Everything posted by Mopar1973Man

-

Radiator leak

Doesn't surprise me at all.

-

Rewiring tail lights

Finally getting around to doing repairs on my own stuff rather than everyone's else vehicles. The previous owner of Thor just hacked up the tail light wiring and made a huge mess out of it. So I went out and order a weather-tight 7 terminal bus bar box. That way all the hitch connectors and the tail light wiring have a place to be without just be hanging under the bed as a knot of butt splices. The interesting part of the 3rd Gen bodies and electrical it is way over wired for the rear. Basically, there are two sets of wiring trailer/tow is one set with solid colors like green, yellow and brown. Then the body electrical is white stripped something. Dodge managed to do everything backward for color typically yellow is left, but Dodge used white/green. After test lighting and going through a ton load of wiring diagrams and retesting again. I found the brown for marker light on the trailer is not working from the TIPM. The green and yellow for turn signals and brakes work fine. I high jacked the body marker light lead (white/tan) for the trailer. I've got to get some plugs for typical push-in light like the round markers on my flatbed. I'll get a photo here in a bit this morning when I head back down to my shop.

-

Brake accumulator

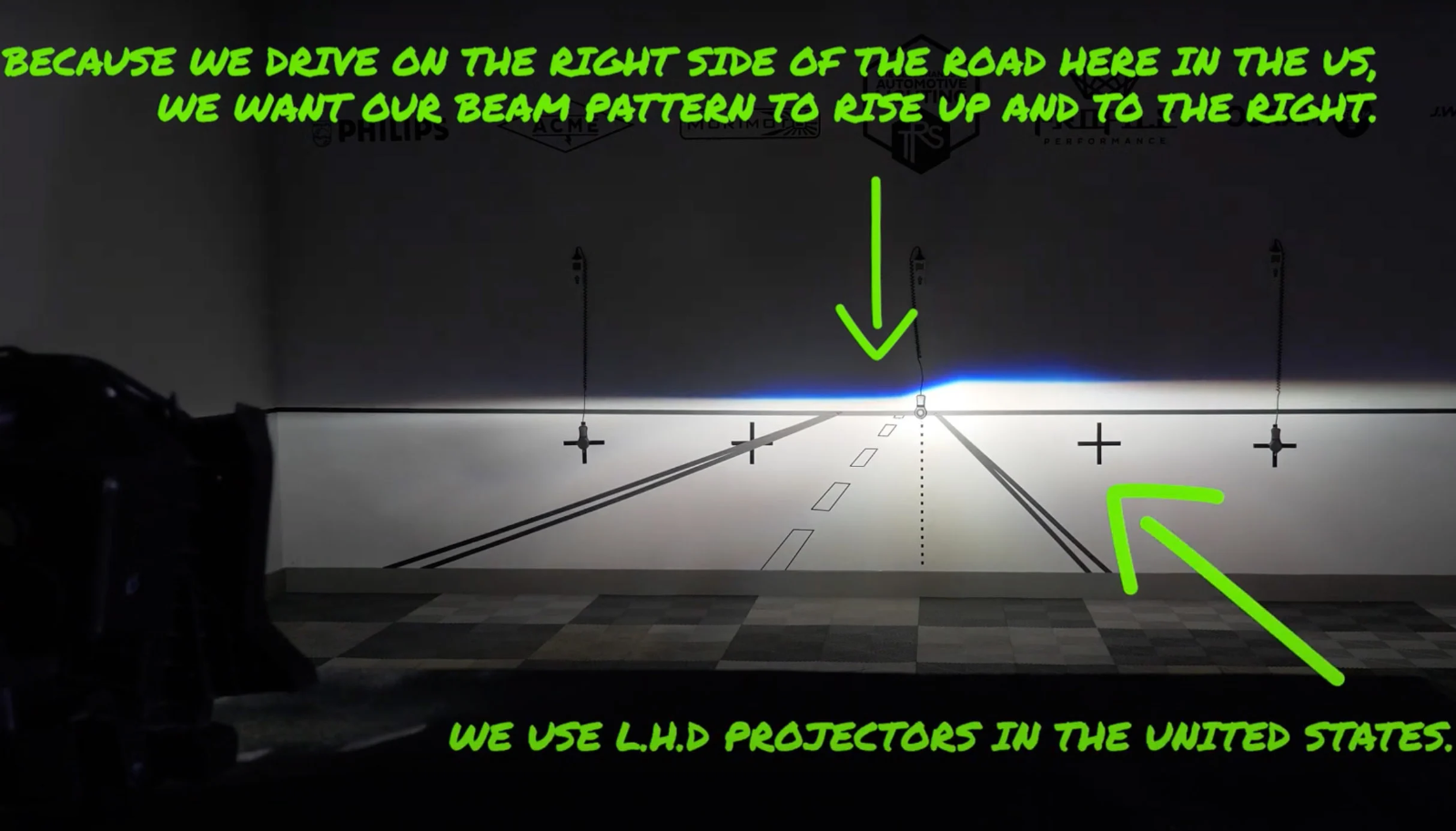

Only other thought would be switch over to UK / EU HID lights. That would have the shutter cut off for the proper side. Like my HIDs in my truck have a step in the light pattern so the on coming traffic is chopped off a bit lower not to blind them but on my side of the road slightly higher path of light to aid in visibility for the driver. That would be my only other way I could see fixing that problem. Being any replacement reflector housing will be for left hand driver vehicles. Since HIDs don't use the reflector at all the shutter and lens would have to be EU / UK design for proper cut off.

-

When Biden Talks about Global Warming...

Like the Good Lord said, " Man can create nothing nor destroy any thing." This meaning that when you look at carbon on the planet the same amount is here and won't change. Kind of like hydrogen when burned it binds with oxygen so now it turns to water. Hydrogen can be separated back out of water with electricity. Sae amount of hydrogen just different forms of it. Back to carbon like oil is nothing more than long chains of carbon and hydrogen which binds with oxygen giving carbon monooxide and carbon dioxide. Carbon never destroyed but changed forms. Trees and planets convert that back to oxygen as well. Adding on... So how is the green new deal going to work? How