- Replies 47

- Views 7.9k

- Created

- Last Reply

Top Posters In This Topic

-

jokra 11 posts

jokra 11 posts -

dripley 8 posts

dripley 8 posts -

Mopar1973Man 5 posts

Mopar1973Man 5 posts -

jlbayes 4 posts

jlbayes 4 posts

Most Popular Posts

-

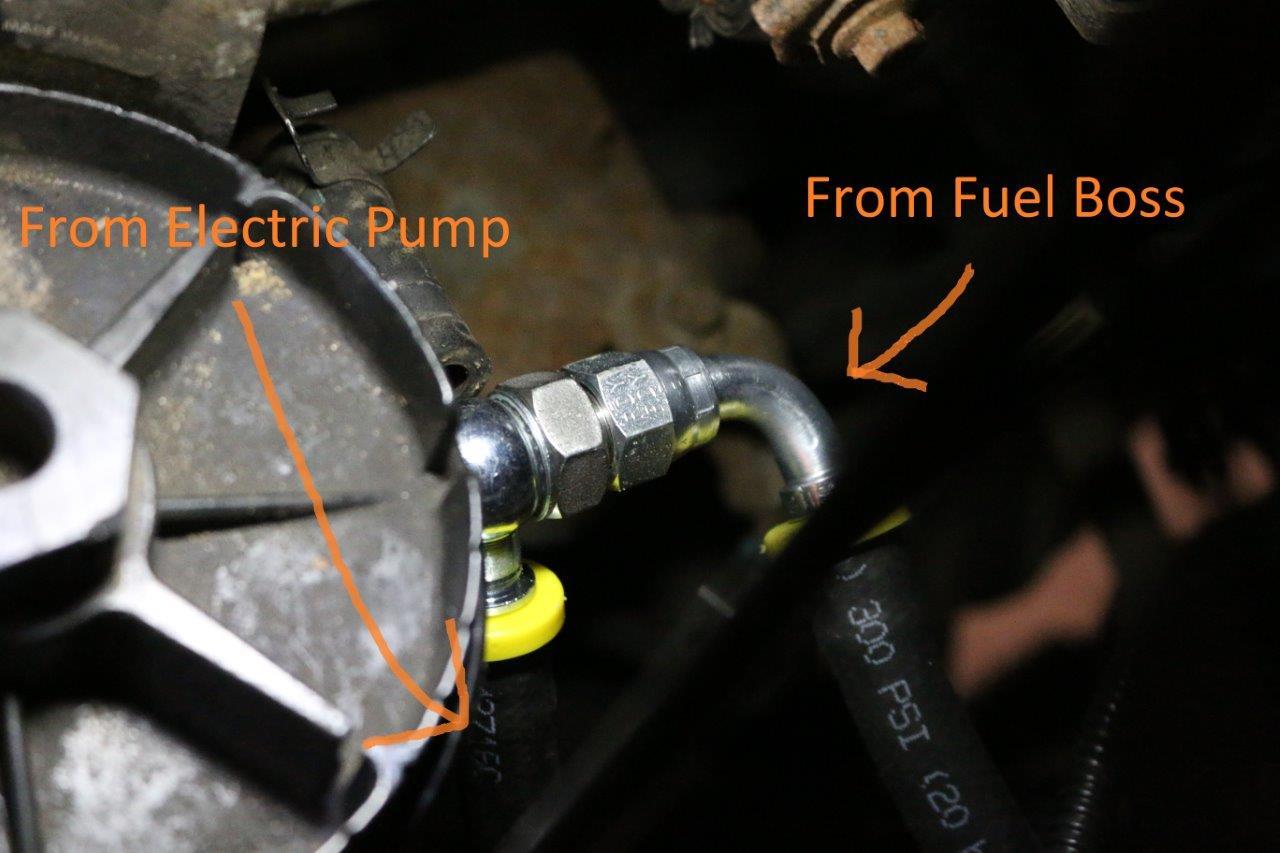

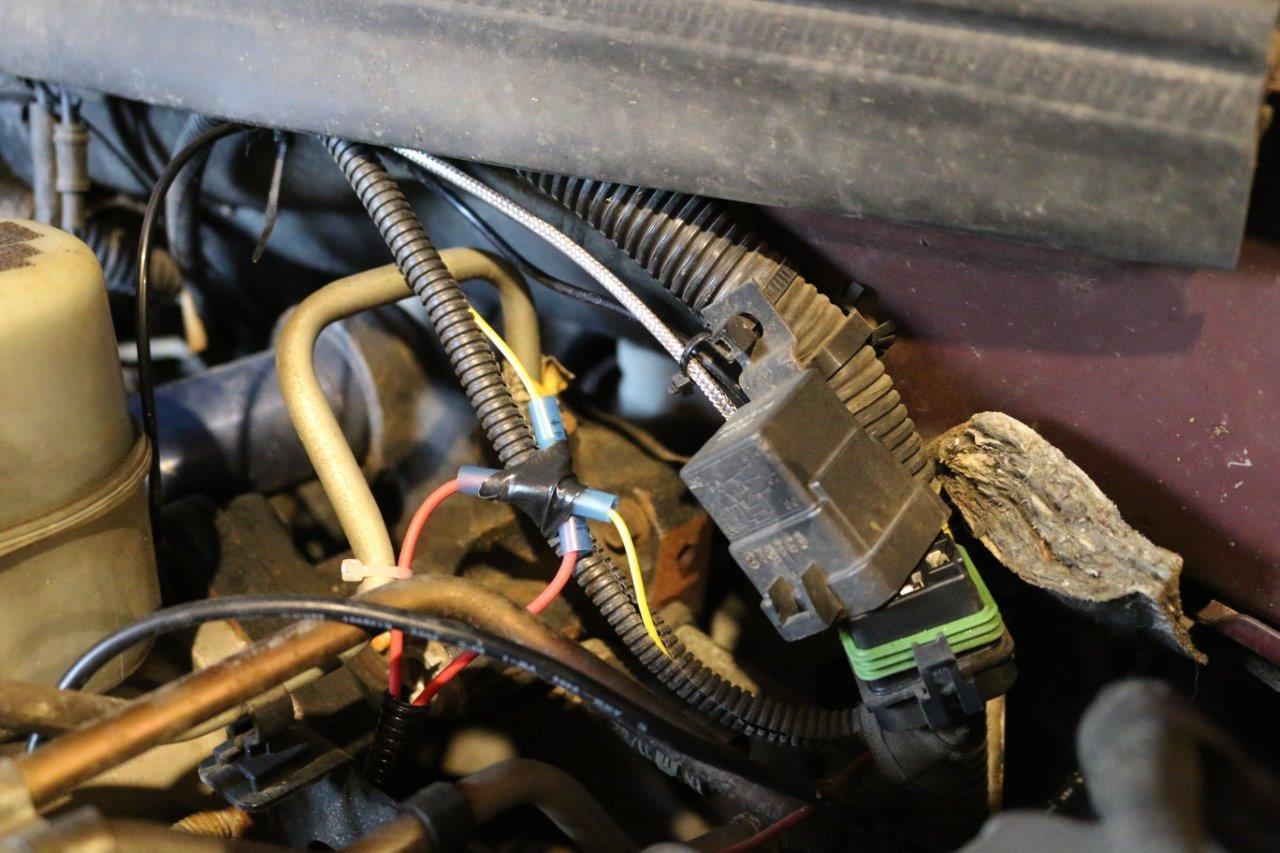

Guys, thanks again for all the advice on this topic. I finally decided on a solution and finished installing it this week. I ended up going with a GDP Fuel Boss mechanical pump that is fed

-

I think with the Fuel boss you cannot have a pre filter before the lift pump. I'm not sure but I think you can put one on after. I like water separating filter before an electric lift pump

-

Just an update for those interested in what Richard@GDP had to say about using a Fuel Boss alongside the in-tank pump on my 2001. First of all, you all were right - what a great guy. Easy to talk to,

Good afternoon! I'm brand new to the forums here, and brand new to the diesel world. This site looks like the best community of 2nd gen Cummins addicts I could find anywhere, so I am honored to join and learn from you, and hopefully one day contribute to helping others as well.

