Everything posted by Great work!

-

Getting stuck in 4th Gear issues for NV4500

That type of cast is generally more friendly to welding then engine blocks. I've had pretty good luck with mig welding. Just a small weld build then grind the weld to get rid of the pits and weld again.

-

Degree wheel VP44

That's why I want to build my own. My VP transistor went out years ago and I rigged it and its still working amazing. My ECM wait to start gets longer all the time up to 10 seconds now and ECM looses its mind sometimes. I have the ECM split wide open and some CAT5 cables soldered on to the pins so I could spy on everything and not have to stand on my head tapping wires down by the starter. The ECM is just hanging by wires Its amazing it still works. Truth is I built an Arduino PSG 3 years ago and my truck actually ran but rough. The poor Arduino was maxed out, I was trying to do too much with software and soon cooked my fuel solenoid. I actually re-wound it (about 10ft of 25 gauge magnet wire on a bobbin made from a nylon spacer made on my lathe and JB weld) and that worked. Then I snagged the ribbon wire going to the sensor in the pump and ripped it in half. I found out the hard way that these parts must be made of unobtainium and had to buy a reject core for parts. I didn't want to be without my truck so that put things on hold.

-

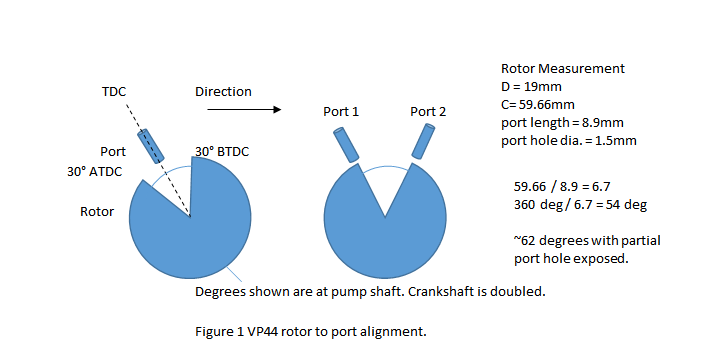

Degree wheel VP44

@Silverwolf2691 and @Mopar1973Man Thank You. Collaboration is great! First the 6.7 is just the ratio of rotor slot length in mm 8.9 to the rotor circumference in mm 59.66. So 59.66 / 8.9 = 6.7, the rotor diameter D is 19 mm X π (Pi 3.14) = 59.66 mm. So if the circumference spans 360 degrees then using that same ratio; slot length in degrees = 360/6.7 = 53.7 degrees. After reading your replies I started digging even deeper with my "degree wheel" and taped the pump shaft to the cam ring. I installed the timing piston and left out the spring and then measured how much range and stroke the timing mechanism has. MoparMan is right I measured 15 degrees (30 crankshaft *) of advance and also noticed that Start of Injection can't really occur after TDC maybe 2* ATDC my measurements are not exact. Then I made a really big discovery, thanks guys. I noticed the plug part that holds the small servo piston and return spring was actually limiting the stroke of the timing piston by 3 mm. I got almost 20 degrees (40 crankshaft) without the plug. I checked the return spring fully compressed it was 15 mm and the piston depth (inside skirt) for the spring was 18 mm, coincidence I think not. So to get more timing for those sled pullers just machine off 3 mm from the skirt of the piston. I almost bet that a timing piston from a European version V44 from a high performance car (BMW, ***) would allow more advance. The cummins timing piston is 63 mm long. We need someone with a VP44 from a different car to measure one of theirs. Or a Knowledgeable rebuilder / parts person to confirm this. I also thought about machining the plug but 3 mm is a lot and the o-ring groove would be almost gone, but this would have been easier then pulling the pump off. Next issue is, will the PSG software ignore any timing command over 30* or obey it? If it doesn't like it there is possibly another way around it. The ECM provides a timing reference signal to the pump on pin 8. This signal is derived from the crank or cam position sensor. It is has a cycle of 120* an on time of 85* and off time of 35*. The falling edge of this signal happens at 20* ATDC. The VP compares its internal position signal from the sensor on the cam ring to the ECM ref signal to compute its actual timing relationship or phase to the crankshaft then adjusts the mechanism via the TCV solenoid to match the desired value received on the CAN bus. By "tinkering" with the timing ref signal, say advancing it 10* the pump will advance 10* then request 10* less then normal with a tuner on the CAN bus for stock. The pump may throw an error because it knows approximately how much duty cycle at the TCV solenoid causes a given amount of advance after all it can run in some capacity with a bad crank sensor or hot wired in test mode.