are they going to mine all the lithium for car batteries? Since diesel fuel is supposed to be no longer used what is going to power all those big dump trucks hauling that out? Then lithium batteries are very toxic and burn rather well again the smoke from the batteries are toxic too. I don't hear power companies expanding and making more power plants. Who is going to pay for the power used to charge cars up? I'm still in a logging area up here in Idaho. I'd love to see how the whole electric-powered over-the-road truck works out pulling logs out the backcountry in the dead of winter. I wonder what gives the driver heat on an electric vehicle because no matter what it will cost the battery quite a bit to produce heat or A/C. Some day just my own travels I can lay down over 400 to 500 miles in a day. I've not seen any electric vehicle that can travel that far in one charge loaded to GVWR. There is going to be a huge impact on freight just think a FedEx truck that is hauling your Christmas present is electric-powered Opps... Only can do 180 to 250 miles on a charge then it will take HOURS to recharge before traveling another 180 to 250 miles. The entire electric vehicle thing is a sham. Just consider I've got to travel 180 miles to get to Boise, ID any electric vehicle would have to be parked at a charging station just to get back home again. My Cummins I can fill up and do 2 trips back and forth from Boise on a single tank of fuel. Remember I'm running 20+ MPG now. If I could hold 28 MPG every trip that would be 980 miles of travel on 35 gallons of fuel. Just food for thought. Now make thing more interesting that the democrats are now looking at pulling the dams off the snake river for the salmon population. Now that means less electricity for Idaho and we would have to buy more power from neighboring power providers. How is helping anything?

-

2WD Napa Ball Joints

Kind of like Mopar oil filters are rebranded Fram filters for most Mopar gas cars. Then like rebranded BLK gaskets sold as Cummins OEM. Or better yet the rebranded Mr.Gasket / Holley Thermostat sold as Cummins OEM. Yeah I know, nothing is what you think it is...

-

AirDog 150 install

Typically I see about 17 to 18 PSI at idle. My spring is shimmed so on factory 17 PSI spring is a bit short at 14 PSI hence why the shim.

-

AirDog 150 install

I ordered 1/2 inch lines, with draw straw outside the fuel basket. On his truck I installed the straw at the rear of the tank. Then added a big line kit to keep the stock filter housing. Then the JIC fittings at the pump. Oh the best part there was only 1/8 tank of fuel and on heavy throttle no pressure drop. This time I got the straw touching the bottom and notched.

