Everything posted by Mopar1973Man

-

Semiannual Sierra Nevada camping

I've been busy going through cabinets getting rid of extra weight. Getting it down to just what I need for a trip. This is my 4th day living in the RV.

-

Orwell's 1984 one step closer to reality

Just shaking my head. I can't believe the amount of BS the government can come up with. Listening to Newsmax on my tablet. I'm glad to be 180 miles away from Boise.

-

New injectors on the way.....

Live data tool.. OBDlink MXis much cheaper.

-

Steering questions

So check tie rod ends for play, check steering shock for function, front shocks are they good, and the last wheel balance... Steering box you can adjust it up snag again. Rare for them to wear out. Just get a bit loose.

-

Angry & can't do it anymore, serious iQuad timing issues

Yeah I can hear the tick it's in the front cylinders for sure. I'm not sure if it's valve train or that's a injector firing early tick?

-

New injectors on the way.....

You welcome. Make sure to rate the article and hit the review and post up too.

-

New injectors on the way.....

New radio heads are both WiFi for Apple products or Bluetooth for Android. Personally Android has the least amount of problems which Apple product typically have issue importing tunes and getting the radio head to hook up. Android, I've never had anyone call with a problem. Me, I normally don't run my Quadzilla display unless tweaking a tune or building tunes. Other than that I just use the a-pillar gauges (Boost, Fuel Pressure, and EGT's) Boost reading on the Quadzilla are only accurate below 25 PSI above is skewed badly. You are not required to keep a display going like Edge Tuner or Smarty Touch. Quadzilla can be ran headless.

-

Semiannual Sierra Nevada camping

Here in the next few days I'm going to be camping out in my RV. This way I'm packing what I need for the trip and more or less test drive the entire unit. I know the furnace is working great being I've had it on the last 5 days drying the humidity out of the RV. It been down to 35F to 38F every night so I've been using the furnace and the water heater. Fridge I've lit temporary but I'm not level right now. I need to hitch up and move to the hard pack for doing the axle bearings. Too much rain and the yard is super soft right now.

-

Semiannual Sierra Nevada camping

Yummy.... im going to be waiting.

-

Semiannual Sierra Nevada camping

I'm game. Beef tongue burritos are delicious, pig tongue will most likely be similar.

-

Semiannual Sierra Nevada camping

Damn right... Maybe I should go over the member map and start calling, emailing and PMing. I could make a crowd in a short order. Hmmm. Maybe I should stay quiet and enjoy my vacation.

-

Semiannual Sierra Nevada camping

OMG Funny though... How about you buy the plane ticket I'll come out. Much easier that the 5 a gallon fuel fees.