Hopefully this is an appropriate place for an introduction, I really enjoy reading the intros from some of you and learning about how your trucks are setup, and their history, so here's a shortened version of mine:

I bought this 2001.5 from a family member who bought it brand new. He purposefully waited until the 2001.5 version to get the disc brakes in back. It has always been meticulously maintained, and was completely stock when I got it. Well, other than driving better than when it was new. Quite a bit of time was put into getting the steering right, I don't know what exactly it has up front that is different than stock, but I can see one of the steering "kits" up there. Whatever it is works, because it drives straighter and with much less steering play than my dad's 99 half ton Ram. This one is also a little unique in that it has the plow-prep package, which I was told includes stiffer springs in front, and the camper package so it has an extra leaf spring in back. So it sits quite a bit taller than others I've been next to, and rides like an oak tree. Actually, it rides much better with an oak tree sitting in the back.

I haven't done much to it. A buddy owed me a favor and installed a 2" coil spacer to level out the front, at the same time we put in Bilstein 5100s. Just the front for now, I have a set for the rear on order but haven't gotten them yet. I also removed the turbo silencer ring because I was new to diesel and excited to whistle, and of course youtube told me that would make it whistle! As you all know, removing that ring does absolutely nothing to how loud you hear the turbo, at least to my ear, so I also installed a BHAF (not just for the whistle). I can't remember for sure as this was last summer, but I am pretty sure the motivation for the BHAF came from Mopar1973Man himself, before I knew how famous you were in this sector. I then showed my dad what I had done and mentioned something about "wonder if I should put a heat shield on that" - and the next thing I knew he had made me one, out of diamond plate. You can see that in one of the pics.

I then showed my dad what I had done and mentioned something about "wonder if I should put a heat shield on that" - and the next thing I knew he had made me one, out of diamond plate. You can see that in one of the pics.

Otherwise it's all stock. Always had FleetGuard filters, oil always changed every 5k, it's never even seen the inside of a car wash, always washed by hand. I'll try my best to maintain it as well as he did, but it's winter now and my garage isn't heated, so that last one may have to change.

She likes to haul firewood. Oh, and you can see the Cummins sticker on the back, which of course adds 80hp at the wheels, what I've been told. ;)

And the fact that it's stock is the reason I ended up on your site and why I wanted to post this message in the first place. Fuel delivery. The good, the bad, and the ugly. The history on my truck is that around 80k the lift pump was replaced with the in-tank by a dealer. They did this just because he had read that they were a common problem and wanted to make it "right" (what they considered to be right at the same, this was in 2008 or so). 100 miles after replacing the lift pump with the in-tank, the VP44 died. I assume the old lift pump was actually bad and the replacement put the VP over the edge. So it got a brand new VP44 from the dealer as well. I just rolled over 154k with it, and the more I read the more I worry. So I got gauges. And found I only have about 8psi idle, and if I stomp on it I can dip it below 5.

I didn't want to create a new forum post to cover information that already exists in so many posts already, and so I searched your forums for anything fuel related, and I read ALL of them. And I thought I had decided on what I was going to do - FASS 150 titanium with a Draw Straw V, until I saw someone mention a Fuel Boss. Then I saw someone else say Fuel Boss, then it seemed like every post I read had at least one comment in it about the Fuel Boss! Lol. So I'm hoping to get a little further insight there. FASS vs Fuel Boss - ideas? Good, bad, indifferent? One consideration is that it sounds like some are using the Fuel Boss with no electric pump whatsoever. Over the long haul, will that be hard on the VP44 to be pulling its own fuel during startup? What if I do something like install a Fuel Boss hooked to a Beans sump...? That way I could leave my in-tank stock pump in place, since it still works? But if I do that, I'm confused as to how I would plumb it properly, since I cannot plumb the T from the Fuel Boss into the in-tank pump, they would be pulling from separate fuel sources. Would that even work? I am not opposed to going FASS+DrawStraw, though I'm not super excited about dropping the tank just because I've never done it before. But if I can make Fuel Boss+Beans Sump workable, it's possible I could get all this working without even having to touch the top of the fuel tank...? Let me know if you see holes in my theory, because I'm sure I'm missing something important that will leave me stuck.

Thank you so much, and it's great to be part of this group!