-

Daily tune advice

How about this... This is my spreadsheet for layout of fuel and timing. It allows me to step through all the values evenly and build any ramp up I wish and can see all the numbers in real time on the spreadsheet. Ubuntu Linux I can use the Excel sheet that someone built but this works as well.

-

AirDog 150 install

Owner just came and collected his truck and was pleased with the custom install of the AirDog 150. Tucked up out of the way and shouldn't have any problems. This is one of the few reasons I don't like to use FASS pumps they are too big to hard to mount without the filter hanging below the frame. This is a absolute no-no if the filter hang below the frame at all. Good way to be struck with flying debris or swiped off the pump base out 4 wheel driving.

-

Just curious

Again I logged in as you and shrunk up my screen and checked. You can test again with a PC as well, just open a browser (Chrome preferred) then continue to shrink the width. The only thing I can think of is cache and cookies. I would dump both and try again. All your permissions should be good (Yearly Subscription). Being it produces correctly for me on your account it got to be on your end. Make sure you go to Browse -> Clubs too. Again logged in with your username and check desktop using Ubuntu Linux 20.04 with Chrome Browser. Now using my cellphone Samsung S21 also with Chrome browser.

-

Just curious

Logged in as you and all 4 JOIN button are very visible.

-

Just curious

Join the club and then posting becomes available. I'd suggest just heading over ot DAP for now till I can catch up with my own side here. Store features are shut off for now till I can get a handle on things on the site.

-

AirDog 150 install

I've got a forum member and local client here at the house with his Dodge Cummins having new +50 HP injectors, new AirDog 150 installed, and a big line kit. Now what I want to focus on here is my custom AirDog install and what it took to make it happen. On short bed trucks, the fuel tank is more forward toward the transfer case. There is not enough room for the AirDog to mount on the inside of the frame. Even on the outside of the frame is really limited using the supplied bracket and fittings. I chucked the whole idea out and started over, now thinking custom install. I had to call back to @dieselautopower and get the old school JIC fittings and have them as 90* elbows, not the straight quick connects. Now I took advantage of the outside of the frame but the rear of the rear cab mount. I'm using this as a guard from thrown debris. The frame is too wide to use the supplied sandwich bracket. So I used only the pump bracket and the plastic pedestal that is supplied. I drilled 4 holes and tapped the holes in the frame and bolted the pump to the frame of the truck. The 3 JIC elbows allow for the tight area and only one fuel line needed to be looped to prevent a kink. The rear cab mount is forward from the two fittings on the left. This guards the filters against being struck by debris. The rear fitting pointing up is the return to fuel tank heading to the filler neck and the one pointing down was my supply to the engine. For the supply to the engine, I added a small loop to prevent kinking. Here you see I completely did away with the sandwich bracket and just drilled and tapped into the frame. I couldn't use nuts because the fuel tank is completely in the way. The plastic pedestal worked out perfect too being allows for the brake cable not to rub the pump or filters.

-

True HX35

Your welcome. I'm trying to get the best speed possible for cell phone users. Being the lag on cellphones counts I've gotta be even faster. I'm already using next generation hardware and software. So I'll compare to Cummins Forum and I've got them beat hands down. There is another tidbit with speed the more I get the response time down the more it improves mt ranking for search engines like Google so Mopar1973Man pops up in the first page for most searches. Mopar1973Man.Com is fully loaded in 4.1 seconds where Cummins Forum is 7.9 seconds.

-

Maintenance App - Simply Auto

I've been using this app for quite some time. So far I'm really impressed with its ability to keep you on track with maintenance and tracking MPG numbers. I figured I'd bring this up and let people know about the app. https://www.simplyauto.app/ Personal dream I had for the website here was to have the author of the Garage Software to add a maintenance record program to the garage so it would remind owners of up coming thing like oil change, brakes etc. That way as you logged on the site and you would add your mileage to the web site and it would notify of service needed. Also would possibly allow members with permission to view your records to provide better understanding of what the troubles could be.