-

I'm Back, Finally! And I have some good questions/ topics

Sway bar mounts I used a couple years ago. I can't remember if I had to adjust holes or not. https://www.amazon.com/gp/aw/d/B003884IJ0/ref=ya_aw_od_pi?ie=UTF8&psc=1

-

Degree wheel VP44

That's right the cam ring revolves around the shaft. The timing piston has limits and the software has limits. That phase relationship determines start of injection timing. I need the port alignment timing which is fixed and never changes. If I try to inject when the port is blocked that dead heads the pump plungers and bad things happen.

-

Degree wheel VP44

I am working on a home made PSG unit and needed to know the min and max absolute timing. So I improvised a degree wheel and blew back into the #1 port with the pump shaft key way centered with the mark on the front of the pump by the seal. I could blow back about 30 deg before and 30 deg after which is +60 and - 60 at the crankshaft. I noticed that the port starts to close up about 3 degrees sooner because of the port hole width. There is also about 1 degree of overlap where two ports are very slightly exposed. I then measured the rotor, slot and ports then did the math and it confirmed my findings. So never try to inject past ~54 degrees either before or after top dead center. o

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Ok but those are normally very solid connectors and should never bump loose. You might take another look at the latches on them. After a certain year you can test the cluster by holding the trip button for along time or hold while turning key on. Can't remember. Also oil pressure sensor is very delicate and maybe intermittent

-

Truck randomly dies. Please help, pulling my hair out, and loosing sleep!

Open the connectors near center of fire wall by vacuum tee. then clean and reconnect a few times to wipe clean.

-

Dead truck

Get it started again and stress things. Tug - tug on all wiring and tap on everything electrical PDC ECM fuses relays with a screwdriver handle or small rubber mallet see if it dies.

-

VP44 Injection Pump Teardown - How it Works

I could see the pictures earlier today but not now.

-

front ball joint time

My 40+ year old Ford with a king pin Dana 60 still drives better than my dodge ever did. It looks like the new Ram has copied the Fords front suspension now but removed the rear leaf springs. I have a bad ball joint now and a sloppy u joint but it's too hot to fix it right now.

-

I'm Back, Finally! And I have some good questions/ topics

Looks great

-

VP44 Injection Pump Teardown - How it Works

@TractormanI agree there is a lot of hype about lift pumps. Probably because of all the warranty claims early in the life of these trucks. However I believe that inside the vp is a very violent and turbulent place and a lift pump keeps some pressure in there to prevent cavitation. The timing piston oscillilates in it's bore causing wear because the rollers have resistance and want to drag the cam ring with them. Just speculating that there needs to be some pressure on BOTH sides (vane pump side and lift pump side) of the timing piston to dampen it. That could be why so many stuck pistons happened when lift pumps failed.

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

Check the air filter it might be sucked into the tube or critters made a home in there.

-

Turn the Key to start = Zap, nothing!

I fixed a 1st gen last month like that checked starter contacts and they were fine. It would roll start or start with jumper cables ok. Turned out the battery cables were changed out and the wire was copper clad aluminum total junk they were almost corroded in half inside.

-

Truck stuck in 3rd gear limp mode

I put something called sure cure by sonnax in my valve body years ago. It had those parts except the retainer. The VB needs to be super cleaned and all the bores brushed and scrubbed out then inspect the spools clearance with a pin light. Best to use wife's kitchen table for this. LoL. You may find another broken spring in there too it's pretty common and doesn't really affect much some are broken for years. Check out a new intermediate band anchor called a wedge while your at it.