-

Semiannual Sierra Nevada camping

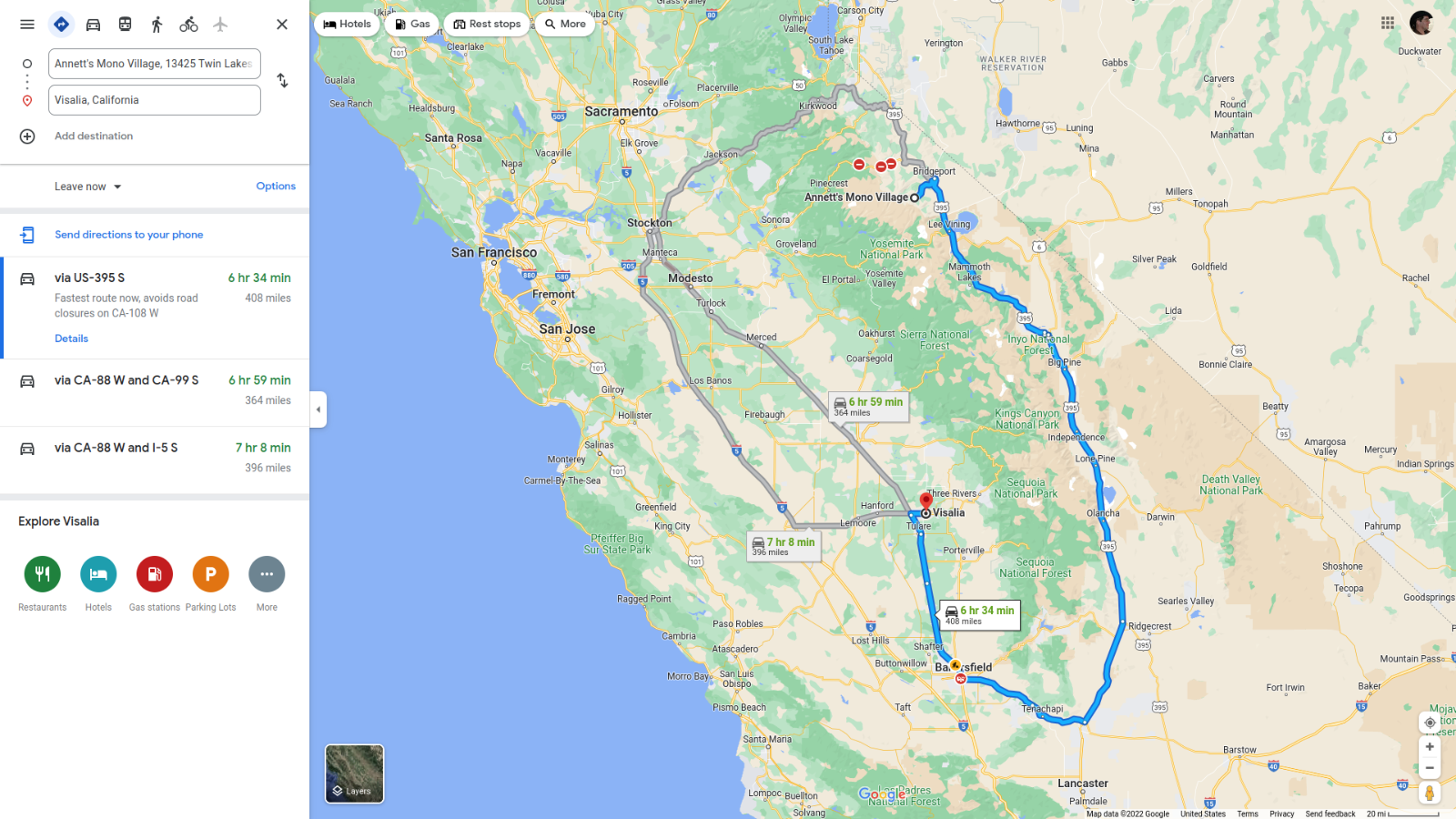

Too far south from where the camp out will be but... You not far and could drive up and hang with me. I did a Google map lookup and figured botched the directions typical California. I'm sure you could make the trip up easier than me coming down that way. I don't use a GPs in that fashion. I know my North, South, East and West... Me I'm heading south and a bit west. East isn't going to happen anytime soon "yet"...

-

Semiannual Sierra Nevada camping

A/C cover installed. The cover I got lucky and found a RV dealer that had a used one with a bad hole. Just fender washer it. Only cost 50 dollars vs 250 dollars for new. Grabbed a new fan belt for Beast. Installed this morning easy peasy lemon sqeezey..squeeze... Now to get my truck clean and inspected.

-

First time towing with new setup.

Non issue... deeper the retard the quicker the spool up. More advancement more the fuel is burned in the cylinder. Now too much advancement you'll created negative torque when the expanding burn is push down on the piston as it travelling up yet. Too much retard the piston is travelling down when the fuel ignites and the little to no knock sound there is loss of power but quick spool.

-

First time towing with new setup.

Becareful, high starting timing might not give good boost building. Something I learned with building my trailer tune. Little secret I backed down more and pulls better.

-

Quadzilla economy towing tune

Roughly 20 MPG with the light weight trailer (calculated guess). I'll be heading out on the 9th and running fully loaded on the RV to Cally. I'm going to be fully loaded, water, propane, clothes, ATV in the bed of the truck.

