 50mph was a bad 3 speed. There were a few times when it got stuck in 2nd gear. Which actually was fine for me, since I can drive 20miles to work and never hit 50mph, its all back roads amd smaller 2 lane highways, there is no spot where the posted speed limit is at 50. We still used the 12v for the farm pulling hay wagons from the field to barn, it was still a very useful truck before I pulled the trigger to rebuild. I also have an 18' 2500 gasser which has put the 12v on the back burner, since I have a working truck. Used that for hay this season. I'm pretty close on finishing the rebuild, have all the main sub-assemblies built up. The one backing plate for the OD was pretty heat soaked so had to order that just got that in. Other self caused / just not enough experience issue I caused...there are 2 sprag roller bearings I thought there was only one had to order those 2 times, the one adapter for my press did not work had to order 2 of those. The kit was supposed to have a sealing ring for one of the Sonnex front accumulator, that was not included, but I tried to dry fit the one they sent, that would up getting stuck in the bore when the smaller ring clipped into the retainer groove, so had to get a new piston....something happened with my pump forget exactly but that had to wait for a 2nd order. Its very hard to buy ALL the snap rings, that took 3 orders. The snap rings take alot of abuse, see post about them breaking, so I wanted to make sure I had all the right ones. So yeah its been a fun process I enjoy the time in the garage, some days are productive others frustrating when you need another part.

-

Pilothouse/RAM3500 build

Looks good. If you ever need a really nice finish that holds up to even light scratches give this stuff a try, its pretty. Awesome stuff. We restore all sorts of small and large mechanisms and the sort, good for hardware finish as well. We call it Galvabrite. Really makes a nice finish. https://www.apidistribution.com/crown-galva-bright-premium-16-oz-aerosol You can shop around and find it at different places, I get from McMaster Carr.

-

47re Trans Service Tips and Tricks

CDI are great tools for the money. Only time I have issues is when the guys leave them set for months on end they have a memory for sure after. You can adjust them to a certain range but loose full scale. Sometimes we waste more time trying to cal them then they are worth. Have 3 or 4 CDIs that need new spring kits. When we start doing them again in a few weeks will do a separate post on them if I have time. And will deff do those 2 husky ones, they alwasy amaze me........ we do 3 checks at 3 points on the tool, they are very acurate compared some other brands. Who knows could be a fluke. When don't you need adjust bands..... when your OD clutch pack is mostly metals and not too many fibers.....this is my one OD clutch pack...should alternate fiber/metal/repeat......... mine was fried.

-

47RE Transmission

Sign up for a membership and the FSM and 47RE books are here for download. The ATSG book is a good resource and goes over some of the basic controls. Then reverse engineer from each book.

-

47re Trans Service Tips and Tricks

I have about 40 torque wrenches for my company, all sorts, I was not happy my guys went out and bought 2 husky in-lb torque wrenches, thought they would be junk, those damn things are some of the most accurate when we do our 6mo calibration check. I would suggest you pick one up can't go wrong with those for the price. We struggle with some of our CDI (snapon industrial) ones when they leave them set for months on end and that damn husky thing works every year go figure. Your friend has shared a link to a Home Depot product they think you would be interested in seeing: Husky 1/4 in. Drive Torque Wrench https://www.homedepot.com/p/Husky-1-4-in-Drive-Torque-Wrench-H4DTWA/206743985

-

99 Ole Rusty - Cab Rust

Looks like its all in great shape. Good find, looks like you made out very well.

-

99 Ole Rusty - Cab Rust

Yep about 50min north of Flemington just keep going up 31 till it ends, then up that way, my dad always brought us to the fair, it's now a Lowe's and a bunch of other stores, fairgrounds and racktrack long gone. The 4H Fairgrounds are still around south in Ringoes I think. I get all our uniforms from Flemington Dept Store, and added to my work fleet from the Flemington Chevy dealer down there in April. Have good friends who live in Neshanic Station, its changed alot. Sounds like you have a good process for getting your truck in good shape. I can appreciate the amt of work you are up against. Worth it for sure should be a nice rig.

