- Replies 37

- Views 3.5k

- Created

- Last Reply

Top Posters In This Topic

-

01_Cummins_4x4 13 posts

01_Cummins_4x4 13 posts -

Mopar1973Man 10 posts

Mopar1973Man 10 posts -

wil440 4 posts

wil440 4 posts -

Tractorman 2 posts

Tractorman 2 posts

Most Popular Posts

-

Too long on intervals. Aim for 75k tops. Long life is a joke being every cold start you dumping 600 to 700 amp over the coolant jacket and will charge coolant and start shifting the pH lower. Do not a

-

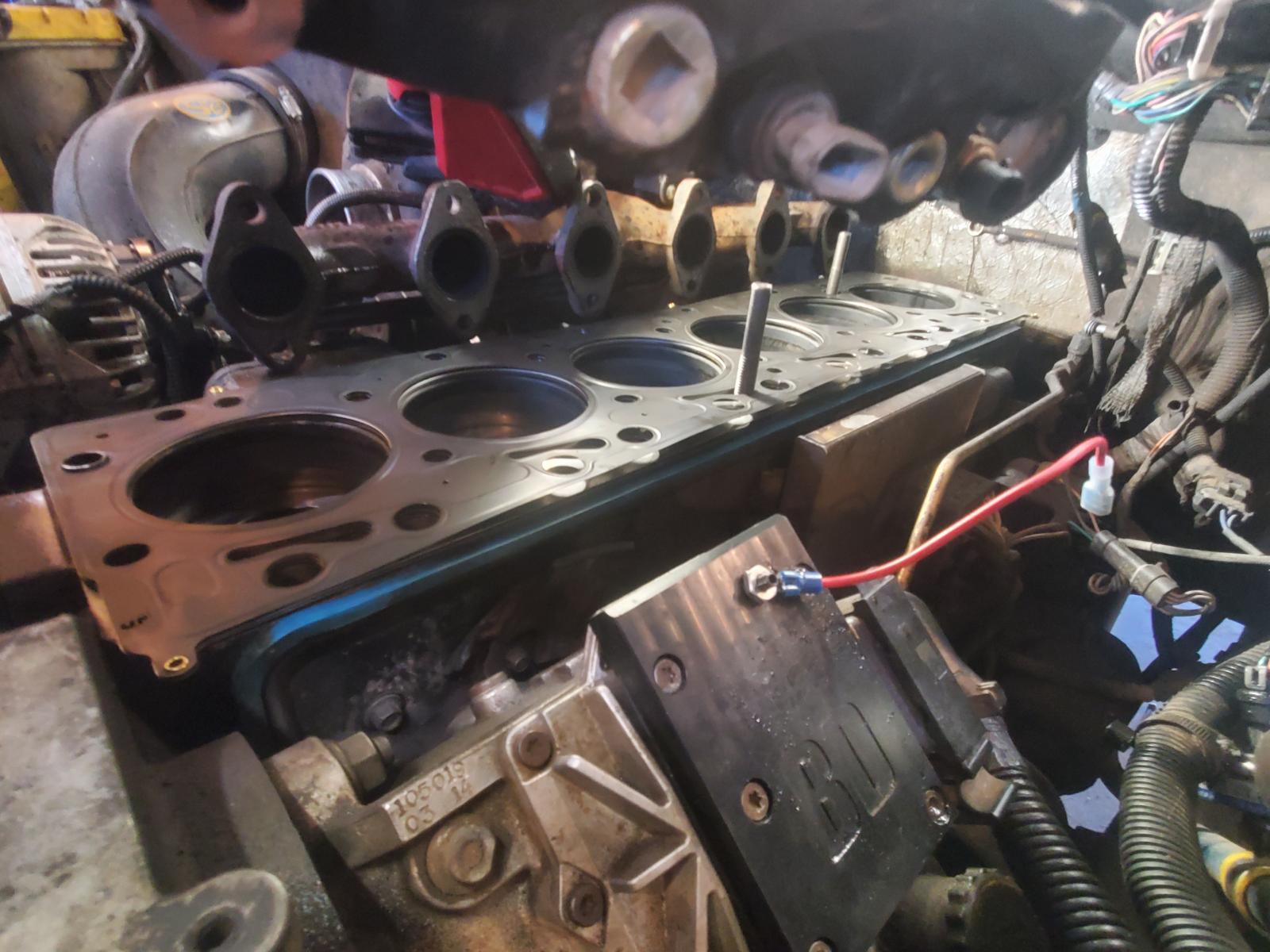

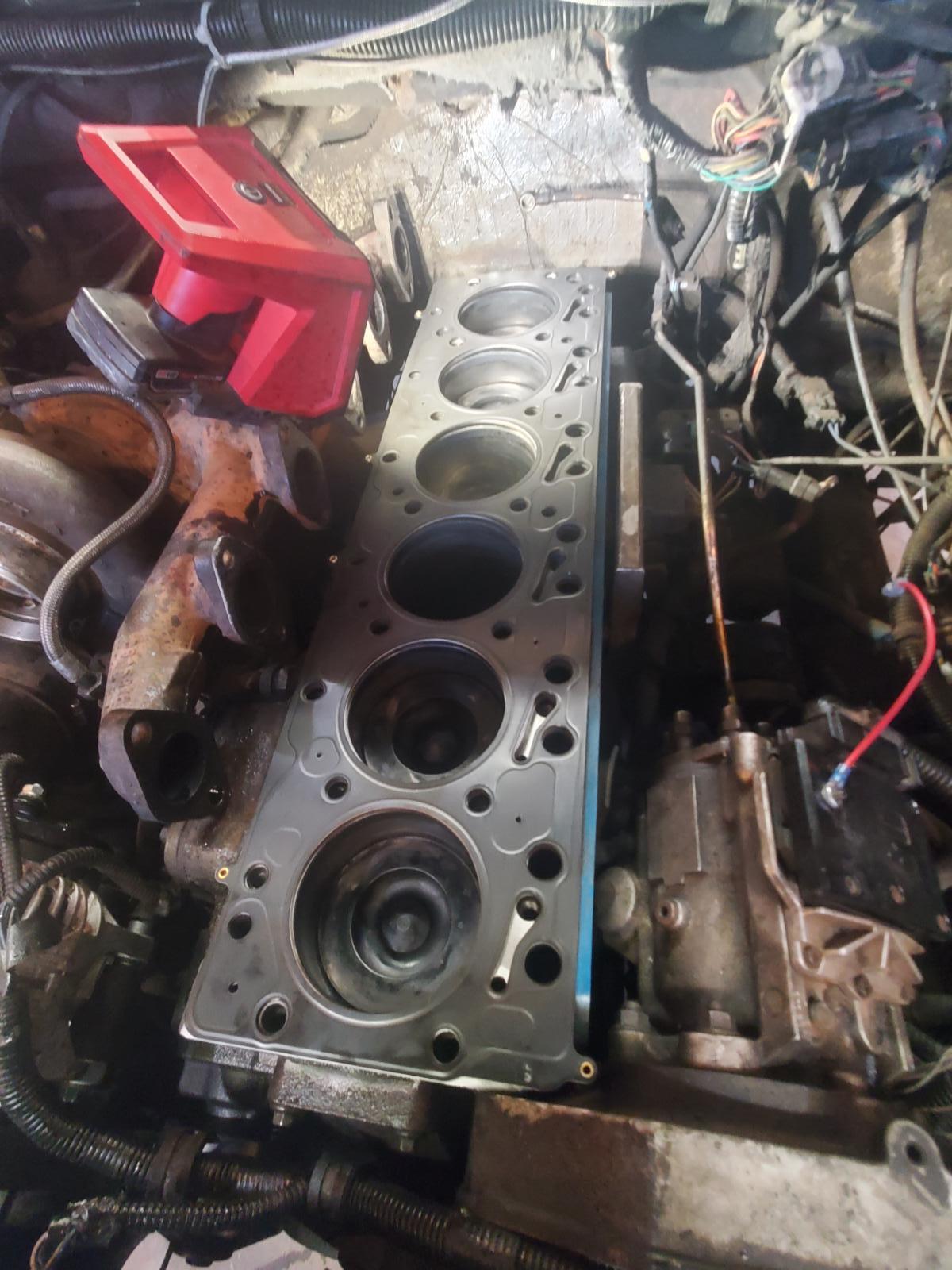

I swapped out the crappy Fel Pro gasket that blew out between cylinder #1 and the front of the head. I ordered and installed a brand new Cometic MLX multi layer stopper steel head gasket .

-

At $230 it darn sure ought to do better than a $50 gasket or I'd be furious.

On Dec 9th 2020 I bought a water pump from O'Reilly's and installed it in my pickup. All was good until last night when it went out. It leaked enough coolant out that the radiator fan airflow splashed it into my alternator and caused it to quit charging. My Edge Juice with Attitude said I had 11.8V when I got home.

I found my receipt for the water pump and it says it's a Murray CP7145 and it doesn't fit my 01 Cummins, even though that's what O'Reilly's gave me. The pump they gave me fits a 98 and older 12V.

A Murray CP6148 fits my 01 and it has a different pump blade design. The 98 pump has a curved plate on it while the 01 style pump doesn't have the curved plate on top of the blades. Is running the 98 style pump on an 01 the reason why the pump went out?

My alternator is the Bosch unit and of course O'Reilly's doesn't have one in stock. I did spray it with electronic parts cleaner and used my air compressor to dry it out. I'm going to have O'Reilly's test my alternator to see if it's dead or not.

Edited by 01_Cummins_4x4