-

Quadzilla economy towing tune

I've got a towing tune coming together. I build a base tune from my economy tune. Tweaked it for use on my Jayco RV which is 31 foot long and typically scales in at 8,000 to 8,500 pounds. As for today I was using my BigTex trailer and headed back down to Middleton, ID to put up my free bed. King size, dual zone adjustable. I had a 1/4 tank and left made to Council, ID and got 30 dollars of fuel (5.6 gallons) and continued to Middleton, ID loaded up the bed and headed out grab 20 dollars (3.8 gallons) of fuel and continued back to Payette, ID. Basically traveling 100 miles on about 5 gallon of fuel. Trailer was empty down (1,800 empty weight) and loaded no more than maybe 2,000 trailer and any other cargo in the truck (maybe an extra 100 pounds). When I was at Payette I got 100 dollars on my Maverik Nitro Card gives me 6 cents off a gallon so it was 20.004 gallons at $4.999 per gallon. I changed up the timing and it builds boost quicker, holding on and grade it might bump the added fuel zone little bit but it falls back to my stock fuel zone pretty quick. EGTs are cool, even on a 7% grade no more than 900°F at 65 MPH. Tune is smoke free, launches good with a load, easy to build power. Even wide open I struggled to even get close to 1,200°F even on the grade passing. Just cruising on the Interstate at 80 MPH (2,450 RPM) I was just about 750°F. This is just my first setup but I'm planning on heading to California with my RV so more tweaking will be performed. Just for the first run I'm very happy in the power even though I'm only using level 3 (CANBus fuel only).

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

Foot off throttle, my truck shows zero constant. EGTs drop to right about coolant temp on long down grades. Winchester Grade is quite long and typically see EGTs right at 180 to 200°F. Quadzilla reports zero engine load, back when I had the OBDLink LX it showed zero fuel injected (flow in GPH).

-

Fel Pro head gasket gave up in 4k miles

Just to prove it's not minerals that cause the issue being both my well and irrigation water is drinkable. Your correct it the pHlevels that city water starts out at and the additive package of the antifreeze can't fix that. Being I'm NOT on city water but natural water there is no issue either. That why the voltage starts to show being when the pH shifts to acidic (heading towards zero) it will create electrical charge in the coolant. Not to mention every time you start your truck cold you dumping 500 to 700 amp charge across the block super charging the coolant. This is why color is meaningless. If you wait for rust or discoloring it too late already the pH of the coolant is oxidizing the metal cast iron of the block, aluminum of the radiator, heater core etc. This is the oxidized metals you're as scale blooms in the radiator they condense out of solution on the core tube ends. Just consider why I've got my factory water pump at 441k miles. Coolant pH has been kept neutral all these years, no damage to the seal or shaft since no coolant is seeping pass the seal the bearing isn't oxidizing either.

-

DIY vp 44 and ECM. It runs, very happy

During start up run the lift pump circuit at 50% duty cycle. This will reduce injection pump fuel pressure. It will also prevent over advancement of the pump which creates hard starting. You can verify this by unplugging the lift pump.

-

First time towing with new setup.

I'm going to take my economy tune as a base and go from 4.5 per timing band to 4.0 per timing band. This will allow for a bit more boost under load. The bit of retard will give more expanding gases to the turbo for more boost.

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

Yes. When engine load is ZERO then the VP44 stops injecting and just bypasses to the return line. This applies to all engine and transmission combos.

-

White smoke, low power when starting

Only thing I would do is ditch the Blue Chip Pump and go back to a stock VP44. Modified pump could pose a problem being like Blue Chip pump do with building tunes. Stock VP44 is much much better for tuning over hot rod or Blue Chip pumps. Proper final ratio has to do with getting the power to the ground without heat. Good final ratio to the ground of 3.55 to 3.73 is required. If your running oversized tires on 3.55 gear I will bet your EGTs are high.

-

White smoke, low power when starting

I'm running... 150 HP injectors popped at 320 bar Quadzilla Adrenaline tuner with my economy tune HX35W turbo 4 inch exhaust straight pipe 30 inch tires (245/75 R16) NV4500 transmission BHAF