-

99 Ole Rusty - Cab Rust

Mine was redone in 2012 by the last owner, he replaced the whole frame and a bunch of sheetmetal, rockers, cab corners, was pretty extensive. He used it for plowing and then the truck sat for a while after he finished, it leaked everything, had some issues and he got tired of it and I picked it up from there in maybe spring of 2015. We went to High School together. I have all the shop reciepts from his work done, he created real invoices from his shop for what was done, the paint and undercoating looks like it was a PPG product, not over the counter stuff, it's actually pretty thin stuff compared to a heavy 3M spray can version. And nothing like a LineX type product. His shop is pretty impressive he is one of 130 certified Porsche shops and is certified Aluminum for most major mfg, really a neat small anti-insurance company shop that knows the customers rights and will fight for you kind of shop. While the body stuff was mostly taken care of there are some problem areas we are in the Northeast lots of salt and the sort, so it takes constant work to keep it nice. Mechanically it had a bunch of issues I sorted out under the hood, I needed to fix all sorts of things that were not in the mix during his restoration of the body and just put back in as it was. I drove mine for 2 or so years as a 3rd vehicle so not daily, now its been sitting as I finish off the transmission rebuild, almost done, then need to freshen the transfer case and reassembly. Even with a full frame off after a few year it needed a bunch of sorting out. So I would say skip the paint if it cleans up nice and focus on the reliability. Pretty nasty to start with. Someone drilled out the battery tray to get to the cruise control. This is the pile of crap not used or replaced. Slowly got it all cleaned up and replaced and rebuilt a bunch of stuff. Its a work truck after all, we use it for Hay and the sort. So looking forward to getting it back on the road again after a long time.

-

99 Ole Rusty - Cab Rust

Downloaded will give it a try. On the truck..... Yeah I miss read your spec of 75" as 7'5", so yeah should be fine. They ride pretty rough but is not horrible for what they are. We had fun with our rental adventure. I found some old pics the previous owner supplied of my truck, he did a ton of work to it. He owns a body shop so not fair really he had some serious time and effort into the truck. He handled most of the body issues, I have a ton of hours into the truck fixing the mechanical stuff, I have a ways to go, Im rebuilding my 47RE right now thats been quite the adventure but fun when I get out to the garage to tinker on it.

-

99 Ole Rusty - Cab Rust

I thought I wrote down the MPG, then remembered I had to use the PA turnpike rest area to fuel up and they were short staffed they do this long winded thing with the paperwork and they gave me this giant piece of paper like I was doing my taxes. But I have a feeling it was 13-14MPG.

-

99 Ole Rusty - Cab Rust

Interior is listed at 7'-8", there were no obstructions inside the box. You will want to call them to see if its 7'8" clear through the door. If so its tight but works. That unit against the back wall is 48" on the one we rented. Maybe to be safe go with a stake body? https://www.enterprisetrucks.com/truckrental/en_US/vehicles/stakebed-trucks/sixteenstakebed.html I'm guessing its as wide as it is tall, and long, so putting it sideways is not going to help.

