- Replies 266

- Views 47.9k

- Created

- Last Reply

Top Posters In This Topic

-

Dieselfuture 103 posts

-

trreed 53 posts

-

jlbayes 40 posts

-

TFaoro 25 posts

Most Popular Posts

-

The people that tell you to sell old and buy new know nothing about fixing vehicles nor do they work on them. I work on hybrids and electrics. There is a huge disconnect between the end user and the v

-

Alright guys and gals, got my turbo today. I'm giving it 9 out of 10 and this is before driving the truck. Came with cnc machined beer opener. On first glance it looks good, on closer observation I've

-

Trying to get valves out so I can take this thing in to shop. What's the best way to release keepers, I usually slightly tap on them and they come apart, but these are stubborn. @TFaoro @jlbayes @trr

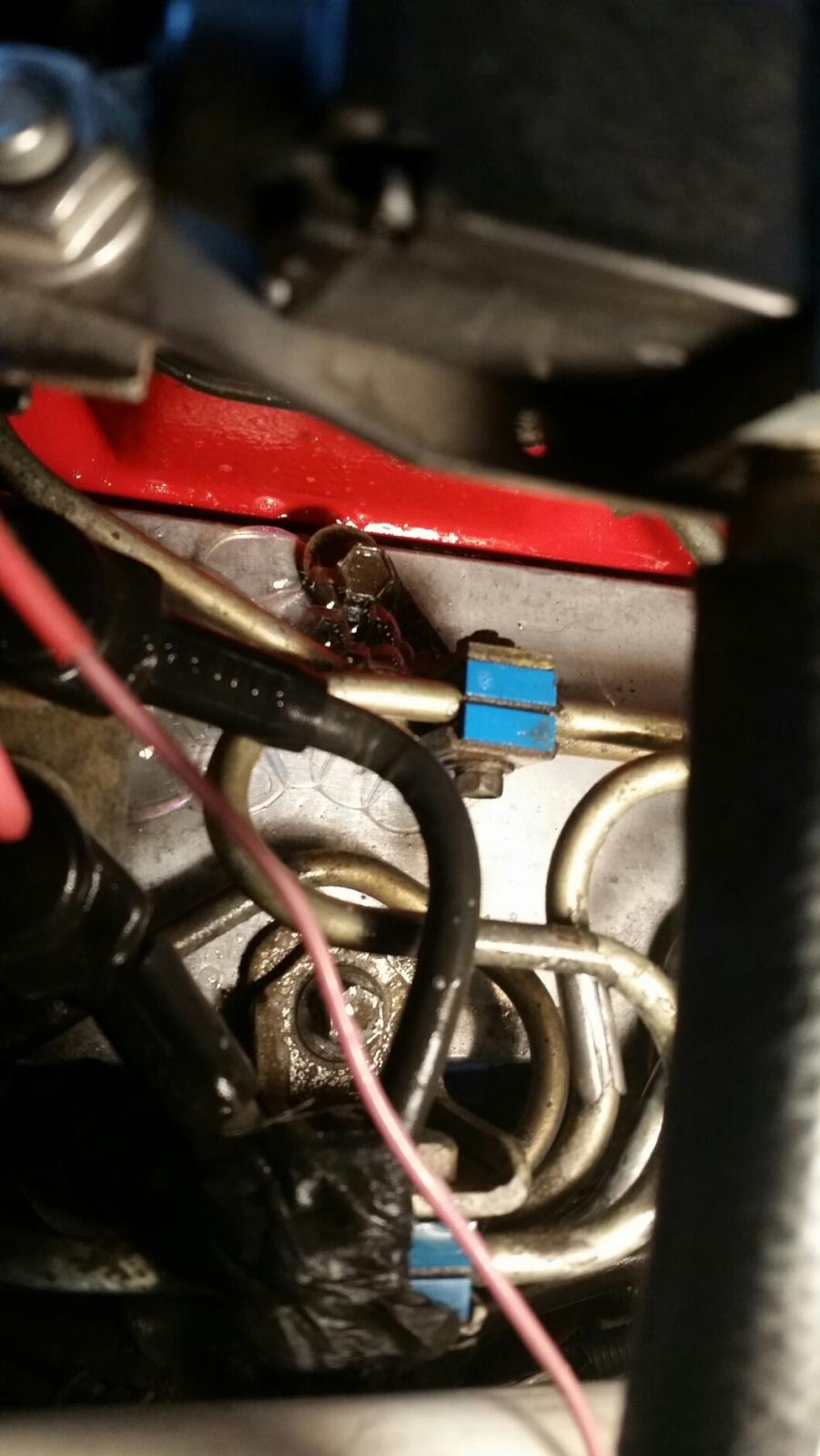

Well I hate to say that word head gasket, but I got oil bubbling out of front right, by head bolt just to the right looking from front( I got ARP's from po. ) It bubbles tiny little bit from head gasket and running down front cover, not enough to drip on the ground yet. Wondering where is a good place to get parts from, like a gasket set and whatever else I may need. Though about mabe going through the turbo but want to up size to at least a hybrid, so might just leave it be. Another thing is I already have ARP studs but not sure which ones, how do I tell, I know there is more than one choise. Will need to know torque on them when putting the hradon backnowledge on. Can I get the head off without removing studs looks pretty close. I will take the head to machine shop to surface and maybe even check for cracks, since I heard 24 valve heads like to crack sometimes. Will probably do a valve job and new seals at the same time. Not sure about ringing the head. The T at the back of the head, what's the best way going about it. Thanks for any advice. I will probably be lining up parts for a while and keep driving the truck, unless it gets real bad or just blows out. I'm guessing there is an oil passage somewhere up front, just not sure how it's getting pushed out, oil pump pressure? Does it have something to do with coolant, I don't think I'm using any, maybe a little I had to put about a quart in the other day, will keep an eye on it.

Edited by Dieselfuture