- Replies 6

- Views 1.6k

- Created

- Last Reply

Top Posters In This Topic

-

IBMobile 1 post

-

comanche79p 1 post

-

Evan 1 post

-

Bullet 1 post

Most Popular Posts

-

Why not just one T off the 1/2" line for the fuel pressure gauge then tap that smaller line with a T for the Quadzilla. This way you only need one snubber and needle valve to eliminate the hammer eff

-

I agree with this. That way you can put the 2nd Tee in a better location rather than cluttering up that area with a bunch of lines and connections.

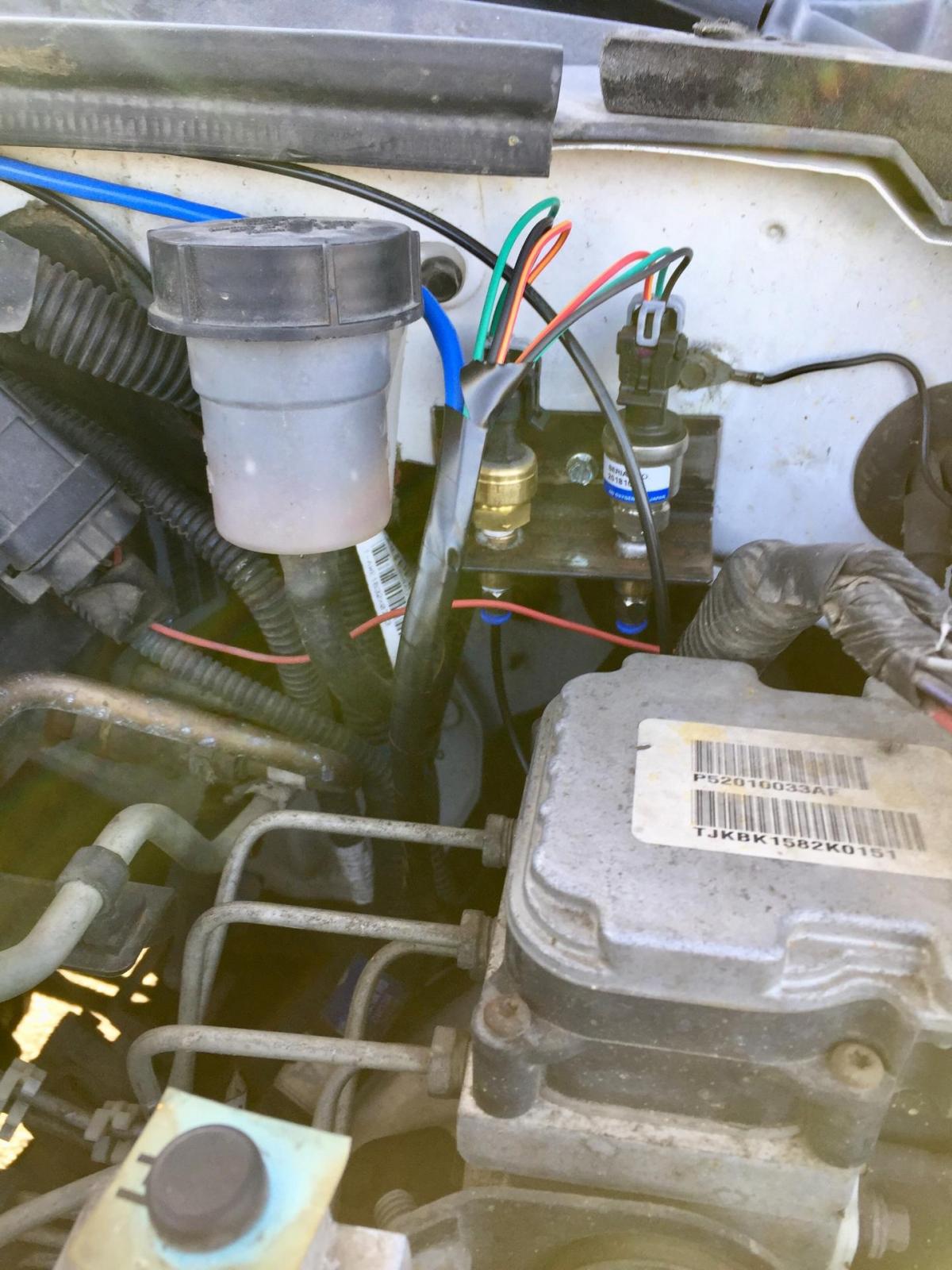

I have had a big line kit for the filter housing to the VP44 for some time and want to install it.

I have 2 “T’s” to splice into the rubber line in order to install the fuel pressure port. One is for the Quadzilla fuel pressure and the other is to

the manual gauge on the pillar.

Anyone see a problem with having two taps close together on the rubber line? Right now I have the banjo tapped on the VP for only the manual gauge.