-

Errant Black Wire

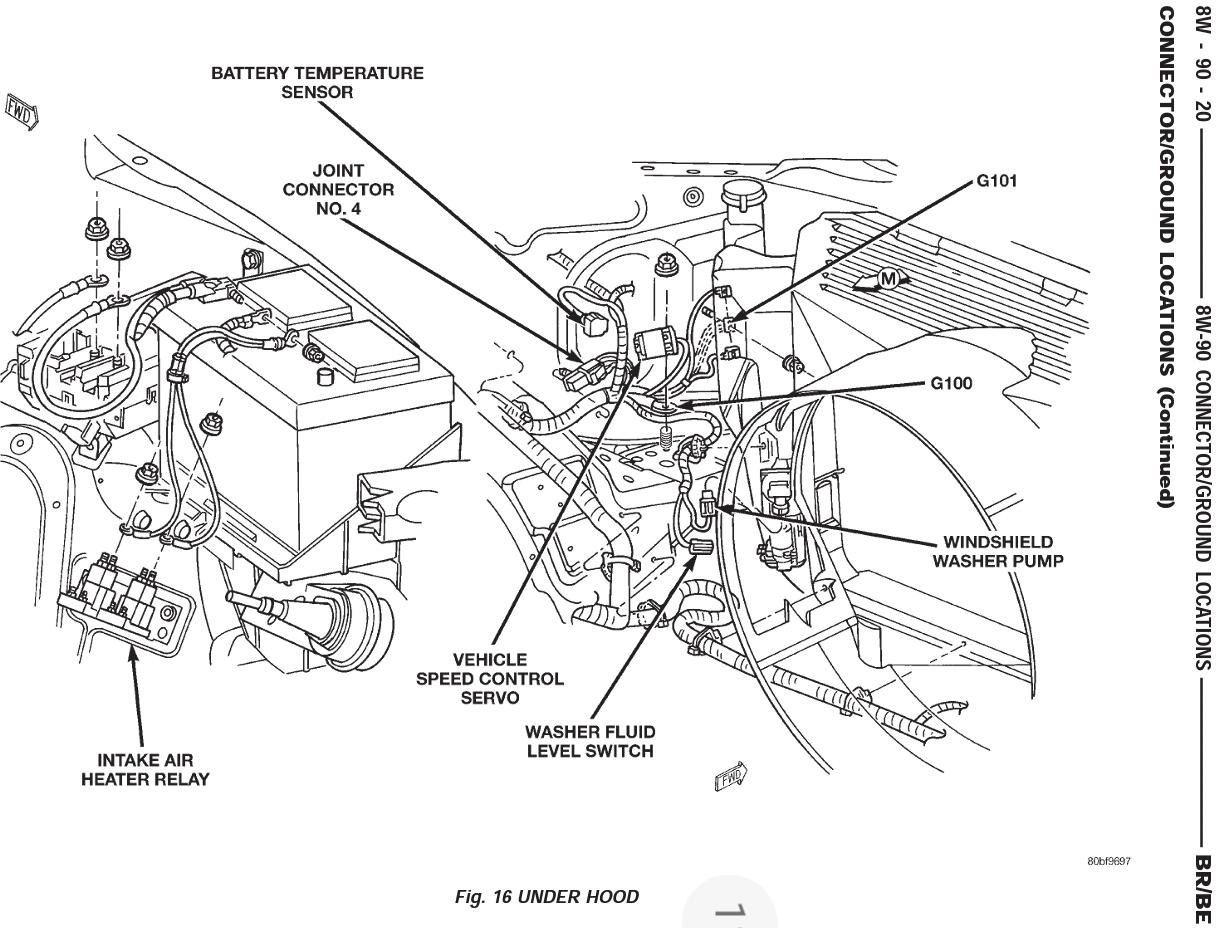

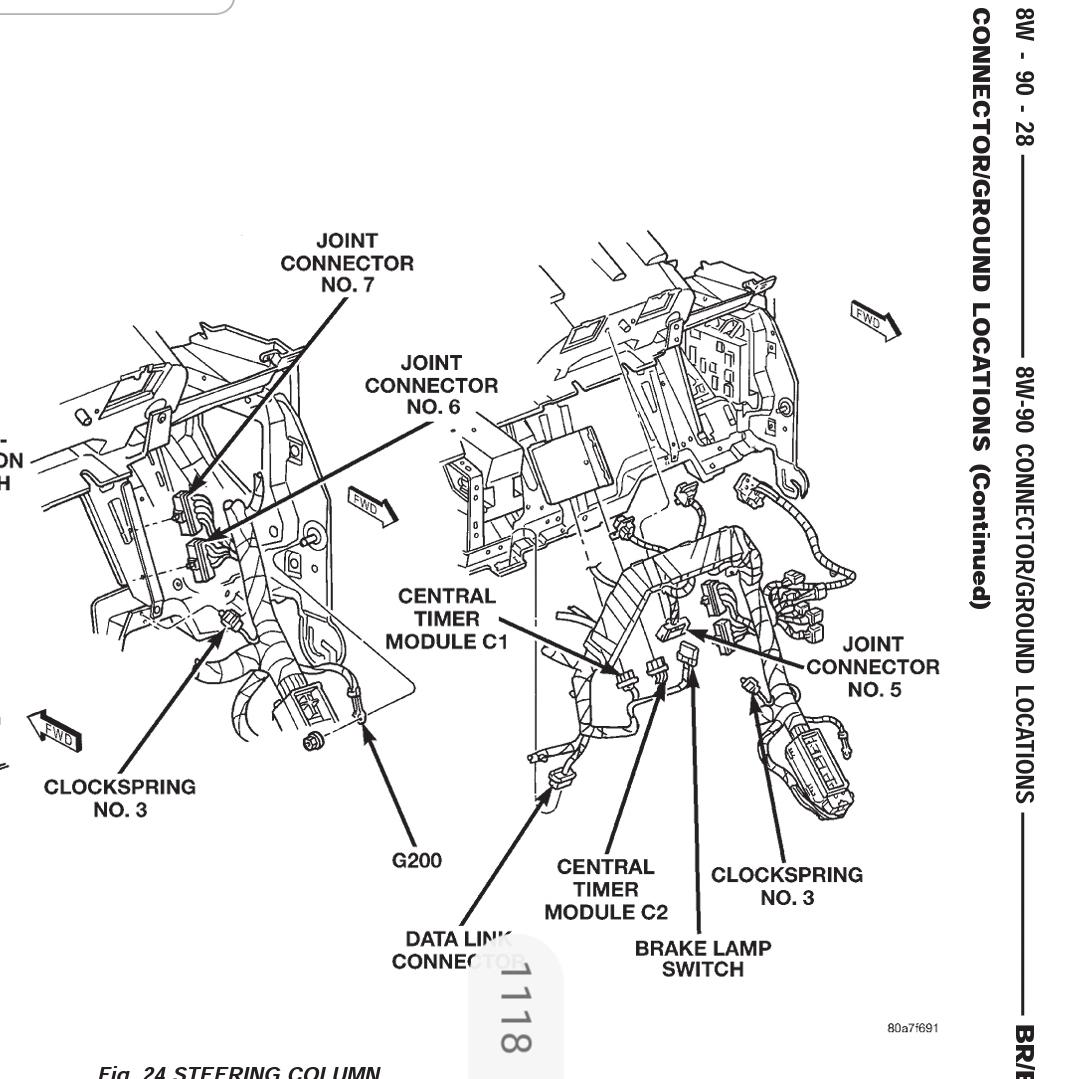

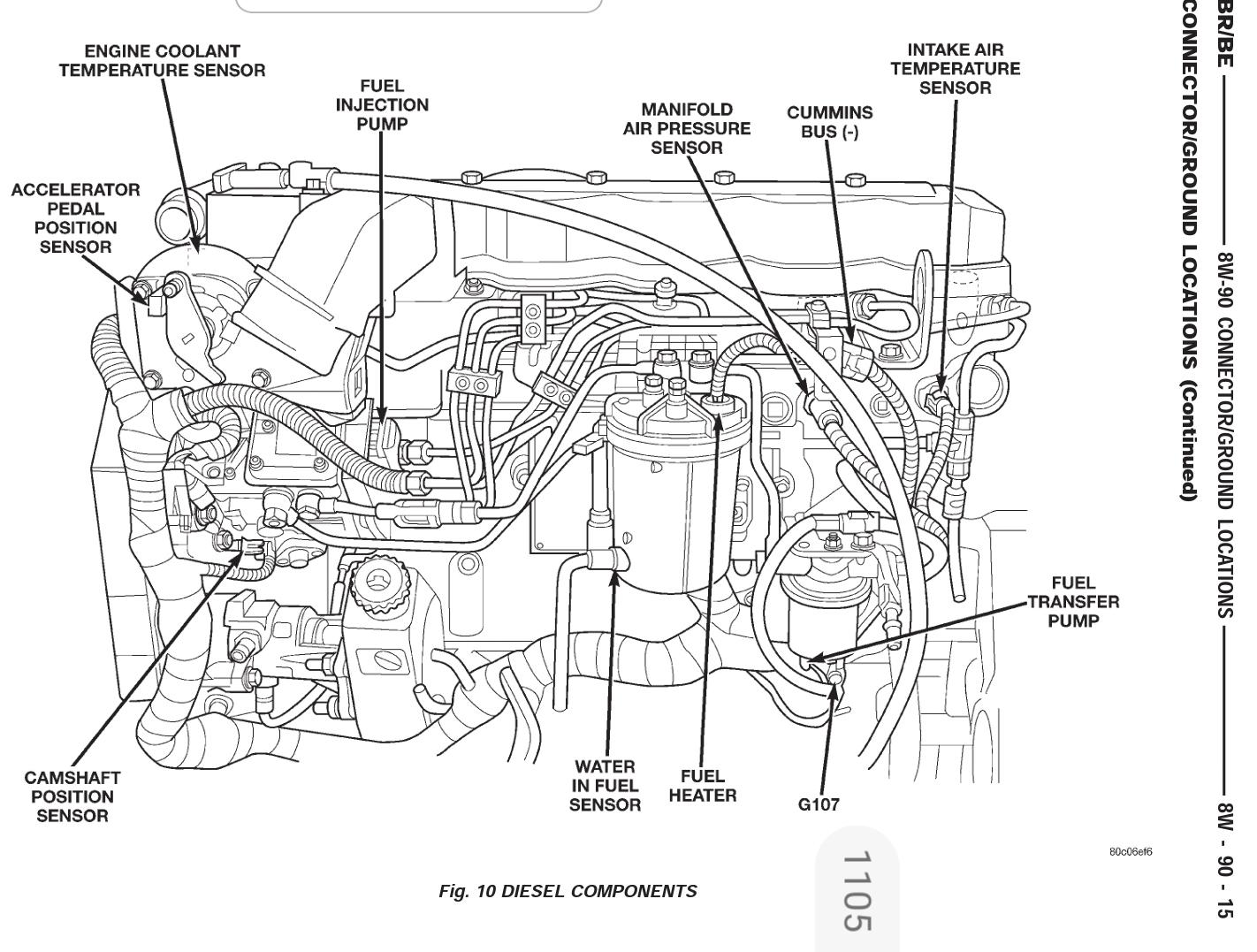

The only all black wire on the ABS diagram I see is G100, and it does not appear to land in that area it's looks to be more up front on the left side. There are 3 other grounds on the ABS sheet G101, G107, G200, they all have color tracers on the wire. Is there a tracer on the wire? Here are the locations of those grounds. The manual is really great for all the info they provide on the wiring and harnesses. G100, G101 G107 G200

-

1998.5+2001=headache

Sign up to be a paid member and there are manuals in the download area.

-

99 Ole Rusty - Cab Rust

https://www.enterprisetrucks.com/truckrental/en_US/vehicles/smallcabtrucks/business16.html Isuzu Cabover, we needed the lift gate, once your in one there are a millon of them all over. Penske, Hertz, Enterprise, they all run those. The lift gates on all of the rentals have a pretty steep angle to the platform. I have a Tommy Gate on the back of my '18 2500, it sits much flatter.

-

99 Ole Rusty - Cab Rust

Got it.... Yeah been there, we rented a enterprise box truck with lift gate was a few hundred for 2 or 3 days. Penske I think owns Rent-A-Wreck, they have those small box trucks, they worked wellfor us once, and could be options. Good luck, it will be worth it in the end.