-

I'm Back, Finally! And I have some good questions/ topics

I had a hard time finding correct rear sway bar bushings by application but 24 mm is about the same as 1 inch. So I found some on amazon by dimensions I think they were for Corvette but they were close enough to work.

-

Cam Plug leaks

I rebuilt a 12 valve it had a swell plug back there that was supposed to seal up when hammered. I didn't much care for it. 50 k mile later has some leakage from either the rear seal or cam plug.

-

VP44 Injection Pump Teardown - How it Works

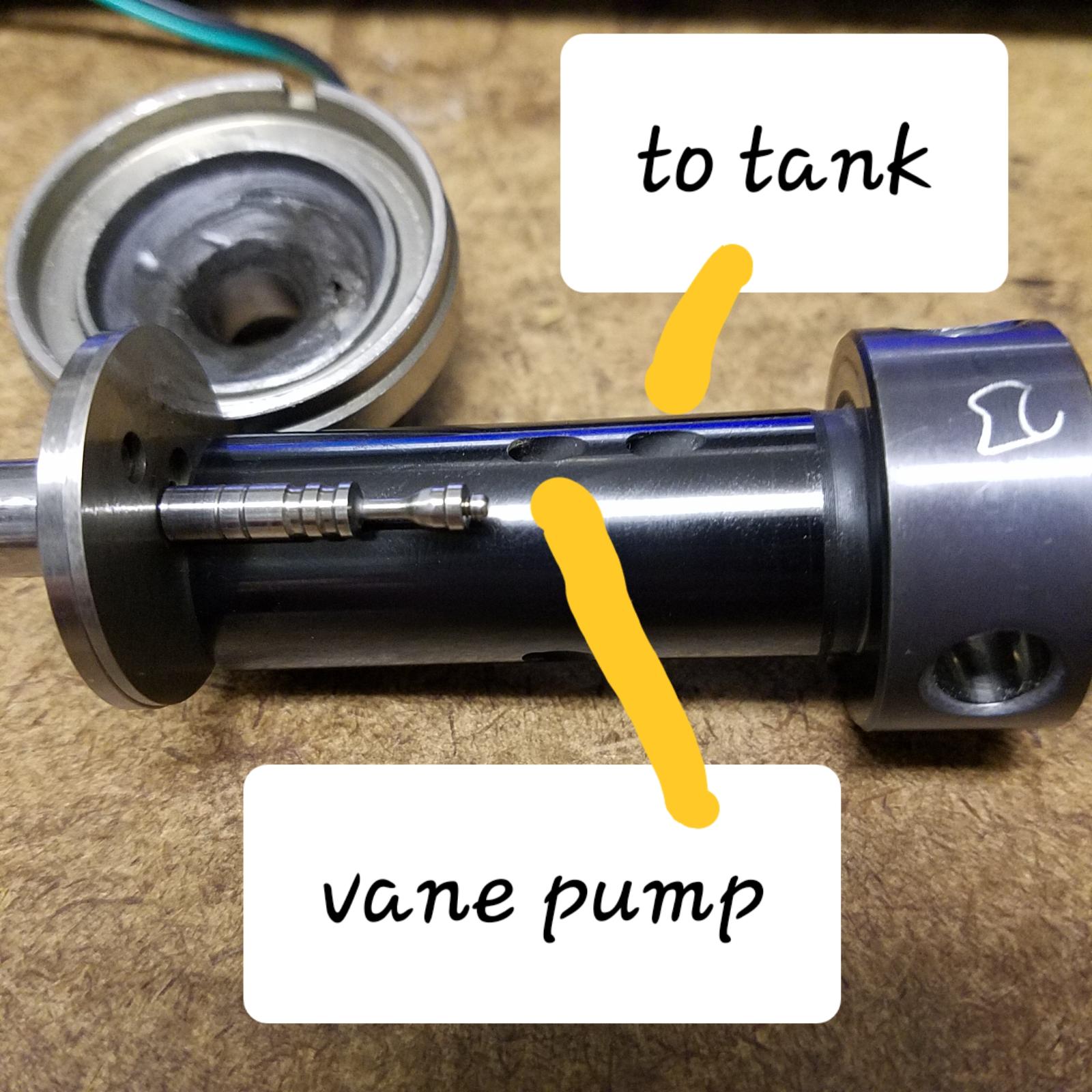

I dug deeper into my spare test pump and need to correct one of my prior statements. It's not just the leakage and lube that get returned to the tank. When the spill valve closes injection occurs AND the vane pump port in the rotor gets routed to the port directly ahead of it which goes to the overflow banjo bolt. The bore in the center of the rotor enlarges very slightly where the spill valve exits so that some fuel gets by and cools the solenoid. The rotor also has lube holes so that flow comes out the end of the rotor. The end chamber where the injection solenoid is has a port with a small orifice pressed into it that flow also goes to the overflow. In the pic the ports are drilled at a slant and meet at the tapered part of the spill valve. So the vane pump gets routed to the tank when an injector is spraying. When the spill valve is de-energized at the EOI the three plungers are still moving inward so that flow is shot back towards the accumularor section that is formed by the diaphragm disk. @TractormanI agree with your explanation that the vane pump is rapidly shifted between charging the plungers and returning to tank during injection. @wil440 I'm just speculating that the 14 psi overflow is for the benefit of the vane pump. It keeps enough back pressure on the vane pump so that at very low cranking rpm when the flow from the small displacement pump is very low there will be enough pressure differential so that the injection plungers will be charged and forced outward to follow the cam ring profile.

-

Vp44 psg removal

Putting some air pressure in the inlet port before removing the top can help push out a stuck solenoid. If the shop is going to put in a new mosfet transistor instead of a whole new psg cutting wires could be safer than trying to force out a stuck soleniod and breaking it.