-

Studs going to brake failure

Ummm... it does lock me inside at 15 MPH. Yeah very true, the way he sounds, way he drives, vibrations, etc.

-

True HX35

Nope... ive working on server performance and some of the cache modules were acting goofy. I've got it sorted out now. Still have some issues on my HTTP server software. Trying to clean up server errors and make it quicker yet.

-

Studs going to brake failure

Well I've got to tell a tale of what has happened to Thor. Back during the summer I had drove through a open field and managed to gather up a roll of barbed wire around the axle. Then when I went in for new tires the gorilla lugs I had on the 18 wheels well they managed to break off two studs on each side of the rear axle. Now getting around to the actually repair of the damages... So started on the passenger side and pulled the tire off and found the caliper slide bolt was bent from the barbed wire event. This in turn now wiped out the inner brake pad and then ate the inside face of the rotor. Ok stop and order new brakes and rotor for the passenger side. Parts come a few days later. Now finish up the passenger side and then move to the driver side. Find out that 2 more of the lugs galled up and required the studs to be cut off or broke. Now that required 2 more studs to be ordered and then find out the caliper frame is stripped out and so was one bolt. Great order more parts. Finally get that all together and back to sitting on the ground. This 2006 has been nothing short of a huge money pit.

-

Cleaning and reusing injector lines

Just think everyone told me buy Cummins OE parts. Everyone knows and trust Cummins. Just like I learned Cummins does not produce thermostats so why pay $70 bucks for a Holley/Mr. Gasket which is who makes Cummins thermostats. Alright... Now how about Cummins OE head gaskets? Cummins doesn't make head gaskets a company of BLK does. So just because you think you know a company or think you know the source of the parts doesn't make them good or bad. This just proves even a big name like Cummins can be selling any kind of products with there name on it. Just like in the past with Carter fuel pump made for Cummins which was nothing but junk lift pumps. I'd rather take a smaller company for products than a big name any more. At least smaller companies want to make a better product.

-

True HX35

Same here. I slowly been walking forward. I started with... Stock RV275 Injectors +50 HP Injectors +75 HP Injectors +150 HP Injectors. As I worked my way forward I dealt with all the weakness. The biggest thing do not run oversized tires or foul the final ratio. The optimal ratio for longevity I'm finding is 3.55:1 to 3.73:1 to the ground after tires are figured in. Like I ditched the 265's and went to 245's which is a 30 inch tire but now get the final ratio to 3.69:1 to the ground providing better longevity being my EGT's at 55 MPH are so low most won't believe me.

-

Cleaning and reusing injector lines

That's what I would do if it was me. Then replace the one injector hold down. Extra 200 to 300 dollars for the other what so special about the line to need extra money for them? Gold plated, life time warranty to never fail or what?

-

True HX35

Forgot to mention I tipped over 50 PSI of boost on my turbo when I finally over did the drive pressure side and blew the head gasket. So yeah HX35 or HX35W should be able to spool up a good 35 to 40 PSI easy.

-

True HX35

I'm running a HX35/40 Hybrid (60/60/12) on my truck with +150 HP VCO injectors. My current Quadzilla tune is netting me a high mark of 28 MPG. I've got enough power to spin the tires loose. Now you could do the Smarty Touch which will give you that ability but at a cost of about $1800 for the full kit so you can write tunes. Then the max your going to get is 65 HP period because Smarty Touch on 24V Cummins is still only a CanBus tuner. Yeah Quadzilla is the best option.

-

True HX35

Smarty isn't a really good tuner for timing control it basically has a few level of advancement but nothing for retarding. So to build boost you need more retard to push more exhaust gases into the turbo. More advancement will reduce boost pressure.

-

Cleaning and reusing injector lines

Personally I would just replace them. No matter what you do the clean one is worn enough to see the step on the tip. The rusted ones are too far gone by the time you clean the tips up it might not seal good. I've had this happen too and they continued to weep in the manifold smelling diesel all the time. I got lucky and a friend had a full set of line that were new I ended up trading for and got. My problem is fixed with new lines. The tapered tips are a precise machined tip and you must be super careful not to make them smaller or have little pits or scars in that small tip. 5,000 PSI and up to 20,000 PSI will leak out for sure. Hence why I suggest full replacement.