- Replies 32

- Views 8.4k

- Created

- Last Reply

Most Popular Posts

-

What servo was used? What do you mean by "no slack" in the TV cable? How did you adjust it? At what RPM does your WOT 1-2 shift occur? EDIT: Also, how is your front band adjust

-

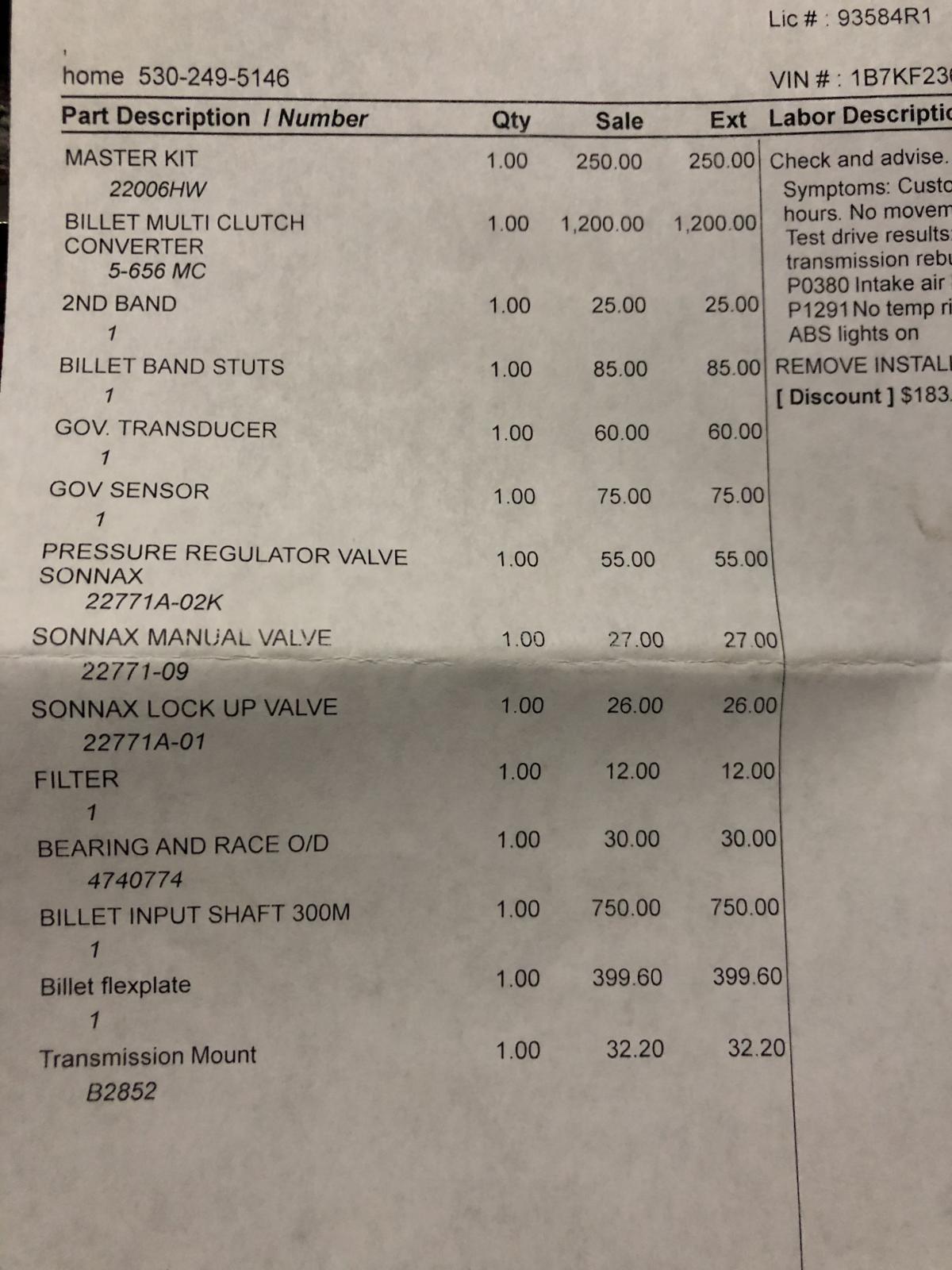

Ughhh... And the prices these corner transmission shops charge people for these "built" transmissions. SMH... I digress... There are 3 Sonnax valves on the invoice, which basically aren't

-

OMG... And they sold you an Aermet shaft? You don't even need a billet shaft at all at that power level. And 900 hp? Ummmm... NO. I'm going to shut up before I say something I might regret later, but

Hey guys, first post! Stoked to be here. Anyways... I bought my truck about 2 months ago and it came with a built trans from Hartnell transmission in Redding. I proceeded to snap the Billet input shaft Which was obviously defective, and this was repaired under warranty that was thankfully transferred to me. They replaced the converter, pump, put in an Aermet shaft that I paid for, and cleaned out the rest of the trans. While the trans was out I had them put in a billet accumulator and 2nd gear servo, 4.2 ratio lever and billet anchor and strut (TCS combo kit). Before this work, the trans shifted great. Now that it’s back in, the 1-2 shift is super fast, near instant and very firm. Perfect, in my opinion. The 2-3 shift has an obvious bind up where the truck slows momentarily before the shift. Once the shift actually happens, it is firm and quick as well though not as good as the 1-2. All other shifts are great, no problems downshifting. I’m going to loosen the band again to see if this helps but it didn’t seem to have any effect when I adjusted the band the first time. The trans stays very cool so I don’t think anything is dragging when it’s in a gear. I used Dex/Merc with a bottle of lubeguard black. Would the band adjustment be different with the 4.2 lever? What would be my next steps in diagnosing this bind up?