-

Truck stuck in 3rd gear limp mode

Strong young guys with the wrong tools dropping a valve body is a recipe for broken bolts and a bad valve body. The bolts must be torqued correctly and the plastic rooster comb on the linkage is delicate. I would inspect the wires inside the tranny very closely for pinches or rub through first.

-

VP44 Injection Pump Teardown - How it Works

W-T, blow up that last pic. Right above the red letter 'd' there is a port plug ( ball thing) where the zip tie goes in the port is drilled all the way to that port plug from there it is drilled straight down and feeds the vane pump. The vane pump excess gets returned back to vane pump input NOT the tank. The leakage / lube for the rotor goes to the back of the rotor, some fuel also gets past the end of the spill valve and cools the solenoid coil all that fuel gets returned to the tank. So when not running there is a lot of restrictions between the inlet and overflow.

-

VP44 Injection Pump Teardown - How it Works

The vane pump output has a regulator it goes from about 100 psi at idle to 300 psi at full speed. Saw it in a Spanish youtube once. The diaphragm can crack from metal fatigue and the outer o ring wears from oscillating back and forth in the bore. The Vane pump feeds the inside of the injection plungers and causes them to move outward and follow the cam ring (no springs). The outer part of the plungers are exposed to lift pump pressures. So low vane pump pressure during cranking on one side vs high lift pump pressure on the other plus a leaking diaphragm causes the plungers to not follow the cam ring which causes hard starting.

-

VP44 Injection Pump Teardown - How it Works

The diaphragm is held in the center with a snap ring the outer edge of it has an o ring. The outer portion 'flutters' as the high pressure fuel gets spilled back toward the chamber that the diaphragm encloses. The injection plungers are still moving when the spill valve opens at the end of injection so the pressure pulse is absorbed by the diaphragm chamber.

-

Dana 70 to 80 swap

Call the shop that's going to shorten it. They will tell you how they want it measured. That's what I do.