- Replies 41

- Views 8.2k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 12 posts

Mopar1973Man 12 posts -

Blueox01 11 posts

Blueox01 11 posts -

LorenS 5 posts

LorenS 5 posts -

Dieselfuture 4 posts

Dieselfuture 4 posts

Most Popular Posts

-

Throttle Brake Parking Brake BOOM! 3 pedals. One hand holding my coffee, the other holding the wheel and operating the turn signal. :D

-

New toys to play with

-

For the longest time I've wanted a 3/4 ton, square body Suburban with an ISB 4 cylinder and one of Fuller's automated manuals. FO5506B may be one of the model numbers that's close. I like to sip coffe

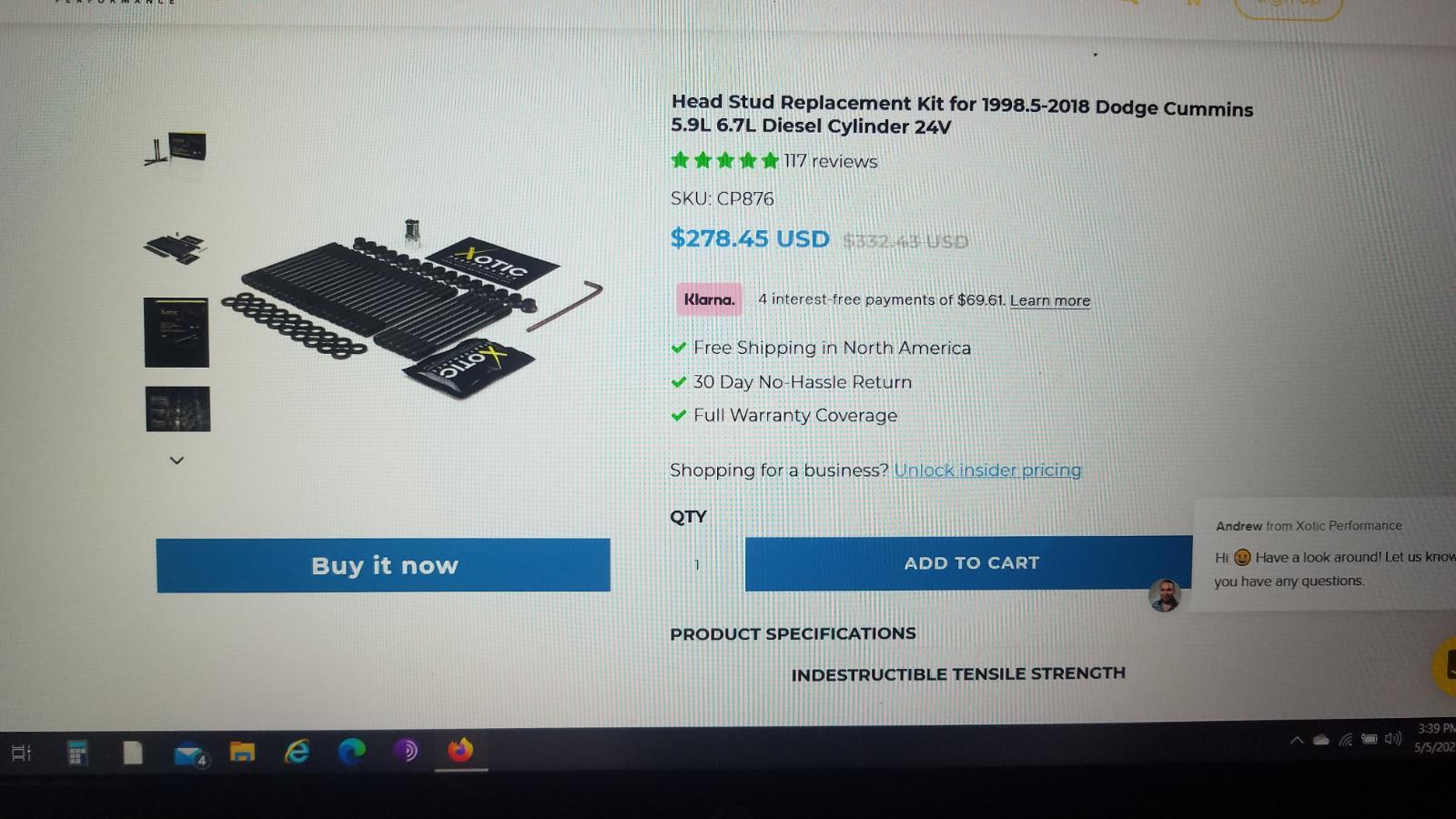

Anybody know anything about Xotic performance head studs